Device for sampling shallow soil of extraterrestrial star

A soil sampling and shallow layer technology, applied in the direction of sampling devices, can solve the problems of excessive degrees of freedom, insufficient flexibility, poor adaptability to the geological environment, etc., to achieve improved motion accuracy and reliability, enhanced sampling flexibility, and control algorithms. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

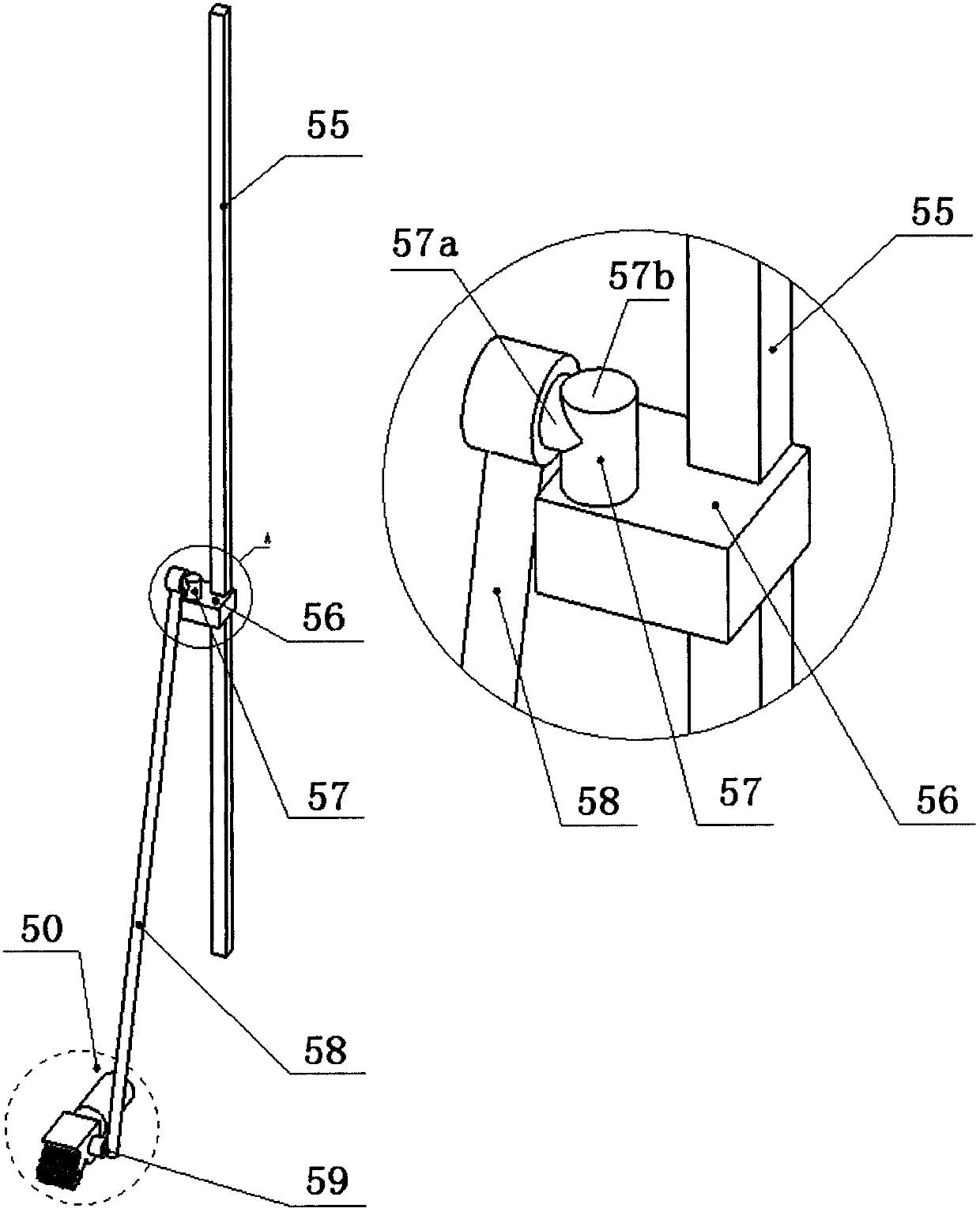

[0044] Such as figure 1 Shown is the structural representation of the extraterrestrial shallow soil sampling device of the present invention, as can be seen from the figure, the soil sampling device includes two parts: a guide rail swing arm type position mechanism and an end actuator 50, and the guide rail swing arm type position mechanism includes a guide rail 55, a motion unit 56. Swing arm joint 57, swing arm 58 and end joint 59, wherein guide rail 55 is connected with motion unit 56, and motion unit 56 can move up and down along guide rail 55, guide rail 55 and motion unit 56 components are mainly used to produce motion unit 56 along The degree of freedom for the guide rail 55 to move up and down, and the movement of the motion unit 56 relative to the guide rail 55 can be realized in various ways: such as rack and pinion transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com