High-speed magnetic levitation flywheel stabilization control system

A stable control and magnetic levitation technology, applied in the general control system, control/regulation system, automatic control, etc., to achieve the effect of increasing critical speed, easy parameter setting, and preventing forward whirl and backward whirl instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

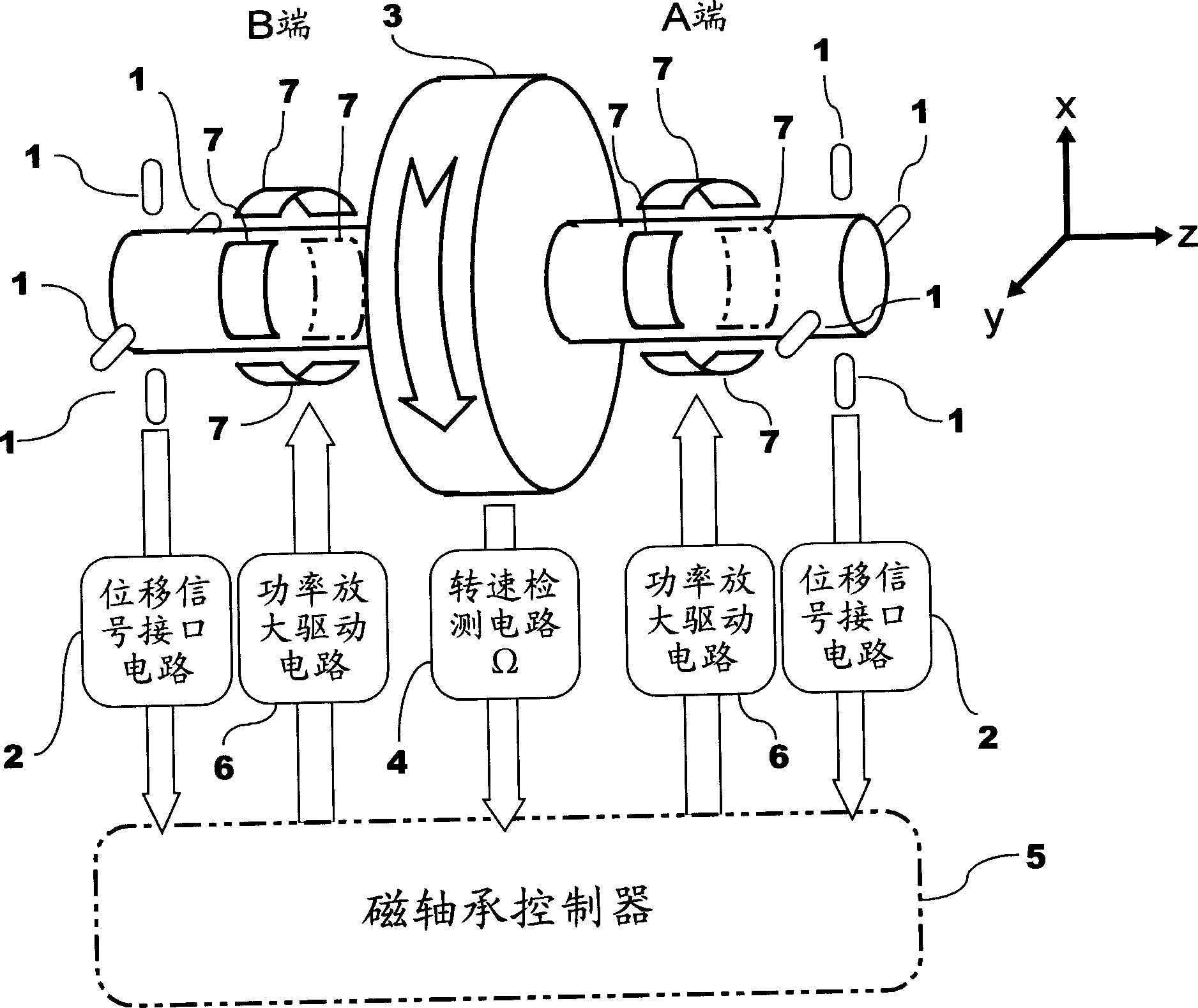

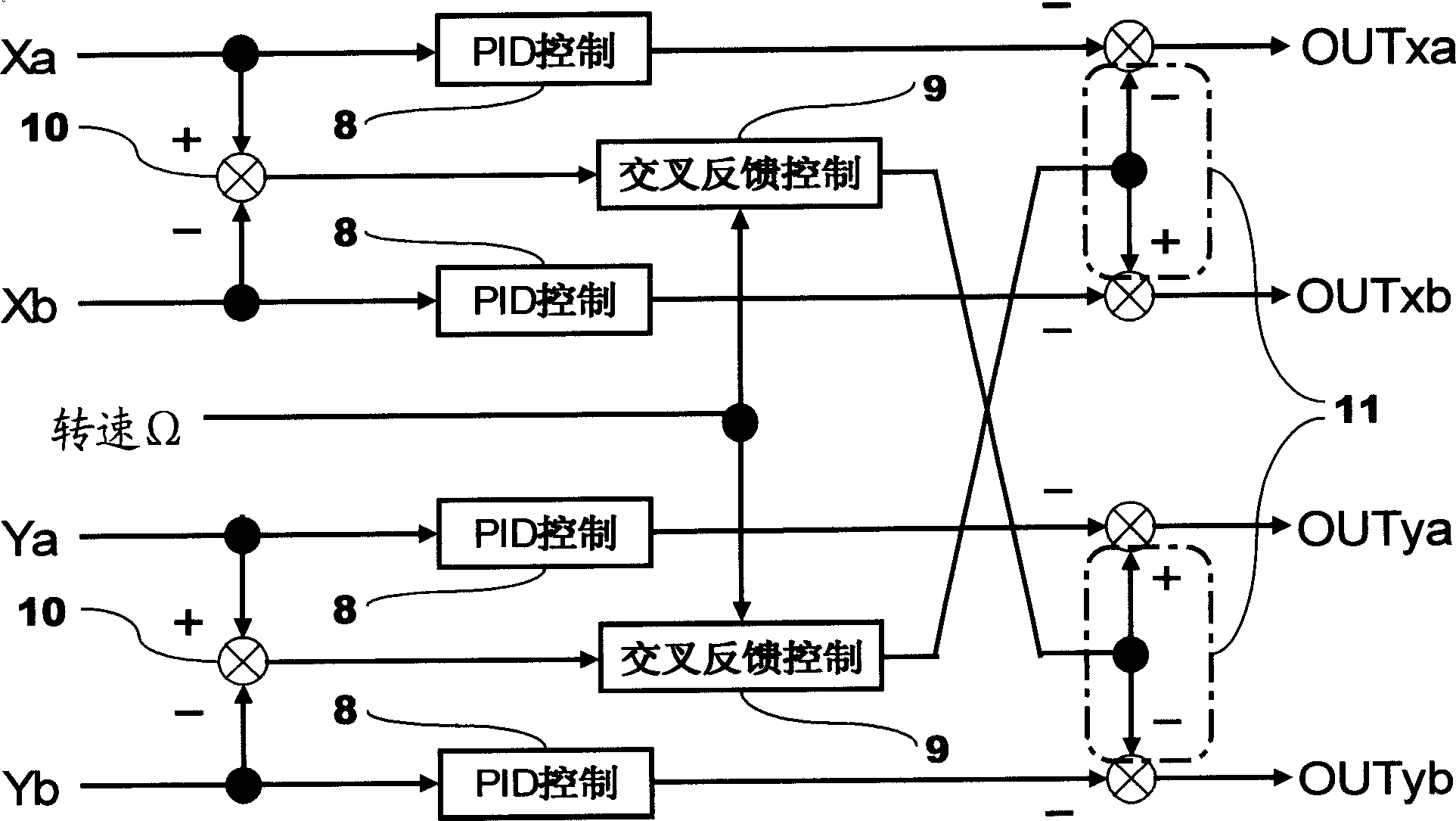

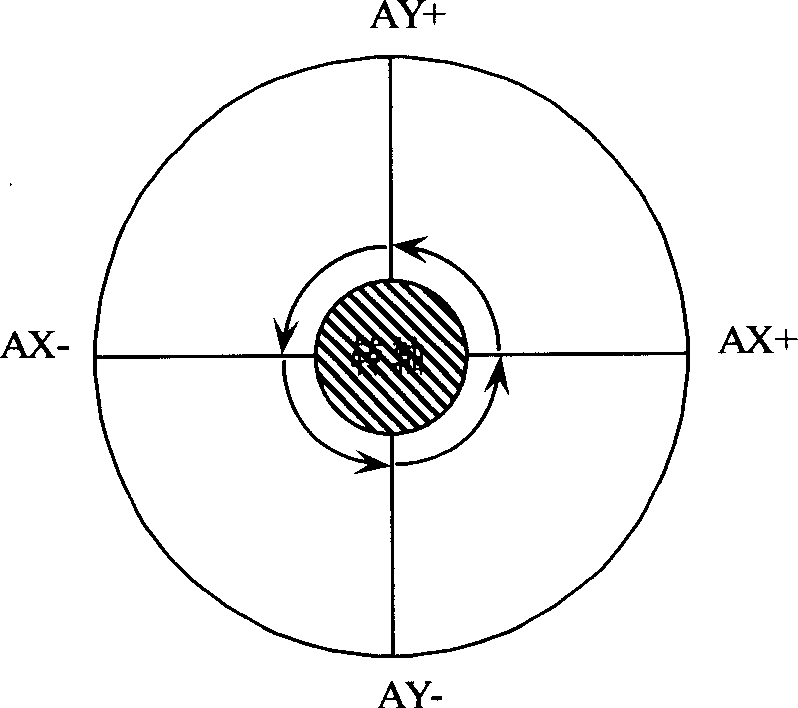

[0023] Such as figure 1 As shown, the present invention includes a displacement sensor 1, a displacement signal interface circuit 2, a rotational speed detection circuit 4, a magnetic bearing controller 5, a magnetic bearing power amplification drive circuit 6, and a displacement signal interface circuit 2, which are used for adjusting the magnetic levitation flywheel rotor displacement sensor 1 The detected four radial displacements of terminal A in X direction and Y direction, the signals of displacement in X direction and Y direction of terminal B and an axial displacement signal are subjected to zero adjustment and high-frequency noise filtering; the rotational speed detection circuit 4 is used to The flywheel speed pulse signal is isolated and quantified (it can be pulse frequency, digital or voltage, determined according to the input interface type of the magnetic bearing controller used); the magnetic bearing power amplification drive circuit 6 is used to convert the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com