Patents

Literature

41 results about "Mechanical pipette" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pipetting head is the mechanical component designed for liquid transfer. The majority of pipetting heads are based on a peristaltic pump system, while some anthropomorphic systems directly use manual pipettes.

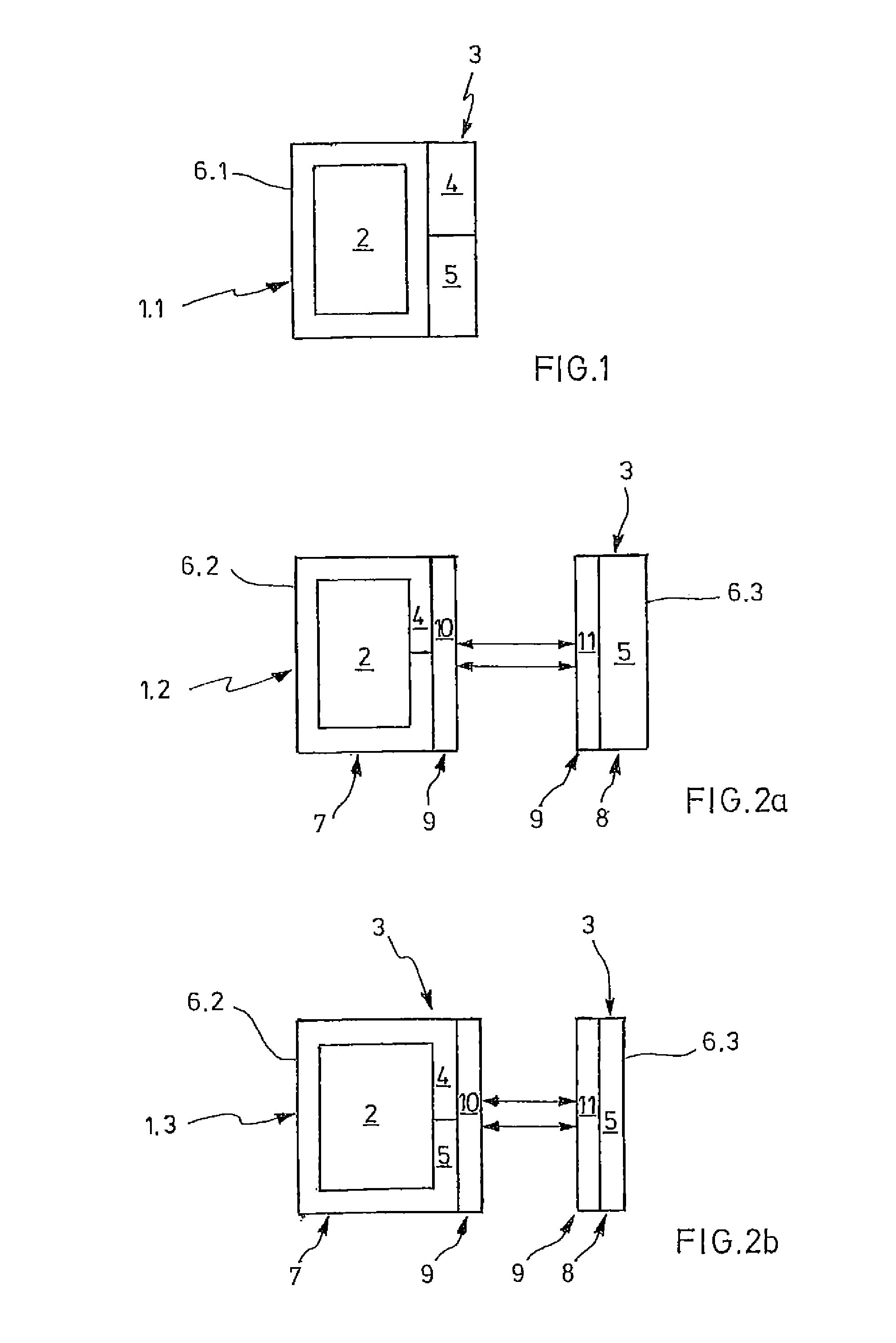

Automated pipetting system

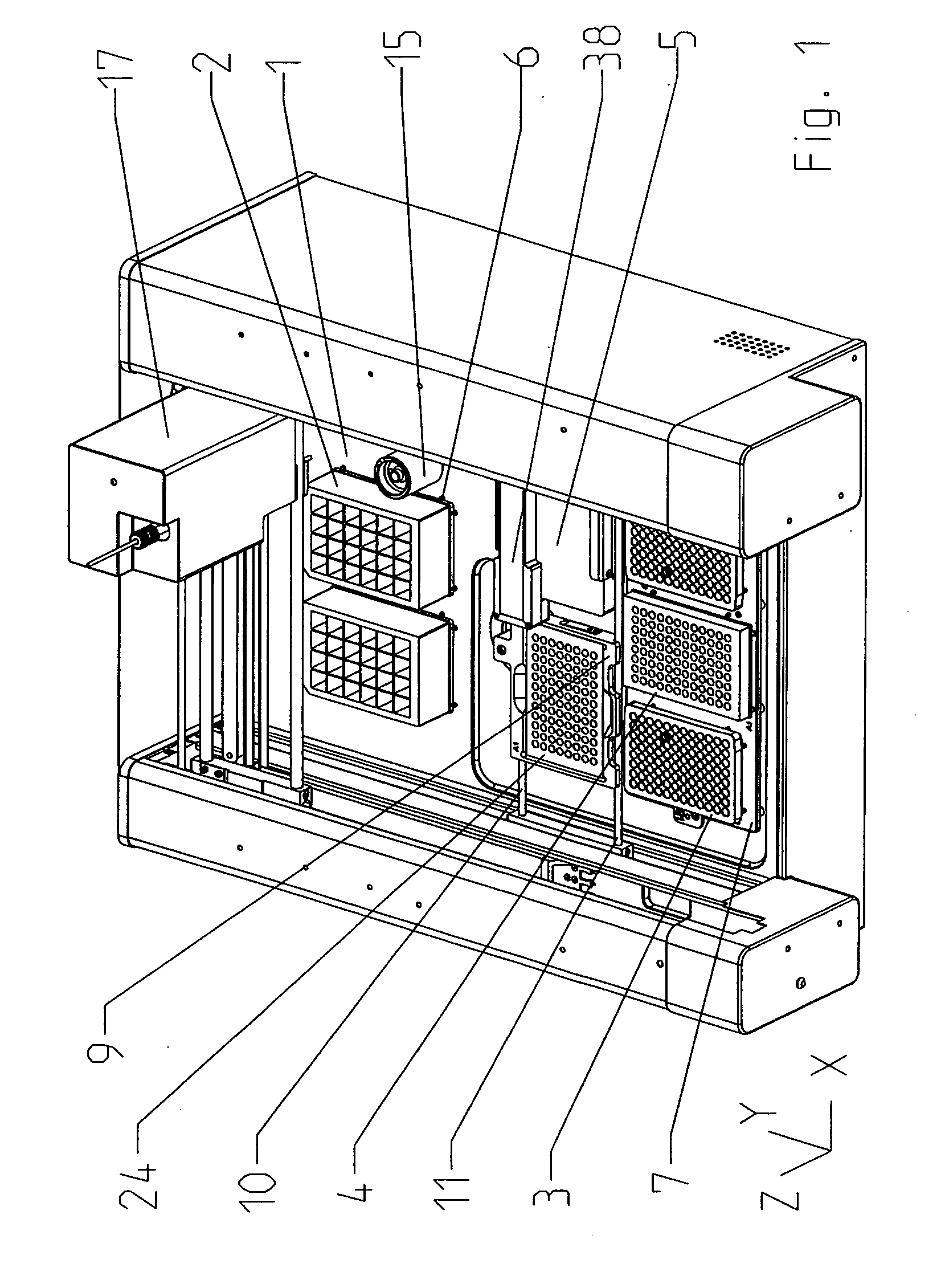

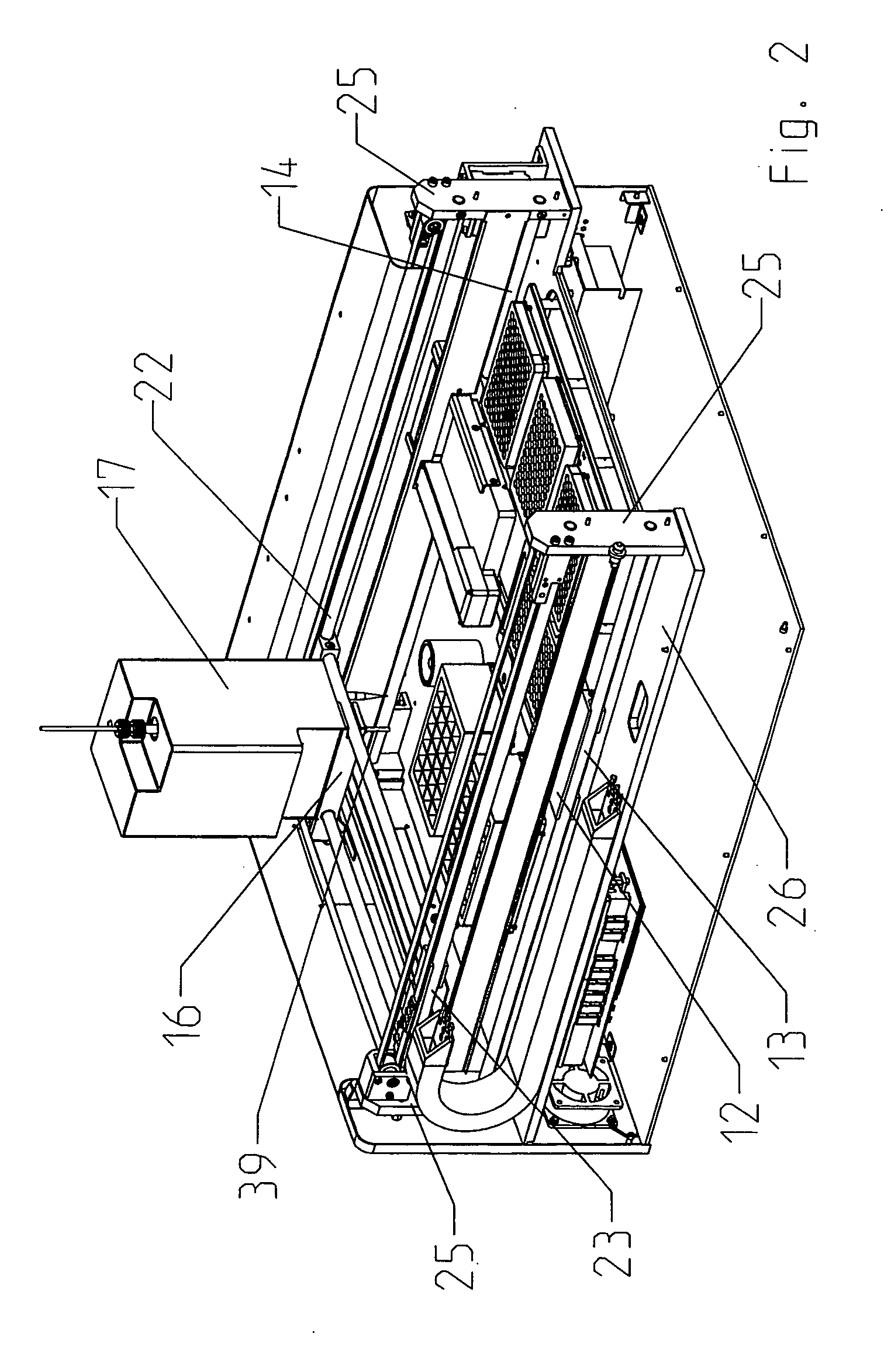

InactiveUS6982063B2Good flexibilityImprove throughputChemical analysis using titrationWithdrawing sample devicesMechanical pipetteManual insertion

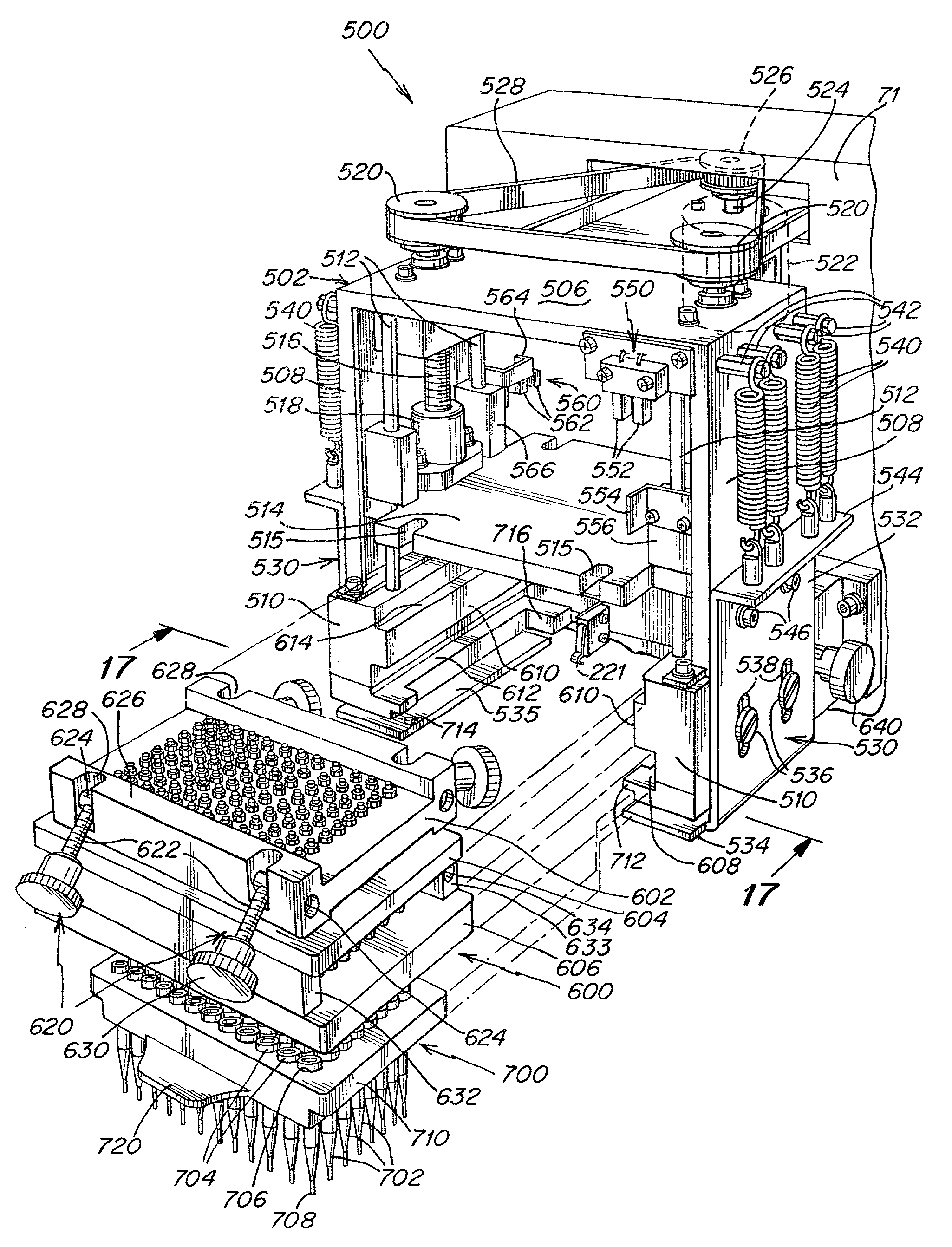

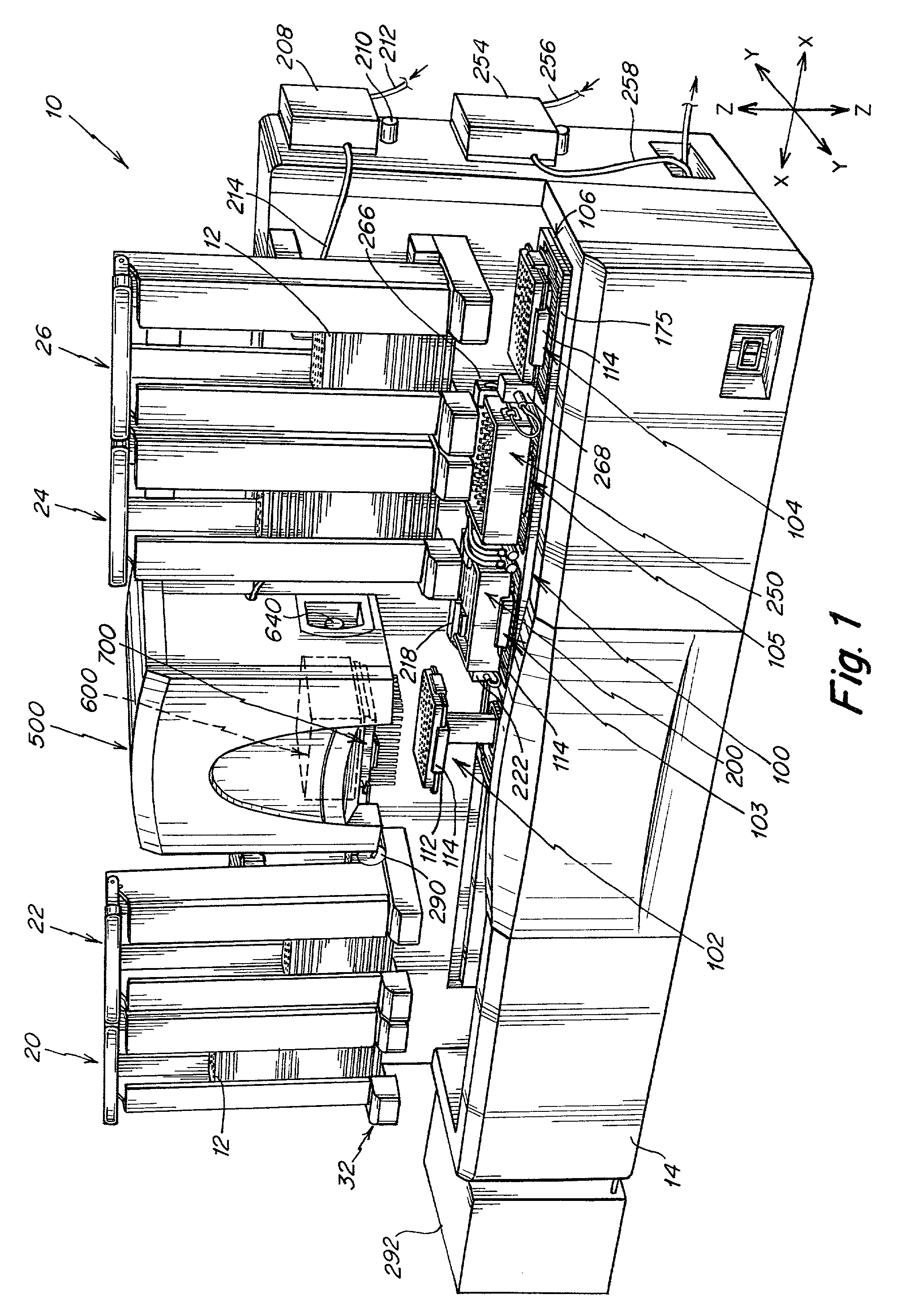

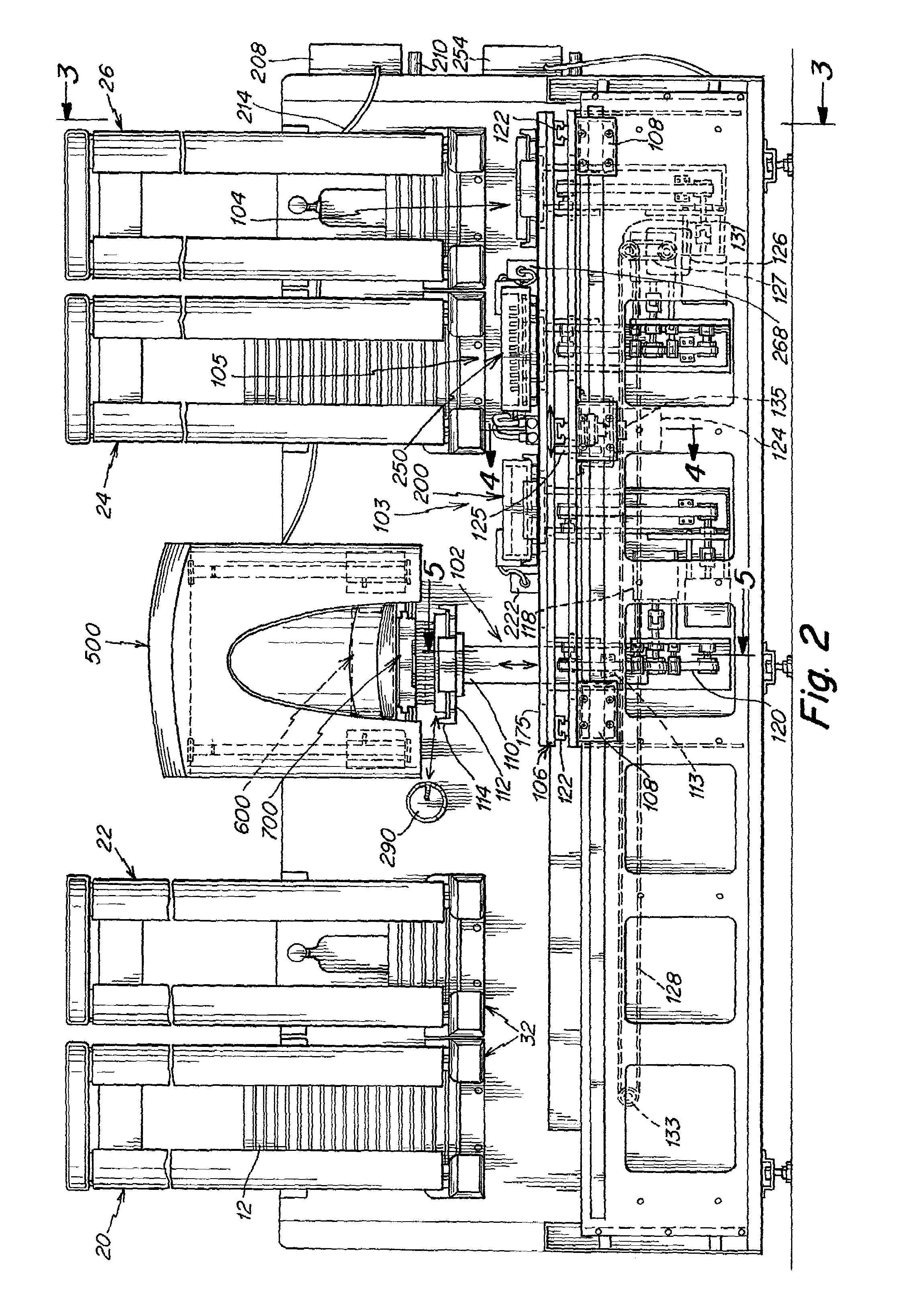

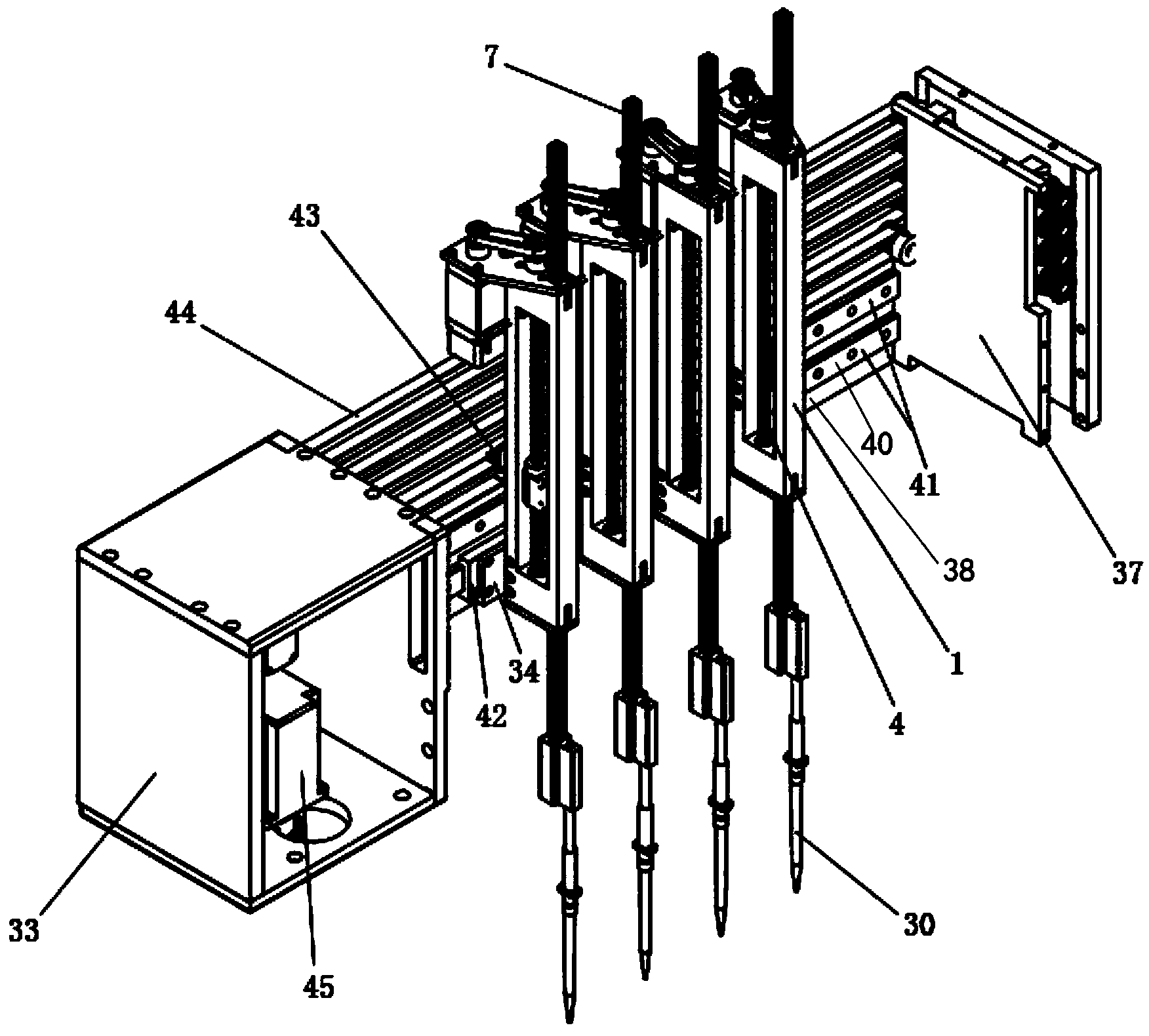

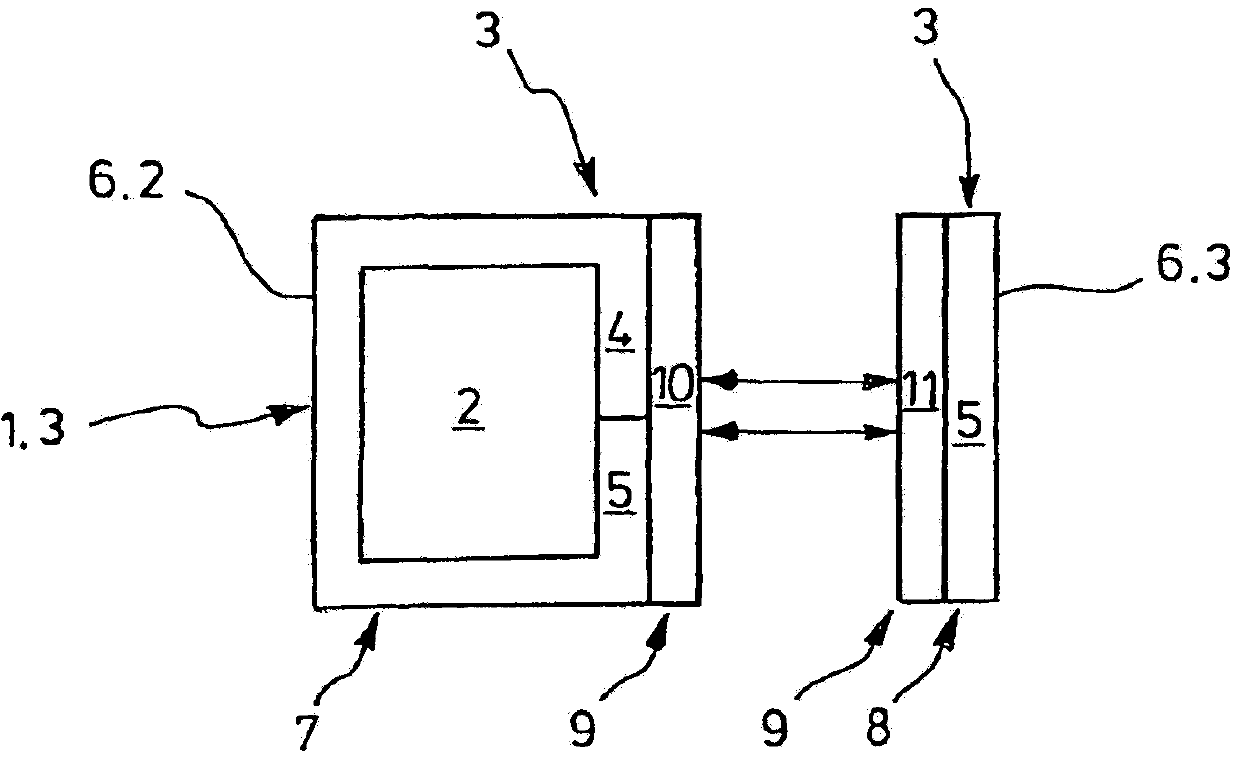

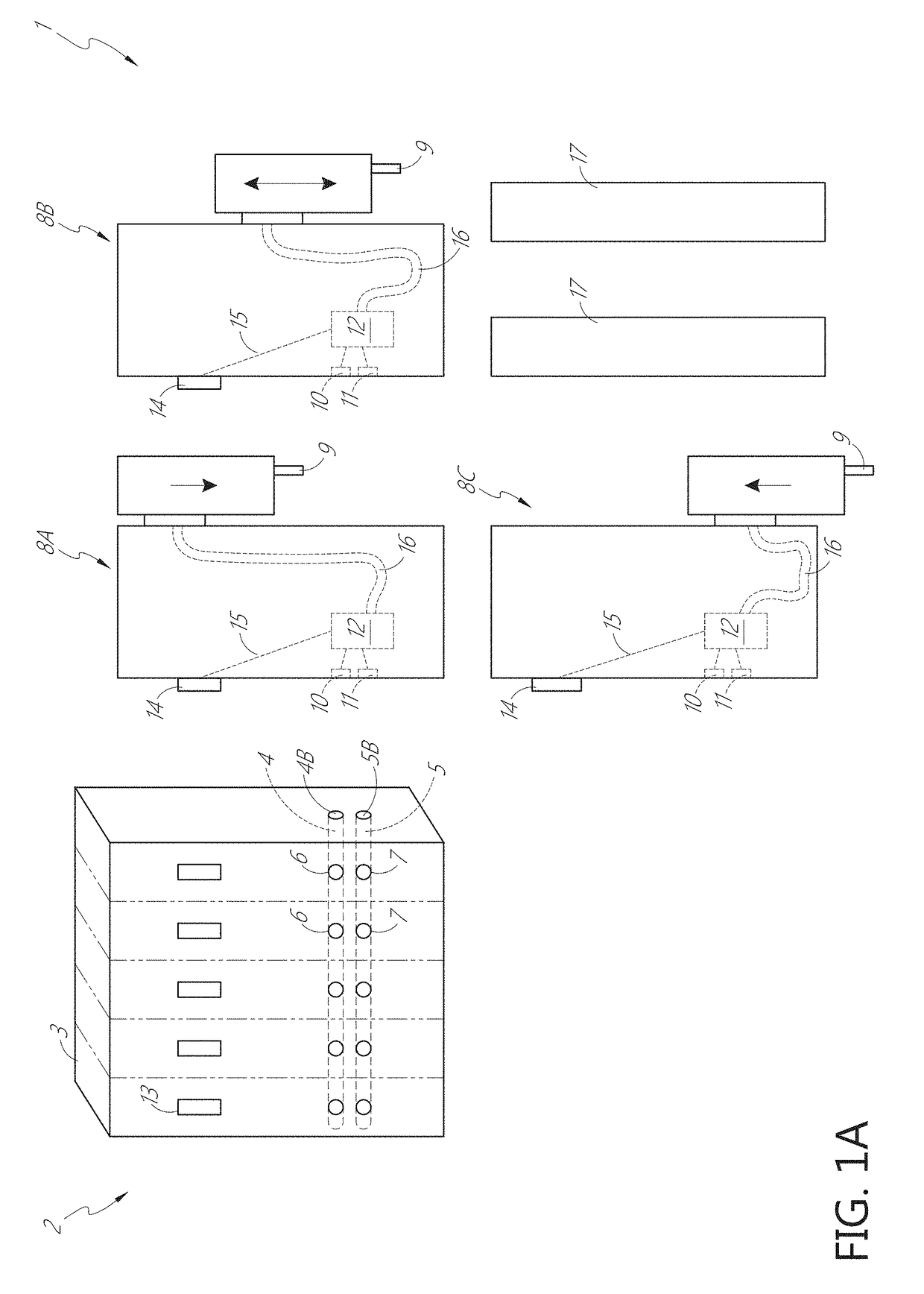

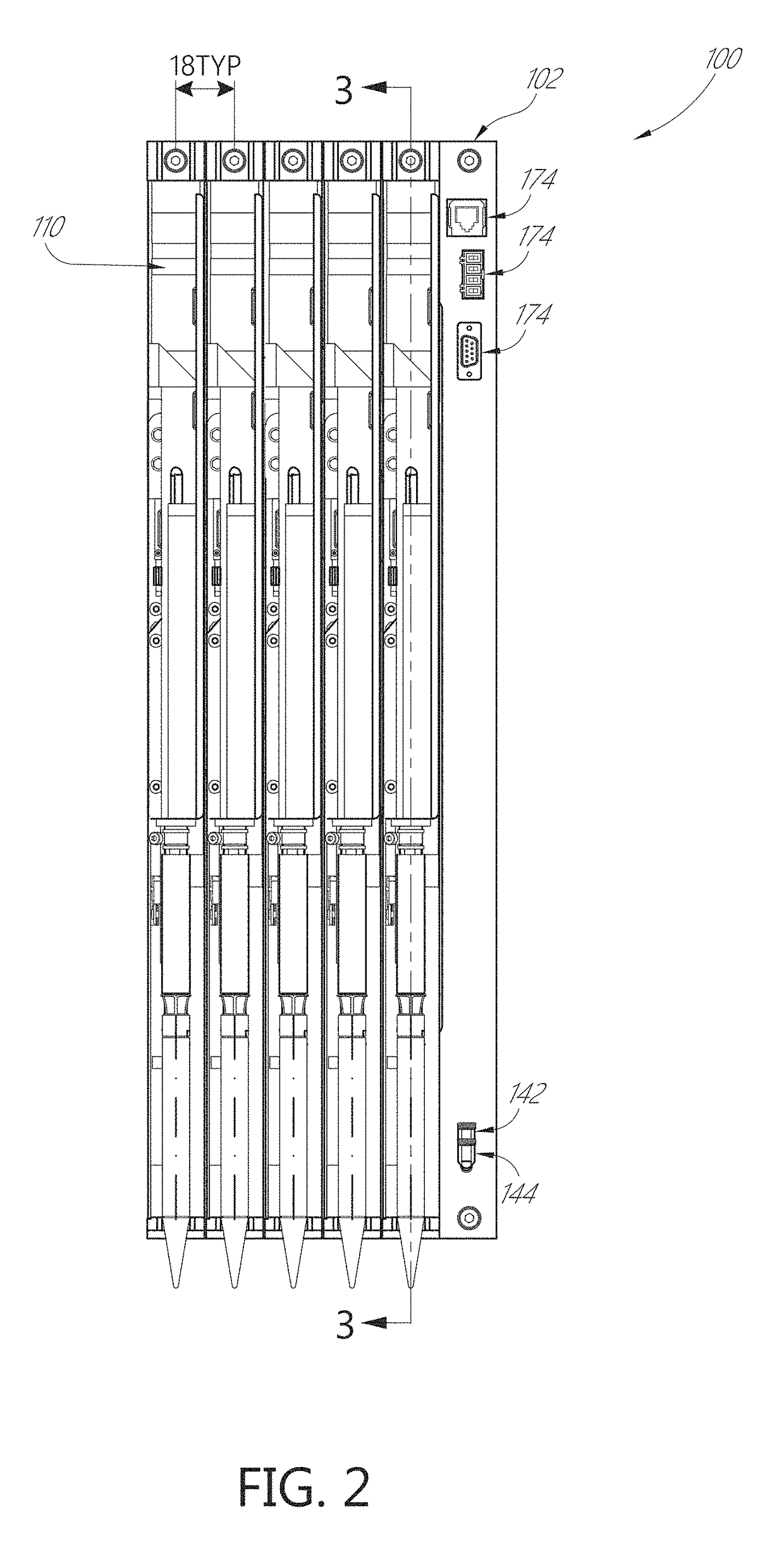

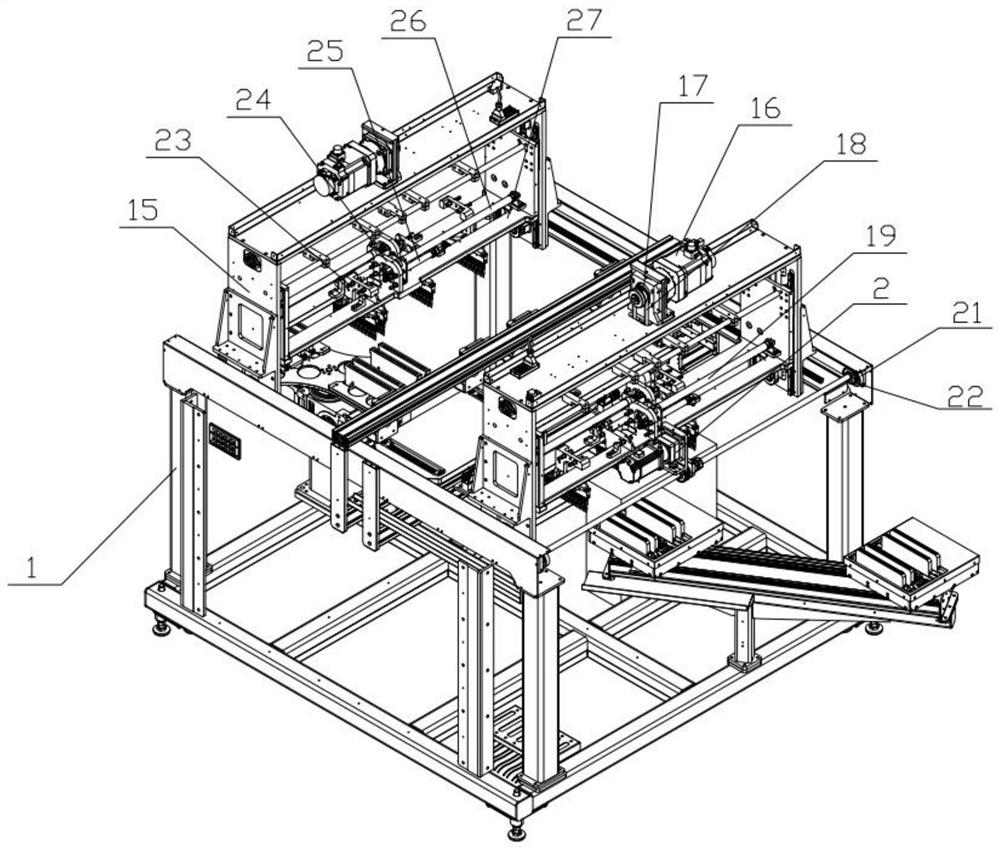

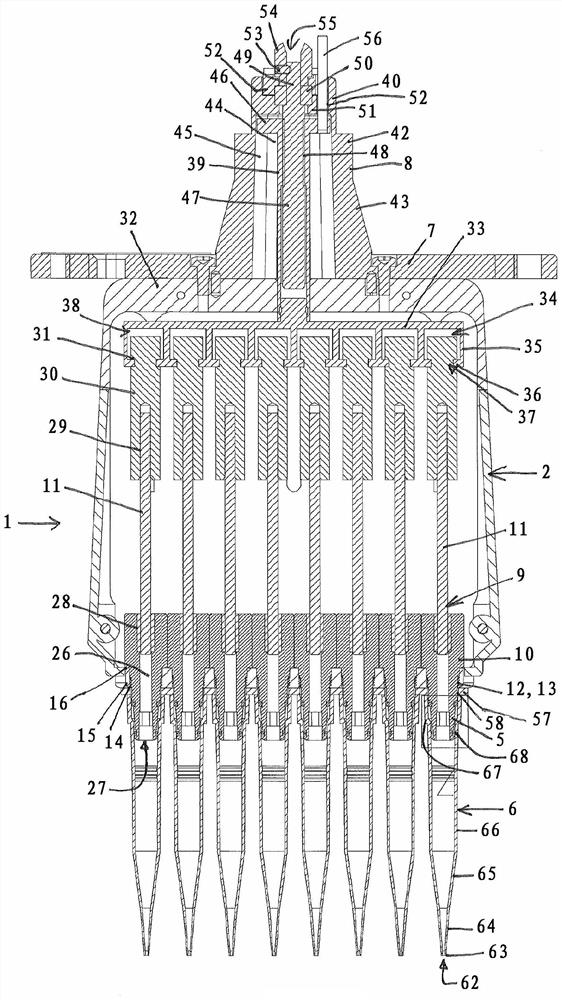

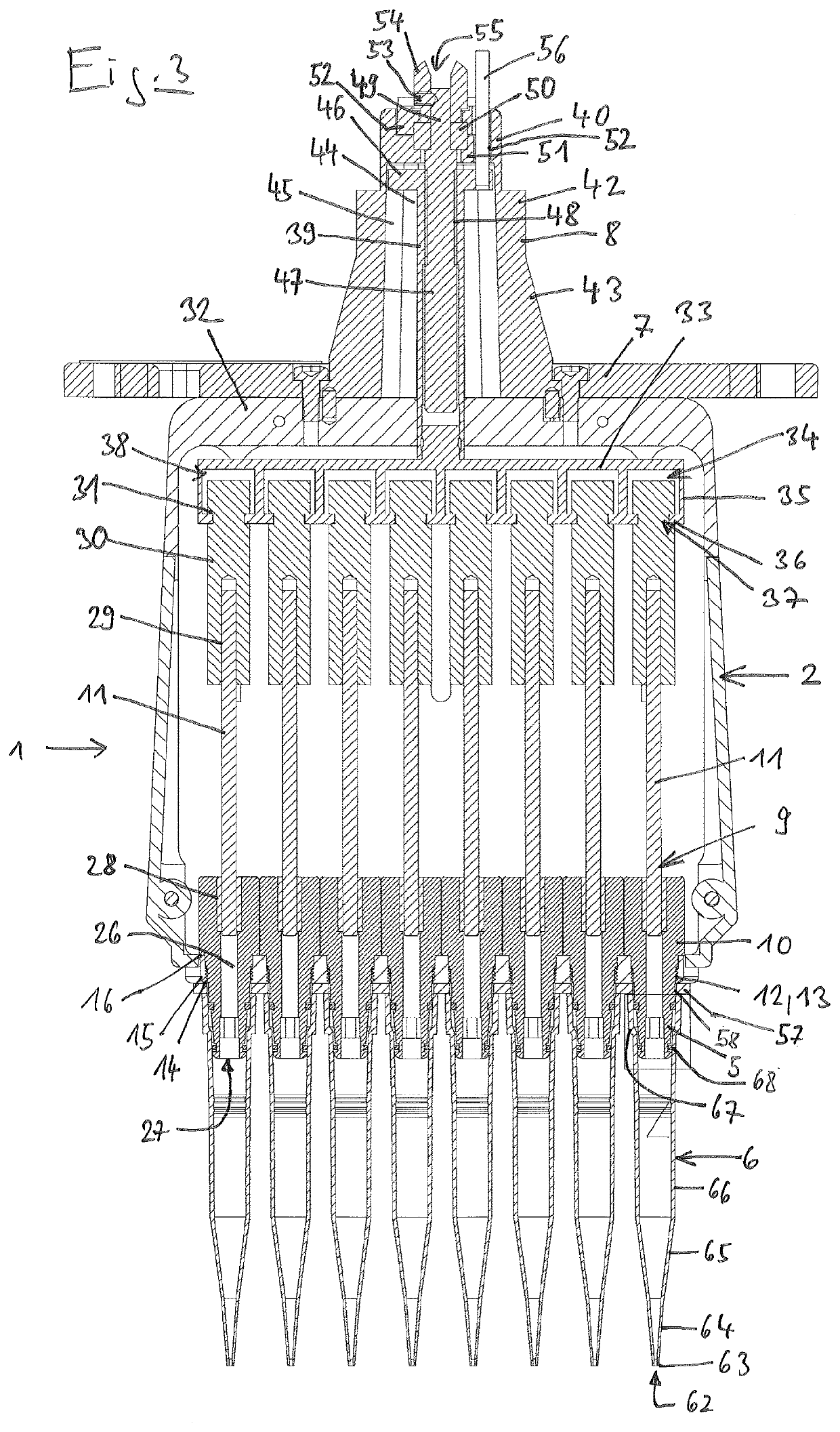

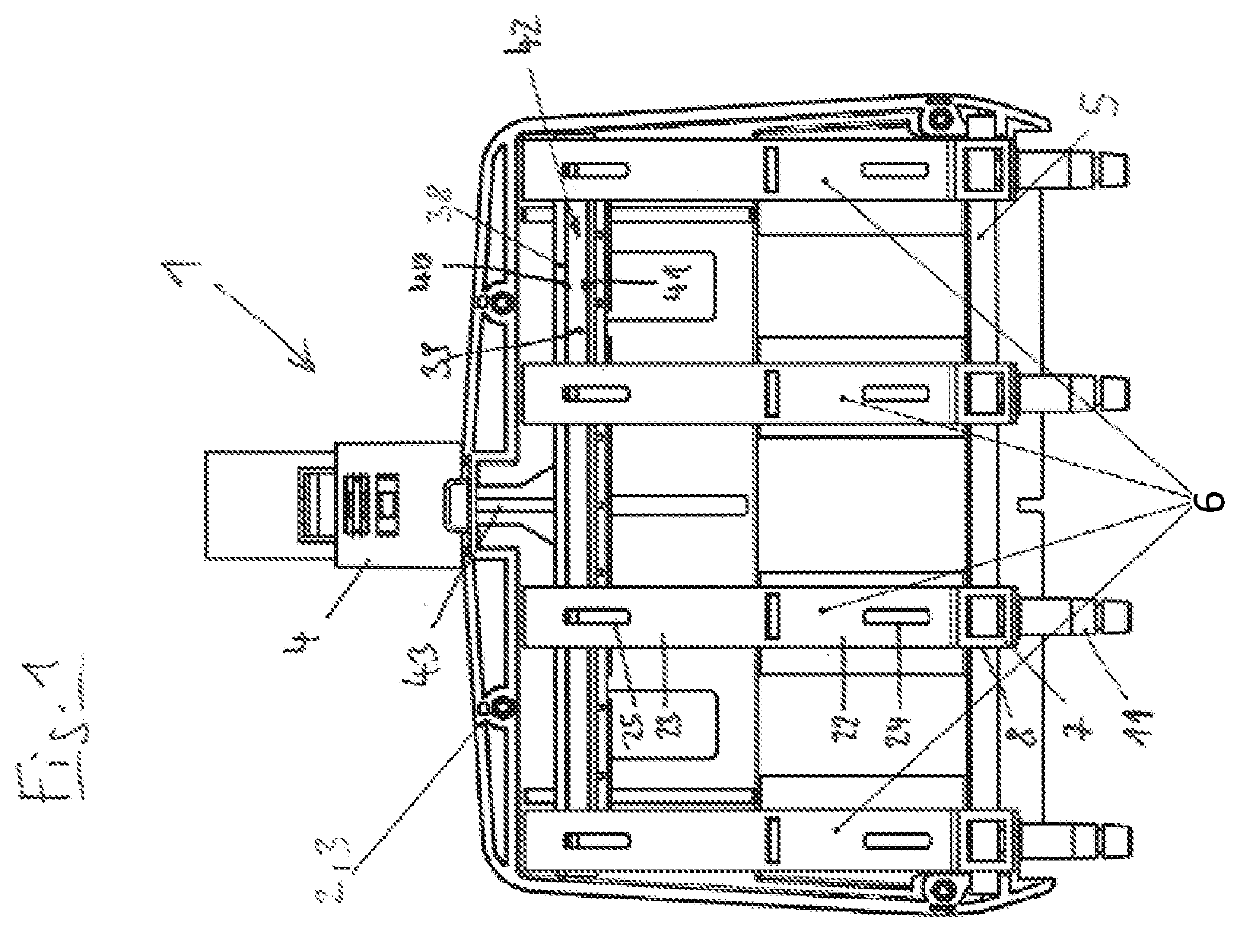

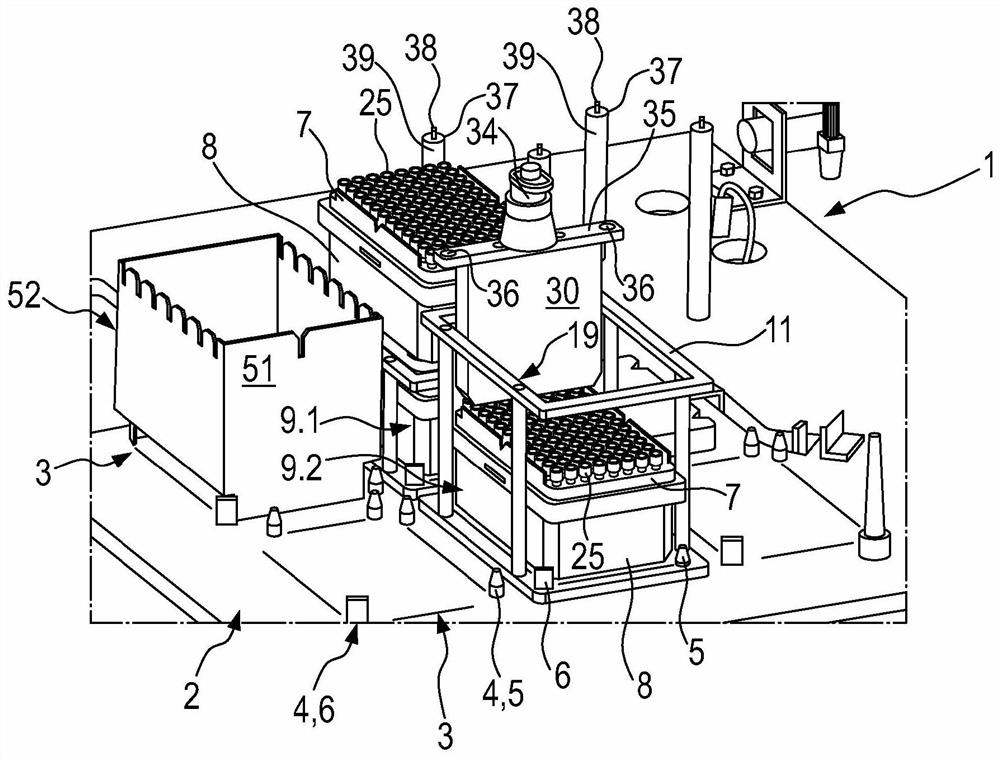

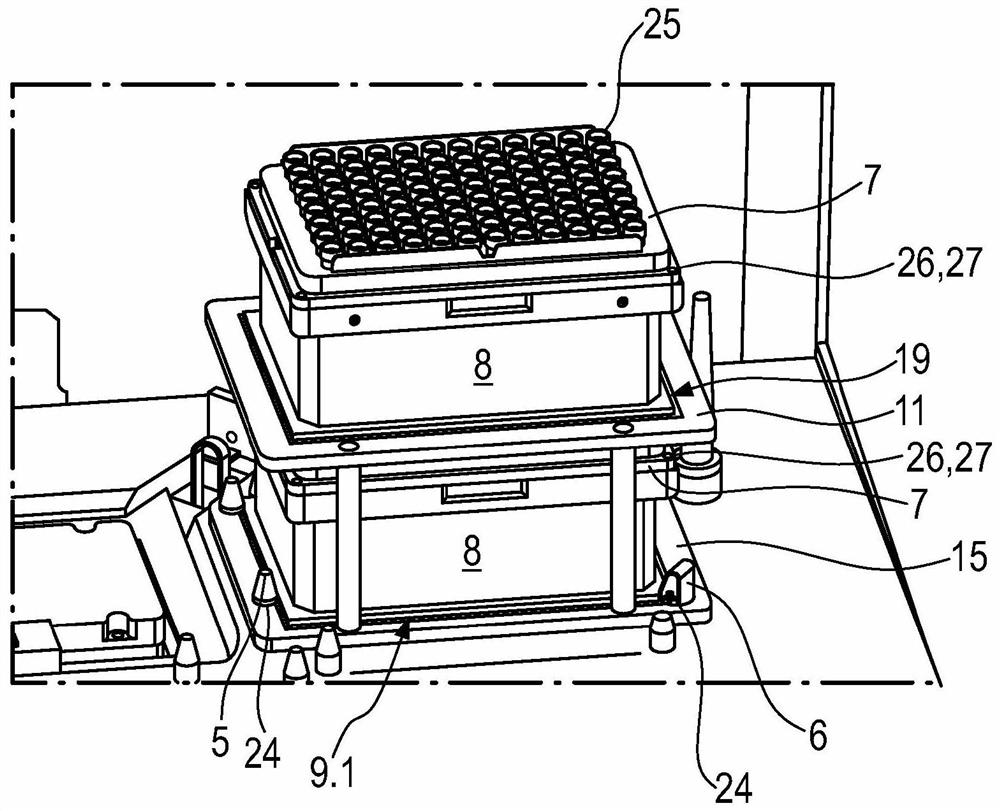

A highly automated, high volume multichannel pipetting system which transfers liquid from mother plates to daughter plates, or from a fill station to daughter plates. The mother plates are stacked in one set of stacker assemblies, while the empty daughter plates are stacked in another stacker assembly. A plate handling assembly which is capable of moving the plates in three orthogonal directions retrieves the plates from the stacker assemblies, carries them to the pipetting head, and returns them to other stacker assemblies. The pipetting head is removable for replacement or repair thereof, or for insertion of another head assembly having a different number of pipetting channels. The head slides into the housing on slideways, and is retained in place by manually operable, threaded knobs mounted on shafts. The stacker assemblies include a chimney which is removable from a base. The plates may be stacked in the chimney and then inserted on the base. The base includes solenoids whose arms are retractable to permit plates to be retrieved or replaced one at a time. The chimneys contain flaps which serve to retain the plates within the chimney if manually removed from the base. Doors in the stacker chimneys allow manual insertion and replacement of plates. Methods of operation of the pipetting system are also disclosed.

Owner:MATRIX TECH +1

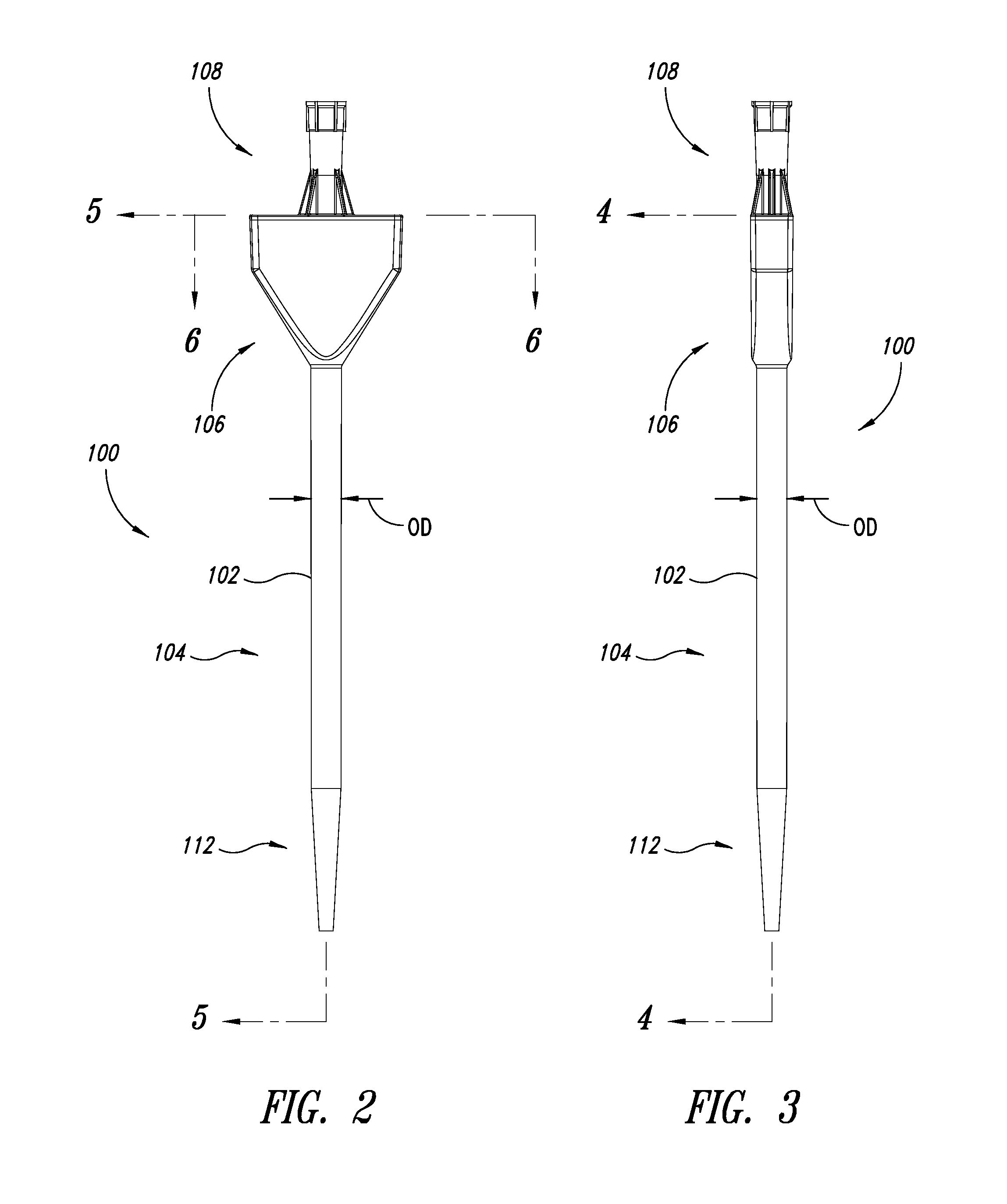

Liquid sampling utilizing ribbed pipette tip for barrier penetration

InactiveUS20060171851A1Analysis using chemical indicatorsAnalysis by subjecting material to chemical reactionMechanical pipetteHand held

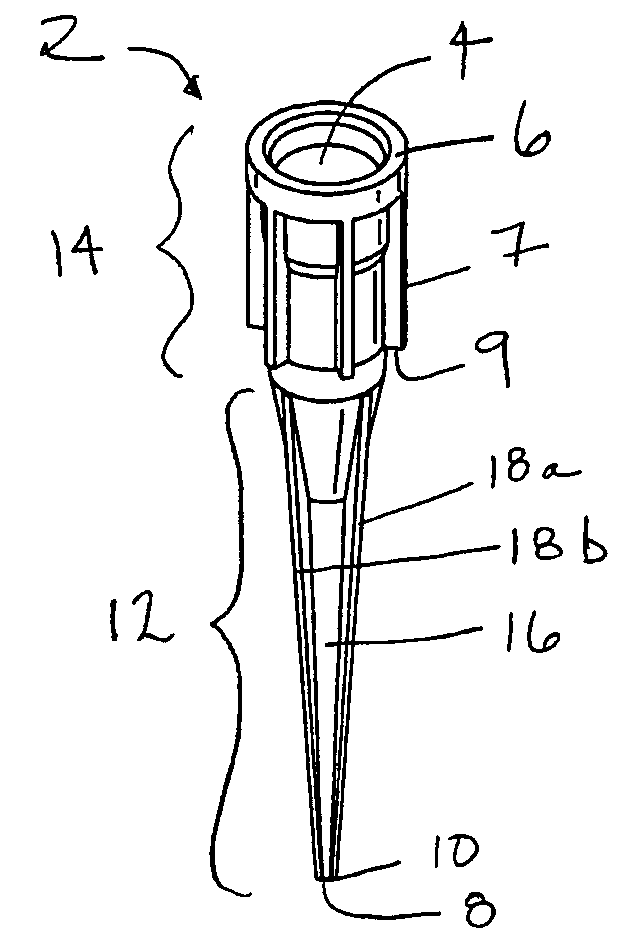

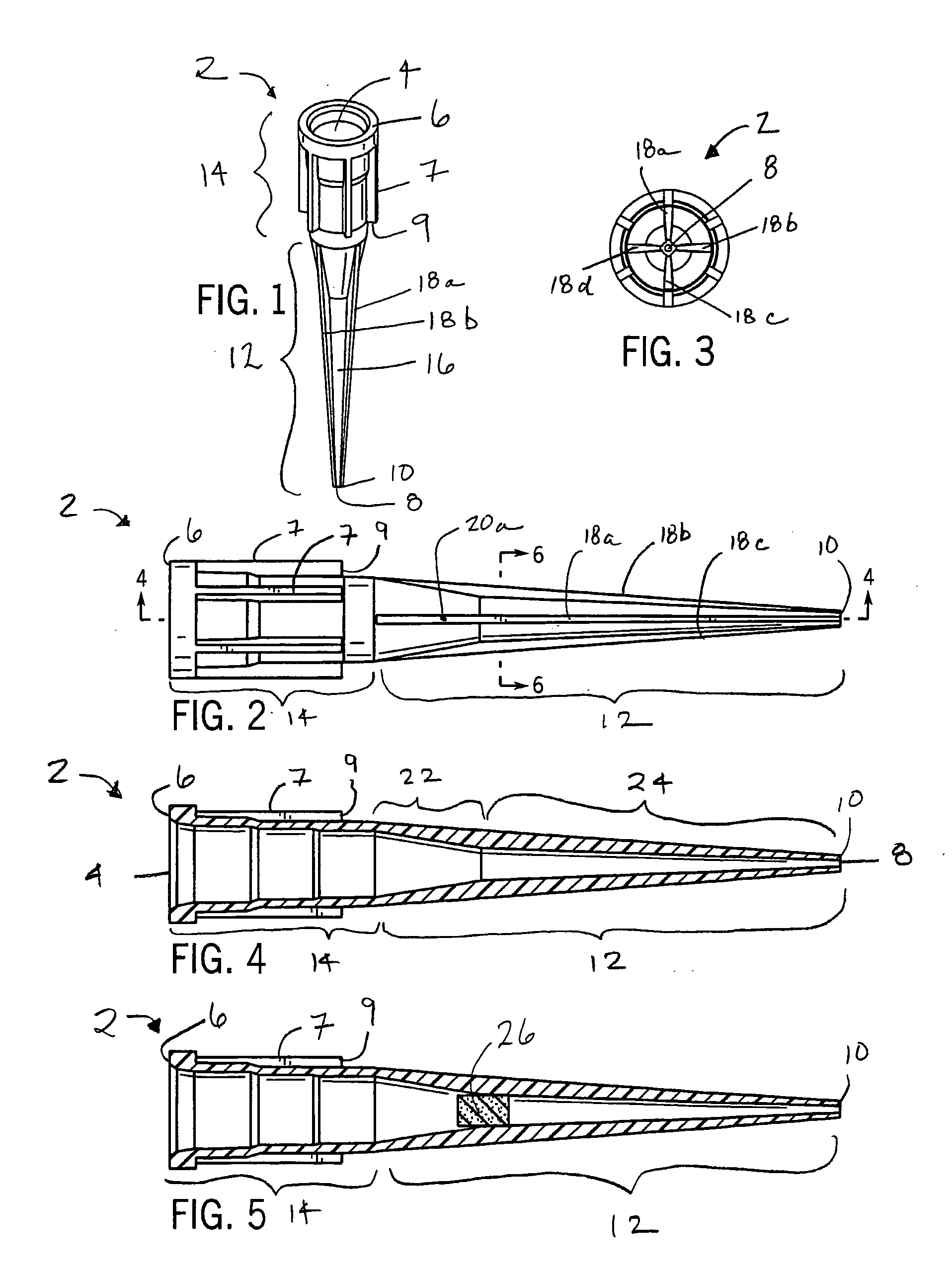

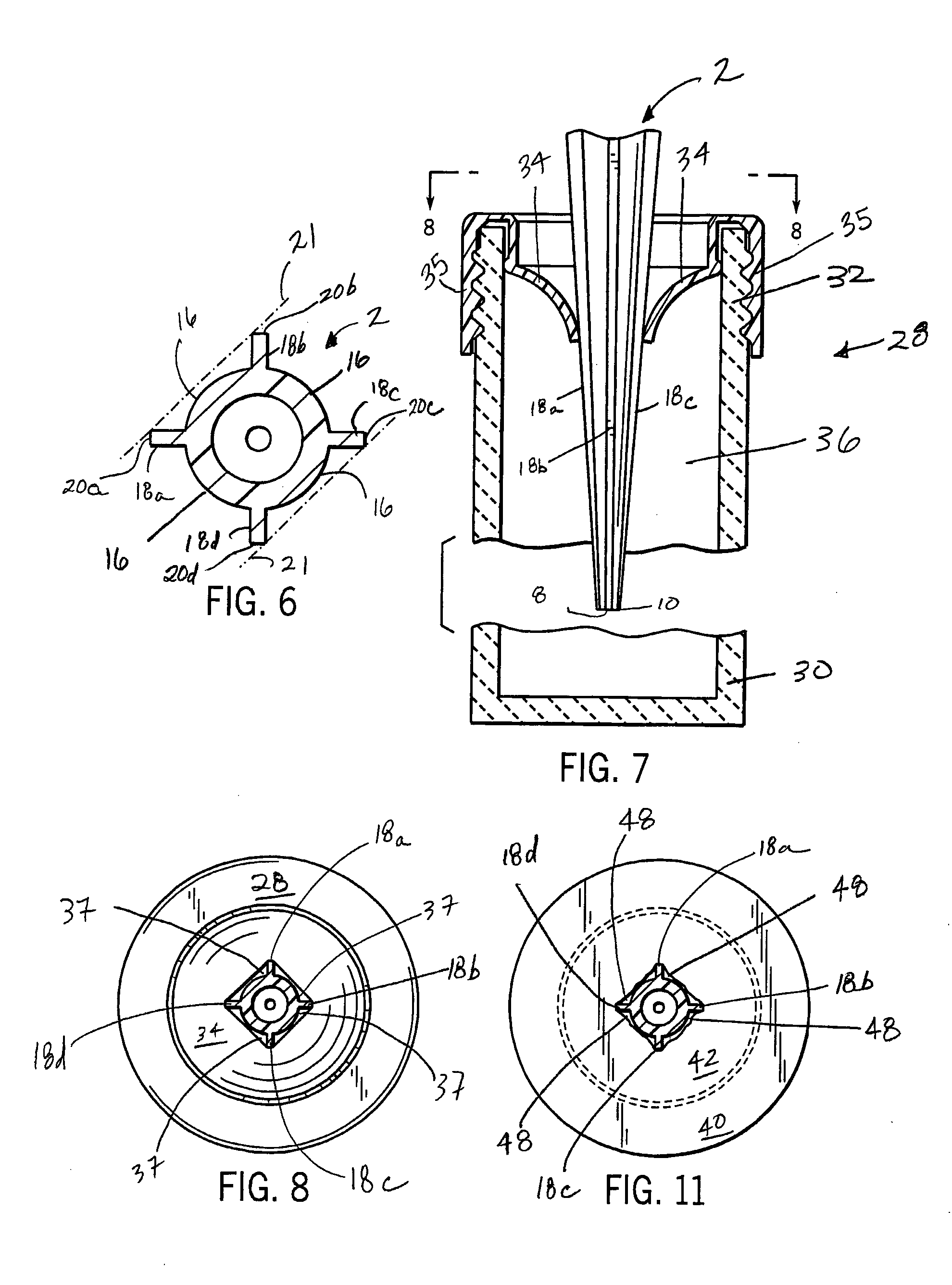

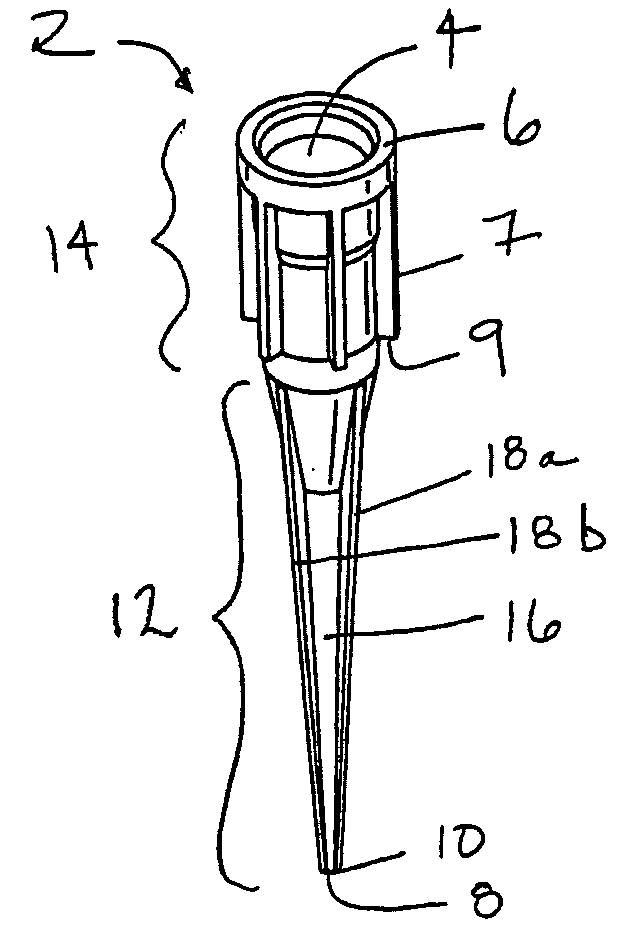

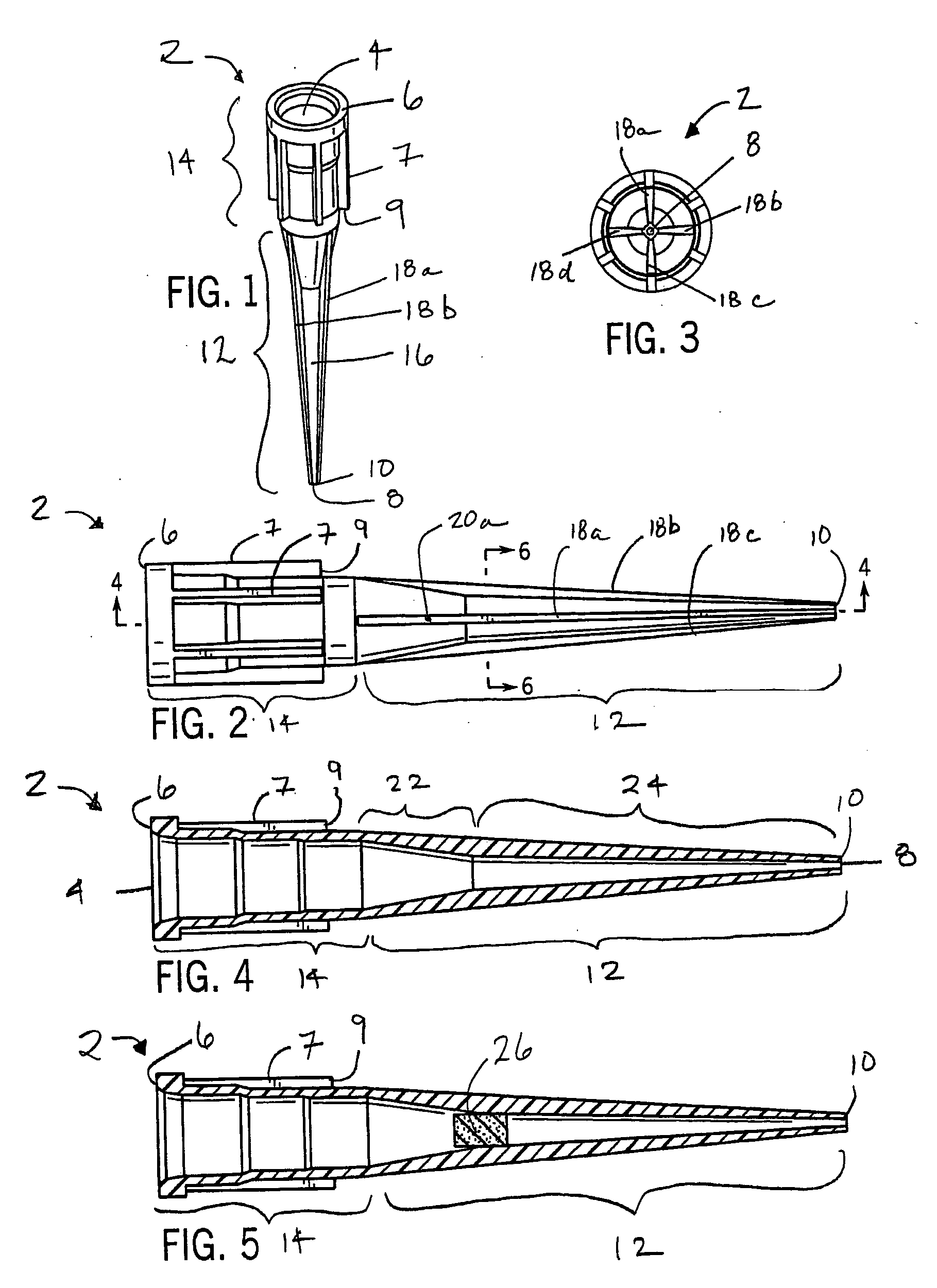

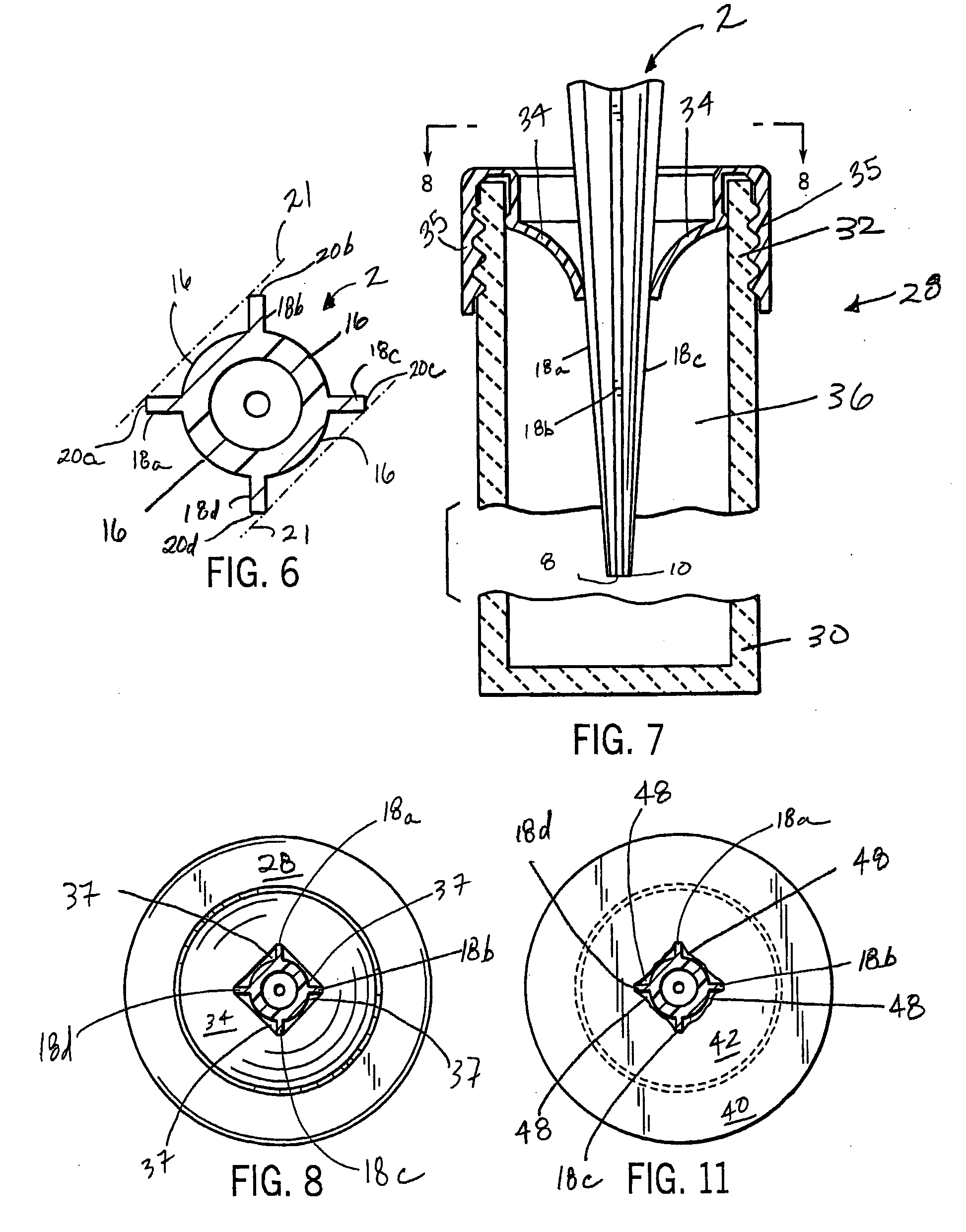

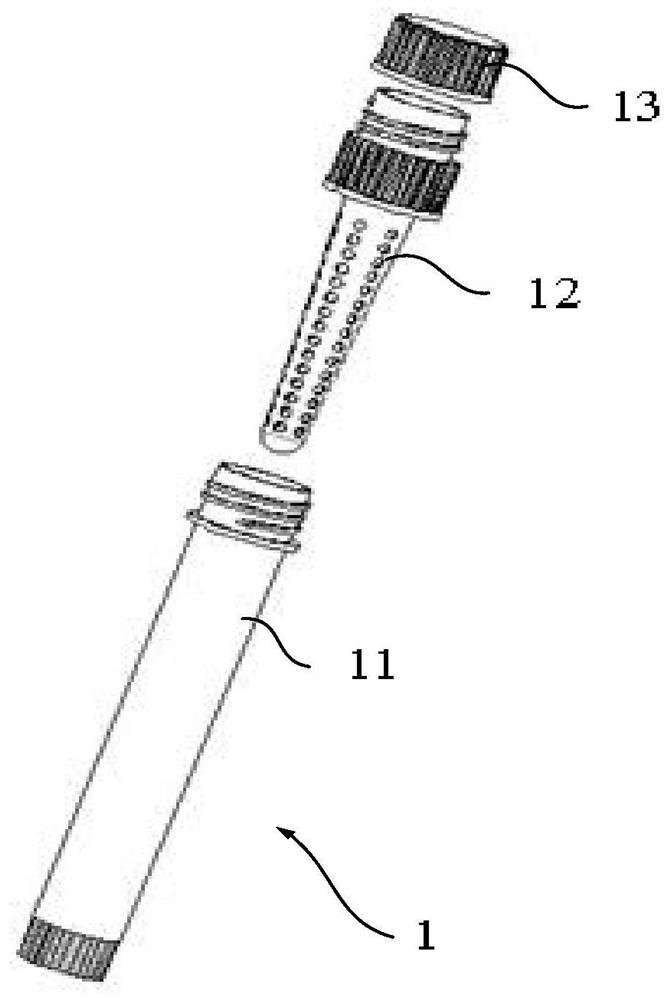

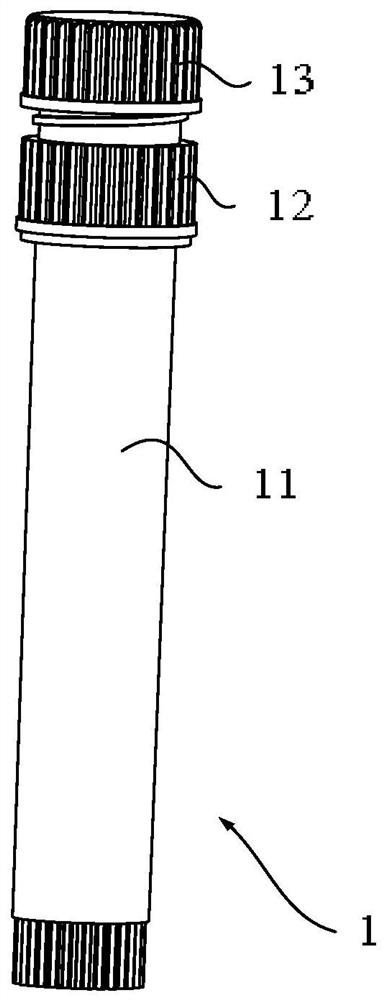

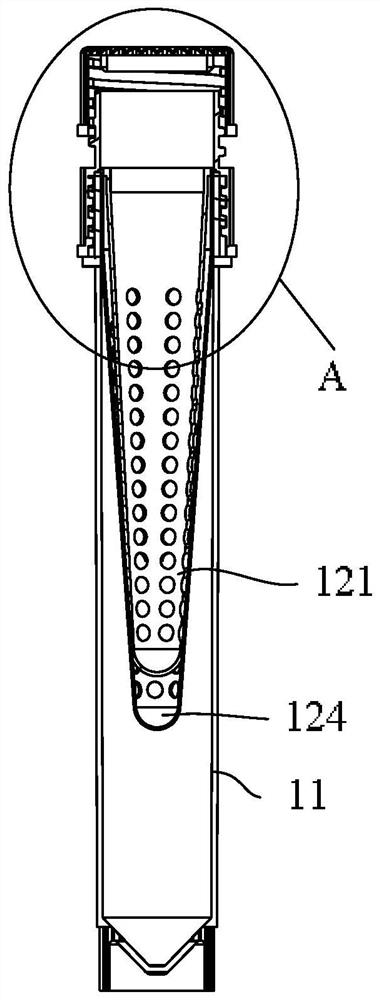

An apparatus and method for liquid sampling utilizing a ribbed pipette tip for barrier penetration is disclosed herein. The unique, disposable plastic pipette tip of the present invention has an outer surface with at least three ribs extending longitudinally along the outer surface of the barrel. Each rib is circumferentially spaced from one another at a uniform distance, with each rib being symmetrically sized and positioned on the pipette tip barrel. The pipette tip is capable of being placed on a mounting shaft of a hand-held pipette or on the mounting head of an automated liquid handling machine. The pipette tip is rigid and straight enough to pierce a barrier sheet or resilient barrier sealing a container holding a liquid to be sampled. The ribs of the pipette tip operate to keep the barrier separated from the outer surface of the pipette tip such that ambient air is allowed to flow into and from the interior of the sealed container assembly during aspiration of the liquid sample into the pipette tip allowing for accurate transfer of liquids while minimizing the risk of contamination. The pipette tip and method of the present invention may be utilized in an automated pipetting system to sample an array of sealed containers, such as sealed wells and the pipette tip is sufficiently. The pipette of the present invention may include a self-sealing filter to prevent cross-contamination.

Owner:MOLECULAR BIOPROD

Disposable tip magazine

InactiveUS6426047B1Sufficient inherent stiffnessIncrease displacementBurettes/pipettesSupporting apparatusMechanical pipetteBiomedical engineering

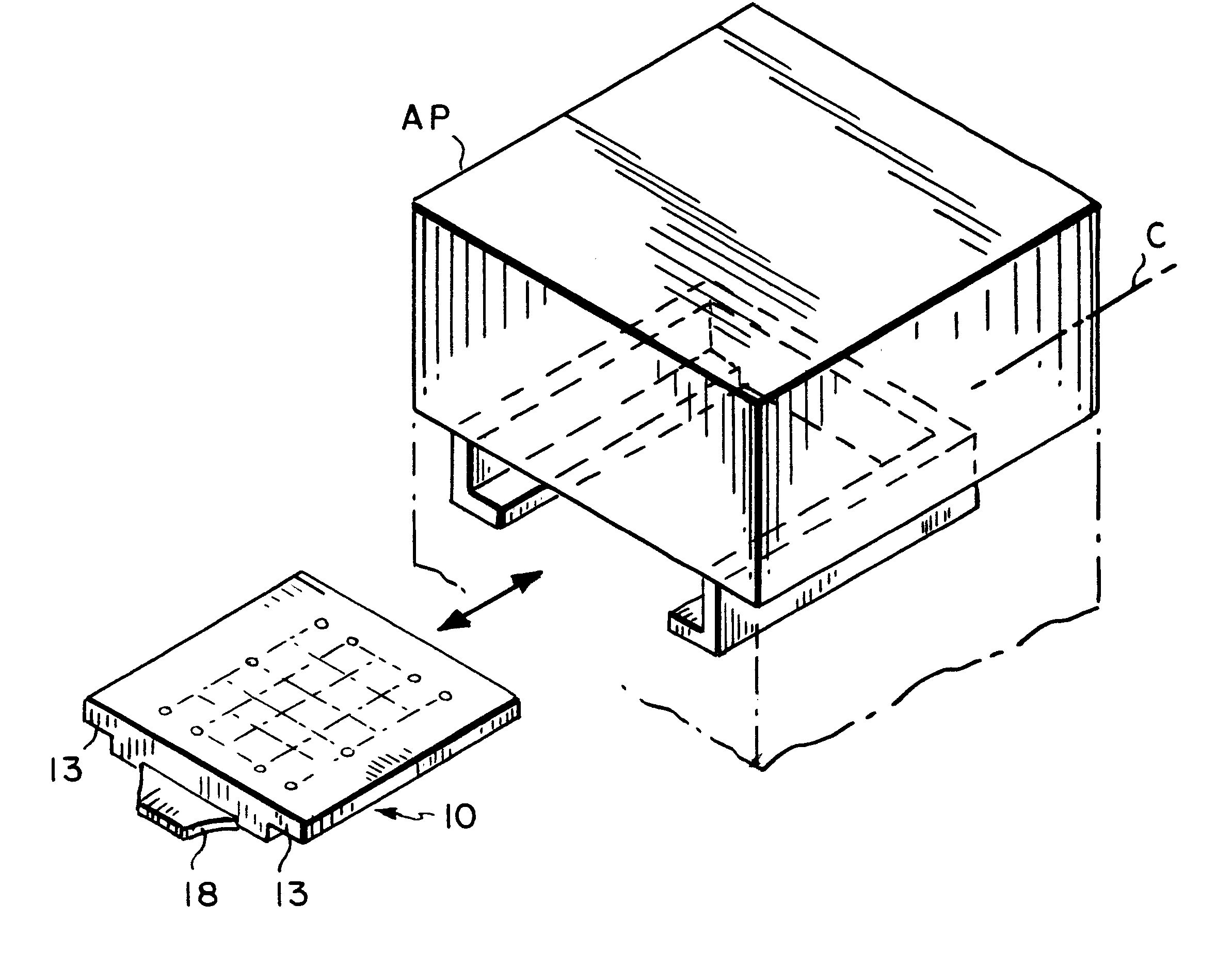

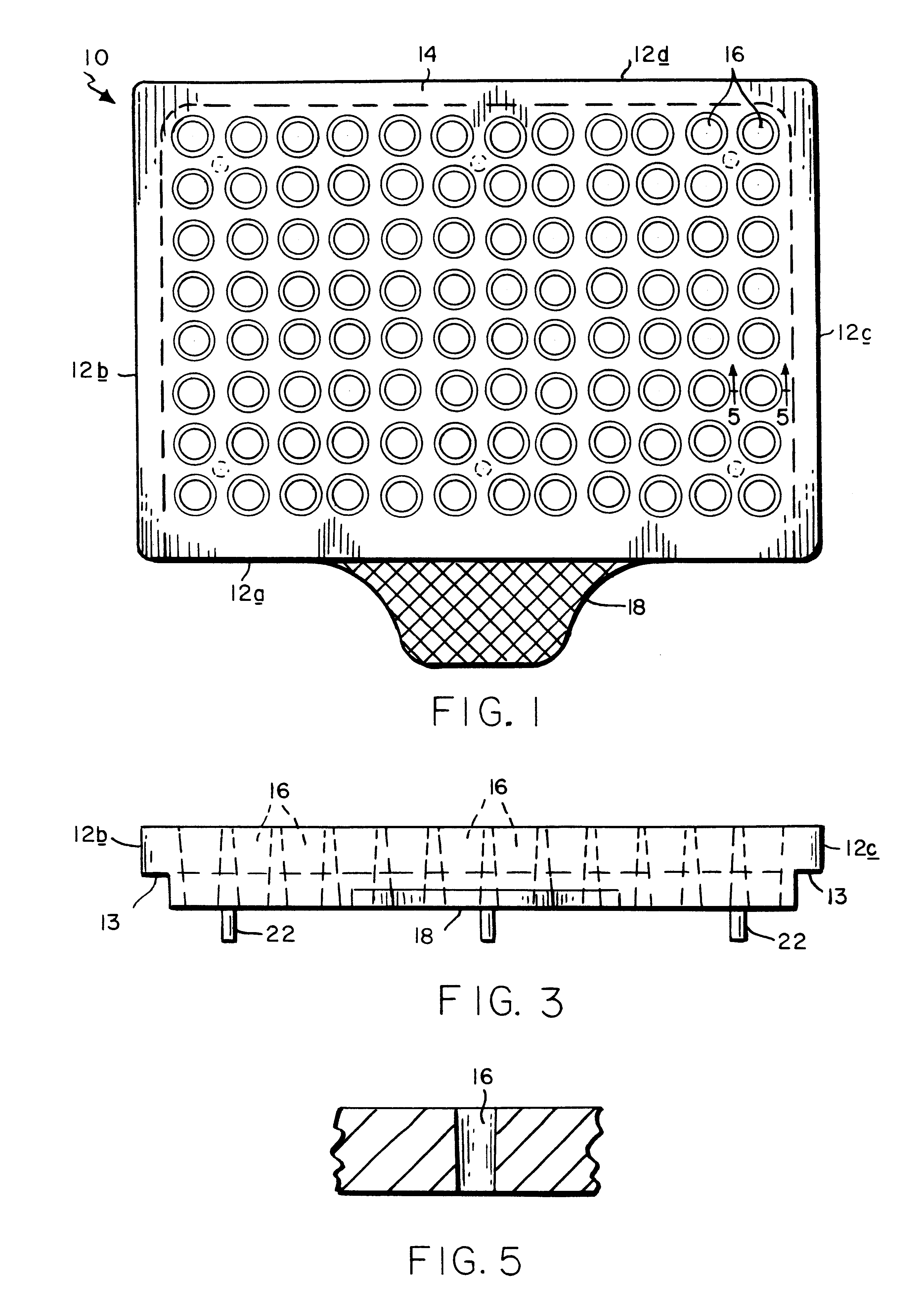

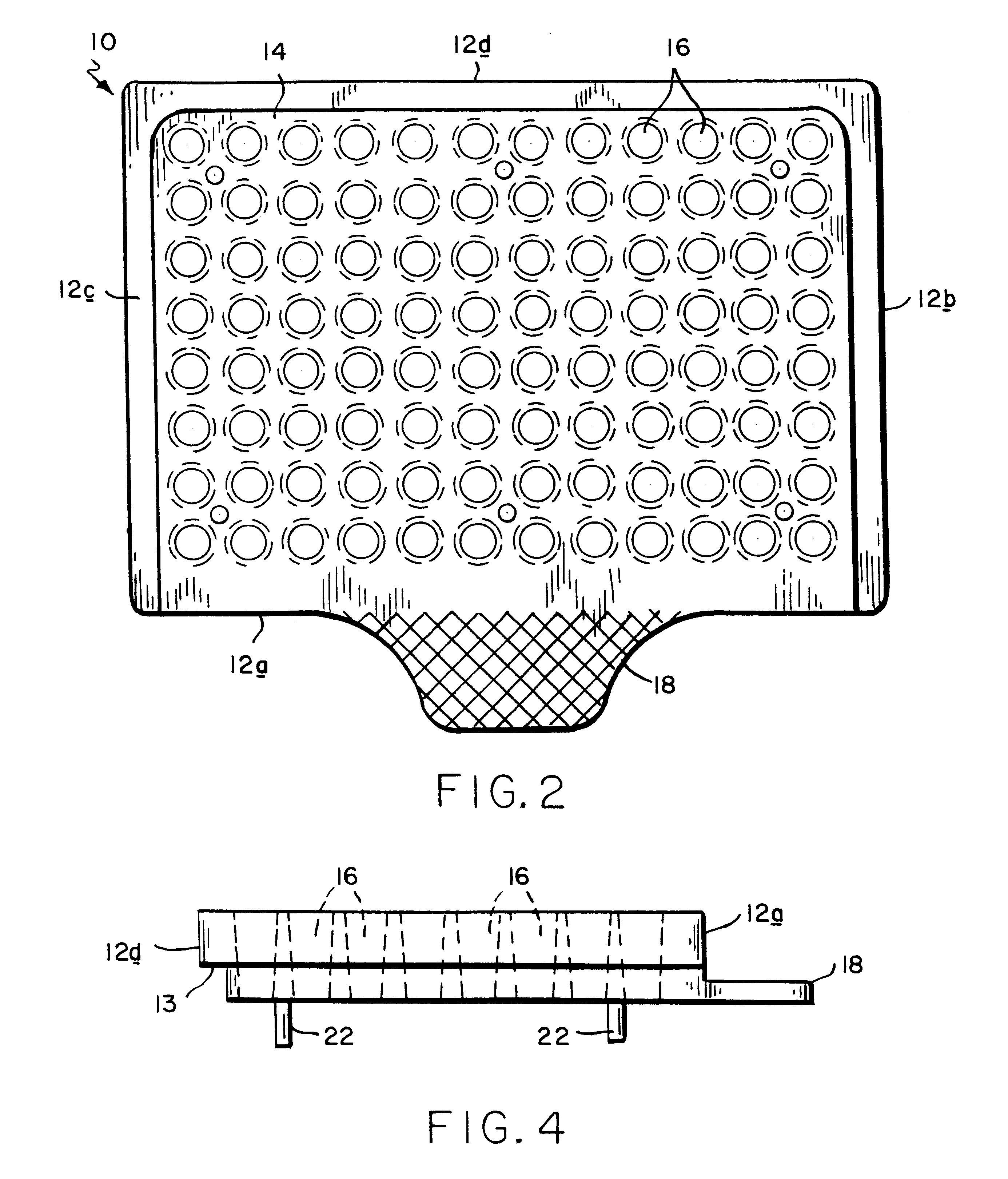

A pipette tip magazine used in an automated pipetting system which has a pipetting chamber with a generally U-shaped ledge. The pipette tip magazine is adapted for insertion into and removal from an operative position contained in the chamber and supported on the ledge. The magazine includes a generally rectangular plate having an undercut edge bordering an inner region. The edge is configured to be supported on the ledge, an the inner region has an array of through openings for vertically receiving and retaining pipette tips. The plate is molded from a polymeric resin reinforced with a fibrous material.

Owner:MATRIX TECH

Fluid dispenser for fluid in assay

InactiveUS20070053797A1Up and downAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionSurface plasmonMechanical pipette

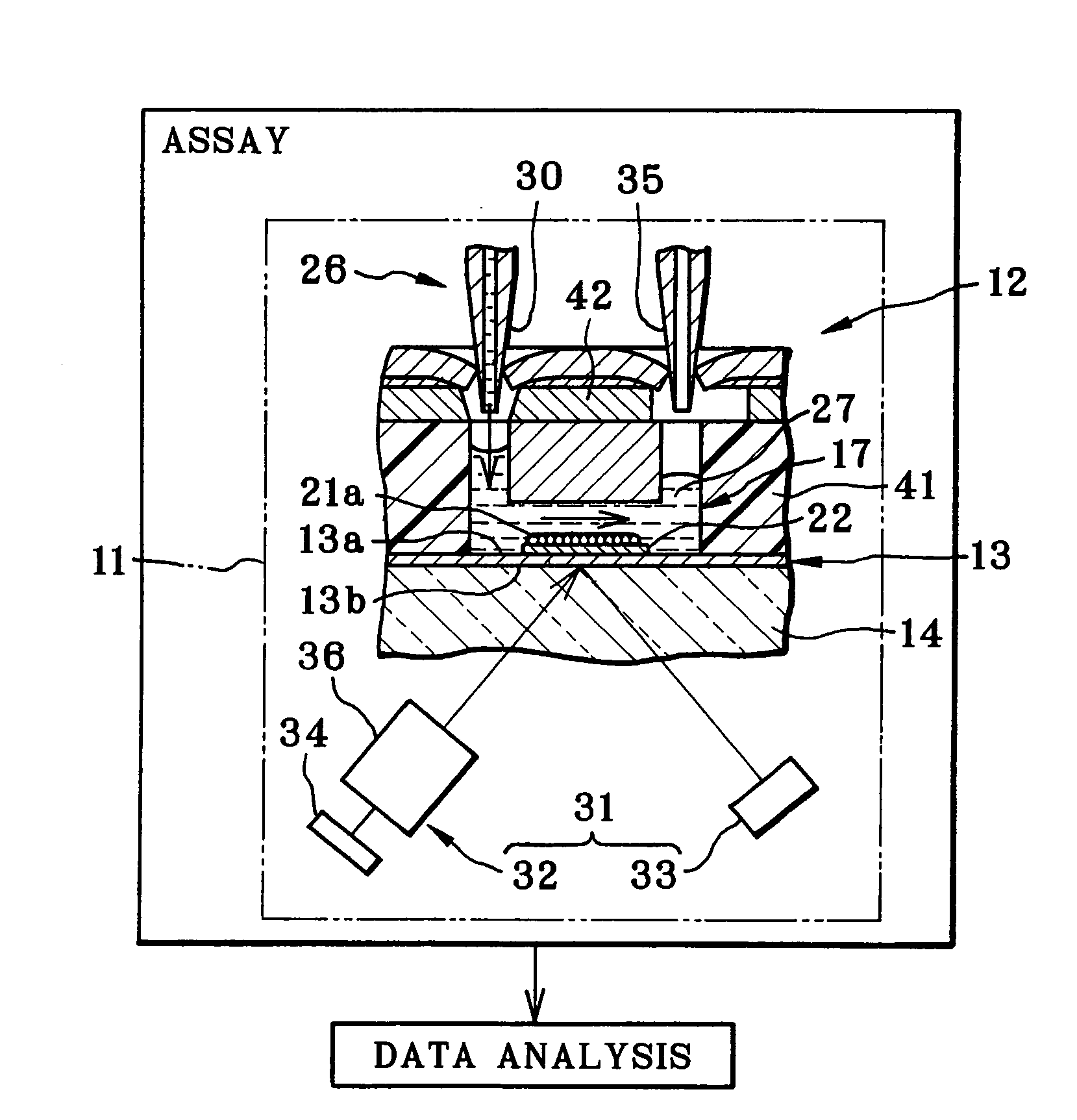

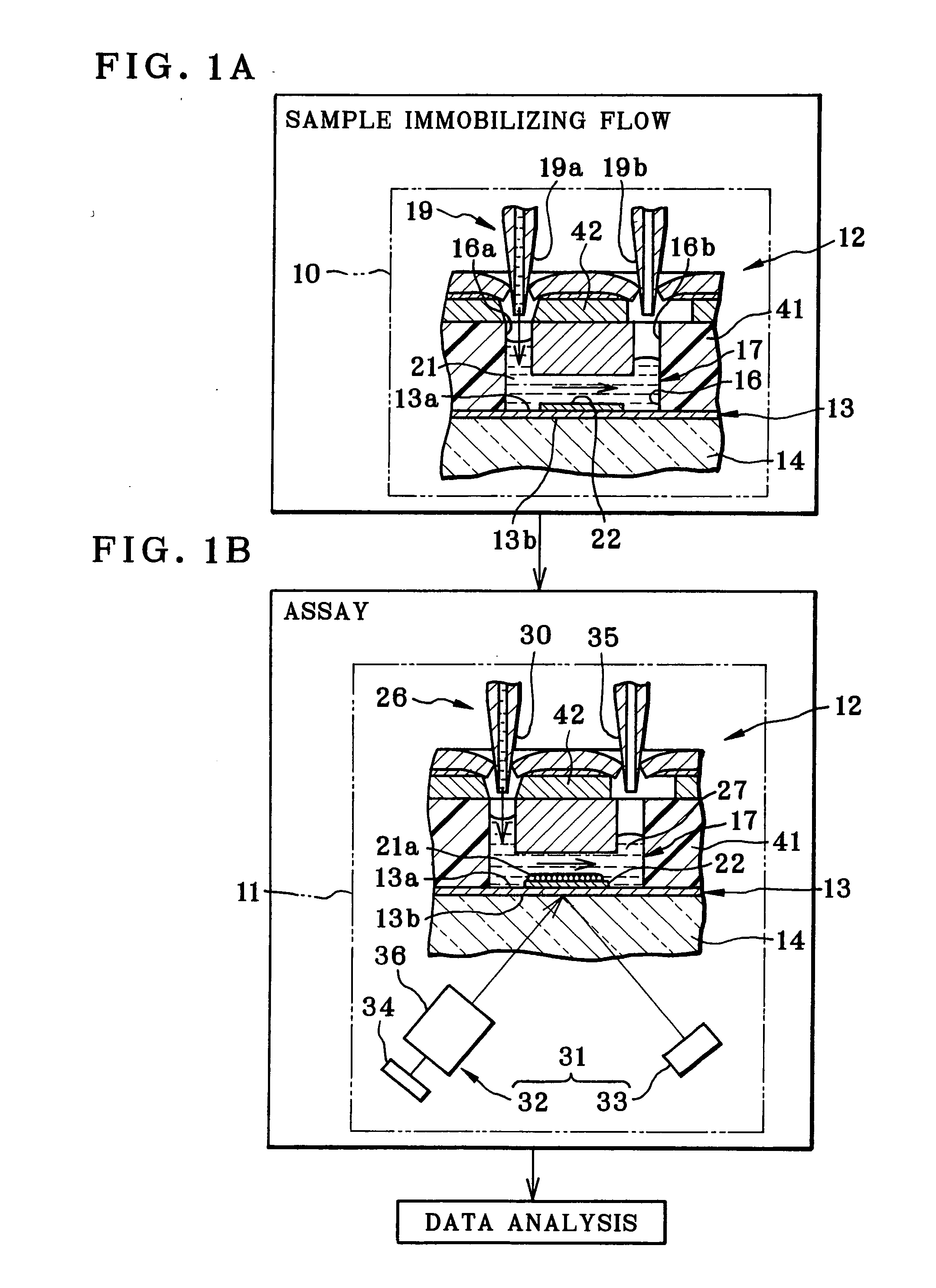

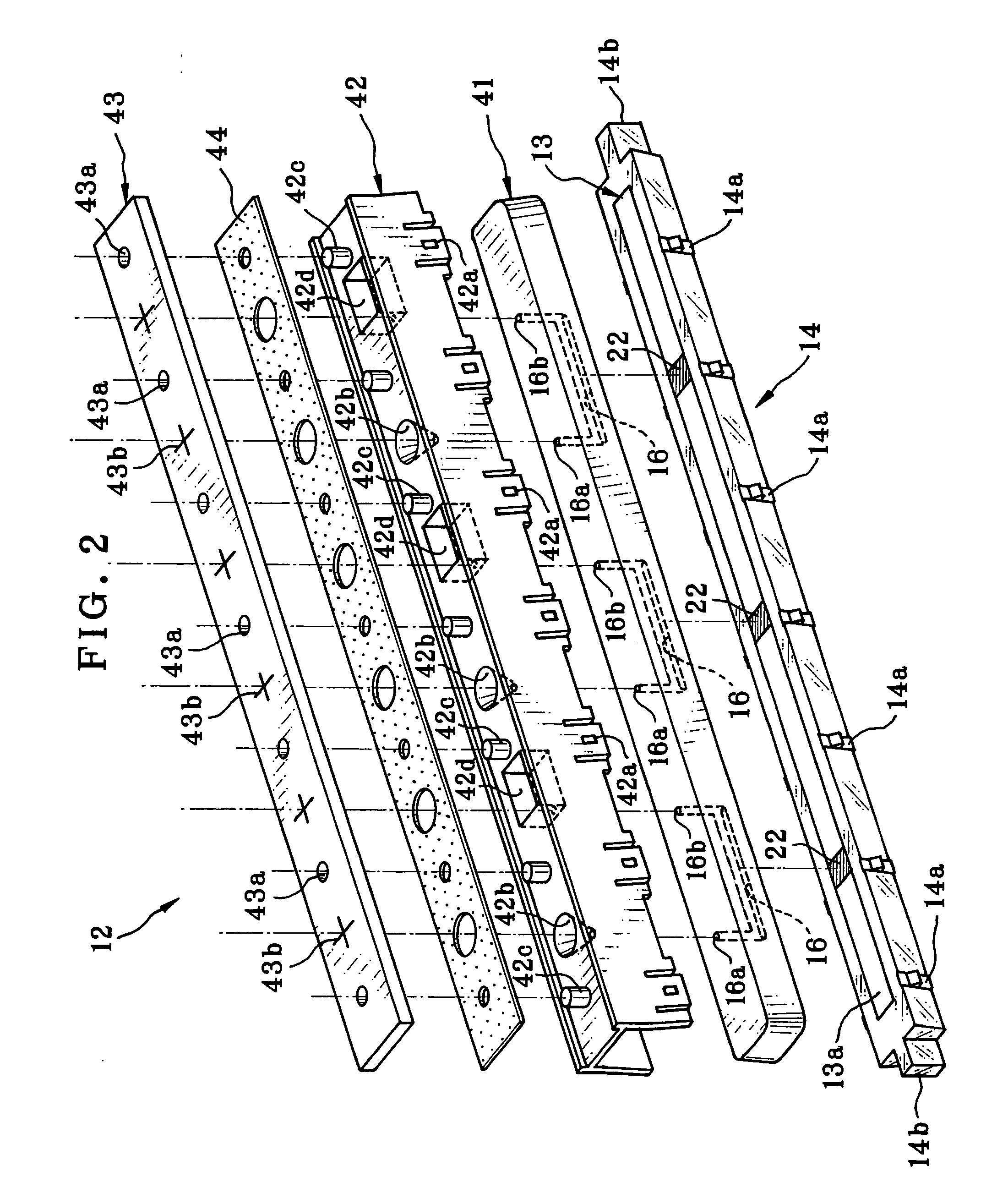

A fluid dispenser for surface plasmon resonance (SPR) assay apparatus includes a first pipette device on a first pipette head, and a second pipette device on a second pipette head. In a standby state, the first pipette head is set in an upper position, a coil spring and a stopper set the second pipette head together with the first pipette head, and locate the second pipette head in a high position. While the first and second pipette devices are in an aspirating position, a driving mechanism sets the first pipette head in a lower position. A blocking mechanism sets the second pipette head in a high position against the coil spring. First, third and fifth pipette tips is positioned lower than second, fourth and sixth pipette tips, to access a well. The first to sixth pipette tips, while in an assay position, are equally lowered.

Owner:FUJIFILM HLDG CORP +1

Liquid sampling utilizing ribbed pipette tip for barrier penetration

An apparatus and method for liquid sampling utilizing a ribbed pipette tip for barrier penetration is disclosed herein. The unique, disposable plastic pipette tip of the present invention has an outer surface with at least three ribs extending longitudinally along the outer surface of the barrel. Each rib is circumferentially spaced from one another at a uniform distance, with each rib being symmetrically sized and positioned on the pipette tip barrel. The pipette tip is capable of being placed on a mounting shaft of a hand-held pipette or on the mounting head of an automated liquid handling machine. The pipette tip is rigid and straight enough to pierce a barrier sheet or resilient barrier sealing a container holding a liquid to be sampled. The ribs of the pipette tip operate to keep the barrier separated from the outer surface of the pipette tip such that ambient air is allowed to flow into and from the interior of the sealed container assembly during aspiration of the liquid sample into the pipette tip allowing for accurate transfer of liquids while minimizing the risk of contamination. The pipette tip and method of the present invention may be utilized in an automated pipetting system to sample an array of sealed containers, such as sealed wells and the pipette tip is sufficiently. The pipette of the present invention may include a self-sealing filter to prevent cross-contamination.

Owner:MOLECULAR BIOPROD

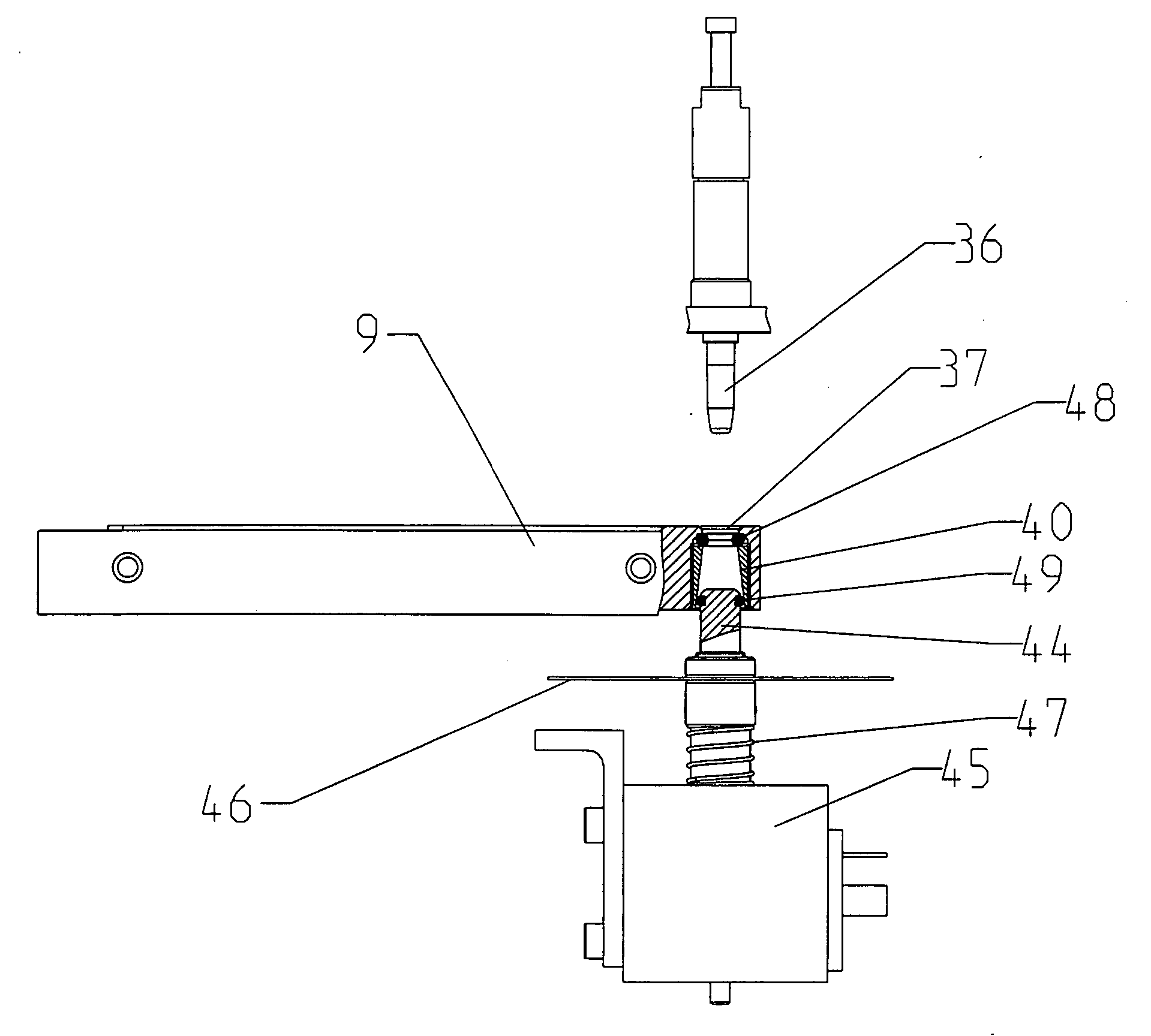

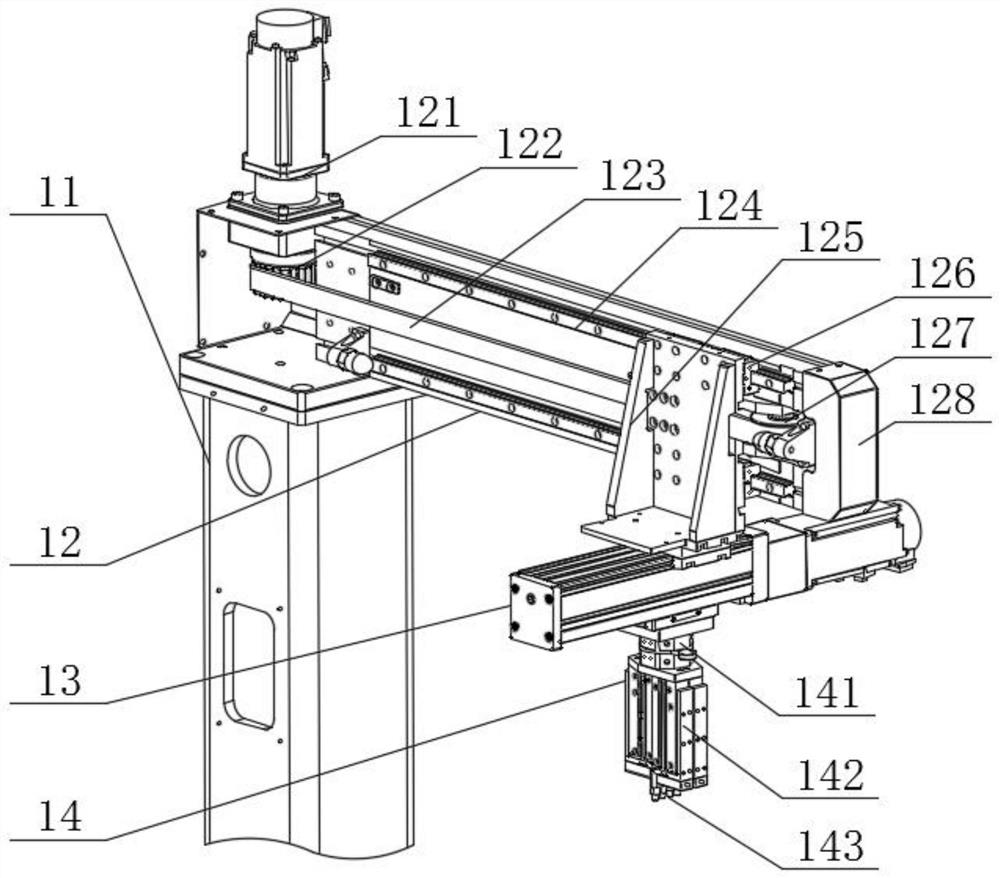

Full-automatic pipetting station and application thereof

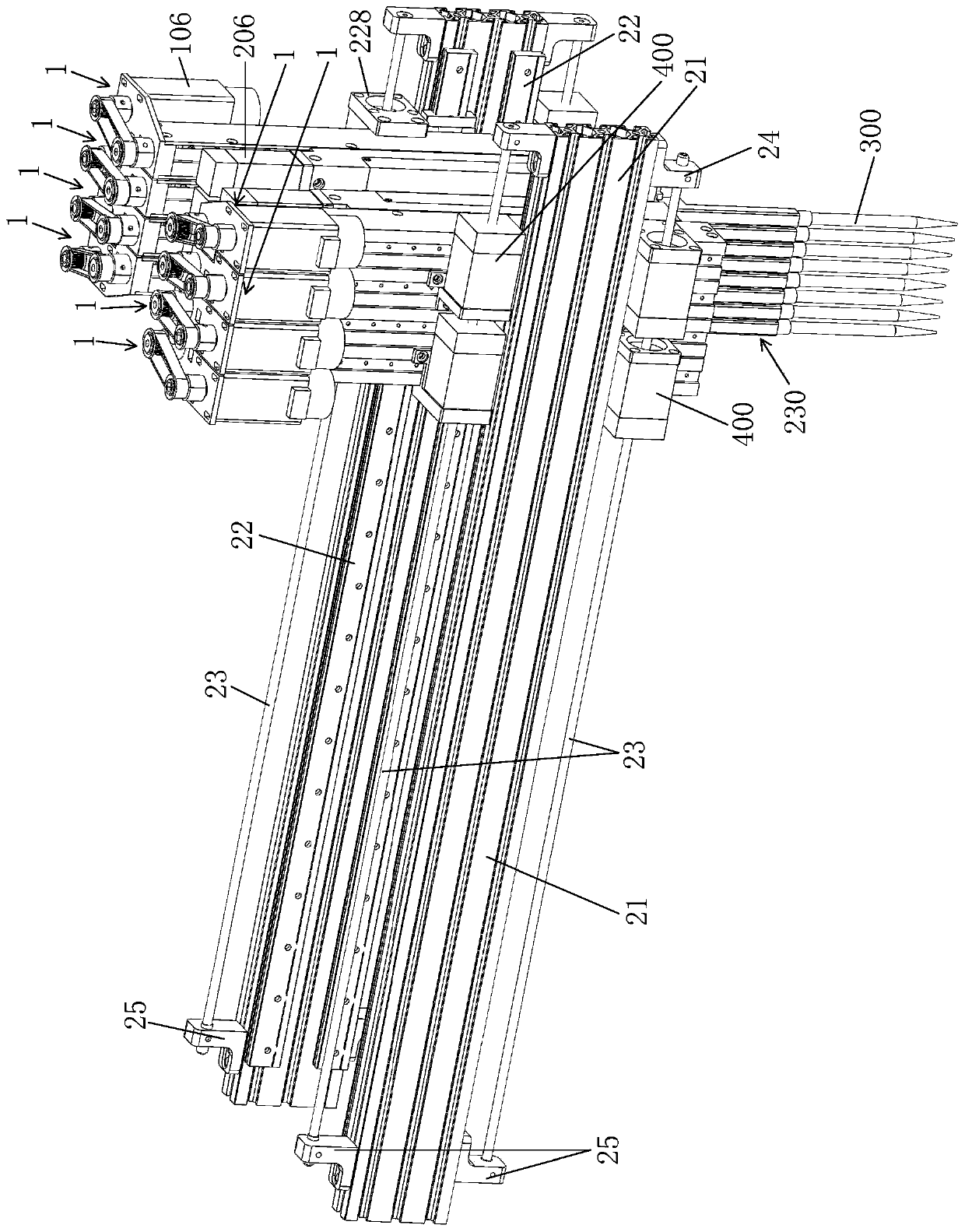

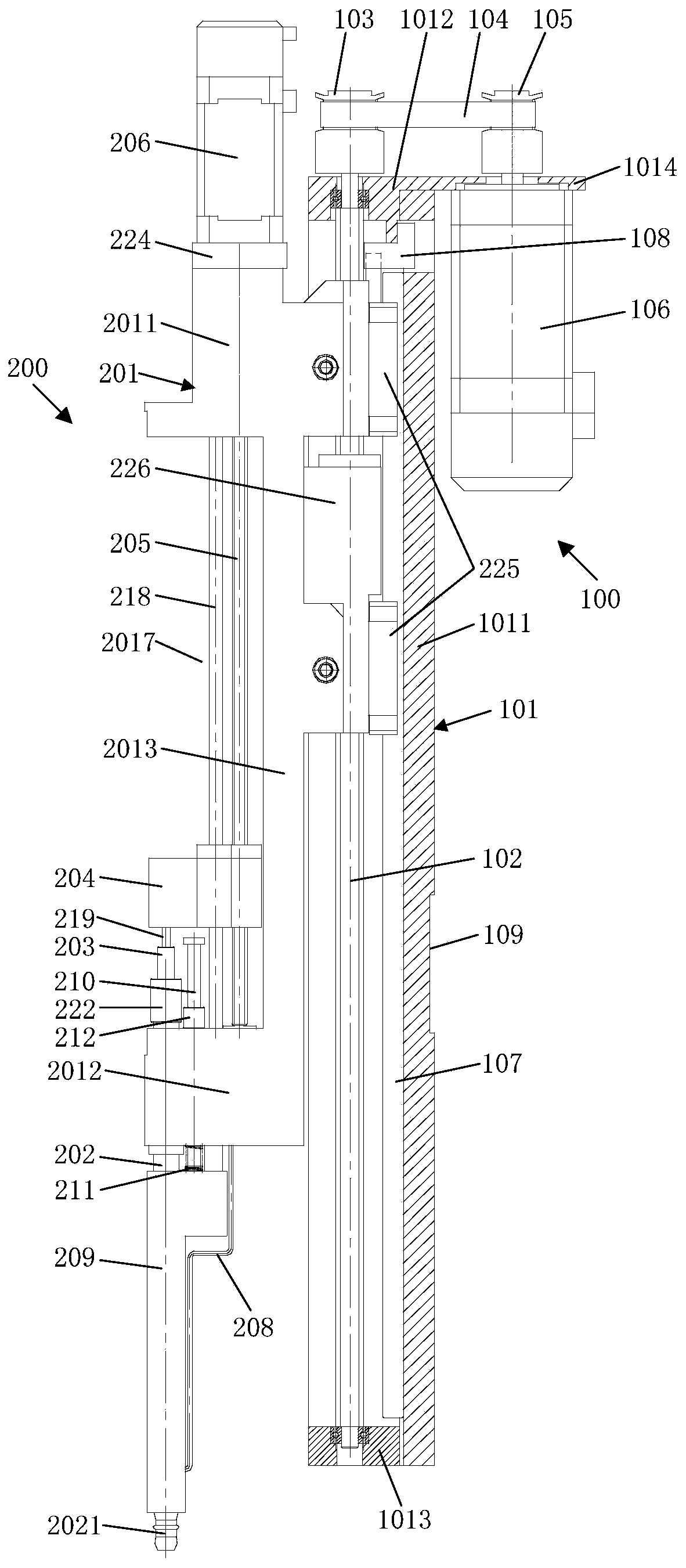

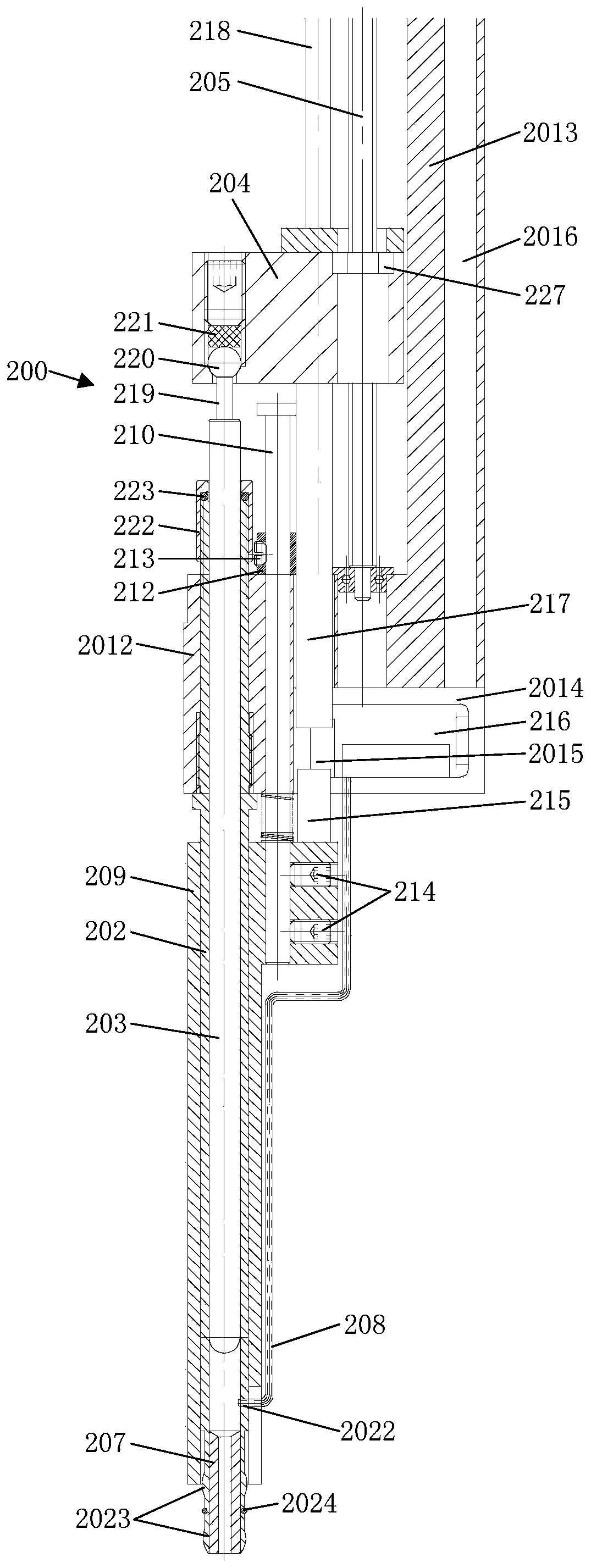

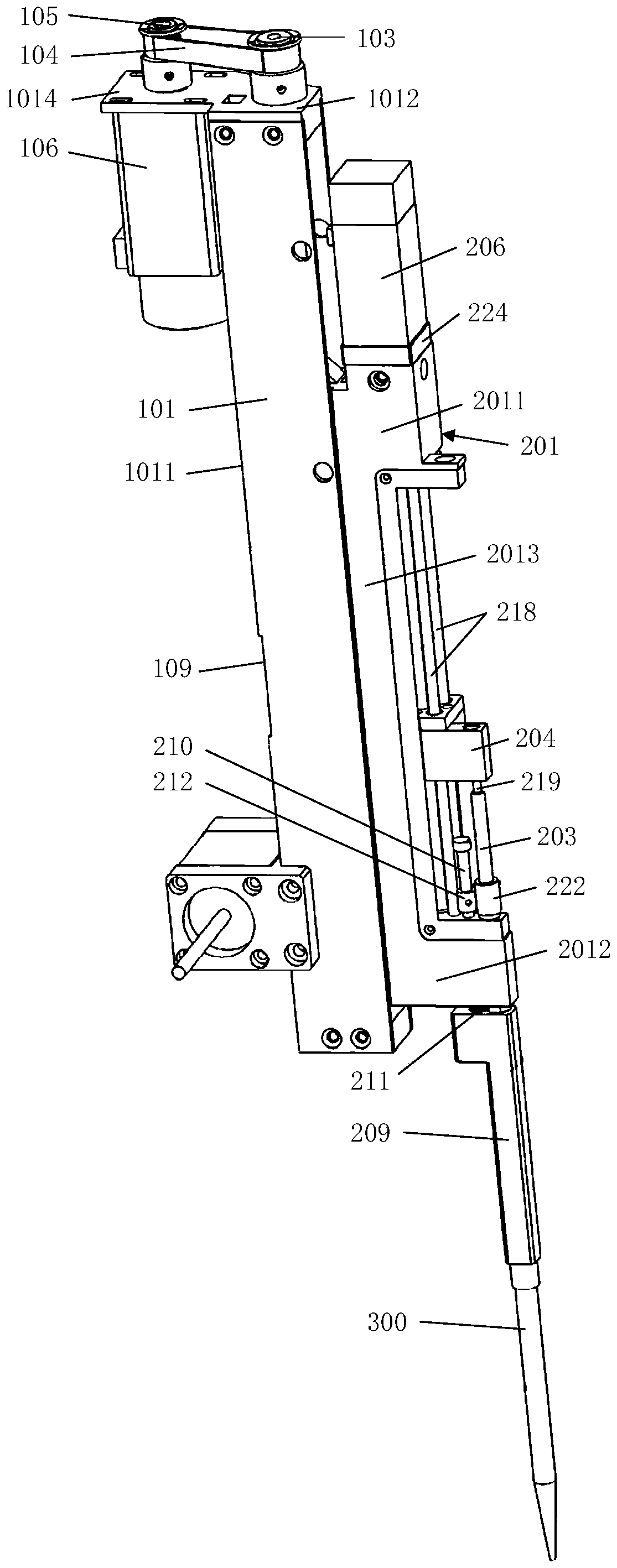

InactiveCN103846114AReasonable layoutSmooth structureWithdrawing sample devicesBurettes/pipettesMechanical pipetteControl theory

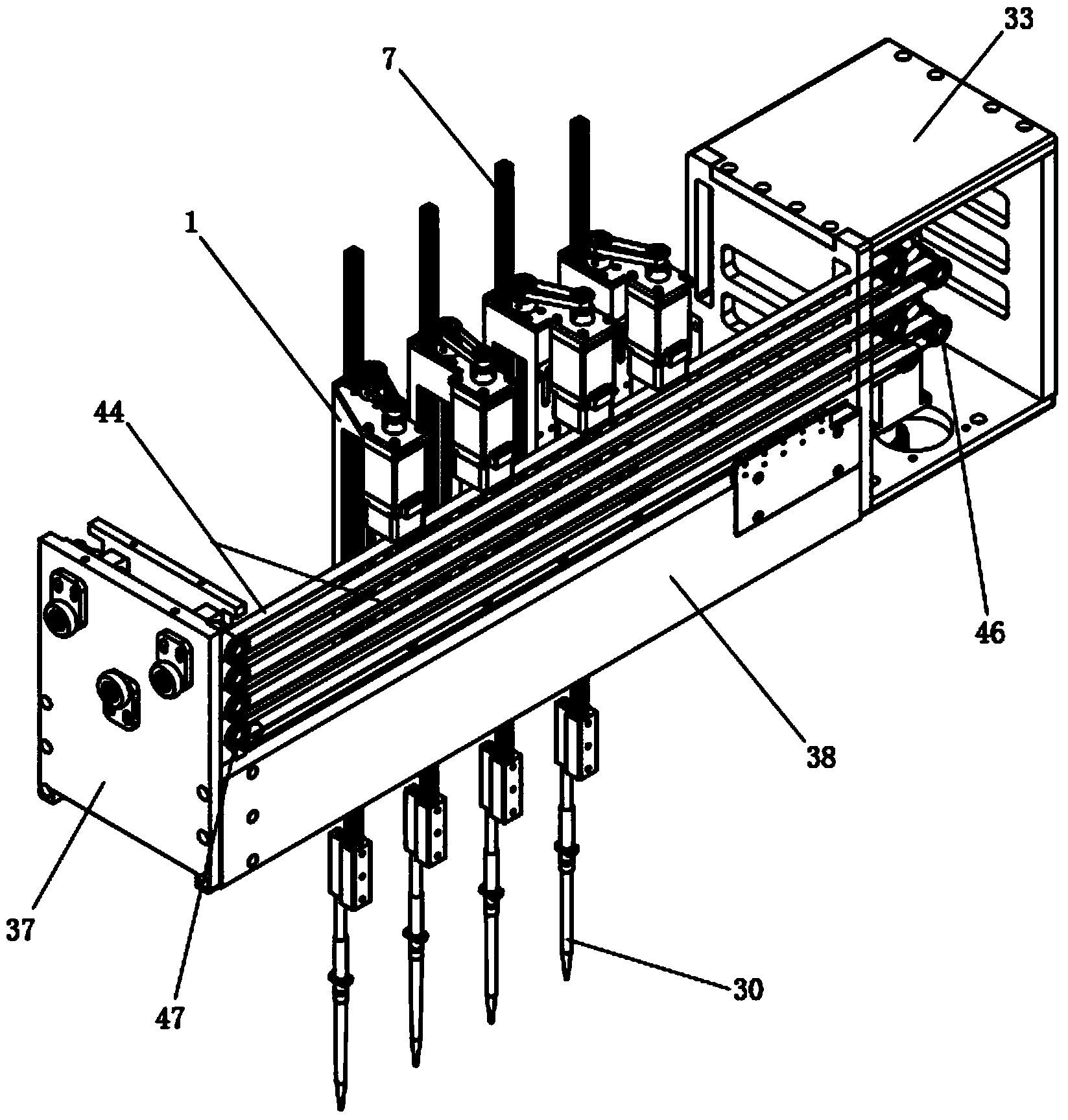

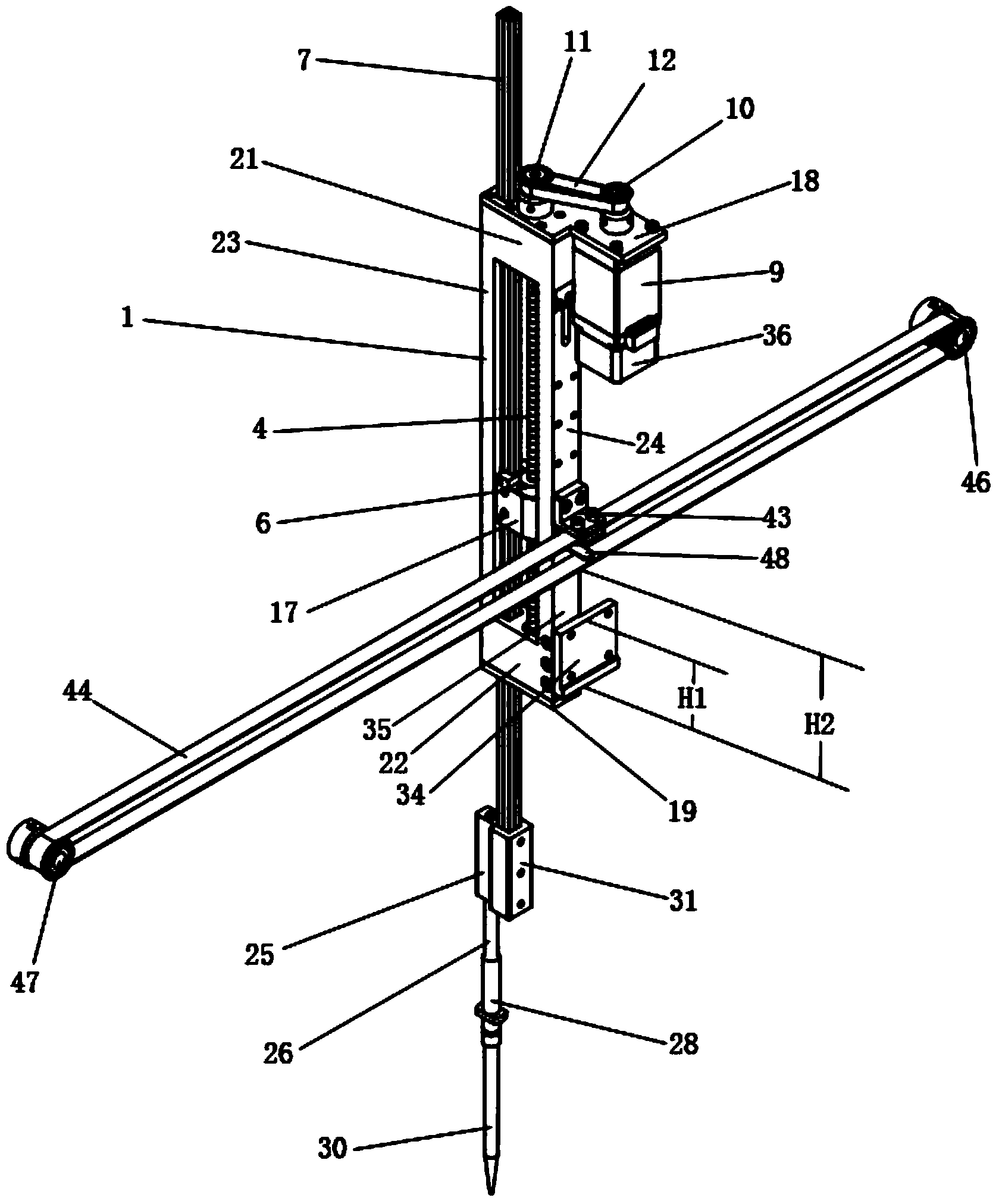

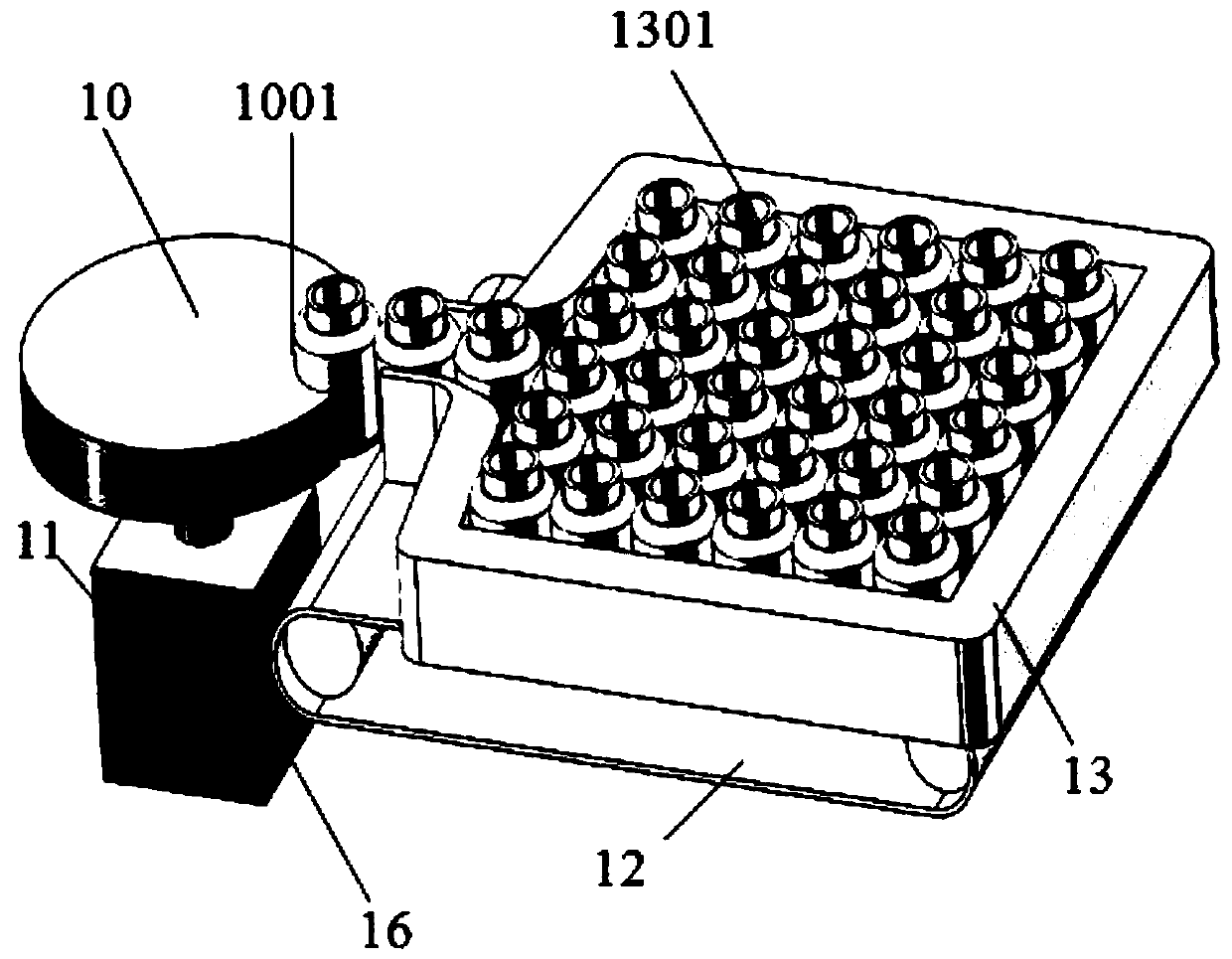

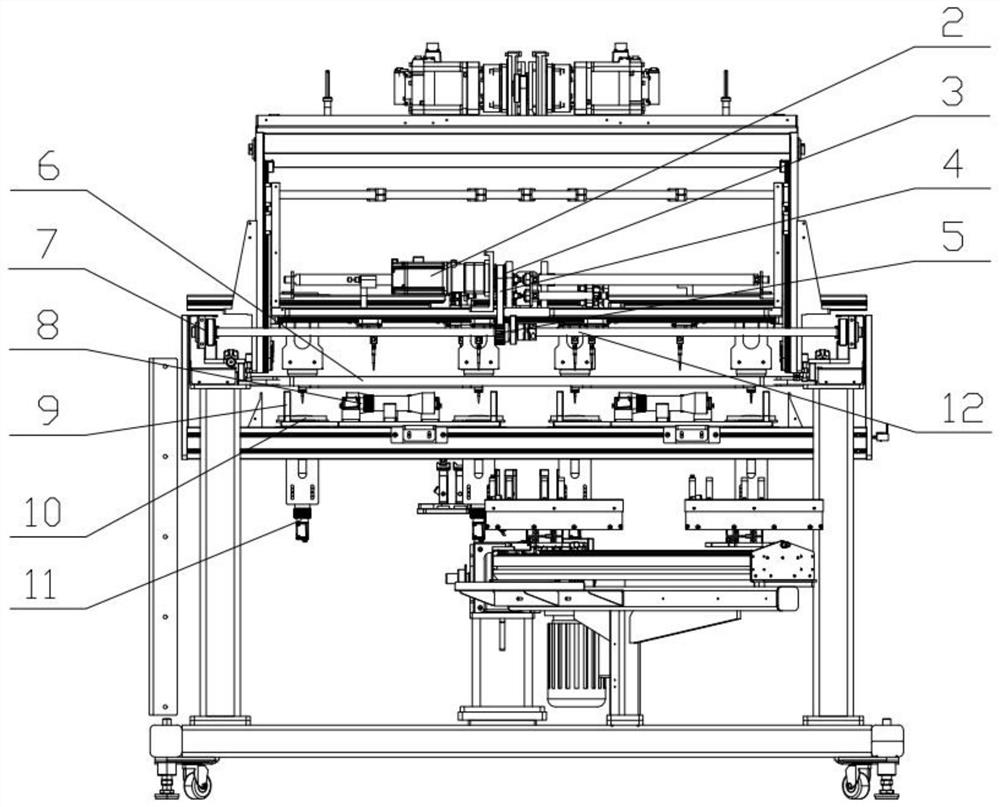

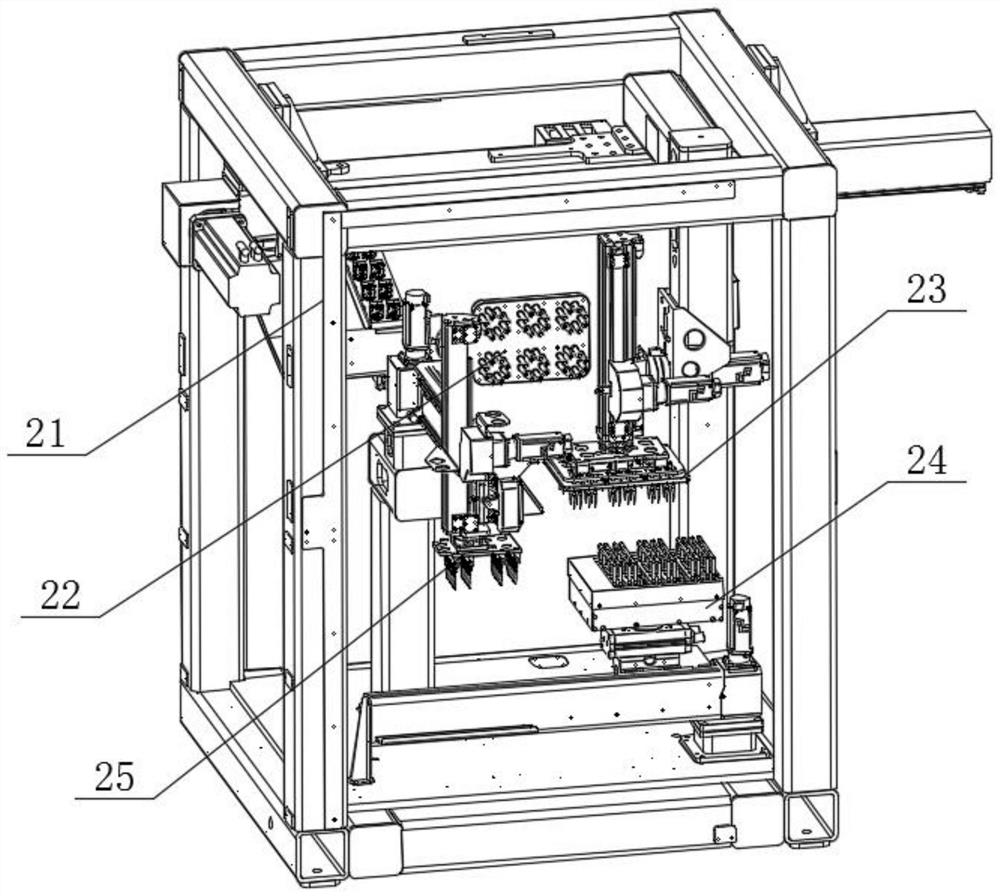

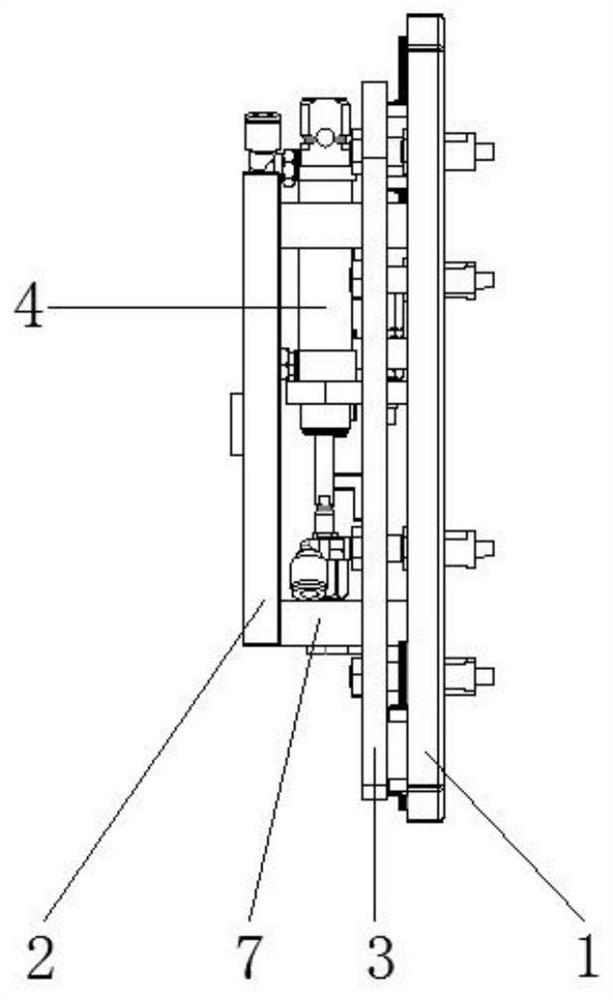

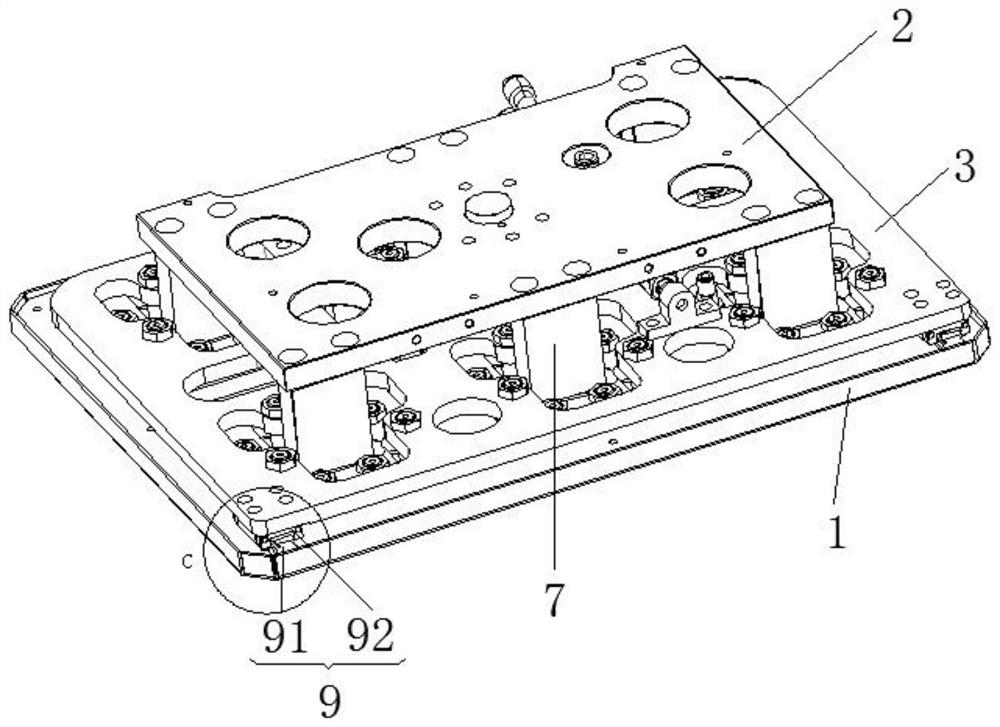

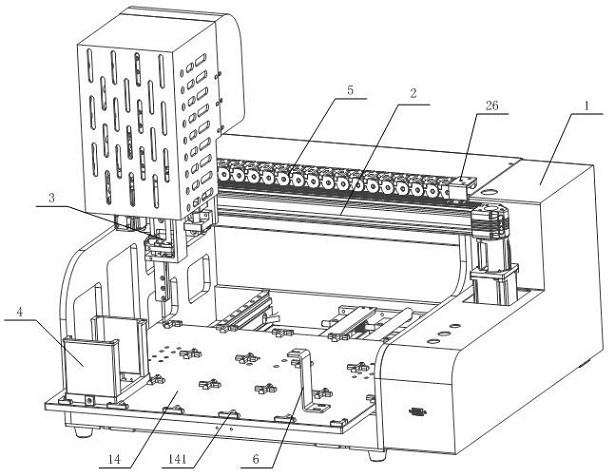

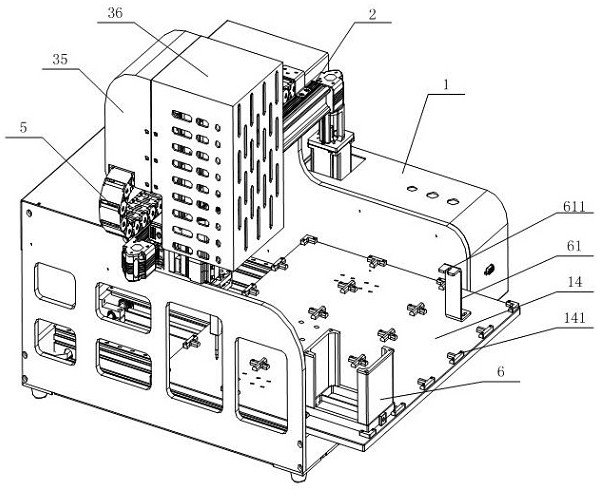

The invention provides a full-automatic pipetting station comprising a pipetting mechanism support and a plurality of pipetting mechanisms. Each pipetting mechanism comprises a moving base, a moving rod, a moving rod driving mechanism, a linear guide rail fixing seat and a pipetting head, wherein the moving rod is movably assembled on the moving base, and the pipetting head is arranged at the lower end of the moving rod. The invention also provides an application of the pipetting station in the aspects of liquid sample injection, liquid transfer and the like. The pipetting station provided by the invention is capable of greatly buffering impact and vibration generated in an operation process, low in driving noise and stable and reliable in driving so that the pipetting mechanisms in the station can more flexibly operate and the pipetting head can operate to more plate positions.

Owner:GENMAG BIOTECH

Large volume pipette tip for loading in an automated liquid handler

InactiveUS20120180579A1Increase speedBurettes/pipettesMaterial analysisMechanical pipetteBiomedical engineering

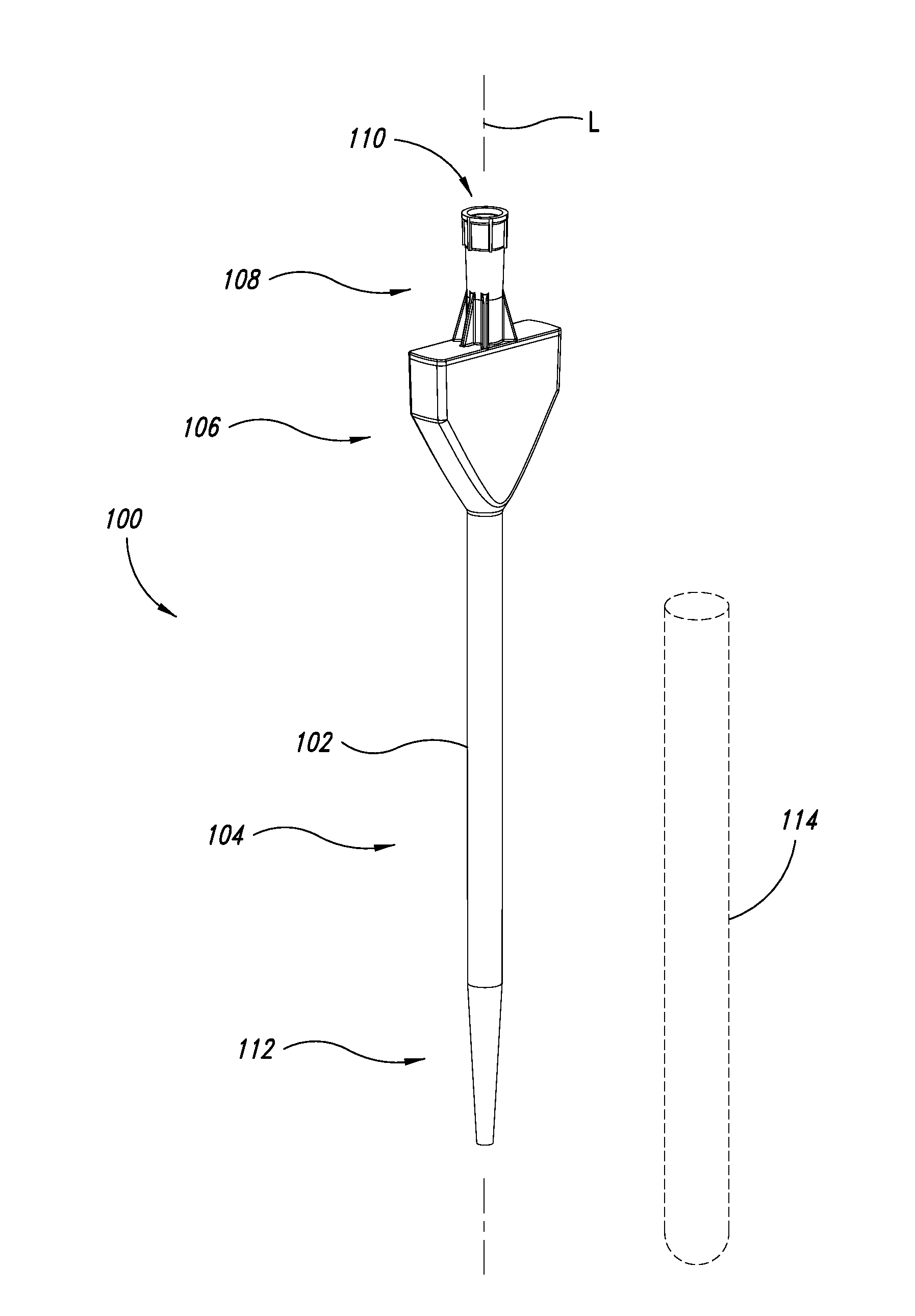

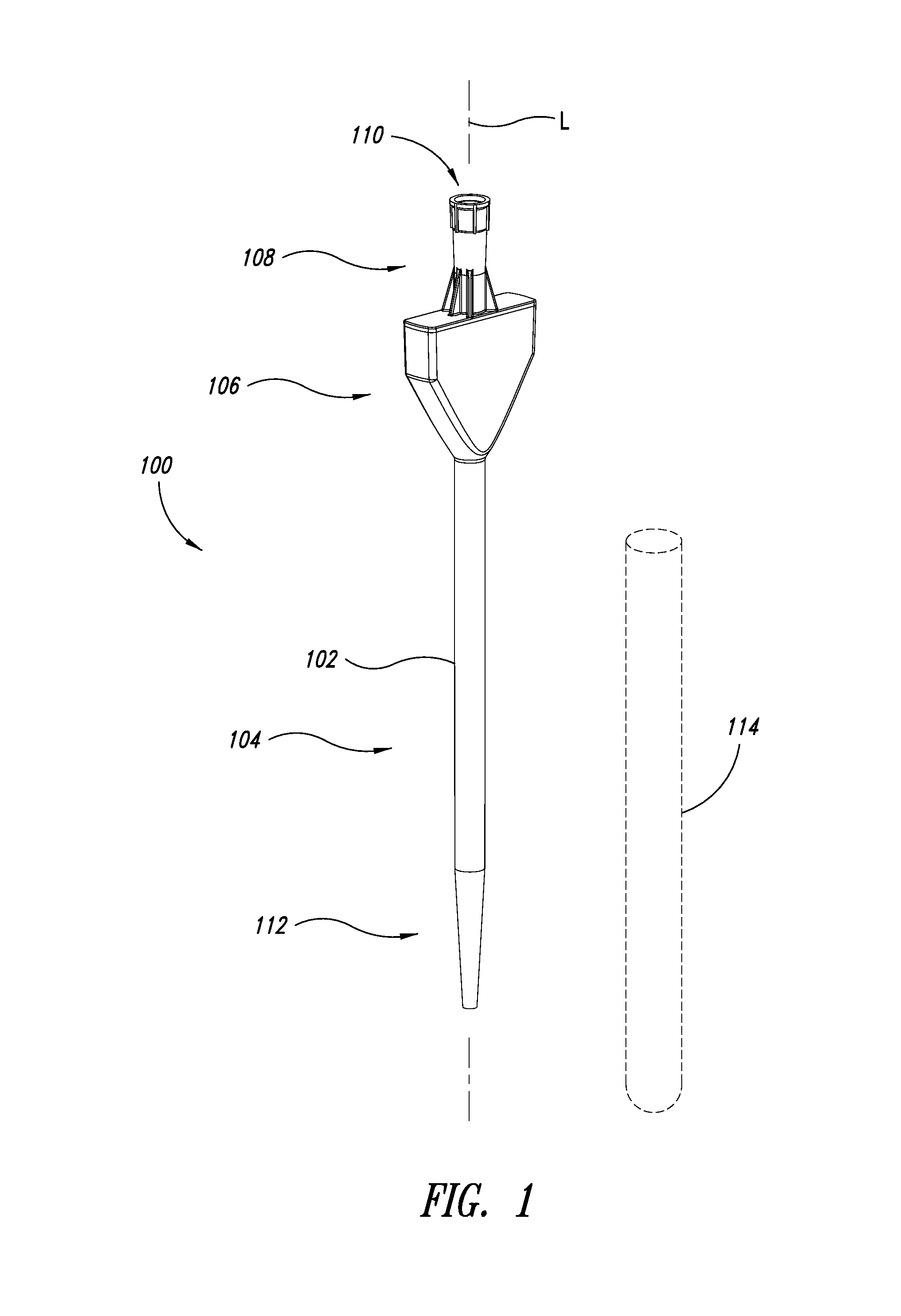

A pipette tip having lower, upper and central portions and a bore extending therethrough. The lower portion is elongated and projects in a first direction from the central portion, and is sized and shaped for insertion into a test-tube. The bore is adapted for aspirating and dispensing a large volume of the liquid. The upper portion projects from the central portion in a second direction opposing the first direction, and its terminal end is sized and shaped to sealingly engage an automated pipetting system. The central portion and a corresponding portion of the bore are enlarged with respect to both the upper and lower portions to allow the pipette tip to hold the large volume of the liquid. The central portion can have a cross-section substantially rectangular in shape. The cross-section can have a height at least substantially similar to the diameter of the lower portion of the pipette tip and a width significantly greater than the diameter of the lower portion of the pipette tip.

Owner:PERKINELMER HEALTH SCIENCES INC

Automatic pipetting and analyzing device

InactiveUS20060110287A1Material analysis by optical meansBurettes/pipettesMechanical pipetteEngineering

Owner:CYBIO AG

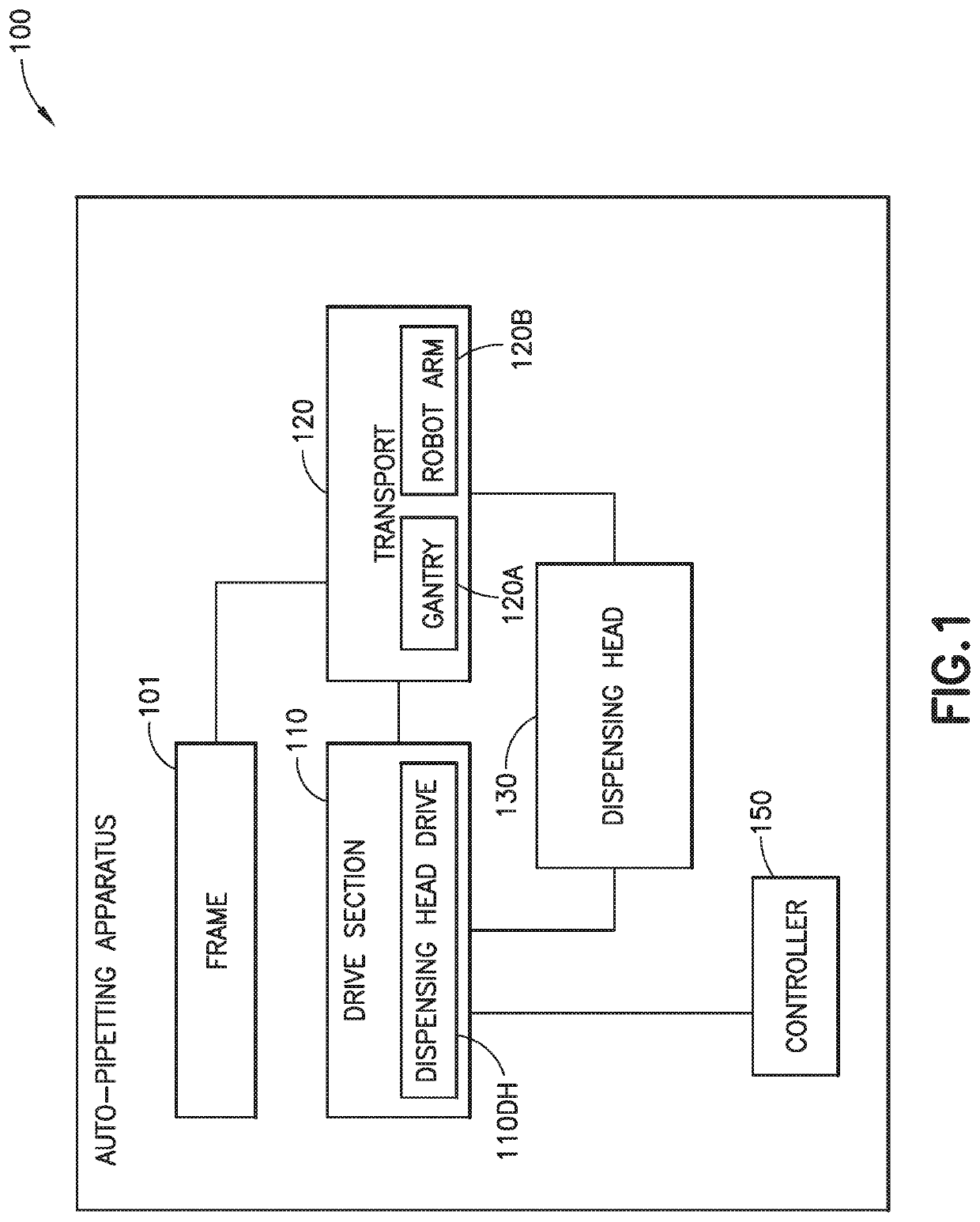

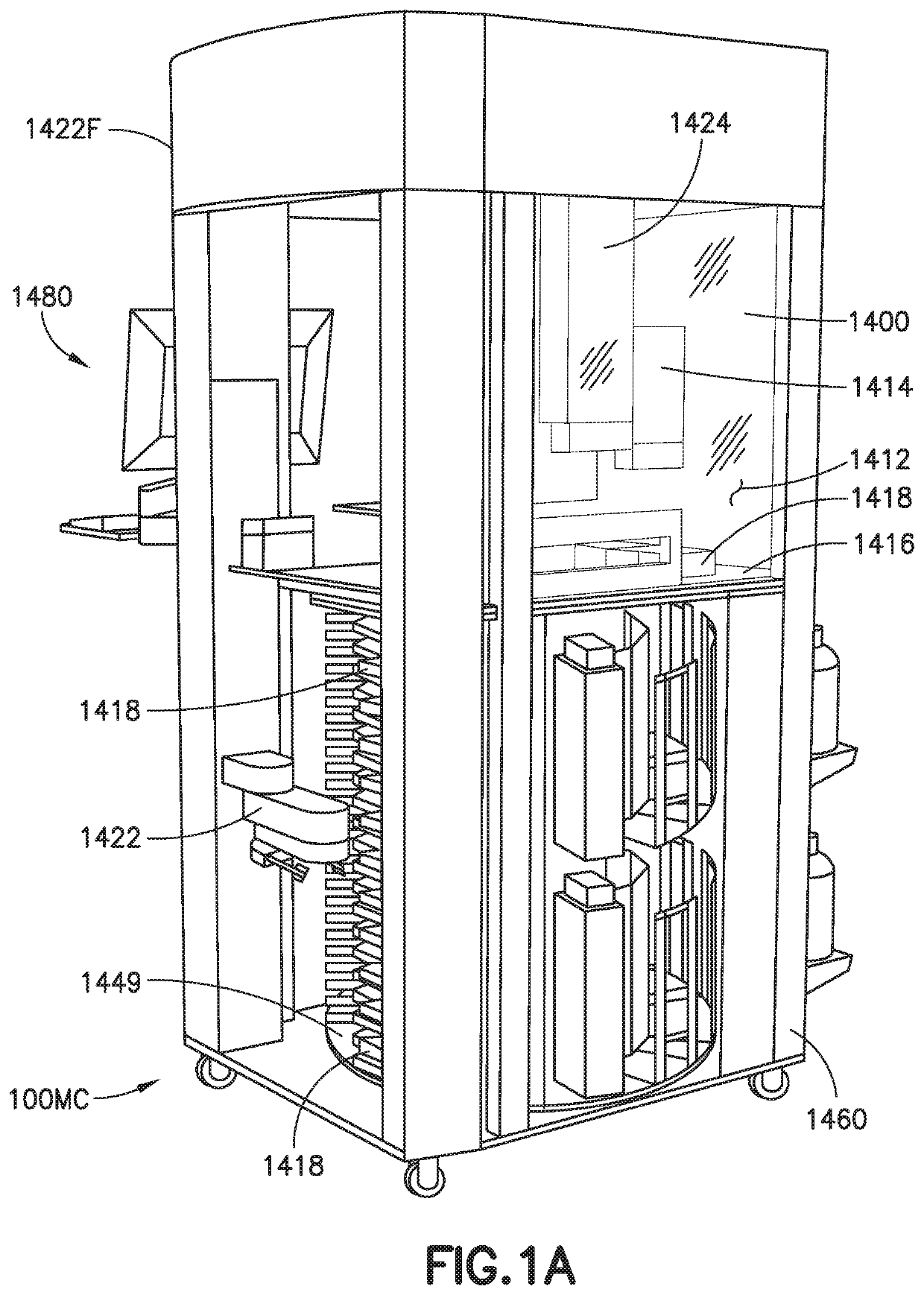

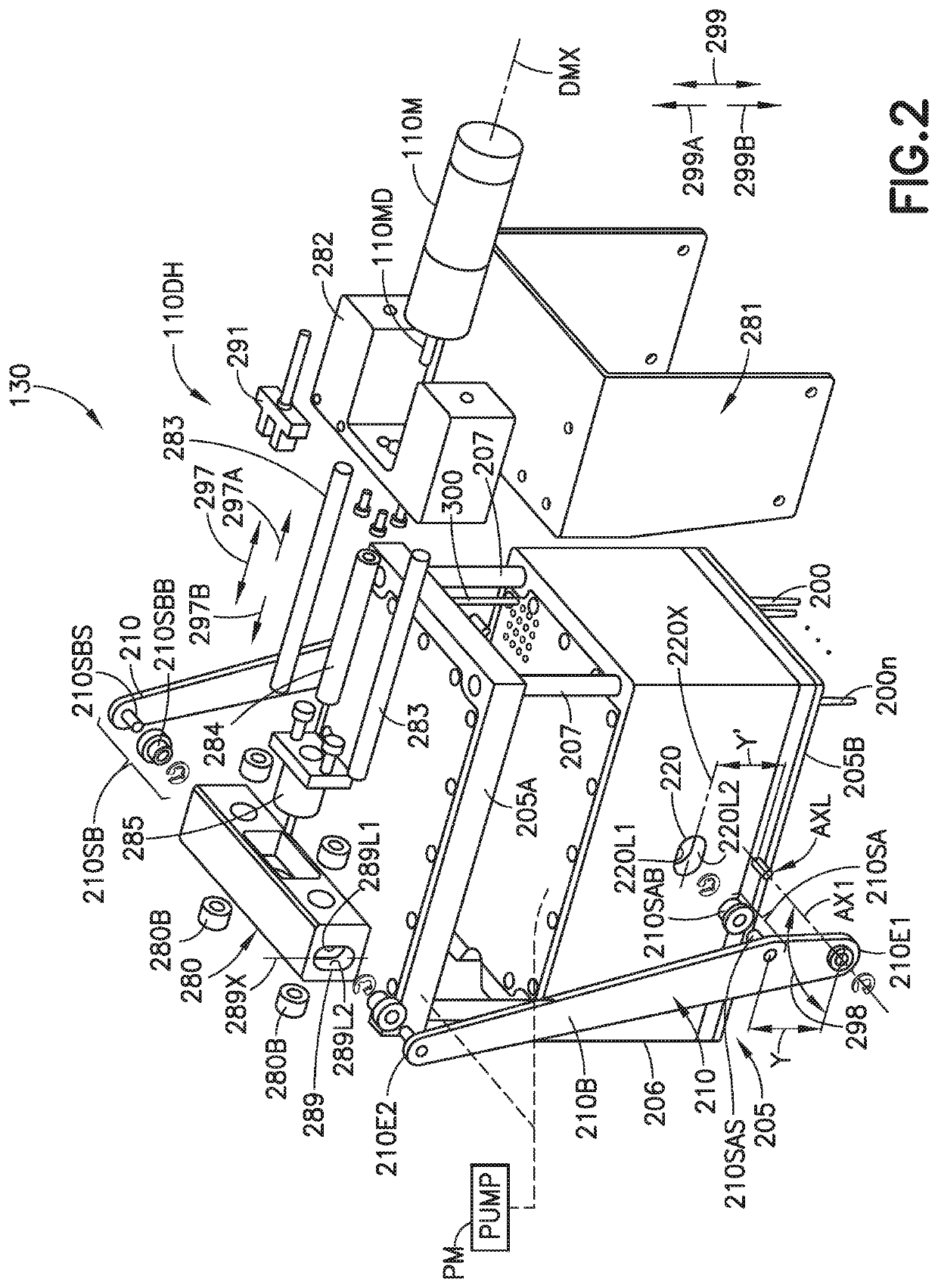

Auto-pipetting apparatus and method

ActiveUS11167282B2Sufficient forceCost of to minimumBurettes/pipettesMaterial analysisMechanical pipetteMechanical engineering

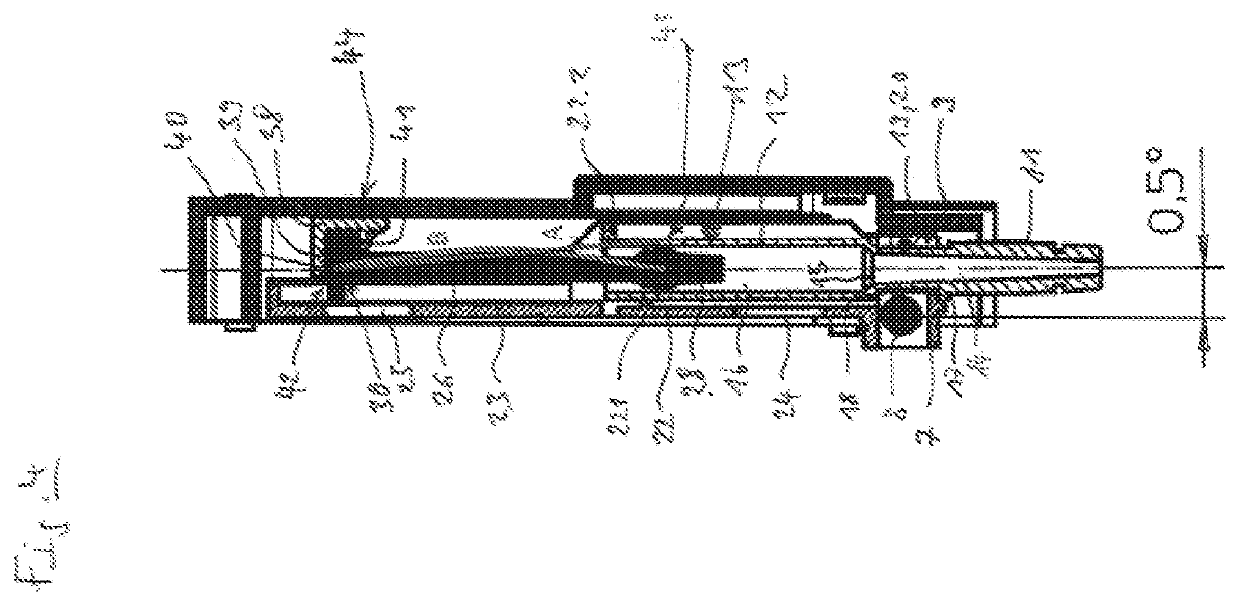

An auto-pipetting apparatus includes a dispensing head with at least one pipetting tip mandrel having an elongated stud body with an insertion end. The at least one pipetting tip mandrel mates with a pipetting tip. A first adjustable seal, disposed on the elongated stud body, and a second adjustable seal, disposed on the elongated stud body, seal the pipetting tip mated to the at least one pipetting tip mandrel. The first adjustable seal defines a snub surface. The snub surface effects a substantially continuous circumferential contact seal with radially impinging contact between the pipetting tip and the at least one pipetting tip mandrel. The second adjustable seal is adjustable between a disengaged position and an engaged position and effects a releasable grip and another substantially continuous circumferential contact seal between the pipetting tip and the at least one pipetting tip mandrel around the pipetting tip.

Owner:HIGHRES BIOSOLUTIONS INC

Mechanical pipette with adjustable volume value of aspirated liquid

Owner:CORNING INC

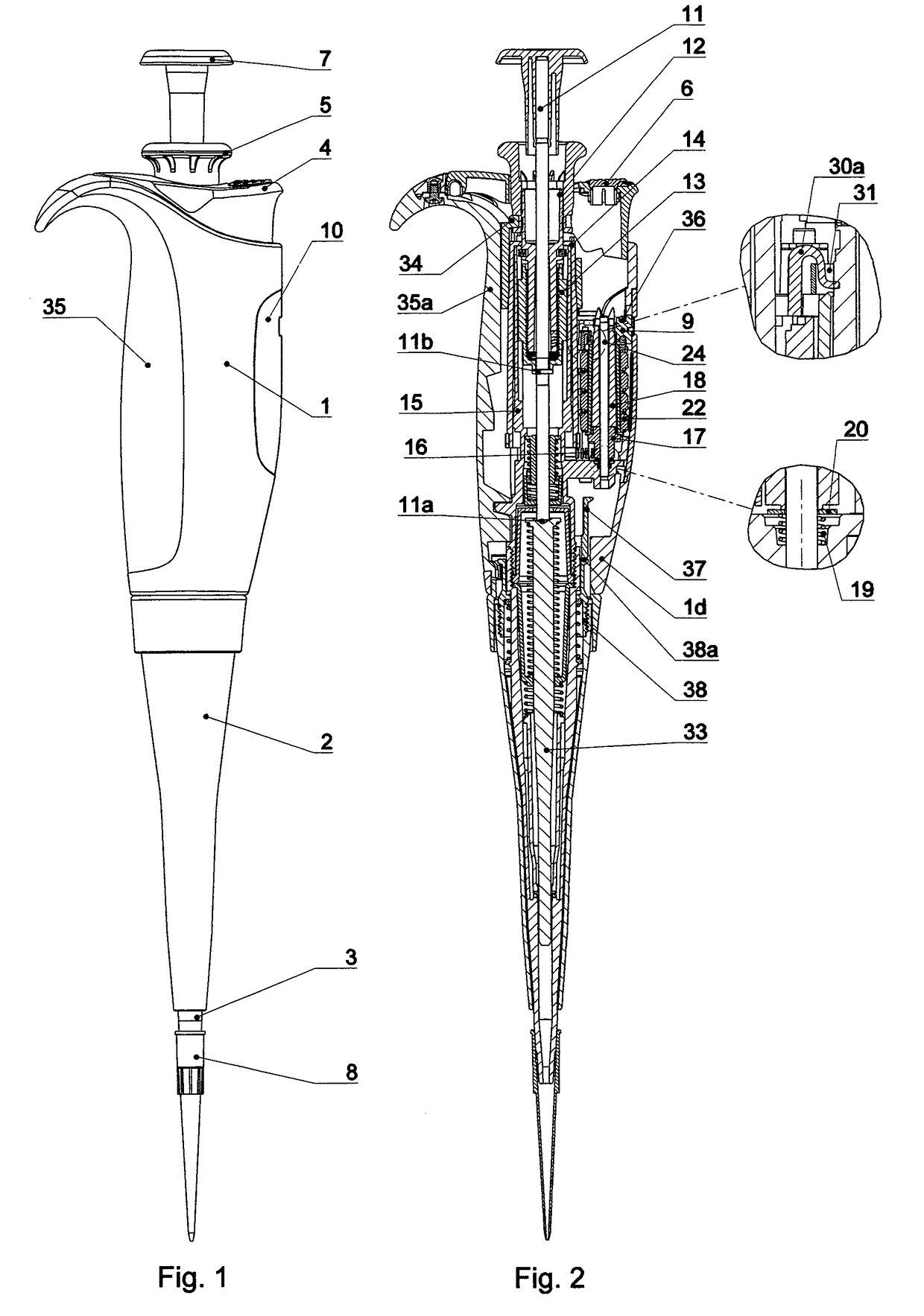

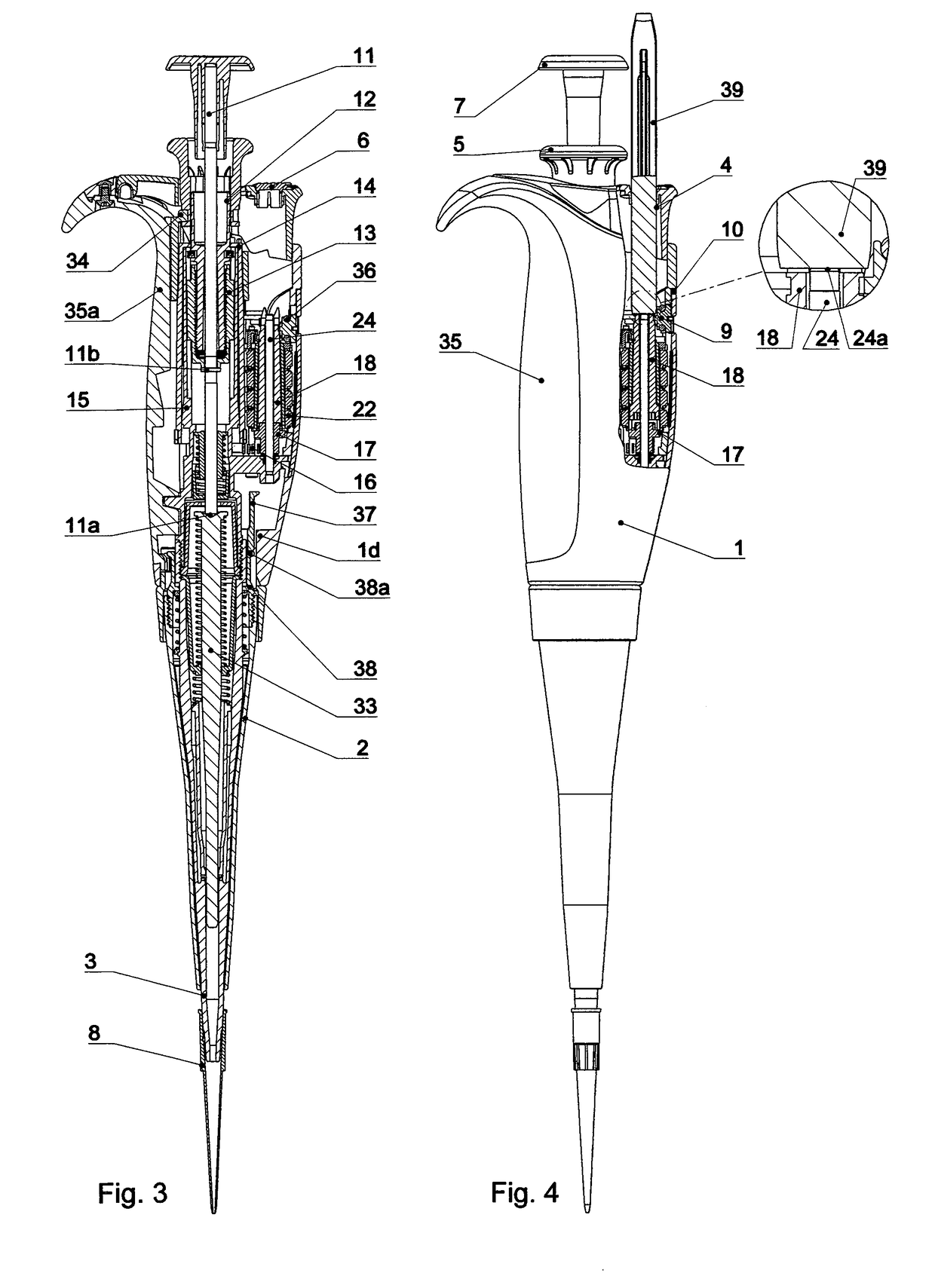

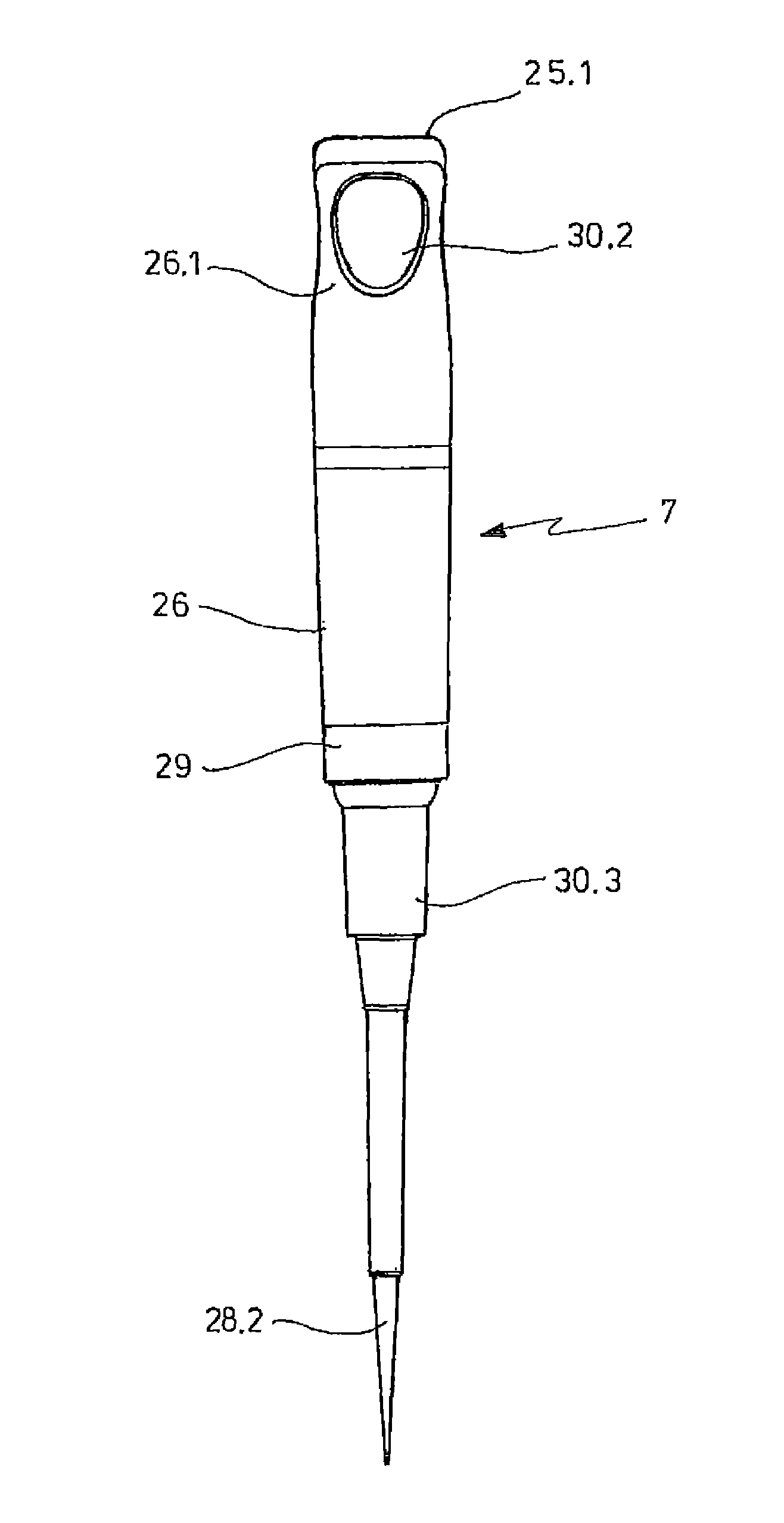

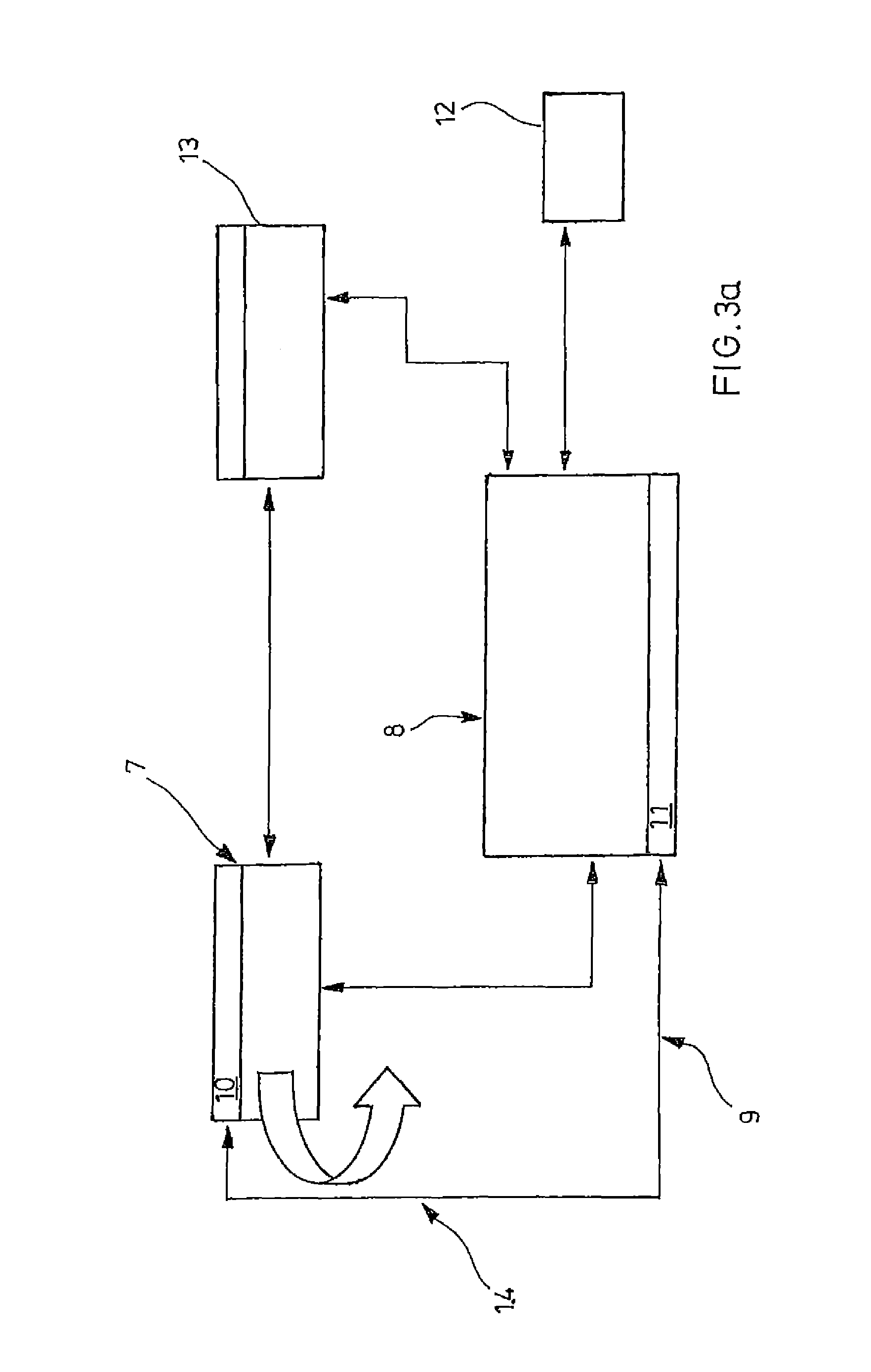

Mechanical pipette

A mechanical pipette comprising: a. a manually drivable mechanical unit for pipetting liquids, b. at least one sensor for detecting operating and / or performance data, c. an operating unit, and d. a display unit, e. wherein a device module comprises the mechanical unit for pipetting, the sensor and operating unit, f. a display module physically separate from the device module completely or partially comprises the display unit, and g. means for wireless communication between the device module and the display module.

Owner:EPPENDIRF AG

Anti-suck-back electronic pipettor

InactiveCN111905847AReasonable structureEasy to useBurettes/pipettesMechanical pipetteElectric machinery

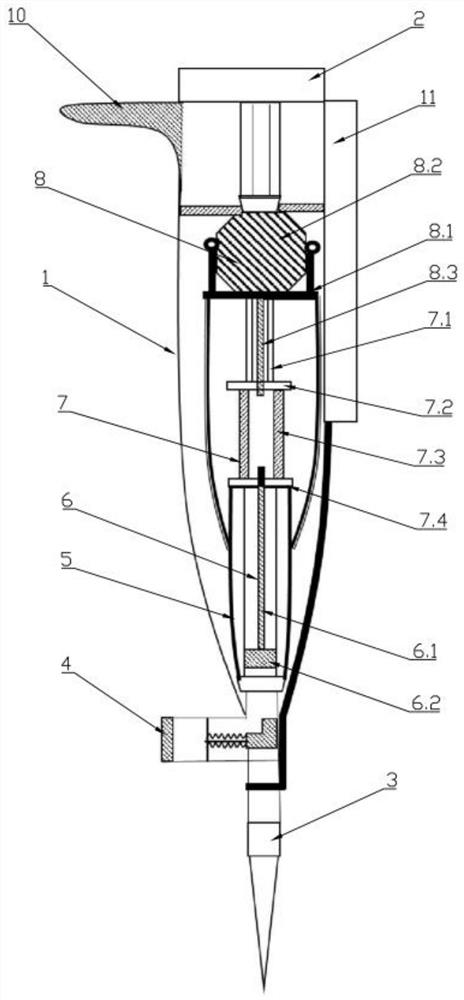

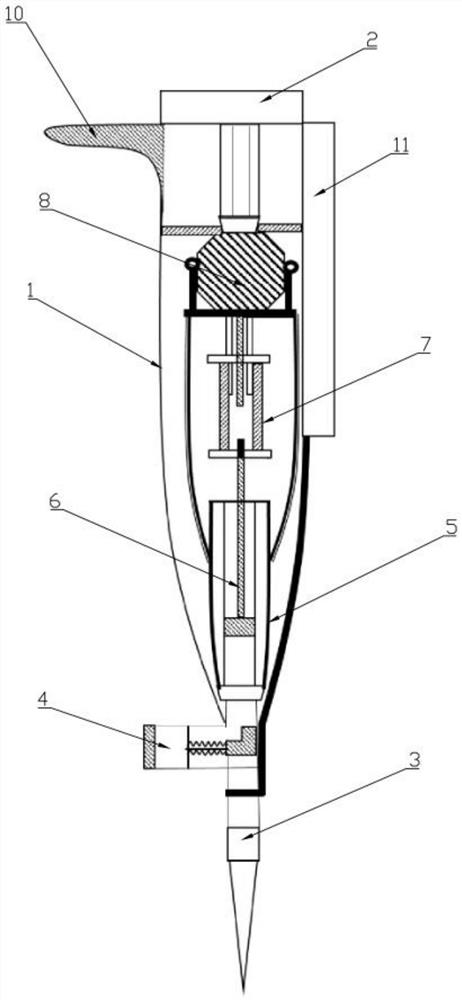

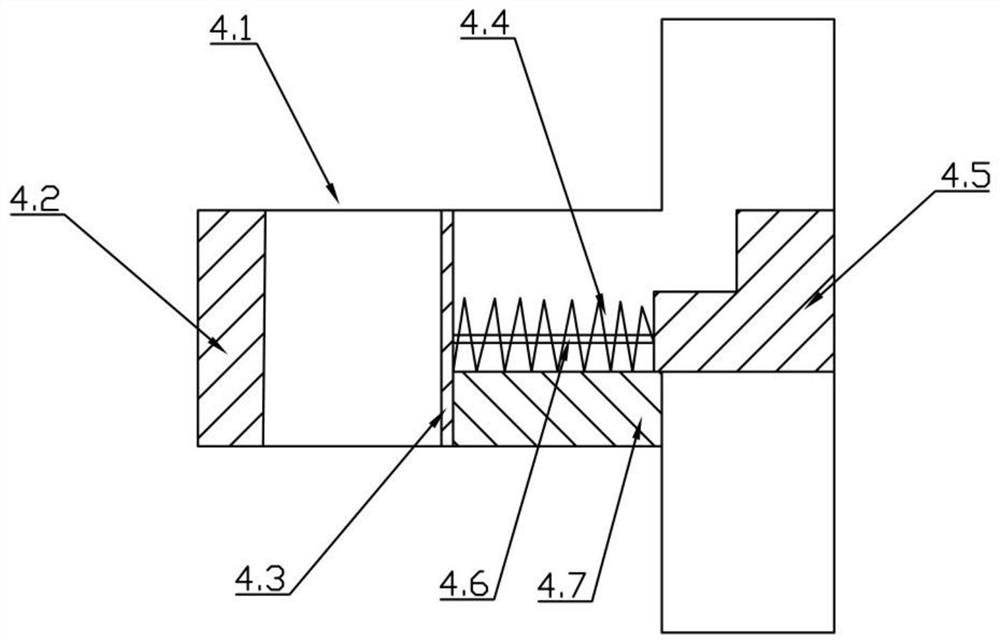

The invention discloses an anti-suck-back electronic pipettor, which comprises a pipettor main body with a hollow structure, a controller arranged at the upper part of the pipettor main body, a pipetting head arranged at the lower part of the pipettor main body and communicated with the pipettor main body, and an electromagnetic valve device arranged at one side of the pipetting head. A piston cylinder, a piston rod assembly, a linkage assembly and a screw transmission assembly are sequentially arranged in the pipettor main body from the pipetting head end to the other end. The screw transmission assembly is in transmission connection with the piston rod assembly through the linkage assembly, and one end of the piston rod assembly extends into a piston cylinder and can be driven by the screw transmission assembly to move along the piston cylinder. The other end of the piston cylinder is communicated with the pipetting head. The pipettor is reasonable in structure and convenient to use,liquid can be prevented from being sucked back to corrode the pipettor by the aid of the electromagnetic valve device, influence of inertia of the motor on pipetting volume can be eliminated, and thepipetting precision can be improved.

Owner:熊凯

Electric liquid transferring device

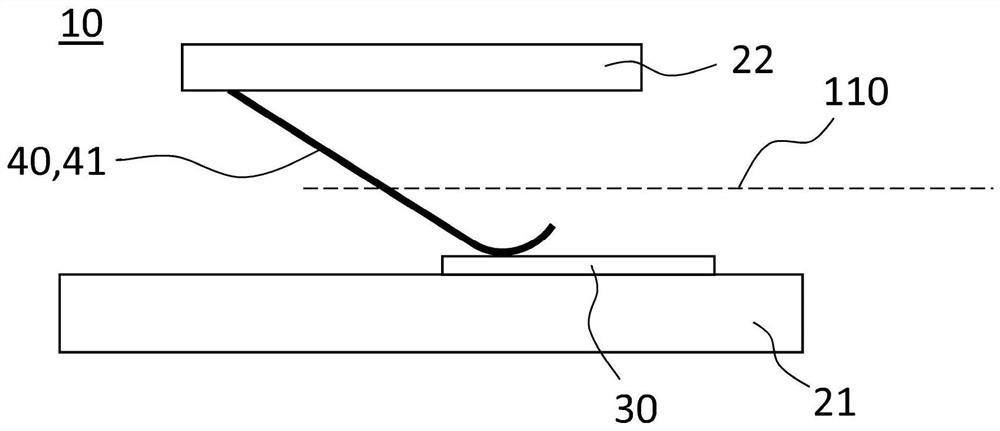

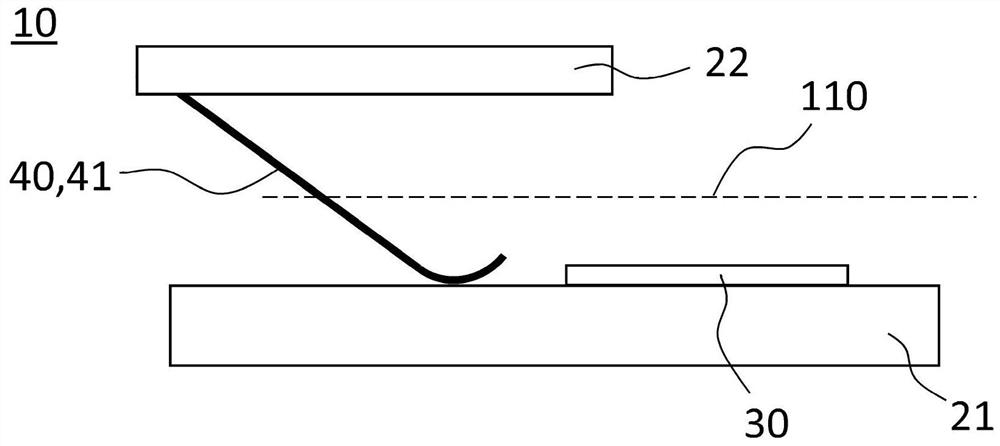

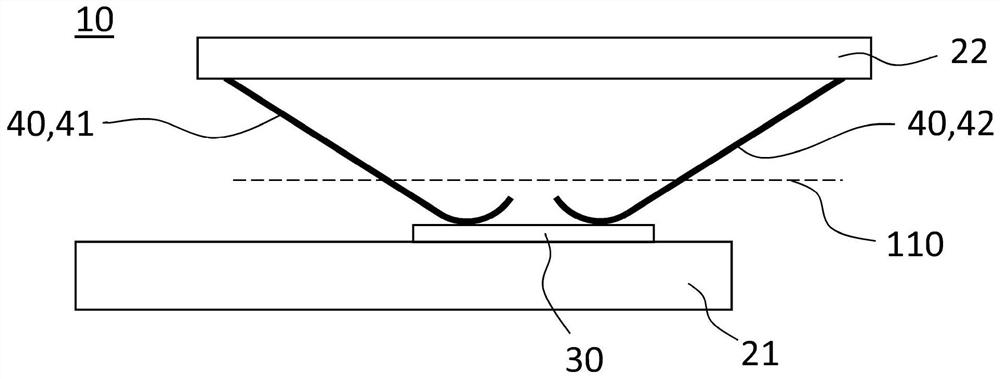

PendingCN111443214ALow priceMinimize vertical distanceMaterial analysisReciprocating motionElectric machine

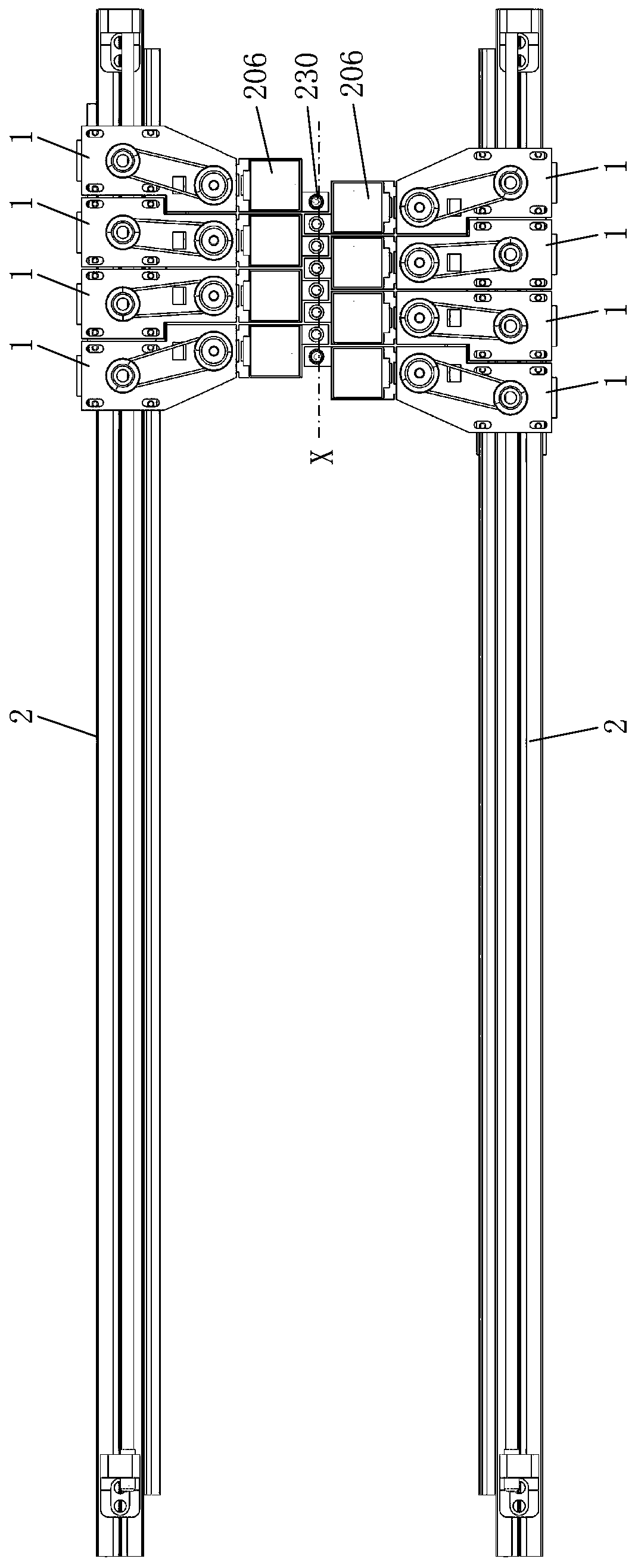

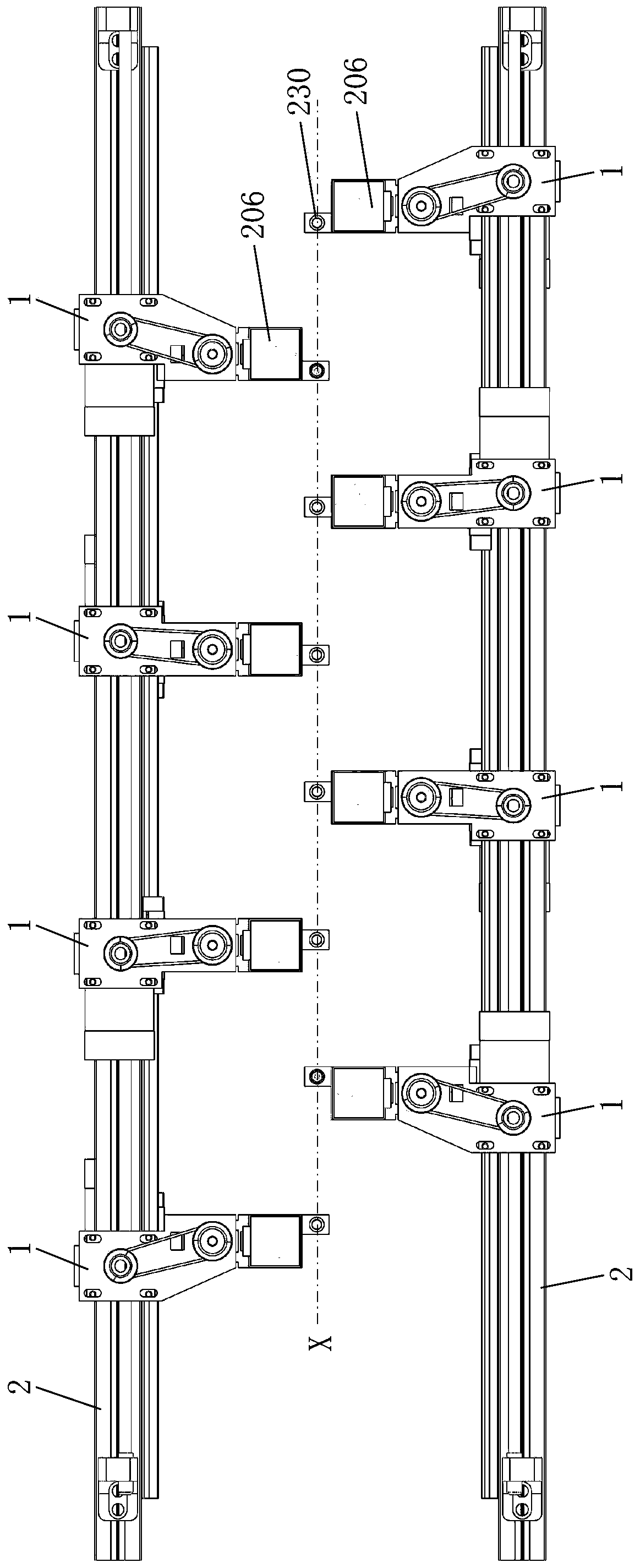

The invention provides an electric liquid transferring device. The electric liquid transferring device comprises two sliding tables symmetrically arranged on the two opposite sides of a central transverse shaft, wherein at least one electric liquid transferring device is installed on each sliding table; each electric liquid transferring device comprises a loading mechanism and an executing mechanism; each loading mechanism comprises a supporting frame and a first motor; each executing mechanism comprises a rack, a second motor and a liquid transferring assembly; the liquid transferring assemblies are positioned at the central transverse shaft; the second motors are positioned on the outer side of the central transverse shaft; the first motors are positioned on the outer side of a supporting point; and when the electric liquid transferring devices on the two sliding tables are gathered side by side, the liquid transferring assemblies of the electric liquid transferring devices on the two sliding tables are sequentially and alternately arranged at the central transverse shaft along the central transverse shaft. On the premise that the requirement for the center distance of a vessel foundation is met, the common motors are adopted, the shortest distance between the reciprocating motion axis of the executing mechanisms and the vertical line between the supporting points is achieved, and harmful overturning moment and fatigue deformation generated when the executing mechanisms are downwards connected with liquid transferring heads in a frequently-pressed mode along the axes of the executing mechanisms are reduced.

Owner:PREMEDICAL LAB

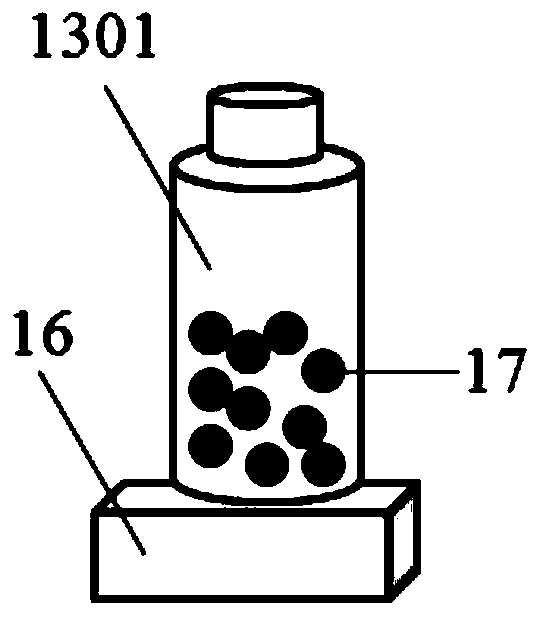

Extraction and purification device and method utilizing magnetic extraction material

PendingCN111282554ASolve the real problemSolve bottlenecksOther chemical processesComponent separationMechanical pipetteEngineering

The invention relates to an extraction and purification device and method. The extraction and purification device comprises at least one pipetting module, at least five station modules, a waste liquidbox, a waste box and a first guide rail; the pipetting module or the station module can move on the first guide rail, the station module is arranged below the pipetting module and comprises at leastone pipetting head station module, at least one extraction station module and at least three reagent station modules, and the station module, the waste liquid box and the waste box are arranged in themoving direction of a first guide rail; an extraction material is arranged in the extraction station module, the extraction station module comprises a stirrer and a power supply, and the power supplycontrols the stirrer to attract, fix and stir an extraction material; the pipetting module comprises a liquid driving device and a second guide rail, and the liquid driving device can move up and down on the second guide rail. The volume of the extraction material is not less than 1 cubic millimeter, and the surface of the extraction material has a mesoporous structure and has adsorption or exchange capacity.

Owner:苏州艾捷博雅生物电子科技有限公司

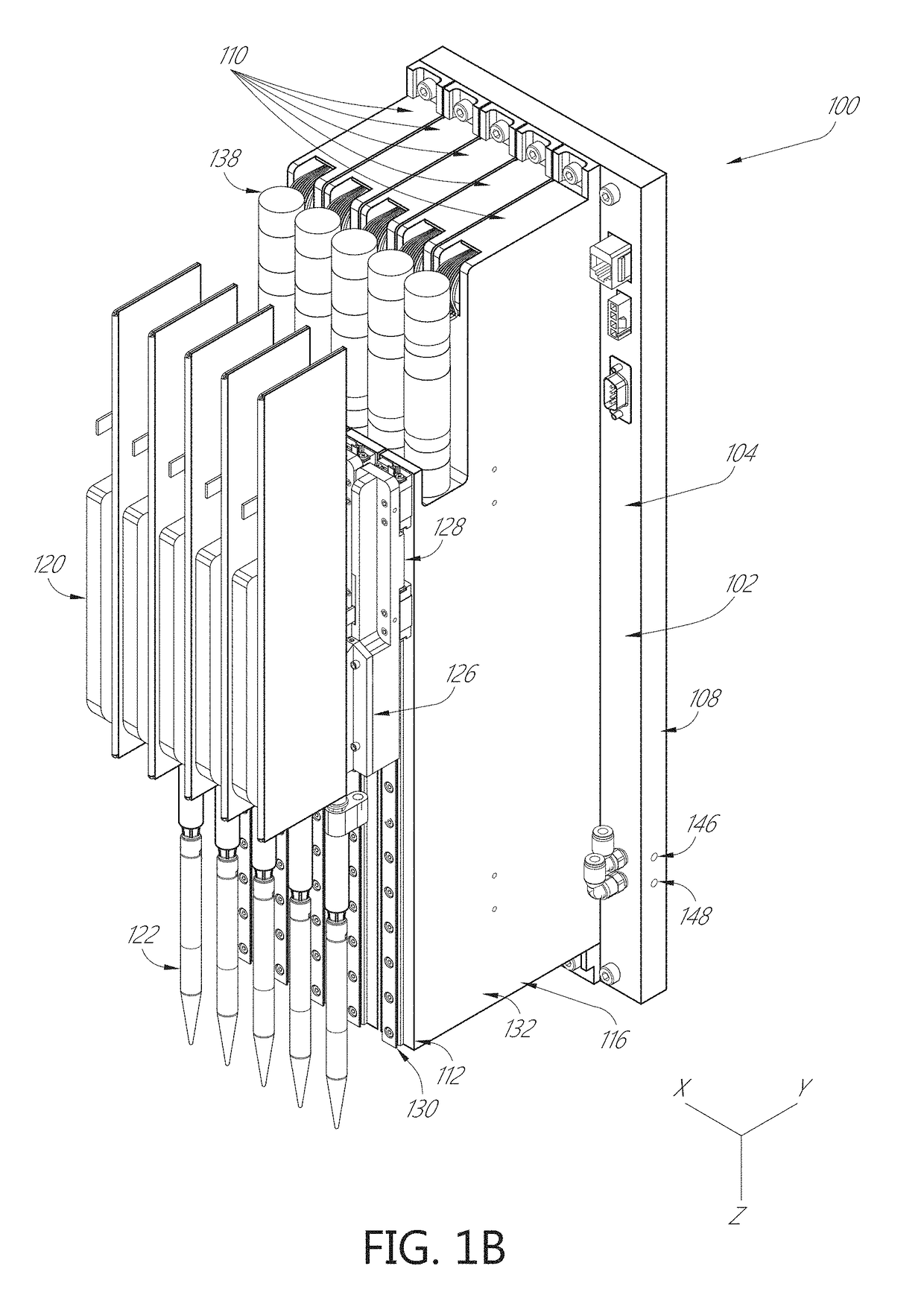

Liquid dispenser with manifold mount for modular independently-actuated pipette channels

Automated pipetting systems and methods are disclosed for aspirating and dispensing fluids, particularly biological samples. In one aspect, a liquid dispenser includes a manifold and one or more pipette channels. The manifold includes a vacuum channel, a pressure channel, and a plurality of lanes. Each lane includes an electrical connector, a port to the pressure channel, and a port to the vacuum channel. The pipette channels can be modular. Each pipette channel includes a single dispense head and can be selectively and independently coupled to any one lane of the plurality of lanes. In some aspects, a valve in the pipette channel is in simultaneous fluid communication with a pressure port and a vacuum port of the manifold. The valve selectively diverts gas under pressure and gas under vacuum to the dispense head in response to control signals received through the electrical connector of the manifold.

Owner:BECTON DICKINSON & CO

Electronic pipette

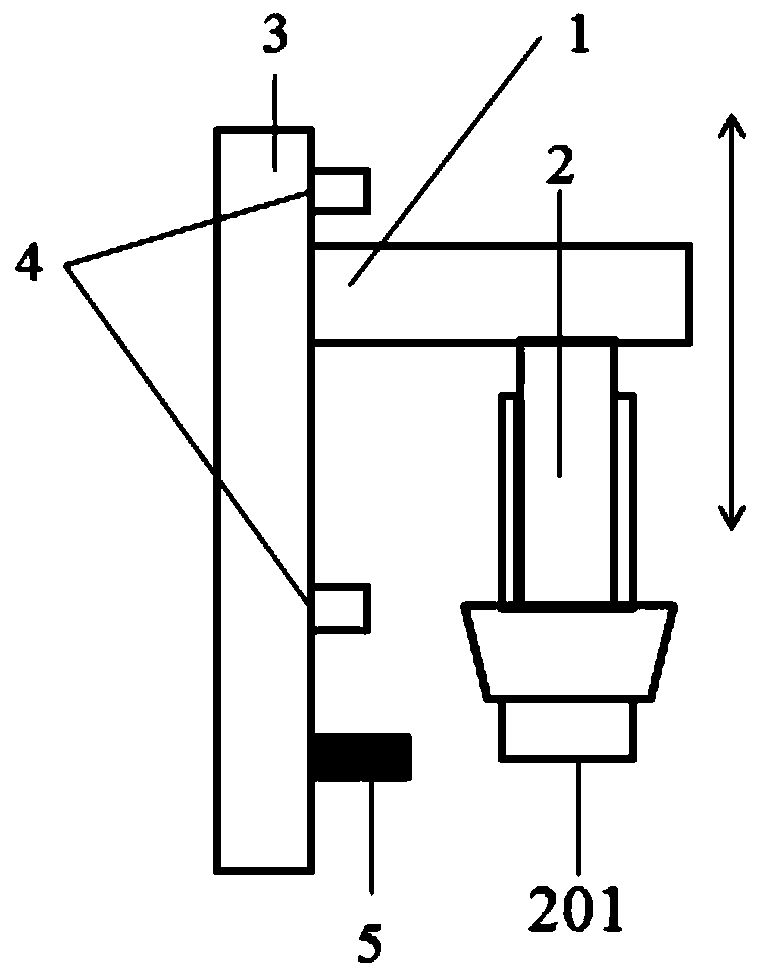

PendingCN110658350ALow priceMinimize vertical distanceMaterial analysisReciprocating motionMechanical pipette

The invention provides an electronic pipette, comprising a loading mechanism and an execution mechanism, wherein the loading mechanism comprises a support frame provided with a fixed pivot, a first screw, a driven belt pulley and a driving belt pulley connected with the driven belt pulley by virtue of a synchronous belt as well as a first motor; the execution mechanism is located at the front sideof the fixed pivot and comprises a rack, an injection pipe, a plunger vertically inserted into and arranged in the injection pipe, a dislocation sliding block connected with the plunger and a secondscrew connected with the dislocation sliding block by virtue of a screw thread as well as a second motor, the first screw rotates a driving rack to drive the injection pipe to axially move, the injection pipe axially moves downward to be inserted into and connected with a pipetting head, the second screw rotates and drives the dislocation sliding block to drive the plunger to axially move, and theplunger axially moves to inhale a liquid into the pipetting head or discharge the liquid out the pipetting head. The electronic pipette provided by the invention adopts the conventional motor, can realize minimization of a distance between a reciprocating motion axis of the pipetting execution mechanism and a vertical line of a pivot of the mechanism and alleviates harmful overturning moment andfatigue deformation which are produced when the pipetting execution mechanism moves downward along the axis to be frequently in press-in type connection with the pipetting head.

Owner:PREMEDICAL LAB

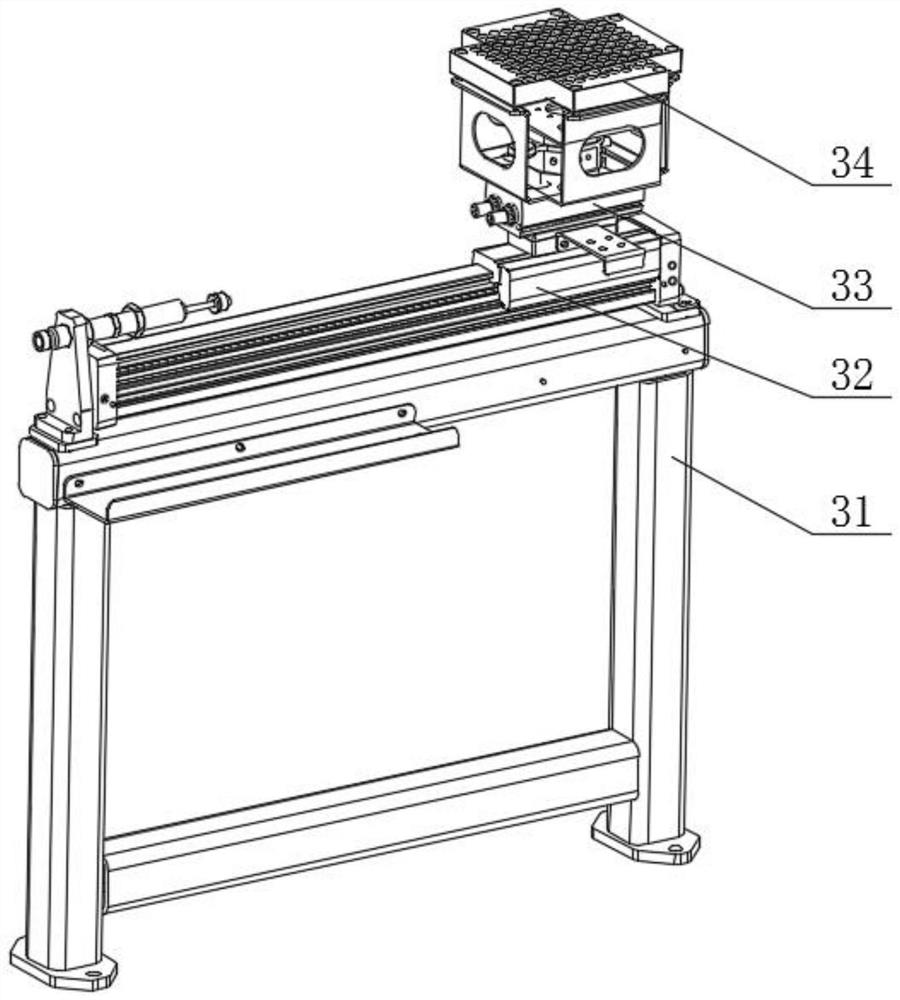

Detection module and detection method for intelligent production line system for pipette tip

PendingCN112845195AAvoid pollutionAvoid leaningOptically investigating flaws/contaminationSortingComputer hardwareProduction line

The invention discloses a detection module and detection method for an intelligent production line system for a pipette tip, and belongs to the technical field of pipette tip detection. The detection module comprises a framework, carrying units and a detection unit, the number of carrying units is two, the carrying units are arranged at the two ends of the framework correspondingly, the detection unit comprises a detection sliding table for bearing the pipette tip and a visual detection device for detecting defects of the pipette tip, the visual detection device is fixedly connected to the framework through a fixing frame, the detection sliding table is arranged on the framework in a sliding mode, and the detection sliding table drives the pipette tip to pass through the visual detection device. According to the detection module and the detection method, manual operation can be replaced, pollution in the placement process of the pipette tip is avoided, the placement precision is high, inclination is avoided, placement and removal of the pipette tip are both automatically operated, meanwhile, a PLC can judge good products and defective products in time according to video images of the detection device, in addition, the accurate position is given, and the detection efficiency is high.

Owner:NINGBO WELLLIH ROBOTS TECH CO LTD

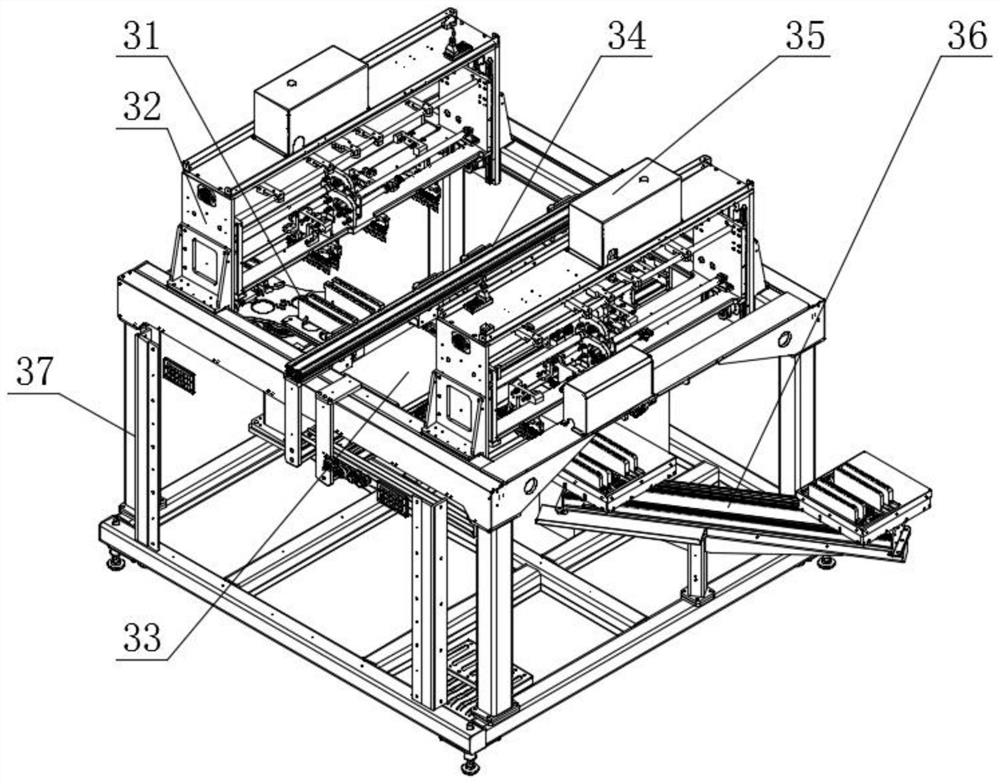

Intelligent production line system for pipette heads

PendingCN112829234AHigh degree of automationImprove quality controllabilitySortingProduction lineMechanical pipette

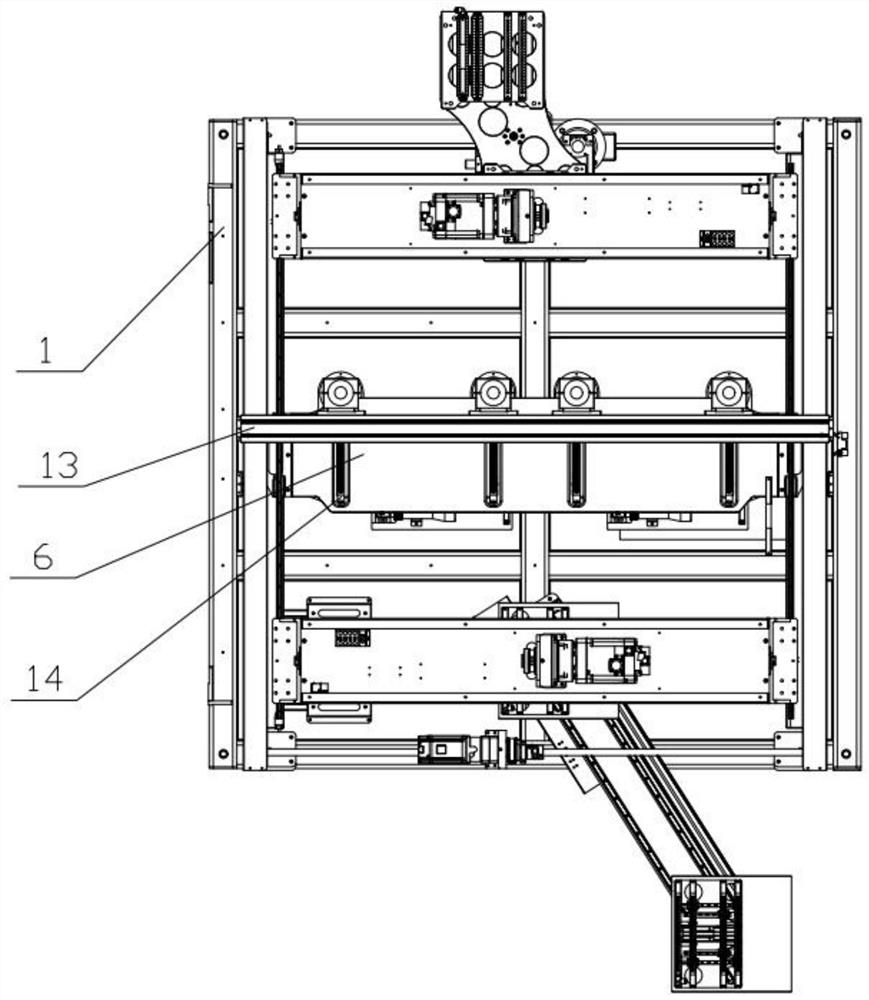

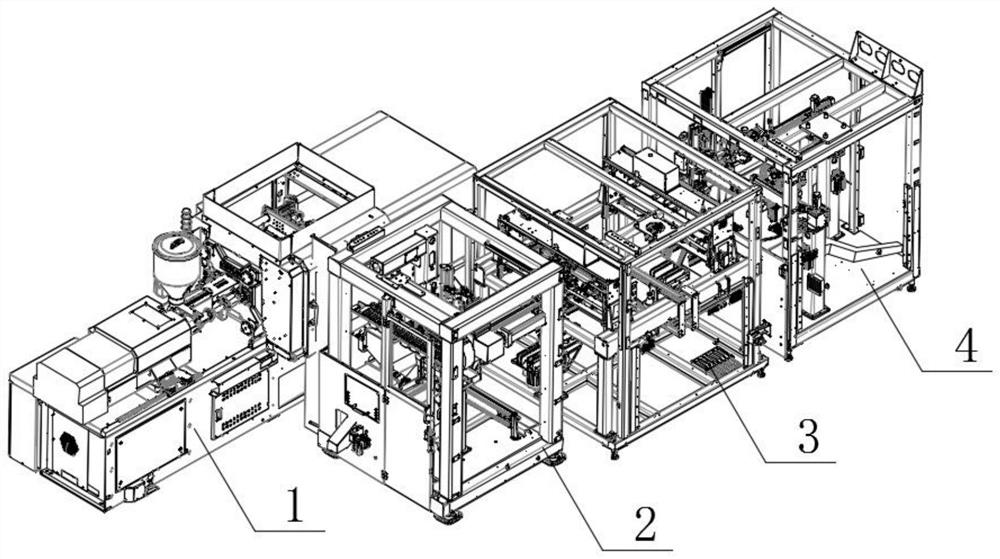

The invention discloses an intelligent production line system for pipette heads, and relates to the technical field of pipette head processing. The intelligent production line system comprises a pipette head injection molding machine, a material taking-out module, a material detection module and a material removing and supplementing module, wherein the pipette head injection molding machine is used for injection molding production of the pipette heads; the material taking-out module is used for taking out the pipette heads in a grinding tool of the pipette head injection molding machine, and the pipette heads are transferred to the material detection module through interval transformation and arrangement; the material detection module is used for detecting the pipette heads, distinguishing qualified products from unqualified products and transmitting the pipette heads and detection data to the material removing and supplementing module; the material removing and supplementing module is used for removing the unqualified products and supplementing the qualified products to the positions where the unqualified products are removed; and finally the pipette heads are discharged. Compared with the prior art, the intelligent production line system has the advantages that the processes from production to detection and discharging are all completed mechanically, the automation degree is high, the qualified products and the unqualified products are quickly distinguished through a visual detection device, the unqualified products are removed, the quality controllability of the products is improved, and the production efficiency is improved.

Owner:NINGBO WELLLIH ROBOTS TECH CO LTD

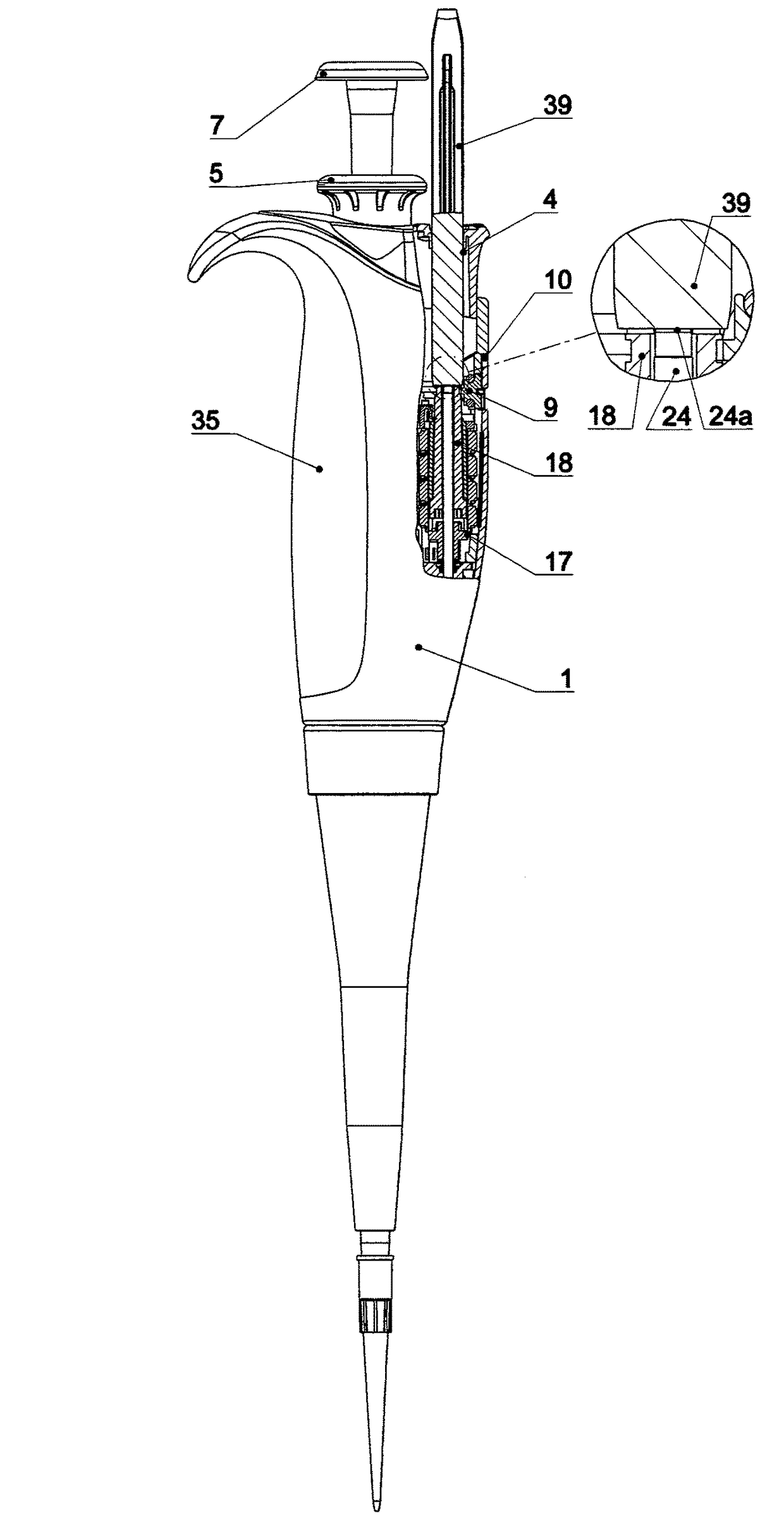

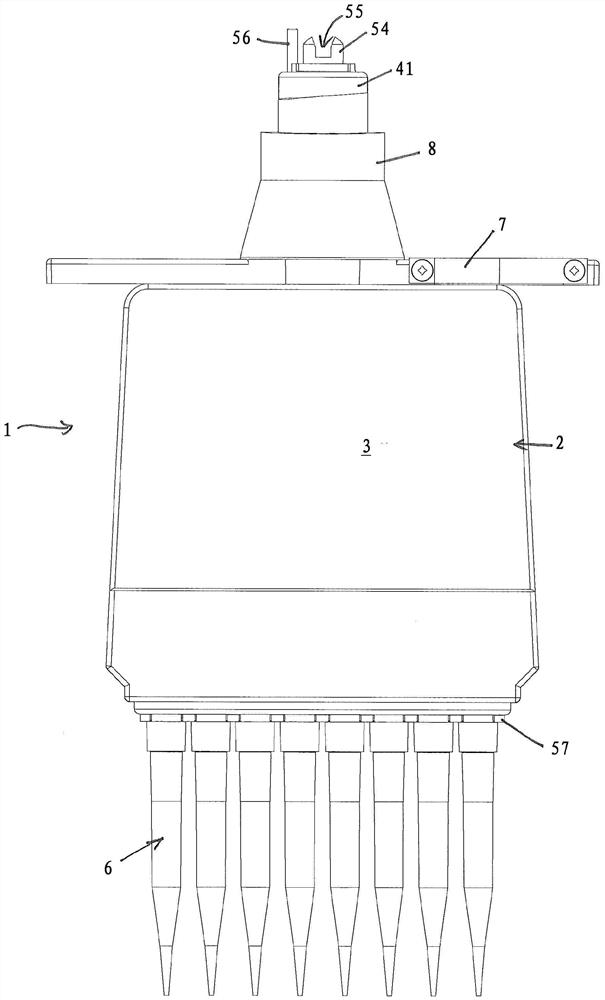

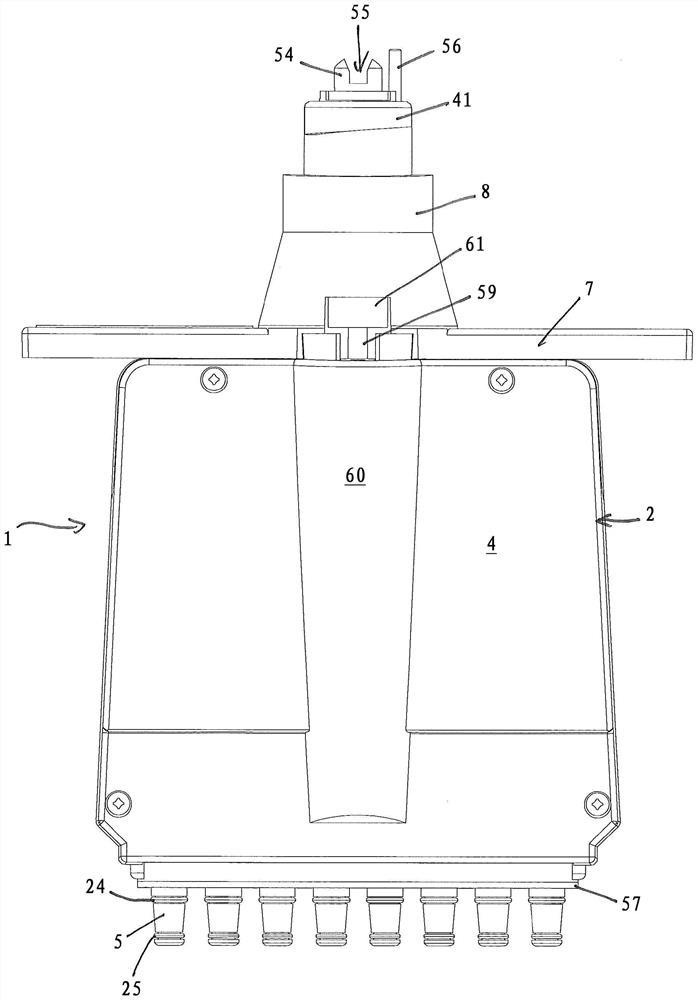

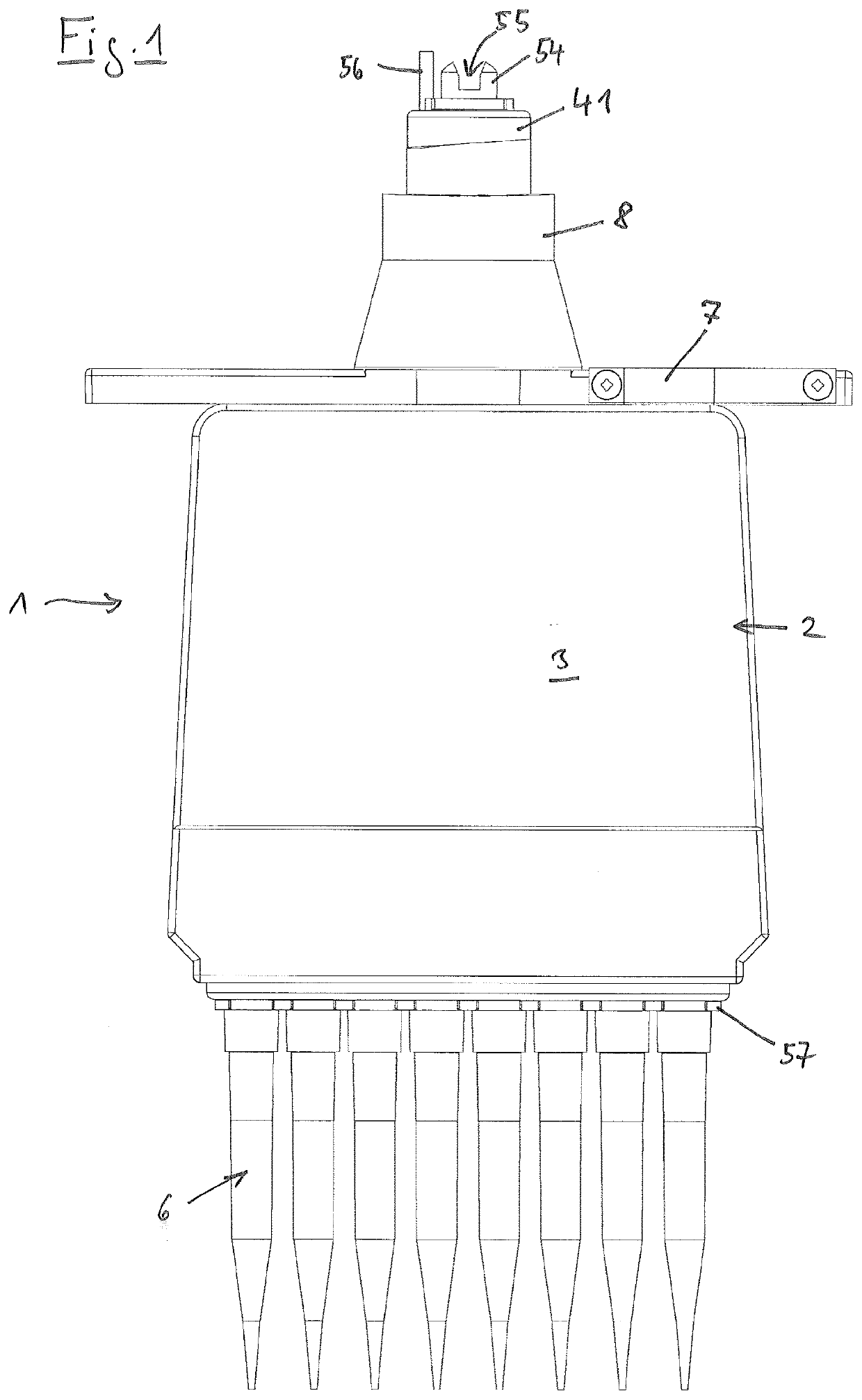

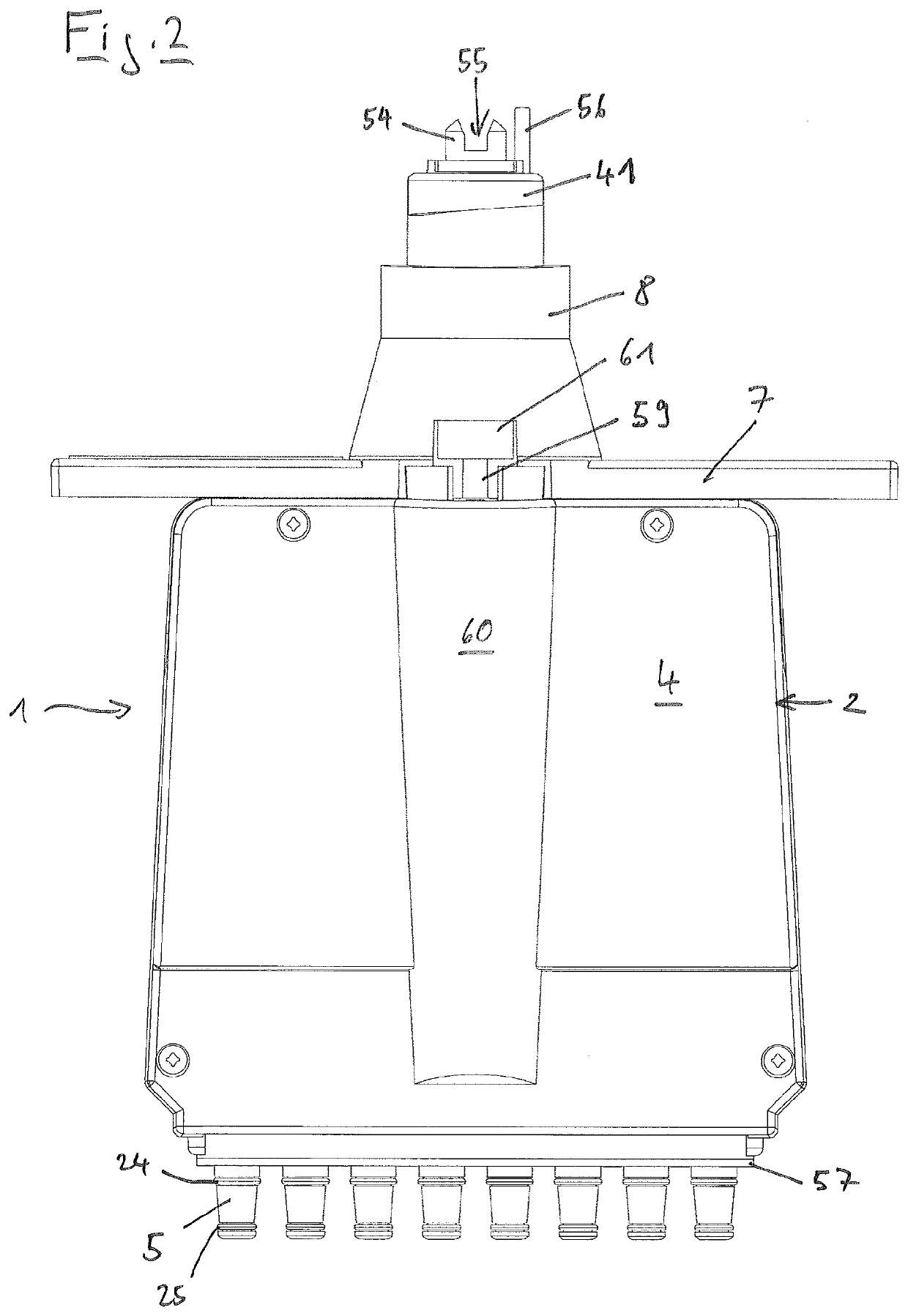

Pipetting head, pipetting device comprising a pipetting head, and method for pipetting using a pipetting head

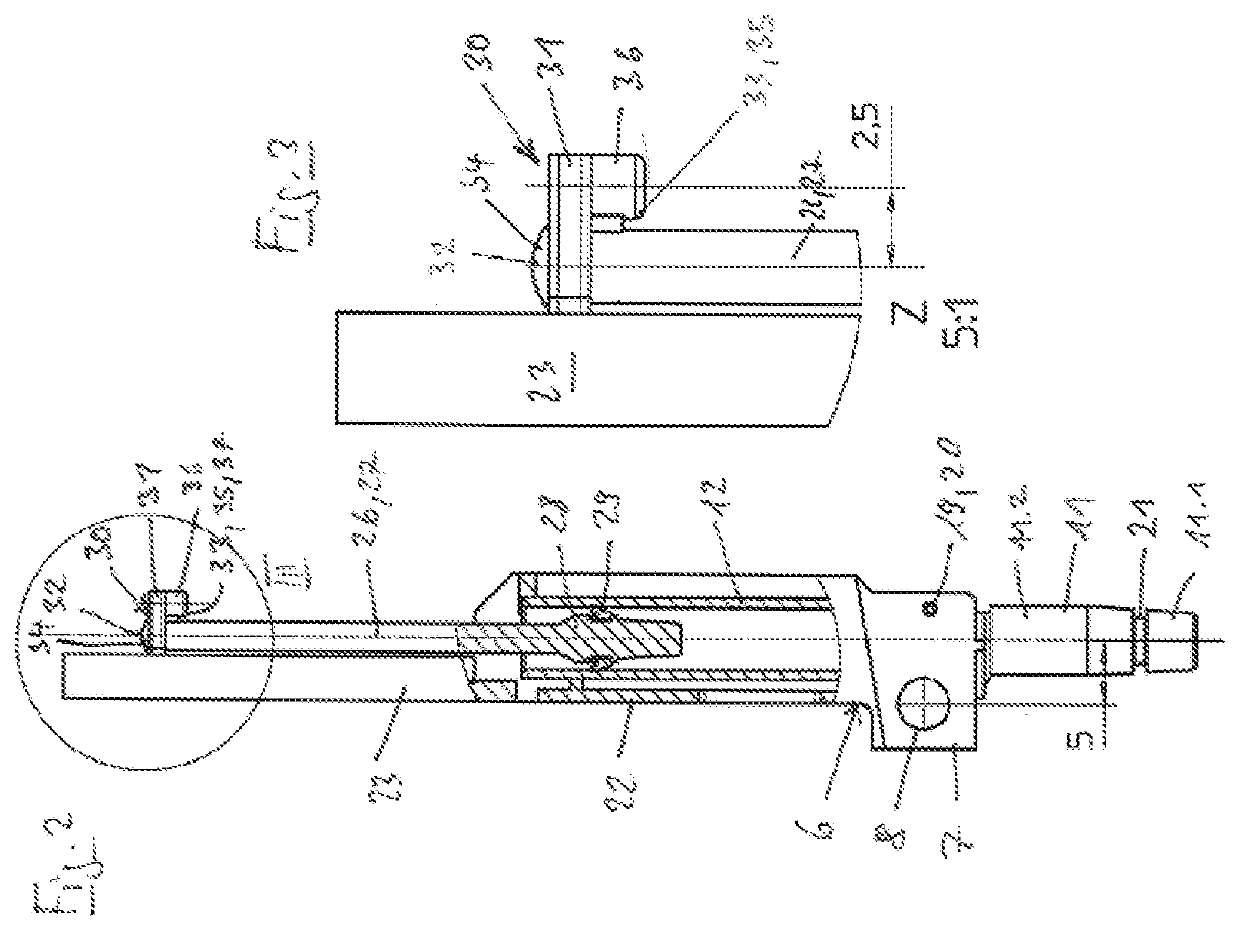

The invention relates to a pipetting head having at least one pipette tip for a pipetting device, comprising: a carrier, at least one projection held on the carrier and on which pipette tips are to be clamped, and two elastomer O-rings held on the projection, wherein the two O-rings, the projection and the pipette tip are designed to securely clamp the pipette tip solely by deformation of the two O-rings on the projection, this being brought about by pressing the pipette tip onto the two O-rings.

Owner:埃佩多夫欧洲股份公司

Sampling containing assembly, sampling pipetting head and sampling filtering device

PendingCN113680411AEasy accessGuaranteed accuracyWithdrawing sample devicesLaboratory glasswaresMechanical pipetteProcess engineering

The invention relates to the technical field of medical supplies, in particular to a sampling containing assembly, a sampling pipetting head and a sampling filtering device, and the sampling containing assembly comprises a sampling pipe fitting and a filtering pipe fitting; wherein the filtering pipe fitting is arranged in the sampling pipe fitting, and the filtering pipe fitting is detachably connected with the sampling pipe fitting; a filtering hole communicated with the interior of the sampling pipe fitting is formed in the filtering pipe fitting. By utilizing the sampling containing assembly, large particles and cotton velvet with cotton swab samples can be filtered out, a pipetting head used for sucking the samples in the sampling pipe, detection equipment used in the later period and the like cannot be blocked, smooth detection is ensured, the automatic working efficiency is improved, and the pipetting precision is ensured.

Owner:安徽博日生物科技有限公司

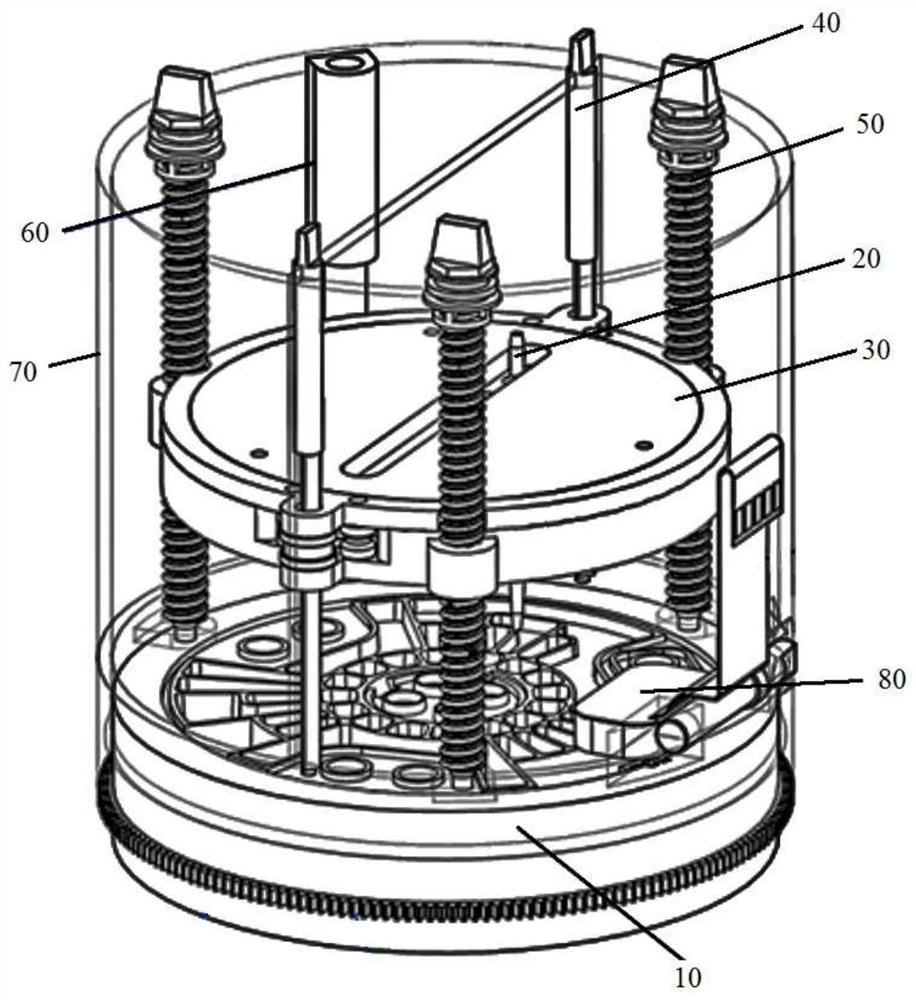

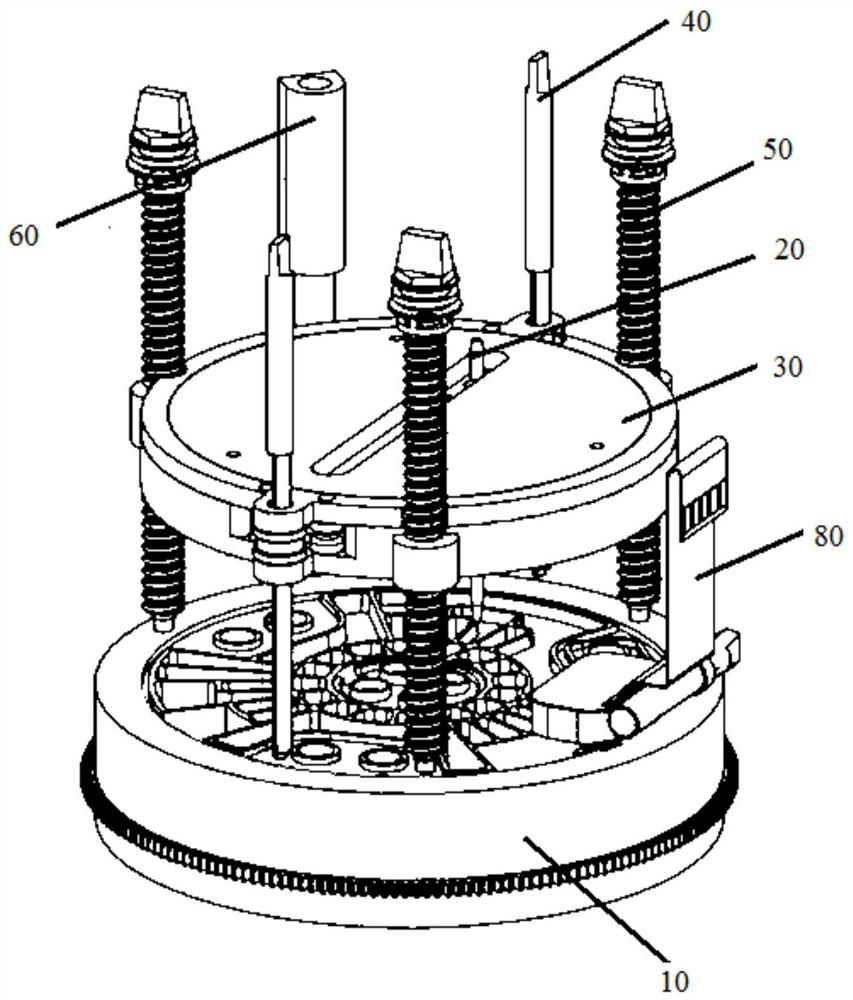

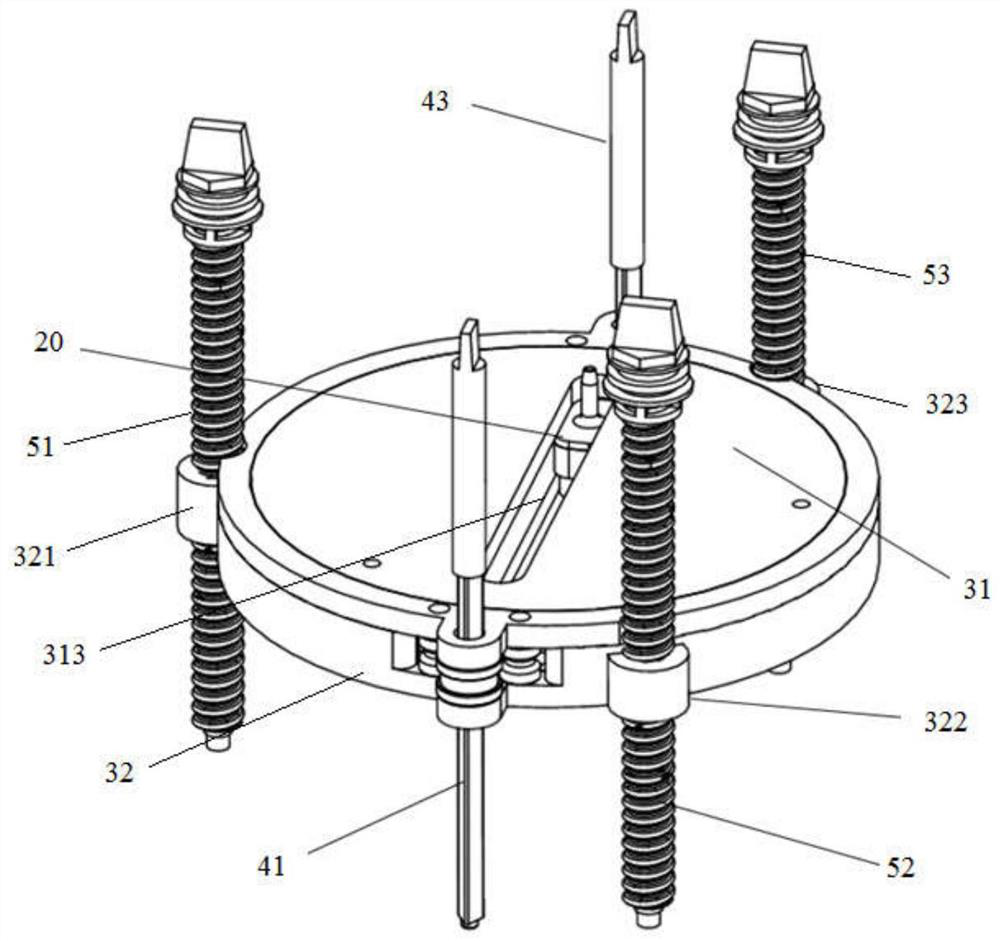

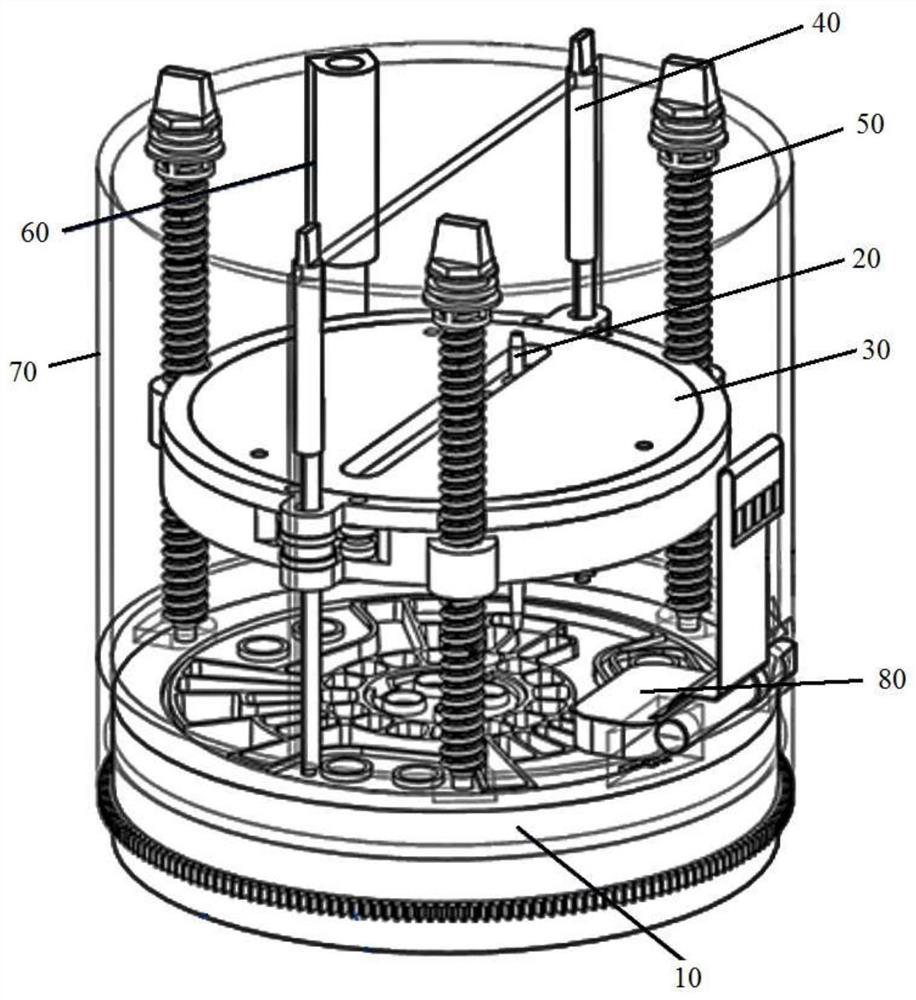

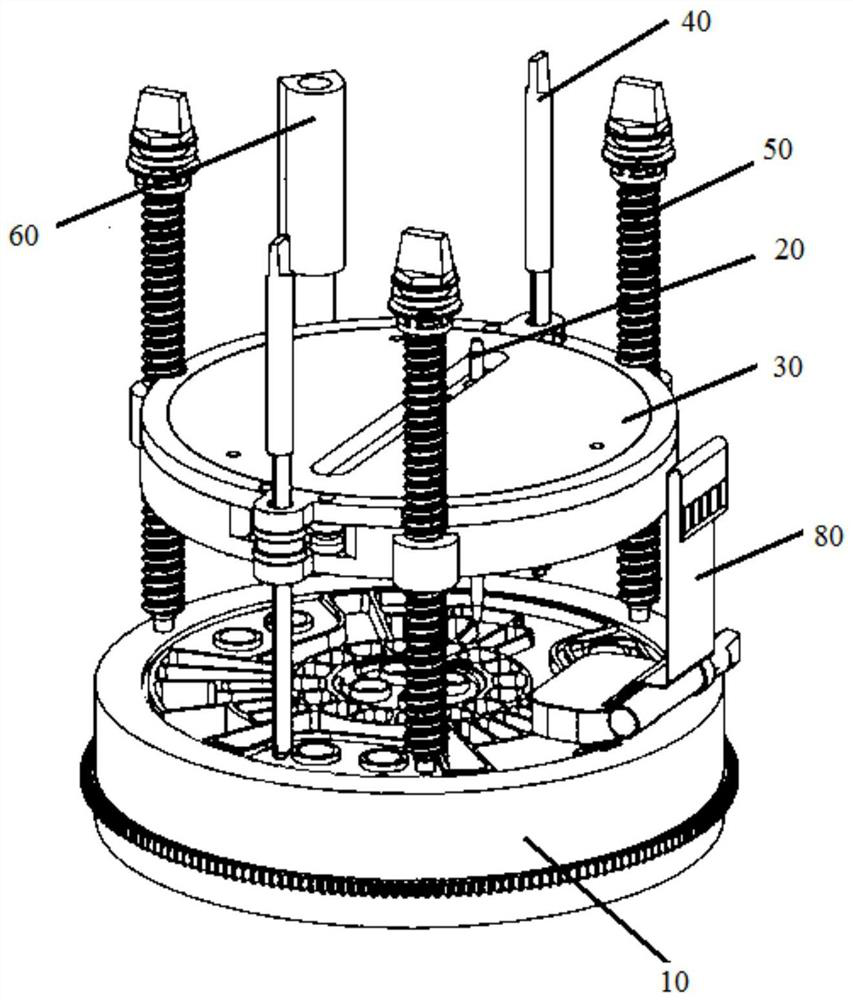

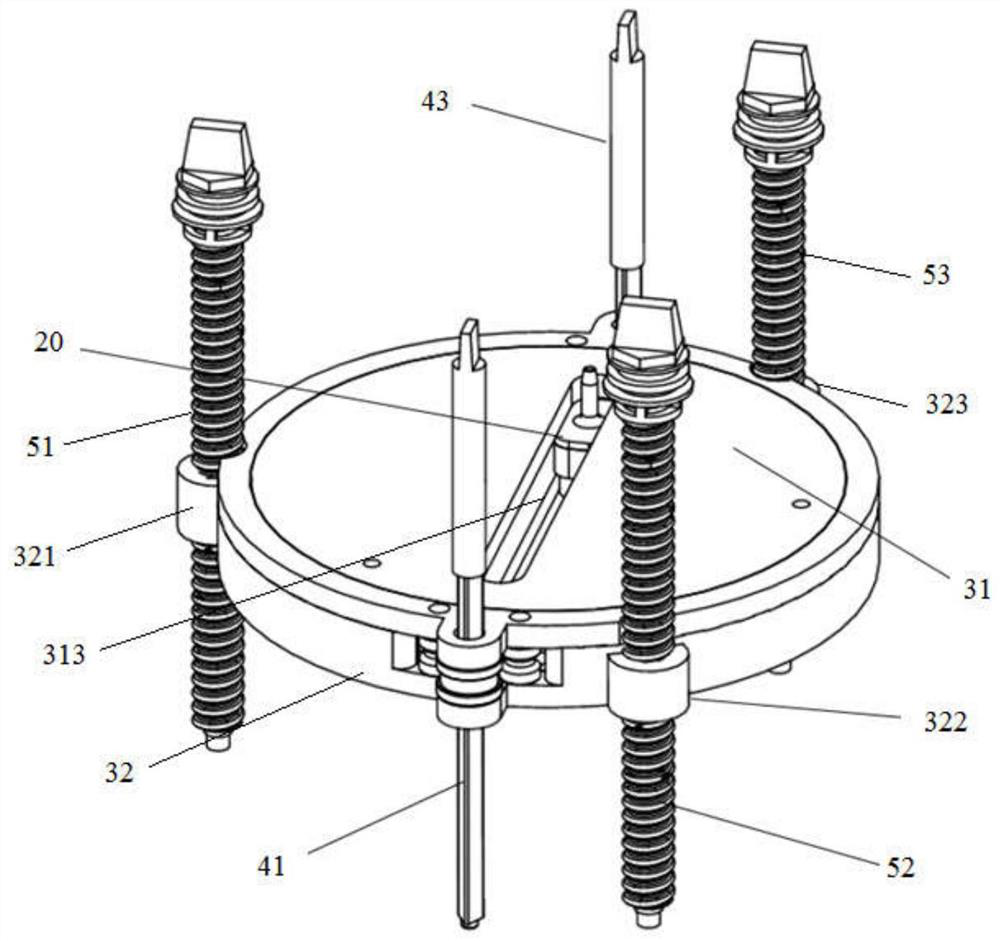

Three-freedom-degree pipetting device of closed card box and closed card box

ActiveCN112623470AEnable mobilityAchieve rotationDischarging meansDamagable goods packagingMechanical pipetteMechanical engineering

The invention provides a three-freedom-degree pipetting device of a closed card box and the closed card box. The freedom degree of the pipetting device is expanded so that more reagent holes can be used in the limited volume of the closed card box. The closed card box comprises a reagent disc, and a plurality of reagent holes are formed in the reagent disc. The pipetting device comprises a pipetting head, a rotating platform, a first driving assembly and a second driving assembly. The rotating platform comprises a rotating base plate and a base plate bearing part, the rotating base plate is rotatably arranged on the base plate bearing part, a sliding groove is formed in the rotating base plate, and the pipetting head is slidably arranged in the sliding groove. The first driving assembly is used for driving the pipetting head to slide along the sliding groove and driving the rotating base plate to rotate relative to the base plate bearing part so as to drive the pipetting head to rotate so that the pipetting head can be aligned with any reagent hole in the reagent disc. The second driving assembly is used for driving the rotating platform to move up and down and driving the pipetting head to move up and down so that the pipetting head can perform liquid suction or liquid injection operation on the aligned reagent hole.

Owner:3D BIOMEDICINE SCI & TECH CO LTD

Material removing and supplementing control method of pipette head intelligent production line system

The invention discloses a material removing and supplementing control method of a pipette head intelligent production line system, and the method is applied to the technical field of pipette head machining. The method comprises the following specific steps that materials enter a feeding station, and first data are acquired according to a detection station; a station rotary table is rotated to enter a material removing station, and a manipulator is controlled to grab defective products according to the first data; the rotation rotary table is rotated to enter a material supplementing station, and the manipulator is controlled to grab good products for supplementing according to second data obtained after the first data are grabbed; and the station rotary table is rotated to enter a discharging station for discharging. According to the material removing and supplementing control method of the pipette head intelligent production line system, data memory is used in the whole process, no detection device participates in the material removing and supplementing process, the material removing and supplementing process is completed on the station rotary table, space is saved, the whole process is full-automatic, manual intervention is not needed, and the automation degree is greatly improved.

Owner:NINGBO WELLLIH ROBOTS TECH CO LTD

Pipetting head, pipetting device comprising a pipetting head, and method for pipetting using a pipetting head

A pipetting head comprises a carrier, at least one attachment held on the carrier and configured to secure at least one pipette tip, and two O-rings retained on the at least one attachment and configured to contact the sealing seat of the at least one pipette tip. The inner diameter of the sealing seat of the at least one pipette tip is smaller than an outer diameter of a respective O-ring where the sealing seat contacts a respective O-ring. The respective O-ring is deformed while the pipette tip is slid onto the at least one attachment to securely clamp the at least one pipette tip. The sealing seat of the at least one pipette tip is dimensioned such that the at least one attachment exerts a force on the pipette tip to deform the at least one pipette tip when it is securely clamped on the at least one attachment.

Owner:EPPENDORF SE

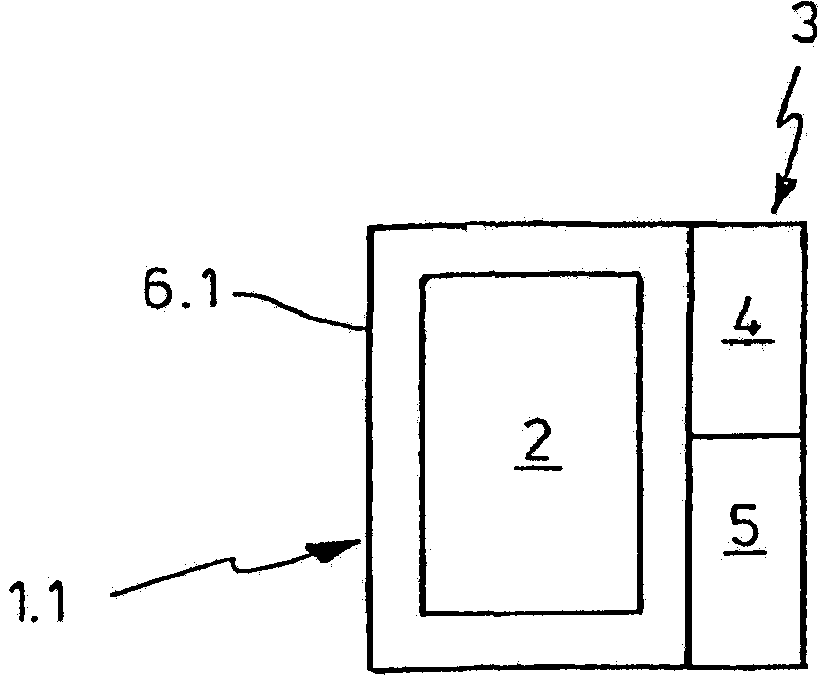

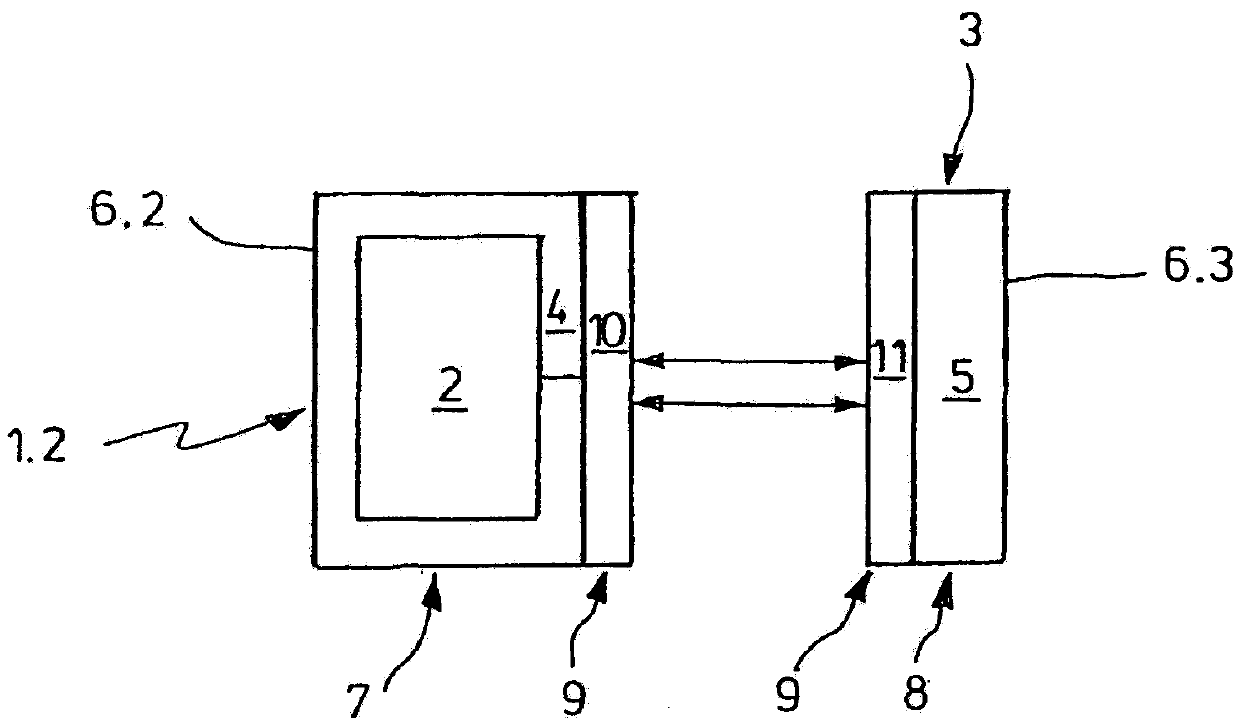

Mechanical pipette

ActiveUS9415387B2Improved and expanded functioningImproved and expanded and handlingBurettes/pipettesOperating pointMechanical pipette

A mechanical pipette comprising:a. a manually drivable mechanical unit for pipetting liquids,b. at least one sensor for detecting operating and / or performance data,c. an operating unit, andd. a display unit,e. wherein a device module comprises the mechanical unit for pipetting, the sensor and operating unit,f. a display module physically separate from the device module completely or partially comprises the display unit, andg. means for wireless communication between the device module and the display module.

Owner:EPPENDORF SE

Three-degree-of-freedom pipetting device of closed cartridge and closed cartridge

ActiveCN112623470BEnable mobilityAchieve rotationDischarging meansDamagable goods packagingMechanical pipetteEngineering

The present invention provides a three-degree-of-freedom pipetting device of a closed cartridge and a closed cartridge, which expands the degree of freedom of the pipetting device, so that more reagent holes can be used in the limited volume of the closed cartridge . The closed cartridge includes a reagent disc, and a plurality of reagent holes are arranged on the reagent disc; the pipetting device includes a pipetting head, a rotating platform, a first driving assembly and a second driving assembly; the rotating platform includes a rotating chassis, and a chassis bearing part, The rotating chassis is rotatably arranged on the supporting part of the chassis, and the rotating chassis is provided with a chute, and the pipetting head is slidably arranged in the chute; the first drive assembly is used to drive the pipetting head to slide along the chute and drive the rotating chassis Rotate relative to the chassis bearing part to drive the pipette head to rotate, so that the pipette head can be aligned with any reagent hole on the reagent plate; the second drive assembly is used to drive the rotating platform to move up and down and drive the pipette head to move up and down, so that the pipette head can be aligned Liquid aspiration or liquid injection is performed on the aligned reagent wells.

Owner:3D BIOMEDICINE SCI & TECH CO LTD

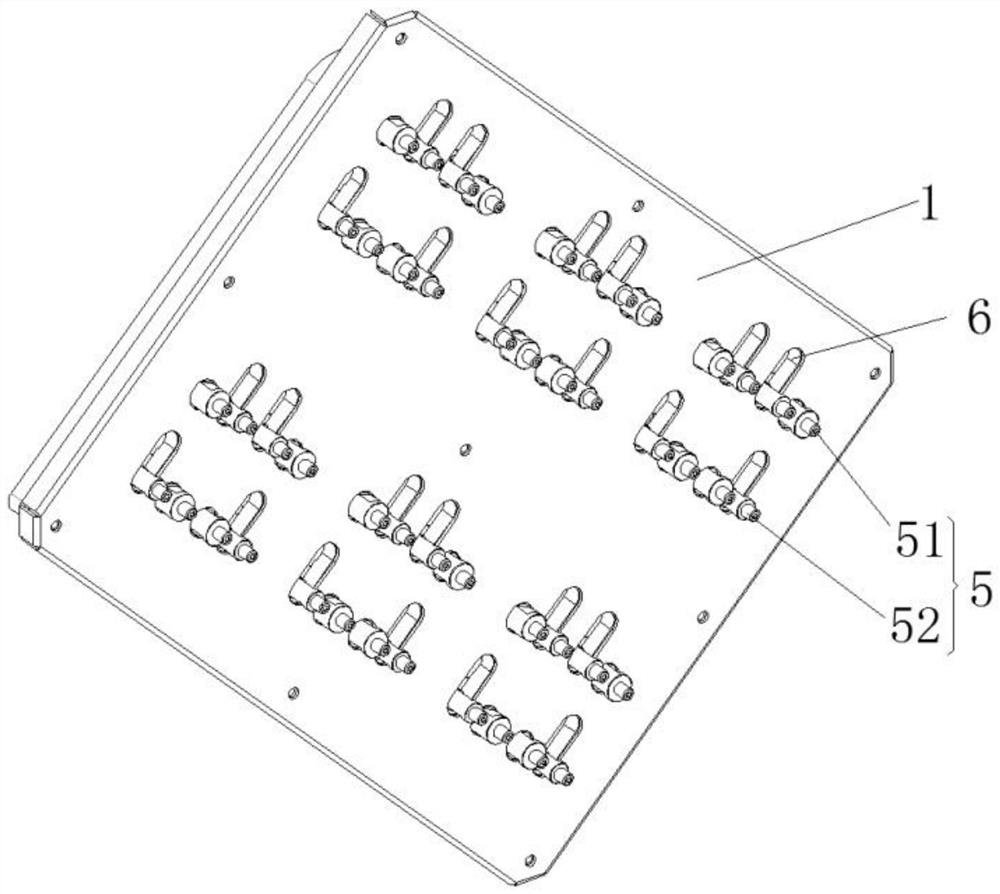

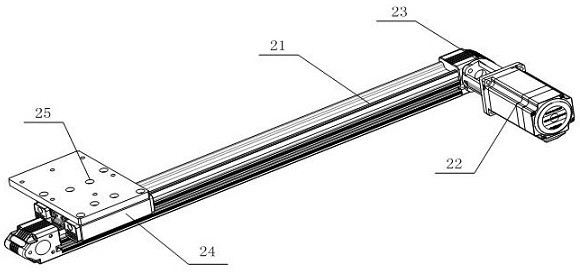

Servo sliding table pitch changing device of intelligent pipette head production line system

PendingCN112810057AImprove work efficiencyReduce processing requirementsProduction lineMechanical pipette

The invention discloses a servo sliding table pitch changing device of an intelligent pipette head production line system, and relates to the technical field of medical instruments. The servo sliding table pitch changing device comprises a first fixing plate, a second fixing plate, a sliding plate, a telescopic device and a suction cup; the suction cup comprises a plurality of first pipette head suction heads and a plurality of second pipette head suction heads; the plurality of first pipette head suction heads are fixed to the first fixing plate, a plurality of first through holes are formed in the first fixing plate, the plurality of second pipette head suction heads are fixed to the sliding plate, the second pipette head suction heads penetrate through the first through holes to form the suction cup with the first pipette head suction heads, and the first fixing plate is connected with the second fixing plate; the sliding plate is arranged between the first fixing plate and the second fixing plate, one end of the telescopic device is connected with the sliding plate, the other end of the telescopic device is connected with the first fixing plate, and the telescopic device drives the sliding plate to move to change the shape of the suction cup. The position change of the second pipette head suction heads in the first through holes is realized through the telescopic device, and the conversion of the suction cup structure is realized.

Owner:NINGBO WELLLIH ROBOTS TECH CO LTD

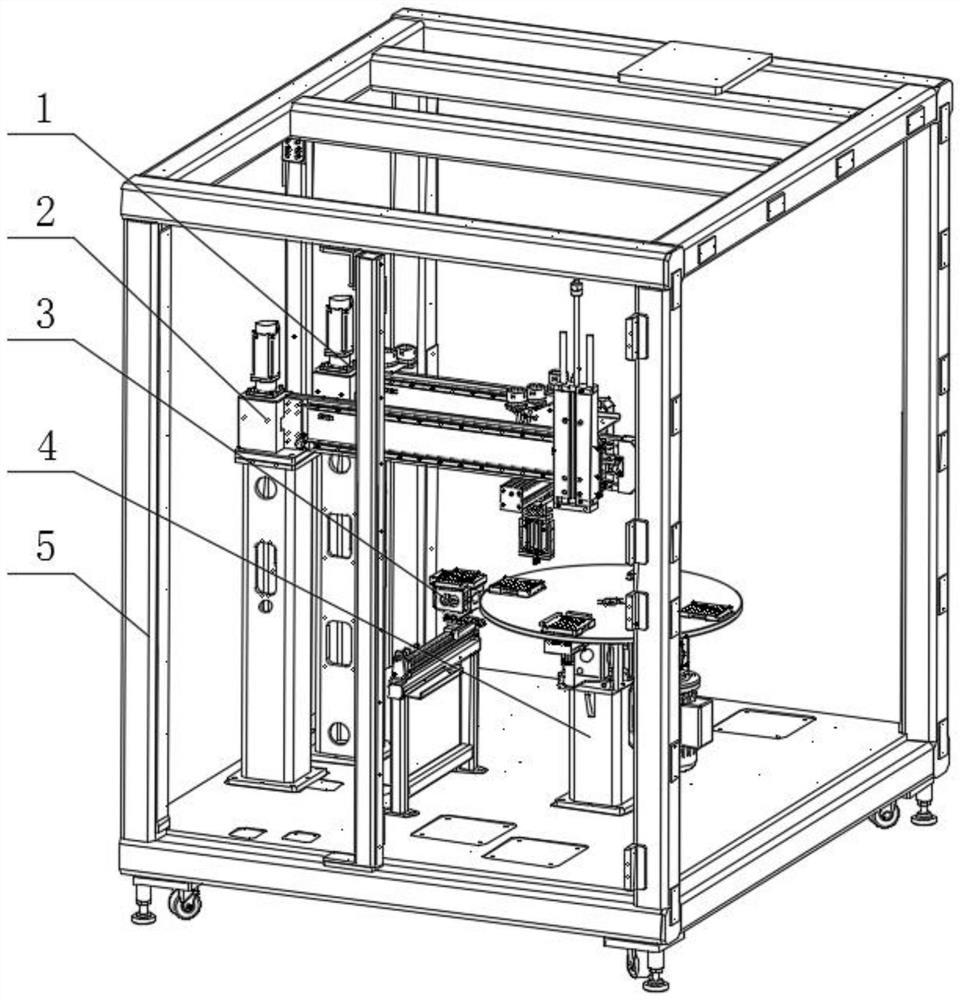

Height-adjustable full-automatic PCR (Polymerase Chain Reaction) sampling system

PendingCN114561278AAccurate volumePrecise suctionBioreactor/fermenter combinationsBiological substance pretreatmentsMedicineRobotic arm

The invention discloses a height-adjustable full-automatic PCR (Polymerase Chain Reaction) sample adding system which comprises a main body, a mechanical arm, a lifting device, a liquid sucking device, a sucking head placing device, a drag chain and a liquid pulling and moving head device, the mechanical arm, the suction head placing device, the drag chain and the pipette tip pulling and moving device are all arranged on the main body; the lifting device is arranged on the mechanical arm and slides on the mechanical arm; one end of the drag chain is connected with the mechanical arm, and the other end is connected with the lifting device; the position and the liquid suction volume of the liquid suction device are controlled through the PLC, and the liquid suction device is used for controlling the liquid suction volume; the suction head placing device is used for placing suction heads, and the pipette tip pulling and moving device is used for removing the suction heads; the synchronous belt wheel is driven by the synchronous belt, so that liquid suction is more accurate, and the minimum liquid suction volume reaches 0.1 microliter; the initial liquid suction height is automatically calculated according to the input parameter instrument, and the instrument automatically descends in the liquid suction process, so that the suction head wall is prevented from being stained with excessive liquid on the premise of ensuring that the liquid can be sucked every time, and the volume of the added liquid is more accurate.

Owner:四川科劲生物科技有限公司

Robot arm of automatic pipetting system

PendingCN114505107AGuaranteed cleanlinessIncrease contact pressureBurette/pipette supportsContact operating partsContact padRobotic arm

A robotic arm of an automated pipetting system, comprising: a pipetting tip adapter; a slide switch that detects the presence of a pipette tip on a pipette tip adapter includes: first and second supports that slide relative to each other along an axis of movement between first and second positions; a conductive contact pad arranged on the first support; an electrically conductive terminal attached in physical contact to the second support when the support is in the first position, the terminal being an elastic and internally stable first wiping member extending along the axis of movement, the first wiping member being not in physical contact with the contact pad when the support is in the second position, and the second wiping member being not in physical contact with the contact pad when the support is in the first position. A current can flow between the first wiper and the contact pad when the support is in the first position, and the current between the wiper and the contact pad is interrupted when the support is in the second position. The use of a robotic arm in an automated pipetting system, a slide switch detects the presence of a pipetting tip on a tip adapter. An automated pipetting system includes a robotic arm that detects the presence of a pipetting tip on a tip adapter.

Owner:帝肯贸易股份公司

Multichannel pipetting head

PendingUS20220001377A1Small volumeImpairs accuracy and precisionBurettes/pipettesLower borderMechanical pipette

A multichannel pipetting head comprises a plunger actuator comprising at least one groove with an upper border, and a lower border. A plurality of plunger-cylinder units, wherein each plunger-cylinder unit comprises a cylinder and a plunger comprising a plunger head. The plunger head comprises a projecting upper abutment region adjoining the upper border, a projecting lower abutment region adjoining the lower border and laterally offset relative to the projecting upper abutment region, a plurality of guides. Each of the cylinders is coupled to a neck and held on each of the plurality of guides. During lateral movement of the plurality of guides, the plunger head is configured to tilt in the groove and to be held with the upper abutment region abutting the upper border and with the lower abutment region abutting the lower border of the groove due to restoring forces that occur during tilting in the plunger-cylinder units.

Owner:EPPENDORF SE

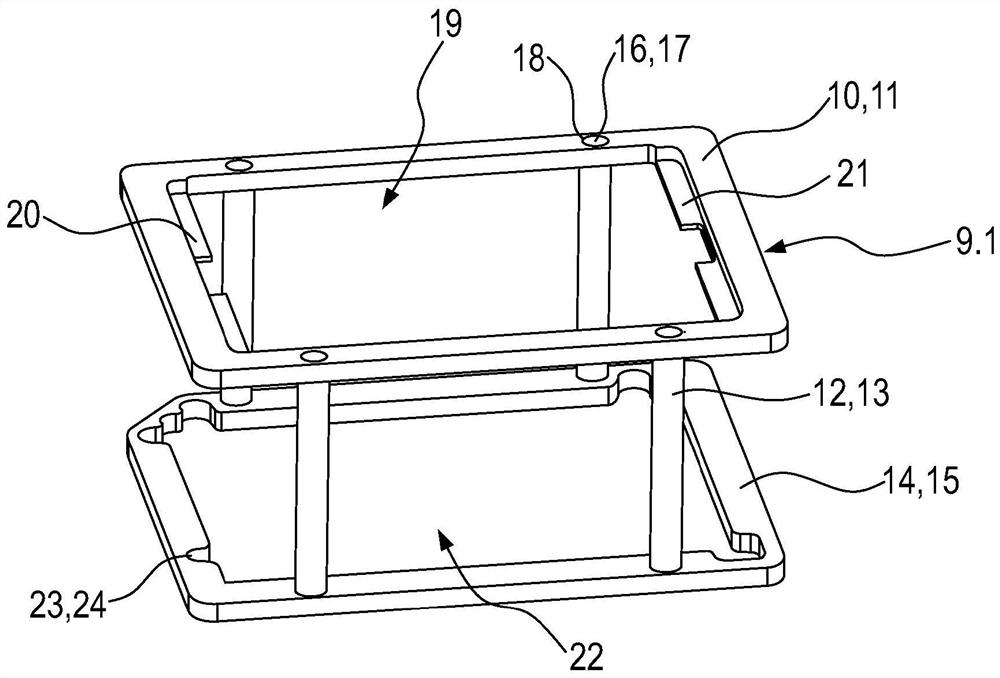

Automated laboratory machine for automatic handling of laboratory samples

ActiveCN113382803AReduced conversion timeSupporting apparatusMaterial analysisExperimental laboratoryMechanical pipette

The invention relates to an automated laboratory machine for automatic handling of laboratory samples, comprising: a working zone; a plurality of predetermined workstations for laboratory articles in the working zone, which workstations have dimensions adapted to the base of a standardized microtiter plate; at least one movement apparatus for moving tools above the workstation; at least one transport tool which is movable by means of the movement apparatus in order to displace laboratory articles in the working zone; at least one pipetting tool which is movable by means of the movement apparatus in order to receive and dispense pipette tips and receive and dispense liquids by means of the pipette tips in the working zone; and a holder for pipette tip carriers, wherein the holder for pipette tip carriers comprises at least one carrying device having a rectangular through-opening and a supporting device connected to the carrying device, and wherein the holder comprising the supporting device is placed on a workstation alongside a pipette tip carrier mounted on the workstation, such that the carrying device is arranged above the pipette tip carrier, which has a base adapted to the base of the standardized microtiter plate, by means of the pipetting tool pipette tips can be received through the through-opening of the carrying device from the pipette tip carrier mounted below the carrying device, and a pipette tip carrier, which has a base adapted to the base of the standardized microtiter plate, can be mounted on the carrying device, wherein the automated laboratory machine comprises an electronic control device which is connected to the movement apparatus and is designed to control the movements of the transport tool and of the pipetting tool by means of the movement apparatus, such that by means of the pipetting tool pipette tips can be received from the pipette tip carrier mounted on the carrying device, the pipette tip carrier can be removed from the carrying device by means of the transport tool, and by means of the pipetting tool pipette tips can be received through the through-opening of the carrying device from the pipette tip carrier mounted below said carrying device.

Owner:埃佩多夫欧洲股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com