Robot arm of automatic pipetting system

A robot arm and pipetting technology, applied to the support of burettes/pipettes, laboratory containers, instruments, etc., can solve the problems of short life cycle, high mechanical resistance, unsuitable structure, etc., and achieve compactness Space, compact design, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

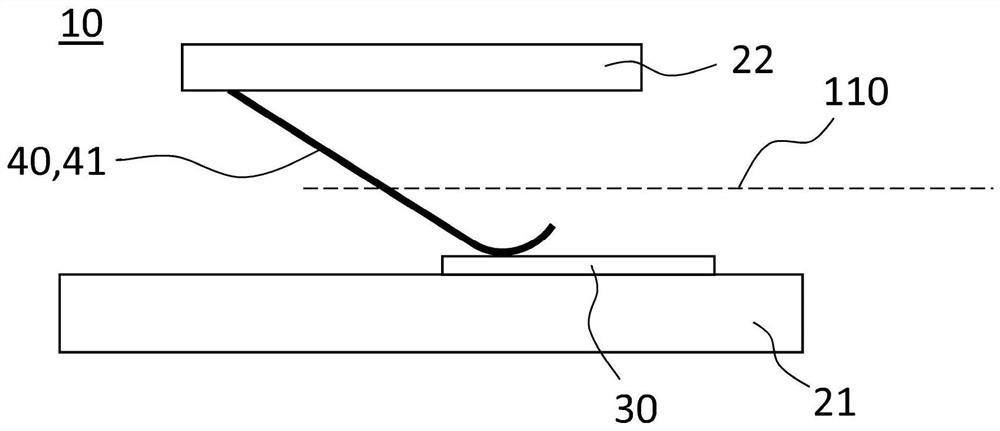

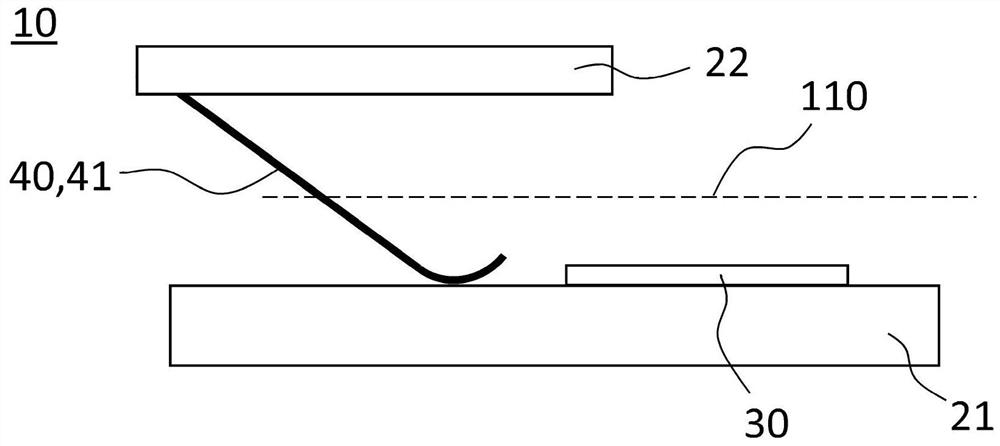

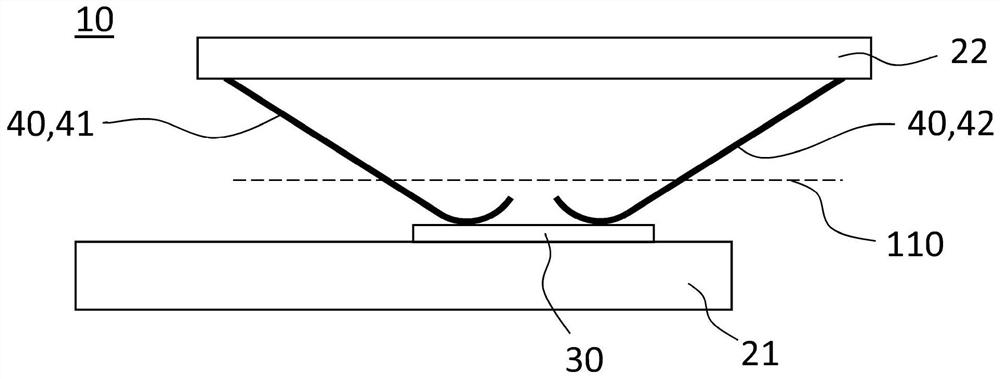

[0056] Figure 1a A schematic diagram showing a full cross-section of the slide switch 10 according to the invention in a first position.

[0057] The slide switch 10 shown here comprises a first support member 21 and a second support member 22 configured to slide relative to each other between a first position and a second position along a movement axis 110 shown in phantom. A terminal 40 in the form of a resilient and inherently stable first wiping member 41 is physically attached to said second support member 22 and is in physical and electrical contact with the conductive contact pad 30 when the slide switch 10 is in the first position shown. . The purpose of the second support member 22 is to hold the first wiper member 41 in place and at a uniform distance from the first support member 21 . The contact pad 30 must be at least superficially conductive so that current can flow between the first wiping member 41 and the contact pad 30 when the support members 21 , 22 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com