Extraction and purification device and method utilizing magnetic extraction material

A purification device and extraction technology, which is applied in the field of in vitro clinical testing sample processing, can solve problems such as long time, large error, and high difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

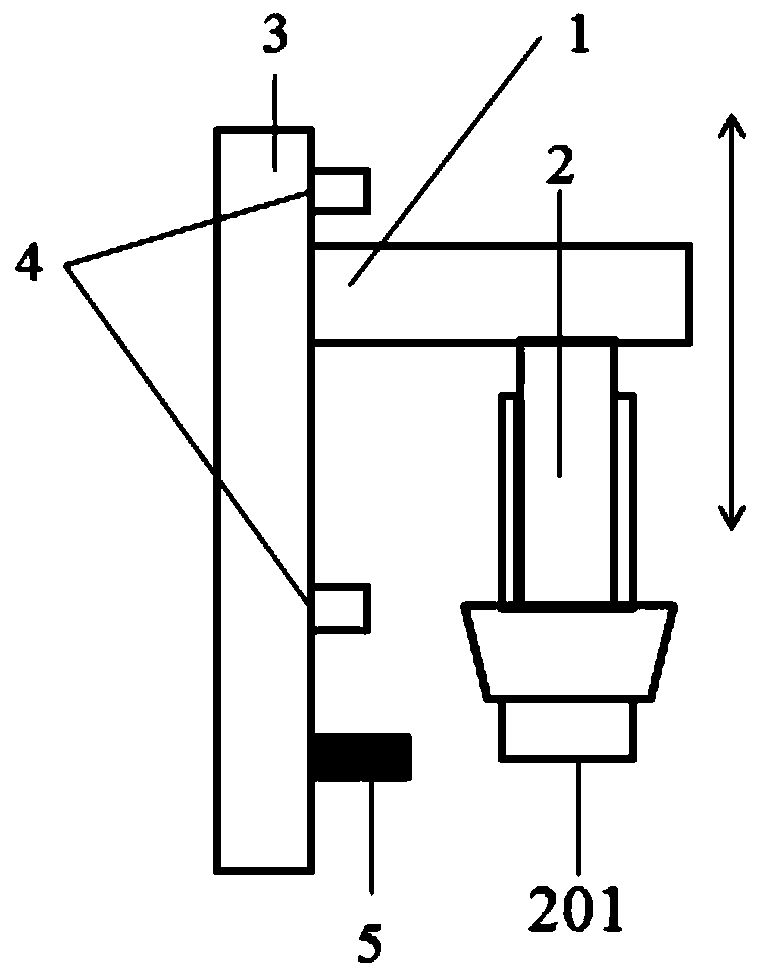

[0086] Embodiment 1 pipetting module

[0087] The structural diagram of the pipetting module of this embodiment is as follows: figure 1 As shown, the pipetting module 1 includes a syringe pump 2 and a second guide rail 3, the second guide rail 3 is connected and can drive the syringe pump 2 to move up and down. The bottom of the syringe pump 2 is provided with a first interface 201. When the pipetting module 1 moves above the pipetting head station module 7, the syringe pump 2 moves downward along the second guide rail 3, so that the pipetting head station module 7 The upper opening of the pipetting head 701 can be tightly connected to the first interface 201 of the syringe pump 2, and moves to the reagent station module 9 and the extraction station module 8 with the pipetting module 1, and the syringe pump 2 provides pressure to make the pipetting The liquid head 701 sucks or discharges reagents.

[0088] The syringe pump 2 provides a negative pressure for the pipetting hea...

Embodiment 2

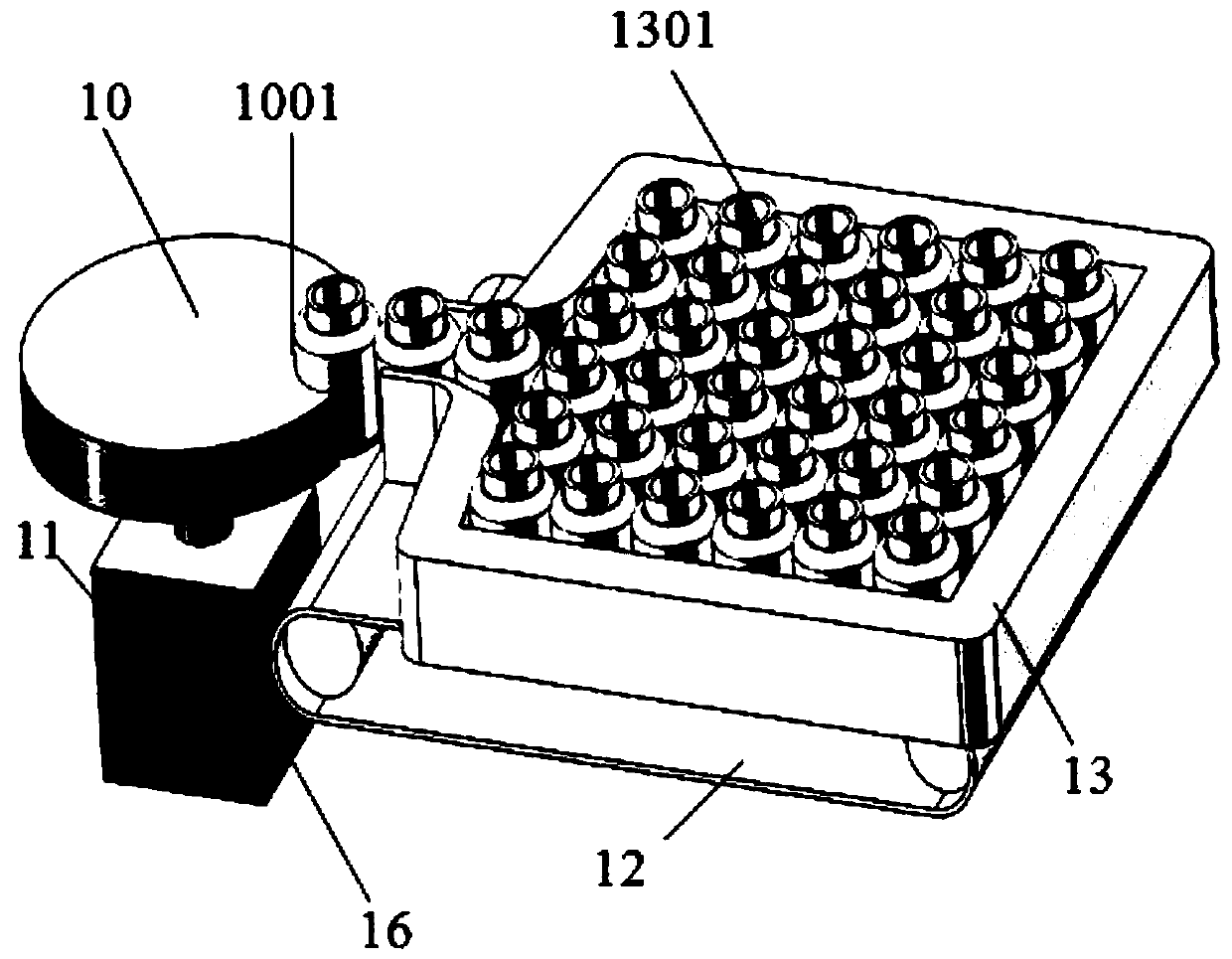

[0091] Embodiment 2 station module

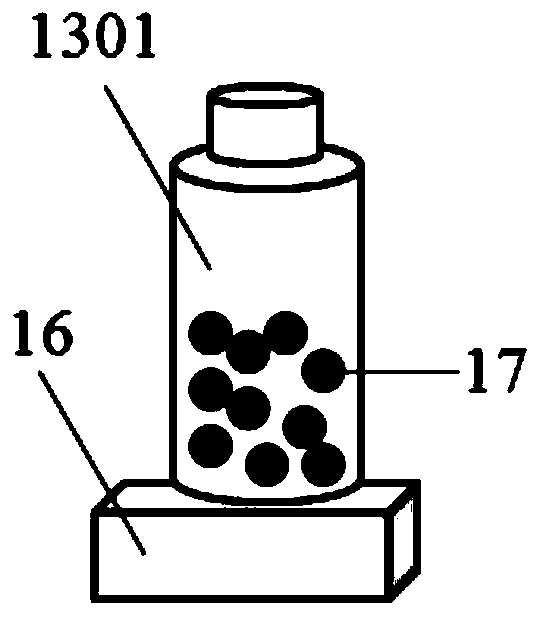

[0092] The station module structure of the present embodiment is as figure 2 As shown, the station module is arranged under the pipetting module 1, including a pipette head station module 7, an extraction station module 8 and three reagent station modules 9, the pipette head station module 7, the extraction station module The position module 8 and the reagent station module 9 are arranged sequentially along the moving direction of the first guide rail 6 , that is, the position of the station module can correspond to the position of the pipetting module 1 up and down. The three reagent station modules 9 are respectively used to hold the sample solution, the eluent and the finished product solution. The finished solution is the liquid formed after the sample solution is extracted and / or purified, and can be directly used in subsequent high-precision testing instruments.

[0093] The station module includes a turntable 10, a transmission me...

Embodiment 3

[0101] Embodiment 3 extraction and purification device

[0102] In this embodiment, the pipetting module 1 of Embodiment 1, the extraction station module 8 , the reagent station module 9 and the pipetting head station module 7 of Embodiment 2 are used.

[0103] The structure of the extraction and purification device of the present embodiment is as follows: Figure 4 As shown, the first guide rail 6 is arranged above the pipetting module 1, and the top of the second guide rail 3 is detachably fixed on the first guide rail 6. The extraction and purification device of this embodiment includes three pipetting modules 1, each The pipetting modules 1 are sequentially arranged on the first guide rail 6 . The first guide rail 6 is an annular guide rail, and each pipetting module 1 performs circular motion on the annular guide rail, so as to facilitate the continuous extraction operation.

[0104] The station module is arranged below the liquid pipetting module 1 and includes a pipet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com