Control method of automatic leveling system

A technology of automatic leveling and control method, applied in the direction of control without feedback, engine frame, mobile frame, etc., can solve the problems of low leveling accuracy, low leveling accuracy and low leveling efficiency, etc. The effect of simple leveling model, high degree of automation and simple control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

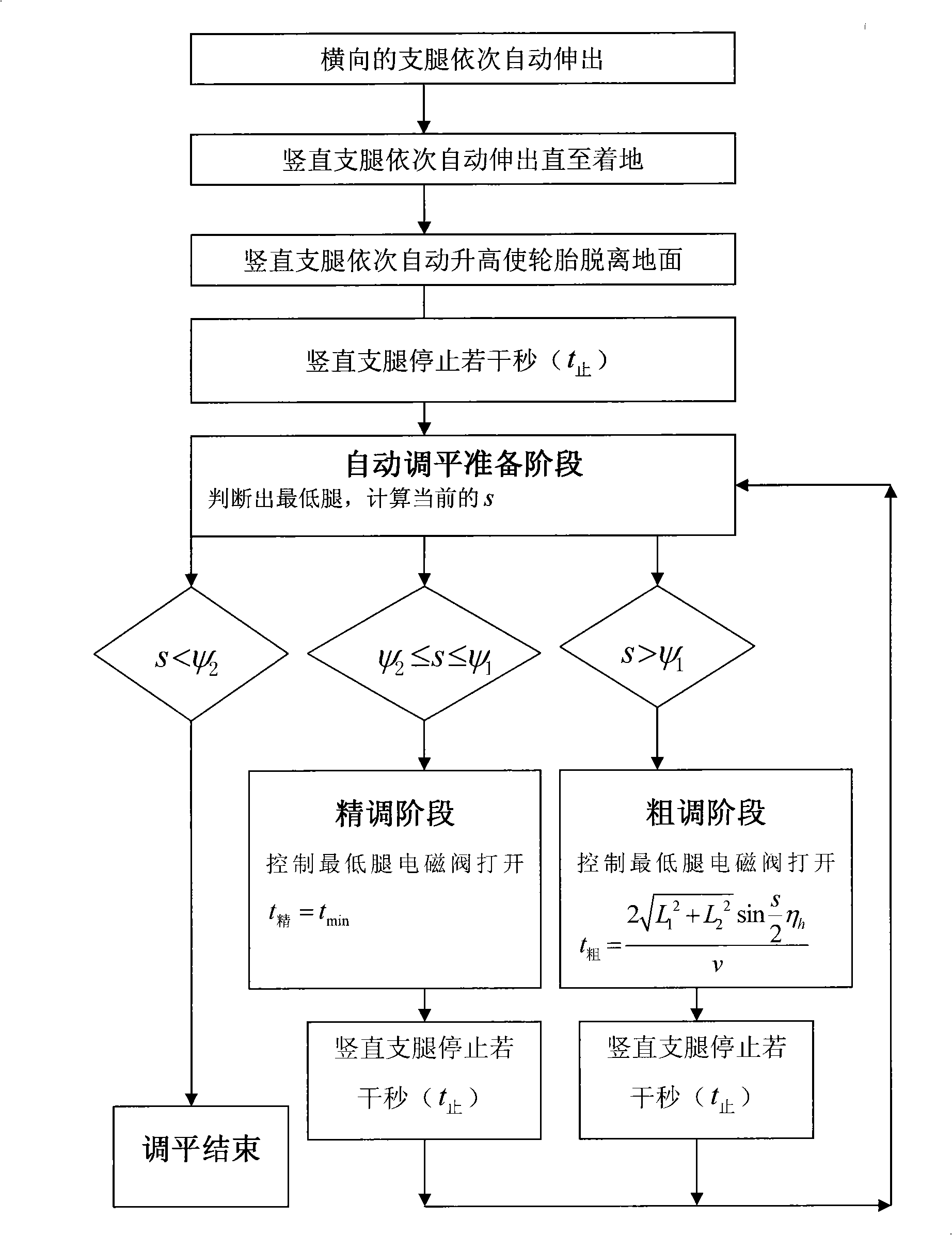

[0030] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific processes are provided, but the protection scope of the present invention is not limited to the following Example.

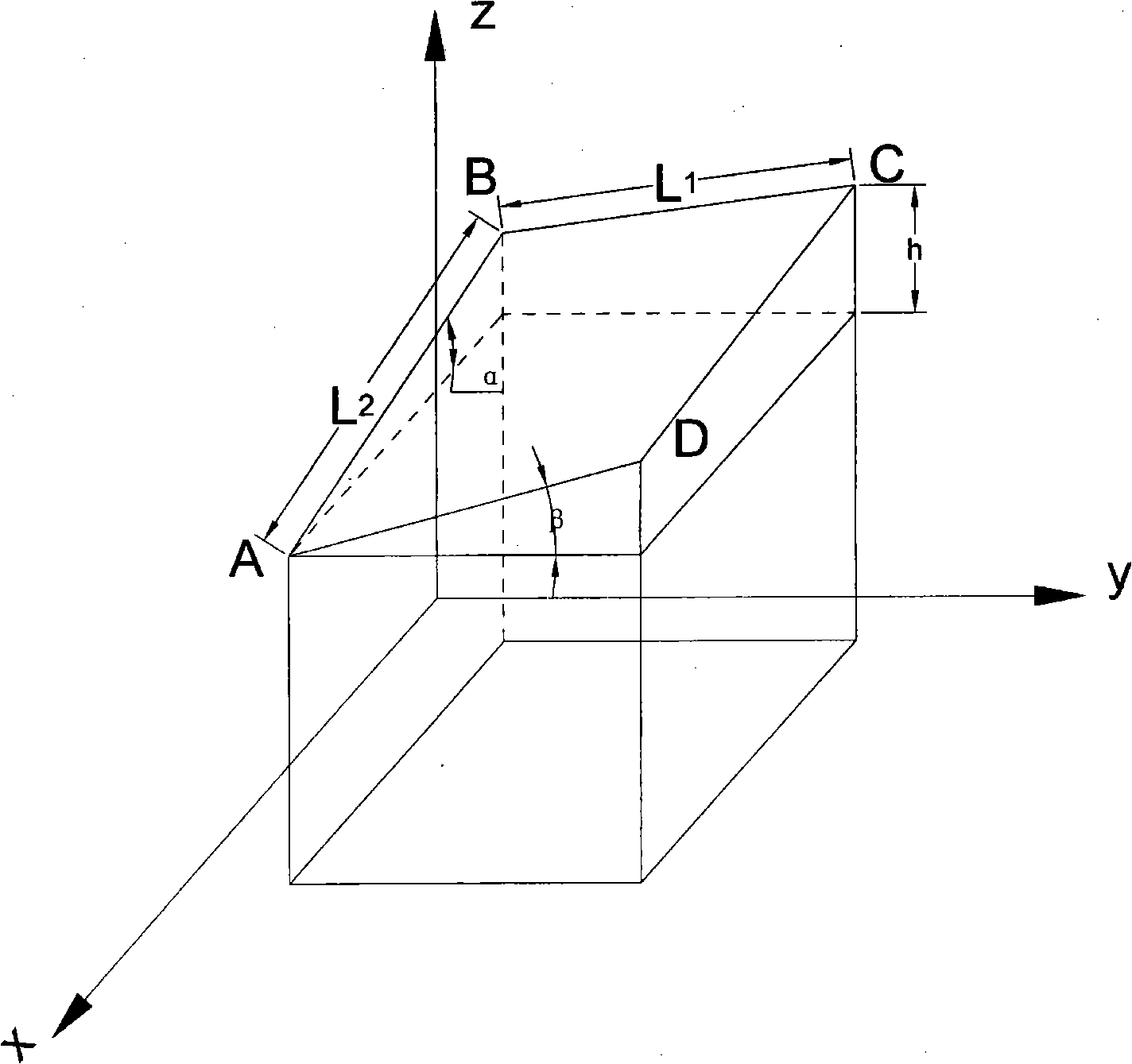

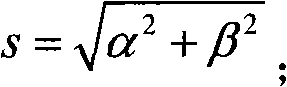

[0031] Such as figure 1 As shown, A.B.C.D is the supporting point of the four legs of the mobile carrier platform. α represents the angle value between the mobile carrier platform and the horizontal plane in the X direction; β represents the angle value between the mobile carrier platform and the horizontal plane in the Y direction; L 1 is the width of the mobile carrier platform, L 2 is the length of the mobile carrier platform, h represents the height difference between the highest leg and the lowest leg; from the above data:

[0032] h = 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com