Visual detecting method and device based on decoupling detection for circular seams

A visual detection device and visual detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting the real-time performance of the system, inaccurate center position, inaccurate deviation, etc., to avoid camera imaging models and reduce requirements , to avoid the effect of matrix transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

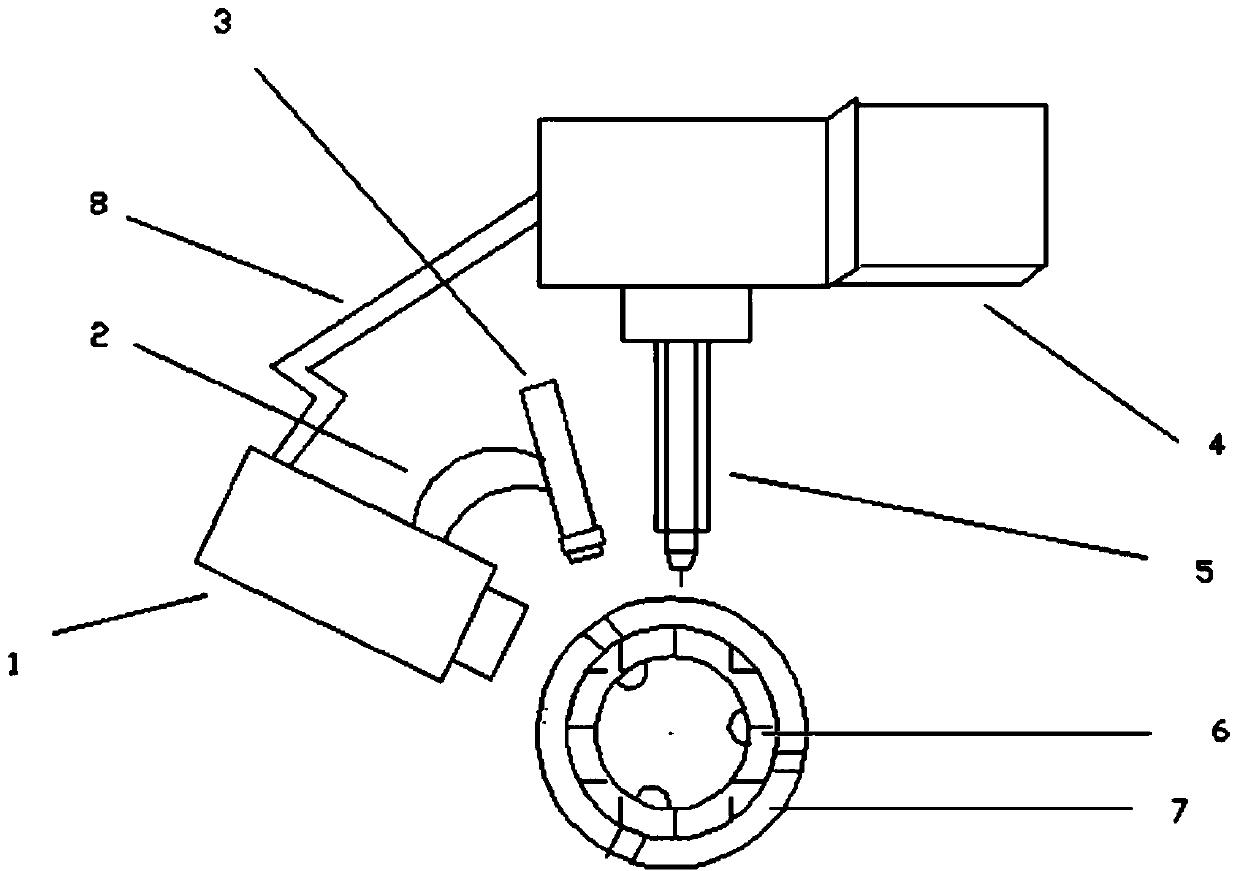

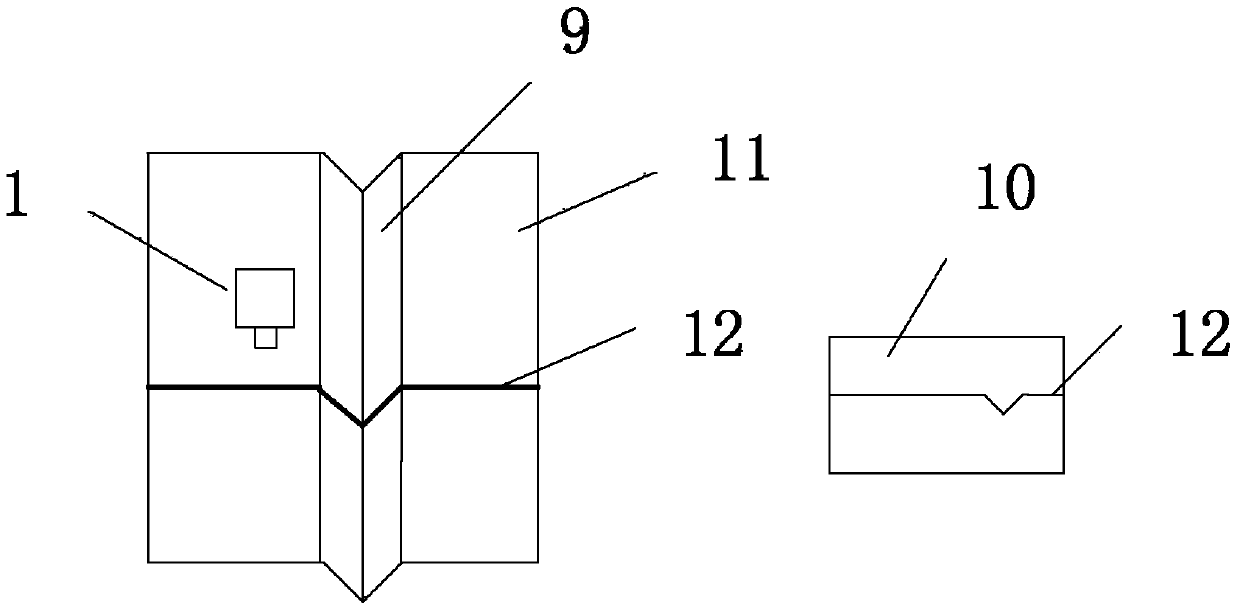

[0106] In this embodiment, the device is connected according to the requirements, and the outer diameter of the V-shaped groove annular weldment is selected to be 195mm, the groove width is 14mm, and the groove depth is 7mm.

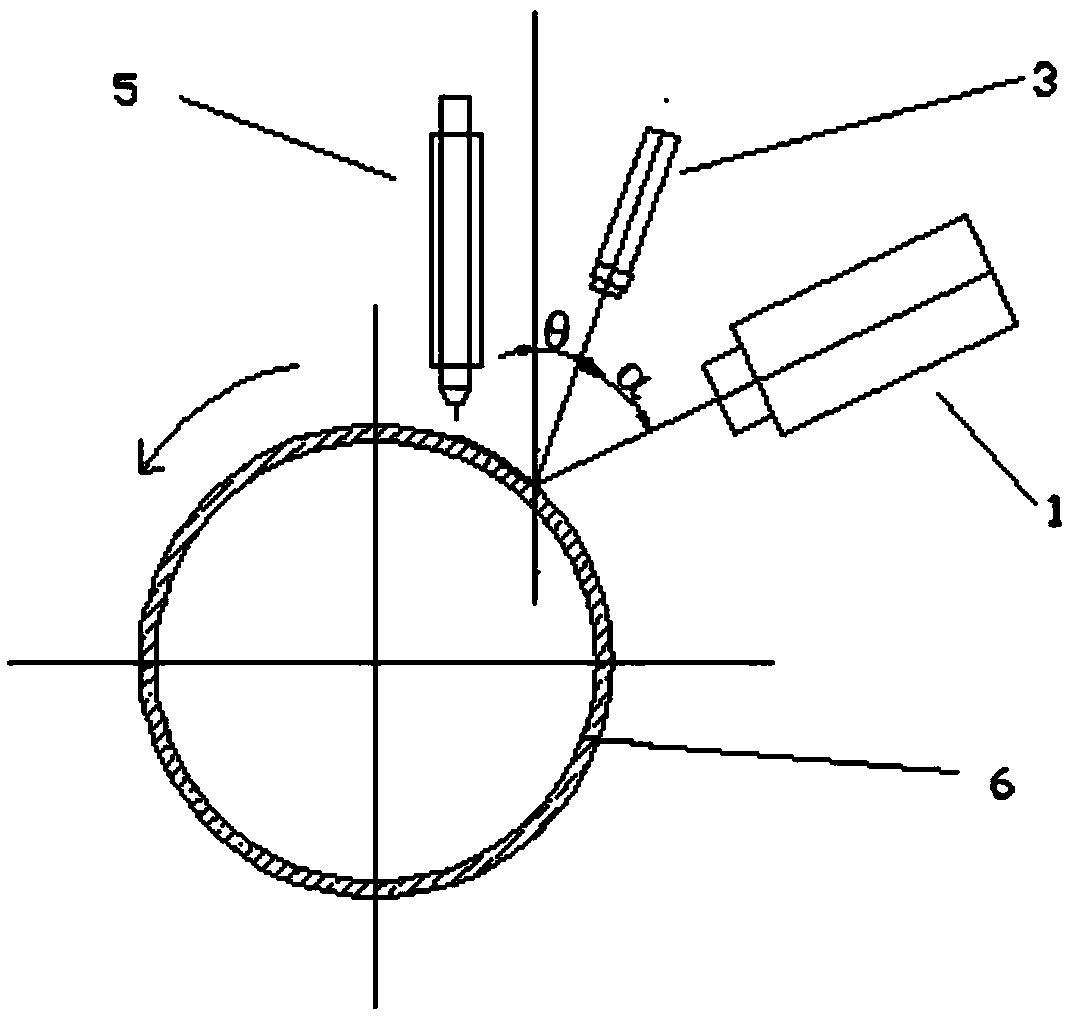

[0107] First turn on the power of the camera, move the welding torch to the initial welding position, and at the same time camera 1 collects and processes images to obtain the weld image coordinates and weld position information, record the reference image coordinates of the initial feature points of the weld, and start welding automatically after completion tracking function. In the process of automatic welding seam tracking, the image coordinates of the welding seam are extracted once in each sampling period as the feedback value of the current welding seam position, and the actual deviation in the two directions of the welding torch 5 is directly calculated through the decoupling detection algorithm based on the image plane.

[0108] The visual inspec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com