Chemical mechanical polishing apparatus and method thereof

A chemical machinery, polishing device technology, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve problems such as pressure deviation, inability to implement and spread out as expected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0129] Next, the chemical mechanical polishing device 1 according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings. However, in describing the present invention, the same or similar reference numerals are assigned to known functions or configurations, and descriptions thereof are omitted in order to clarify the gist of the present invention.

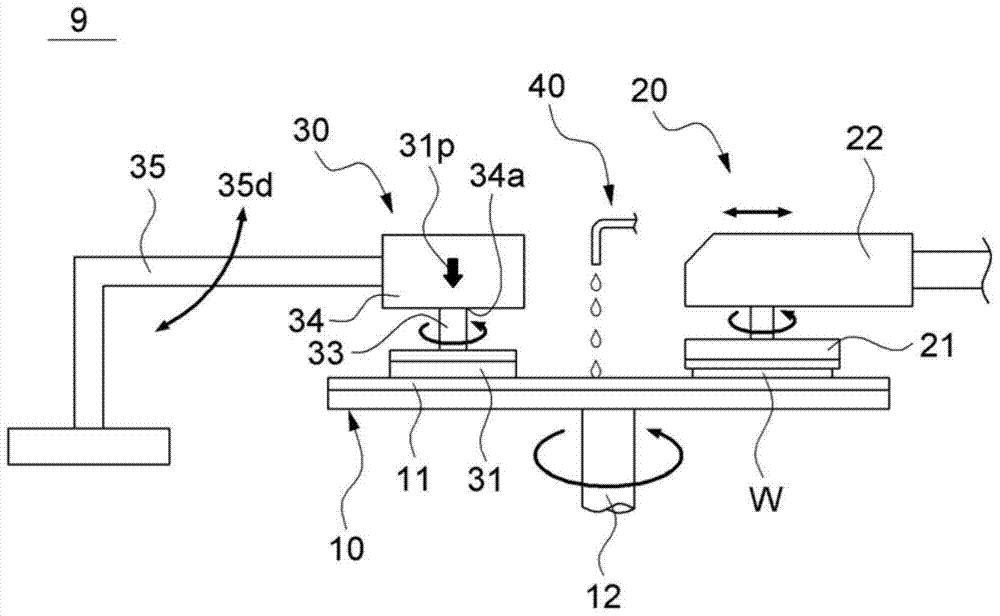

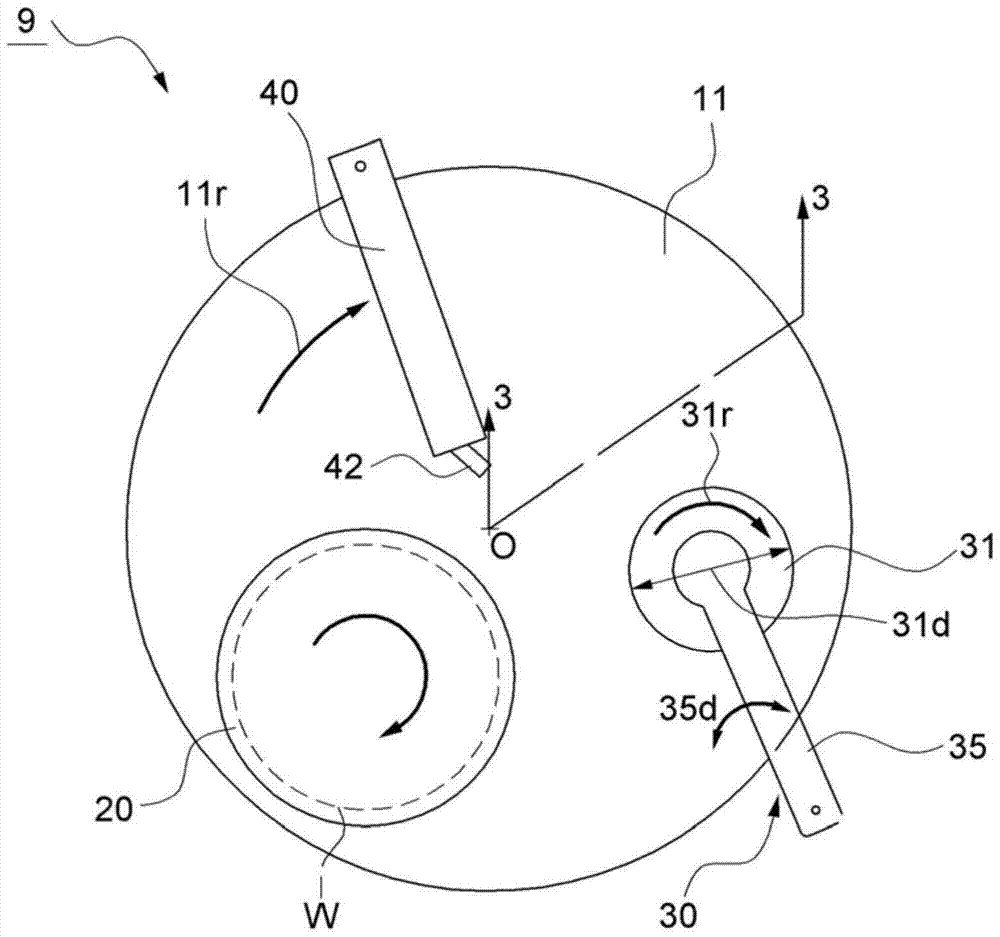

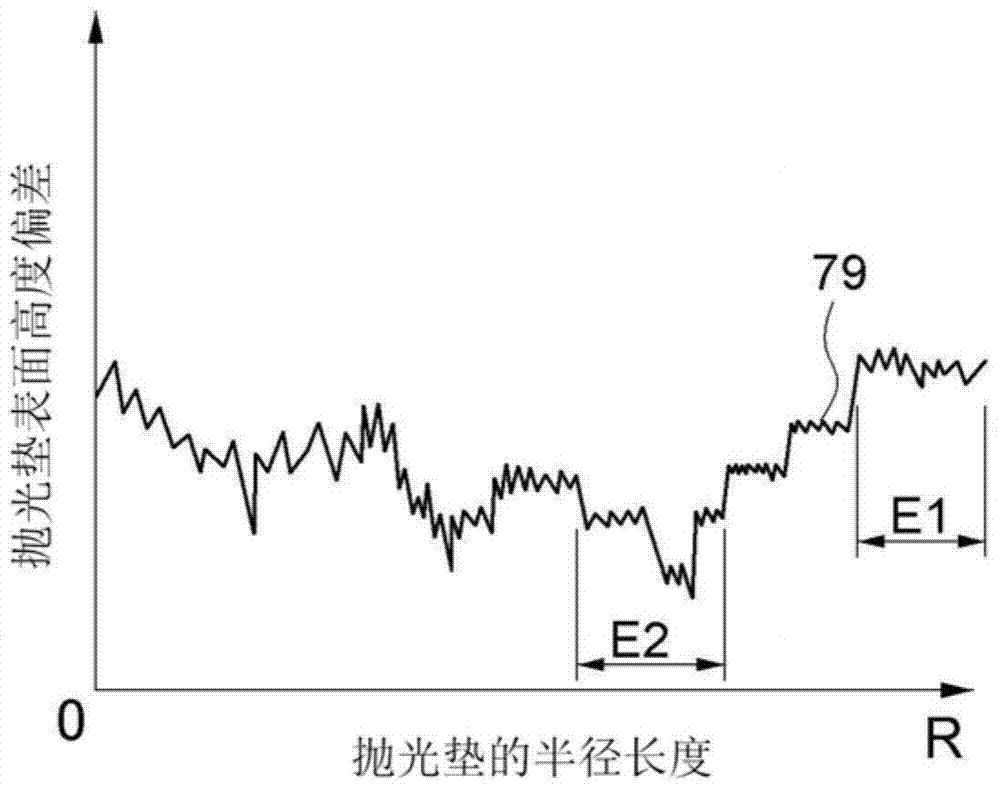

[0130] Such as Figure 4a and Figure 4b As shown, the chemical mechanical polishing device 1 according to an embodiment of the present invention includes: a polishing flat plate 10, the above-mentioned polishing flat plate 10 rotates 11r with a polishing pad 11 on its upper surface; a polishing head 20, to form The process surface of the polishing layer of the wafer W is close to the contact state of the polishing pad 11, and it is rotated 20r while applying pressure; the regulator 100 is used to modify the surface of the polishing pad 11; the slurry supply part 40 , for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com