Patents

Literature

138results about How to "Accurate modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods Of Modifying A Sequence Using CRISPR

InactiveUS20160053272A1Effective positioningAccurate modificationFermentationVector-based foreign material introductionNucleic acid sequenceBioinformatics

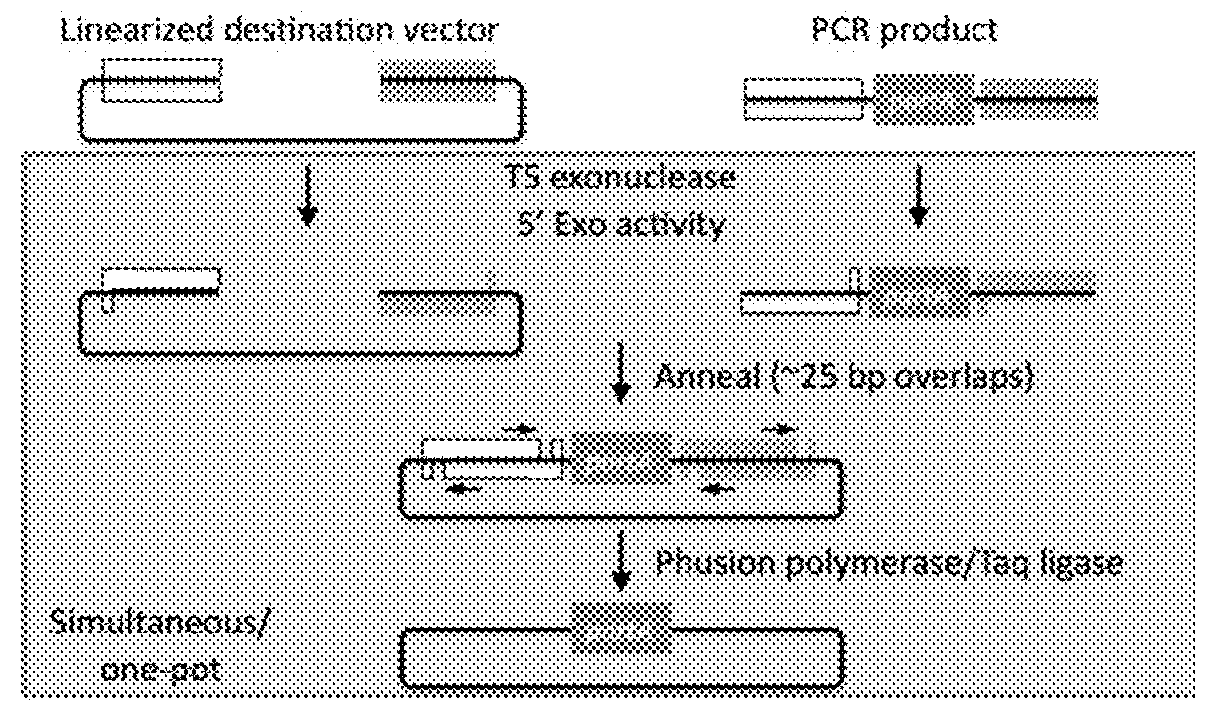

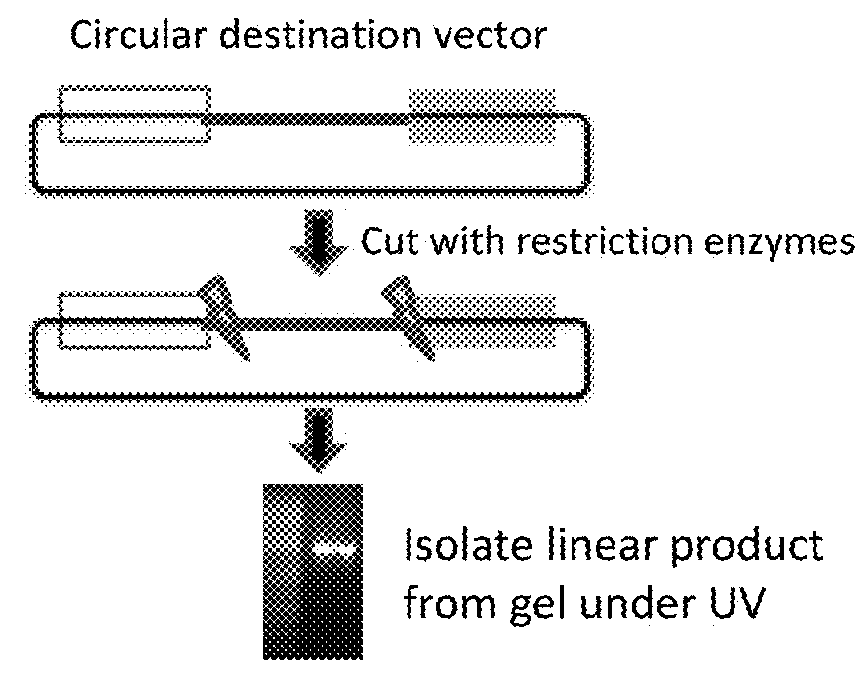

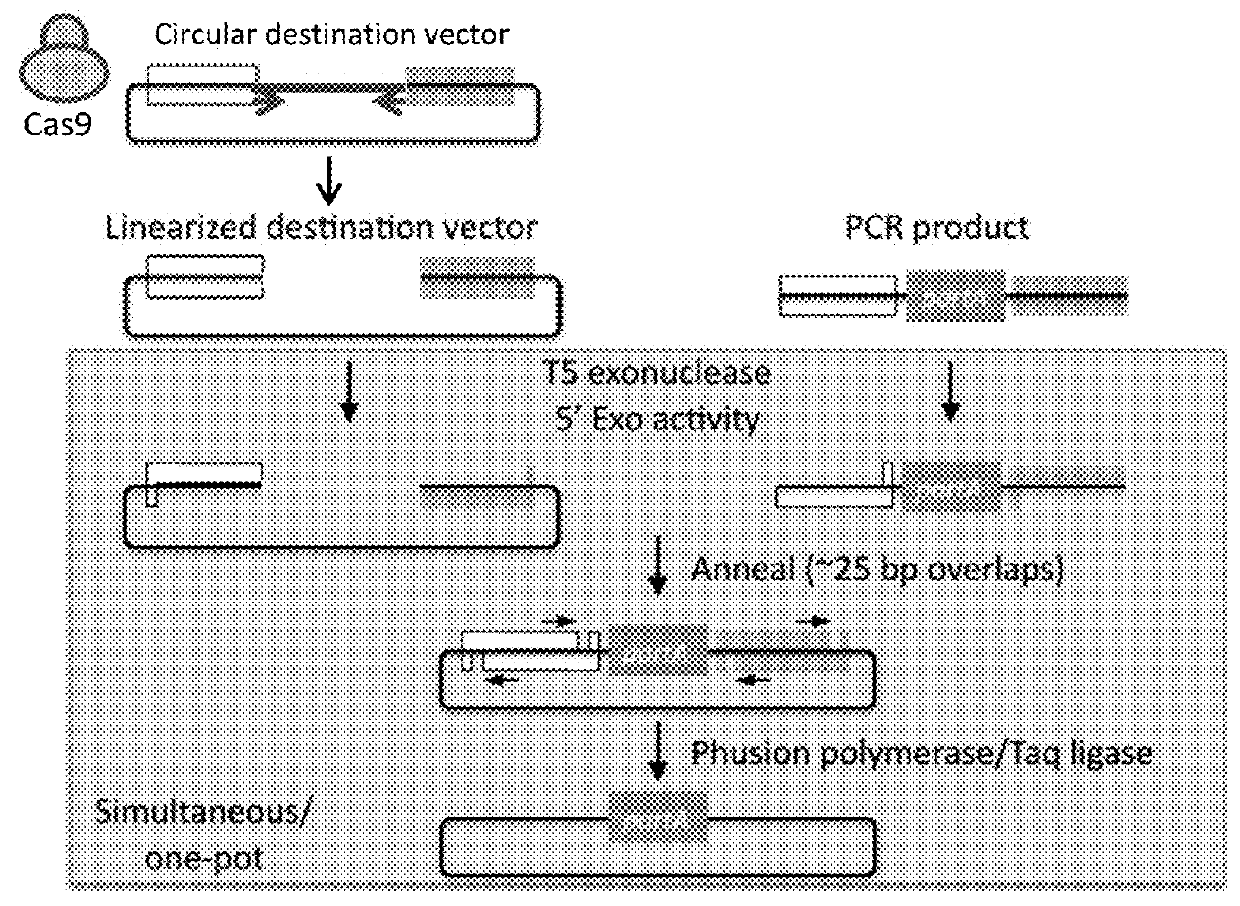

Methods of modifying one or more target nucleic acid sequences using the Clustered Regularly Interspaced Short Palindromic Repeats (CRISPR) and CRISPR associated (Cas) proteins (CRISPR / Cas) system are disclosed. Methods of introducing one or more exogenous nucleic acid sequences into one or more circular nucleic acid sequences using the CRISPR / Cas system are also disclosed.

Owner:WHITEHEAD INST FOR BIOMEDICAL RES

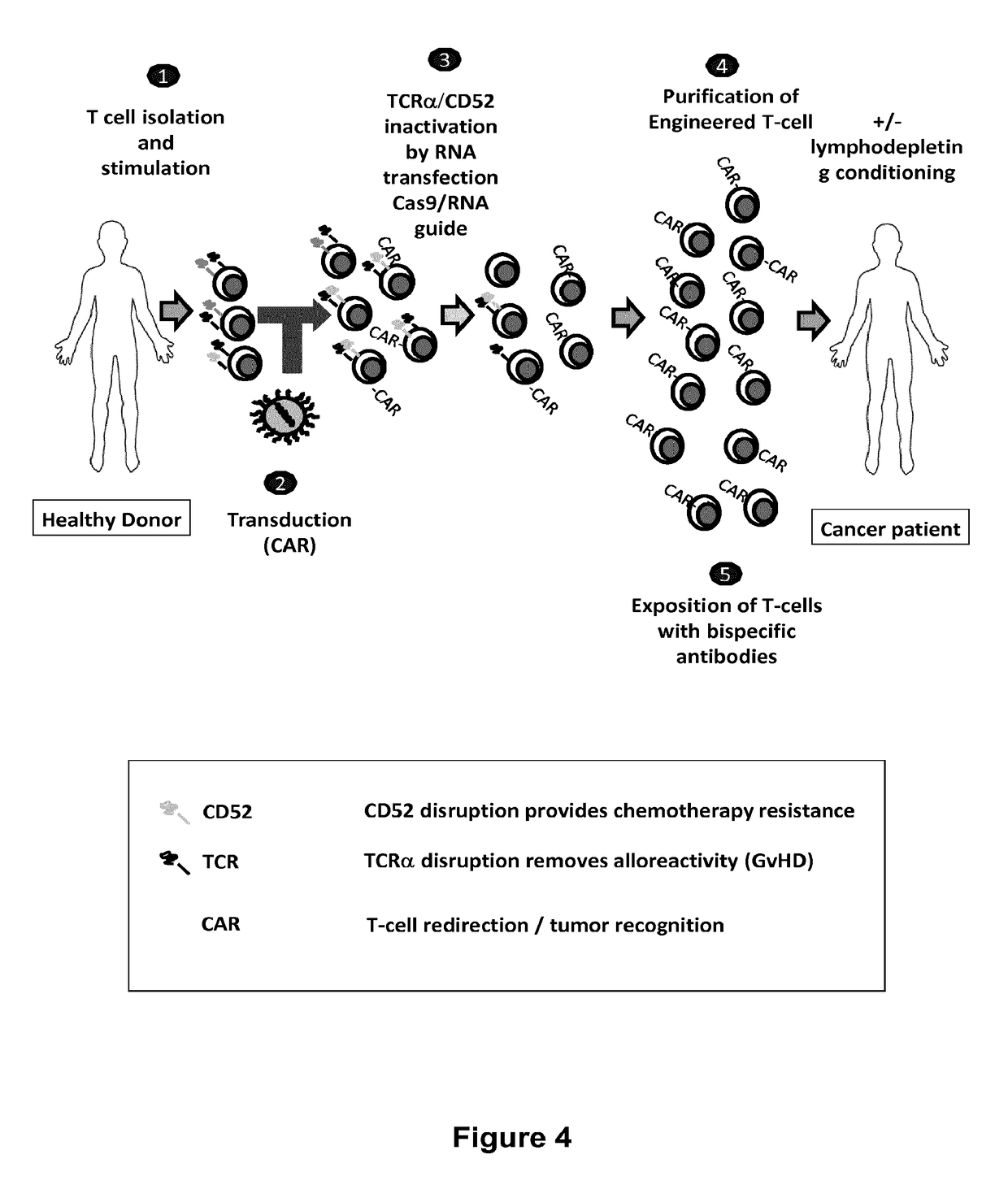

Methods for engineering t cells for immunotherapy by using rna-guided cas nuclease system

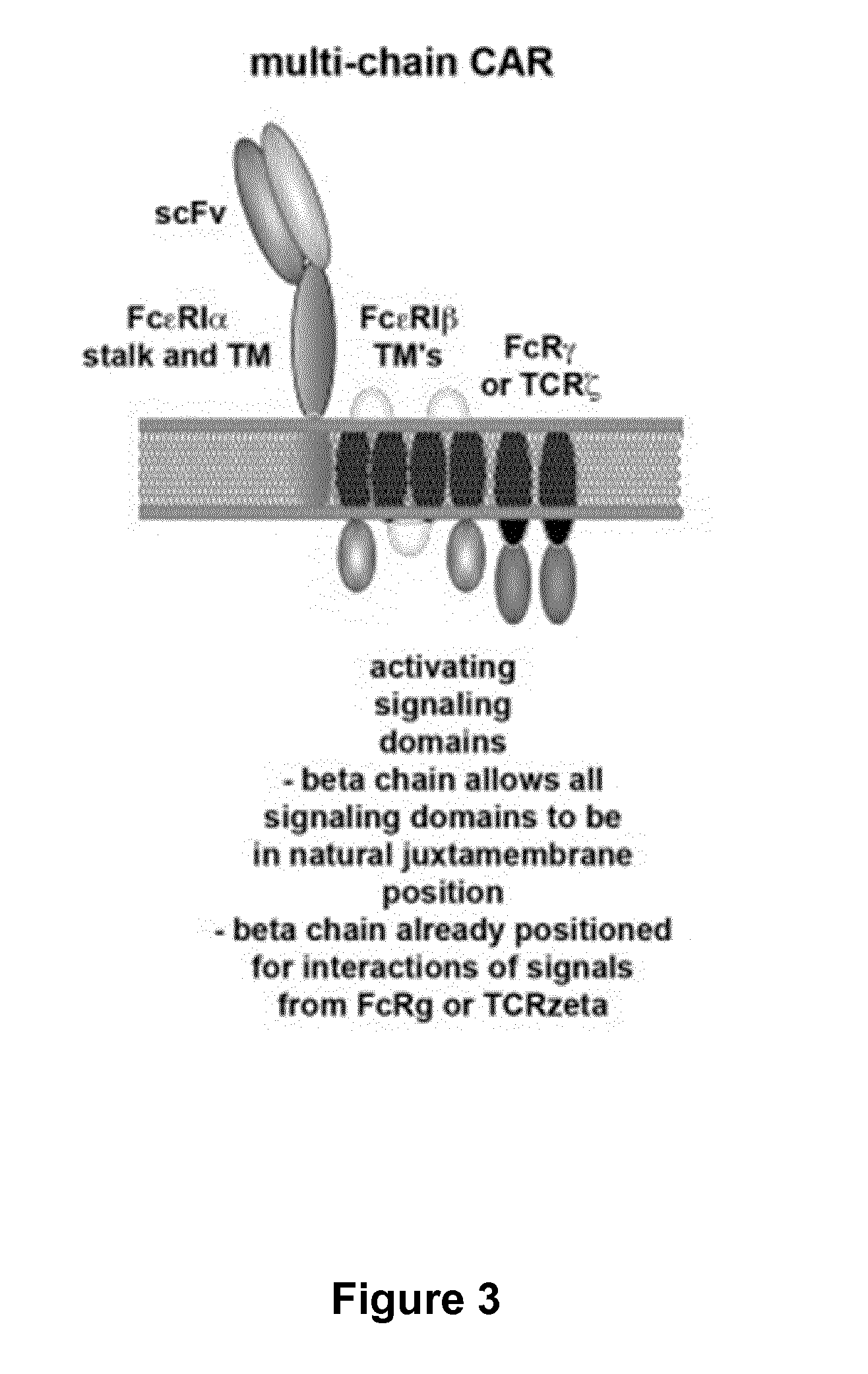

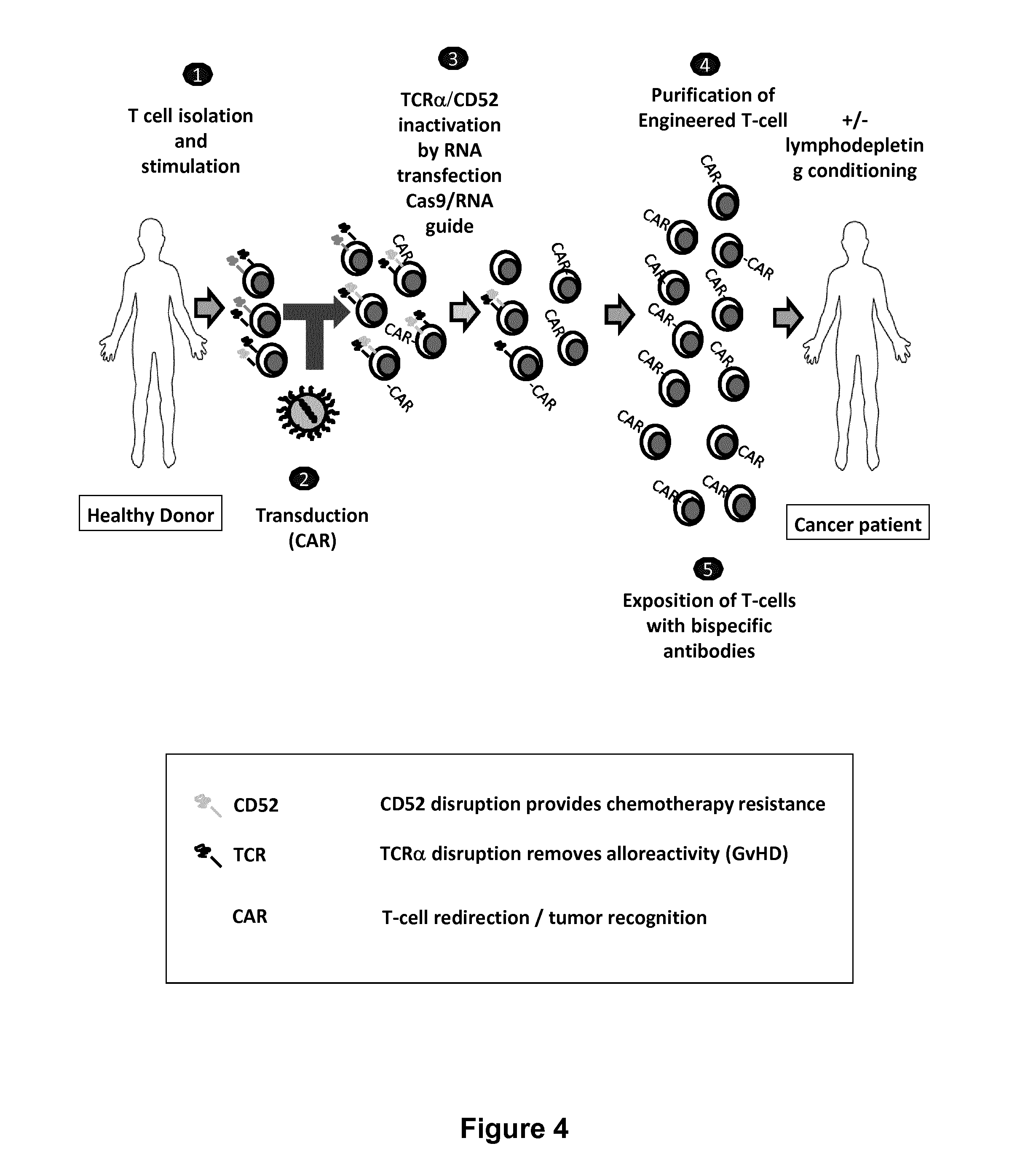

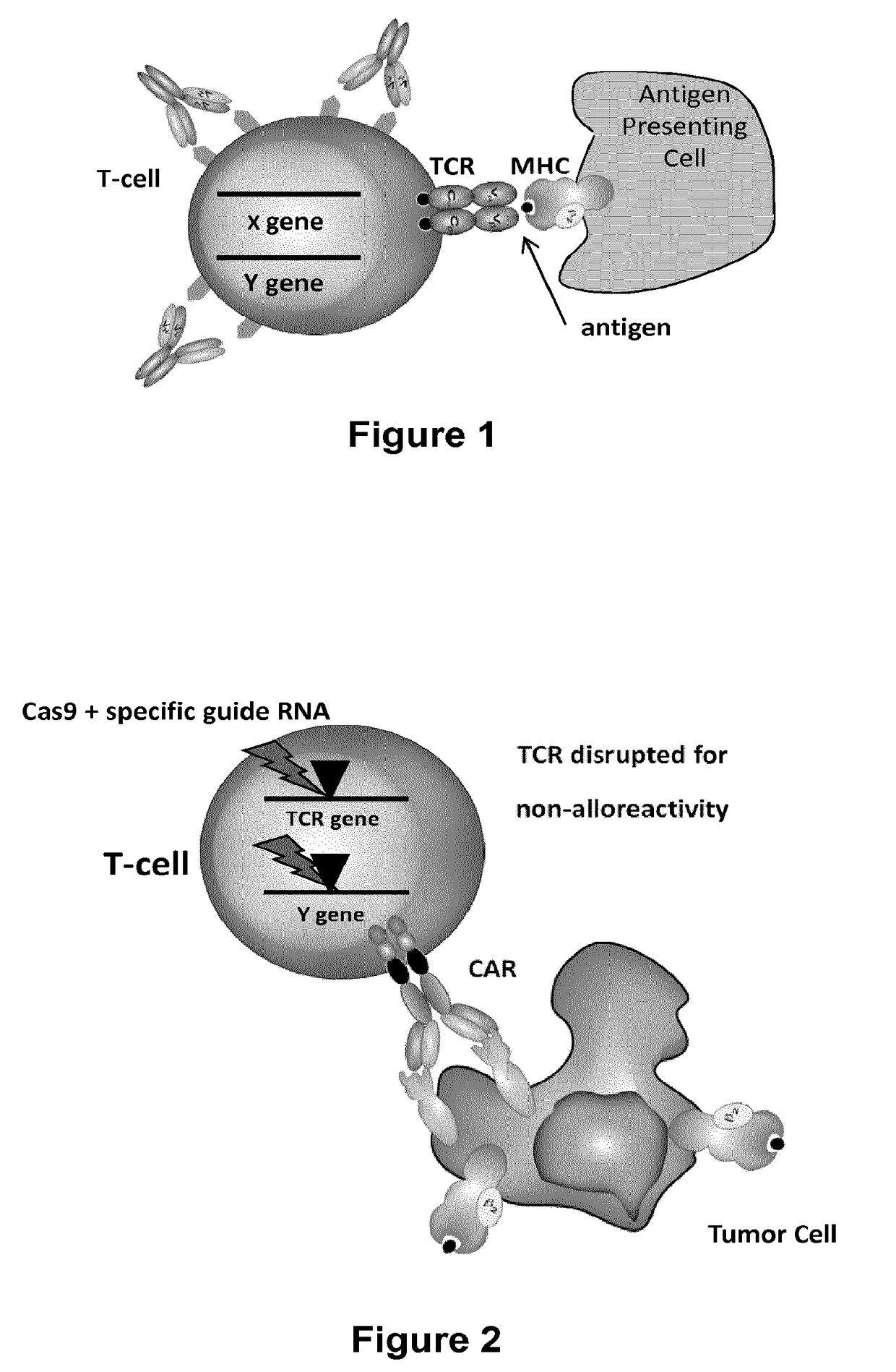

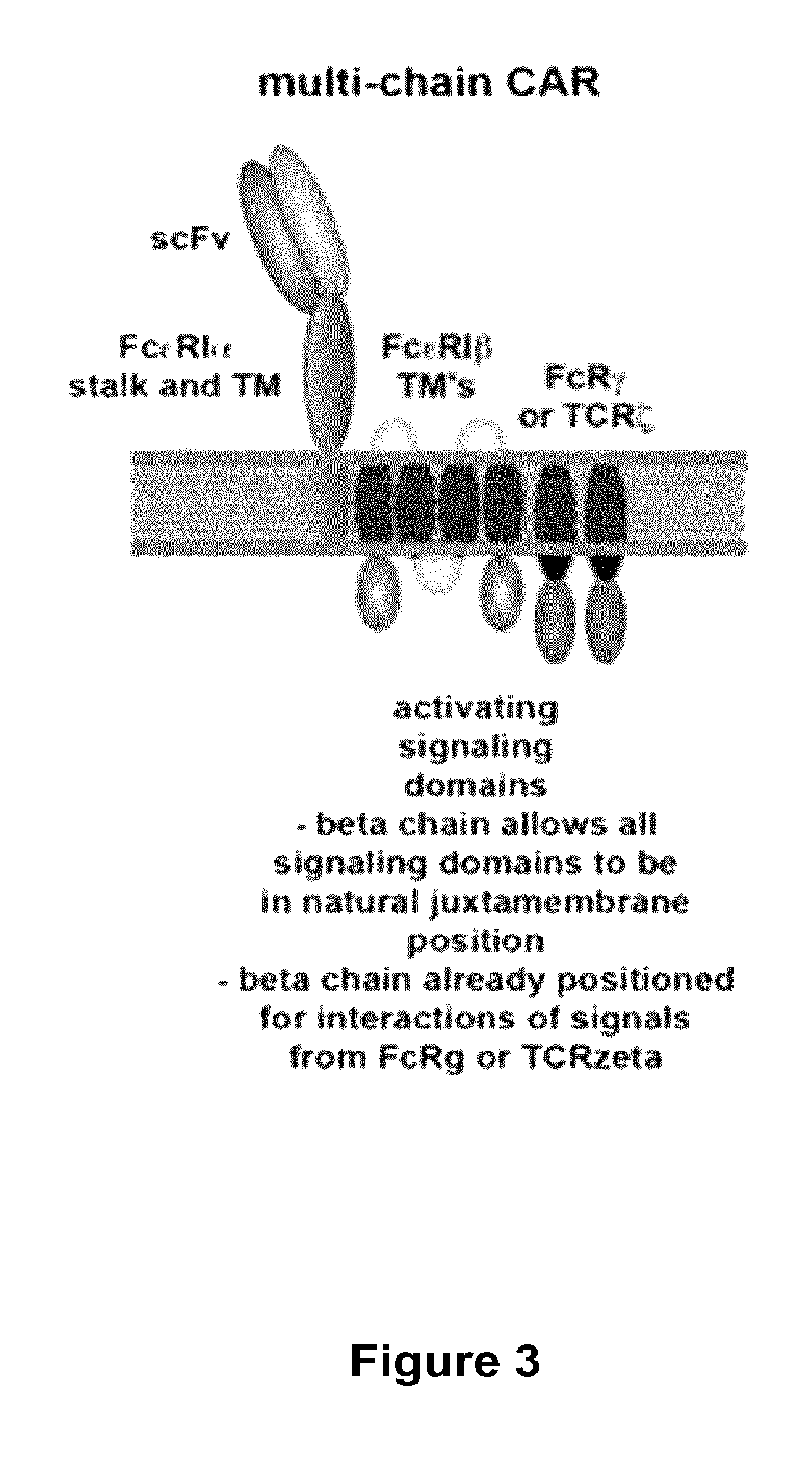

ActiveUS20160272999A1Accurate modificationHydrolasesGenetically modified cellsInfected cellAntigen receptors

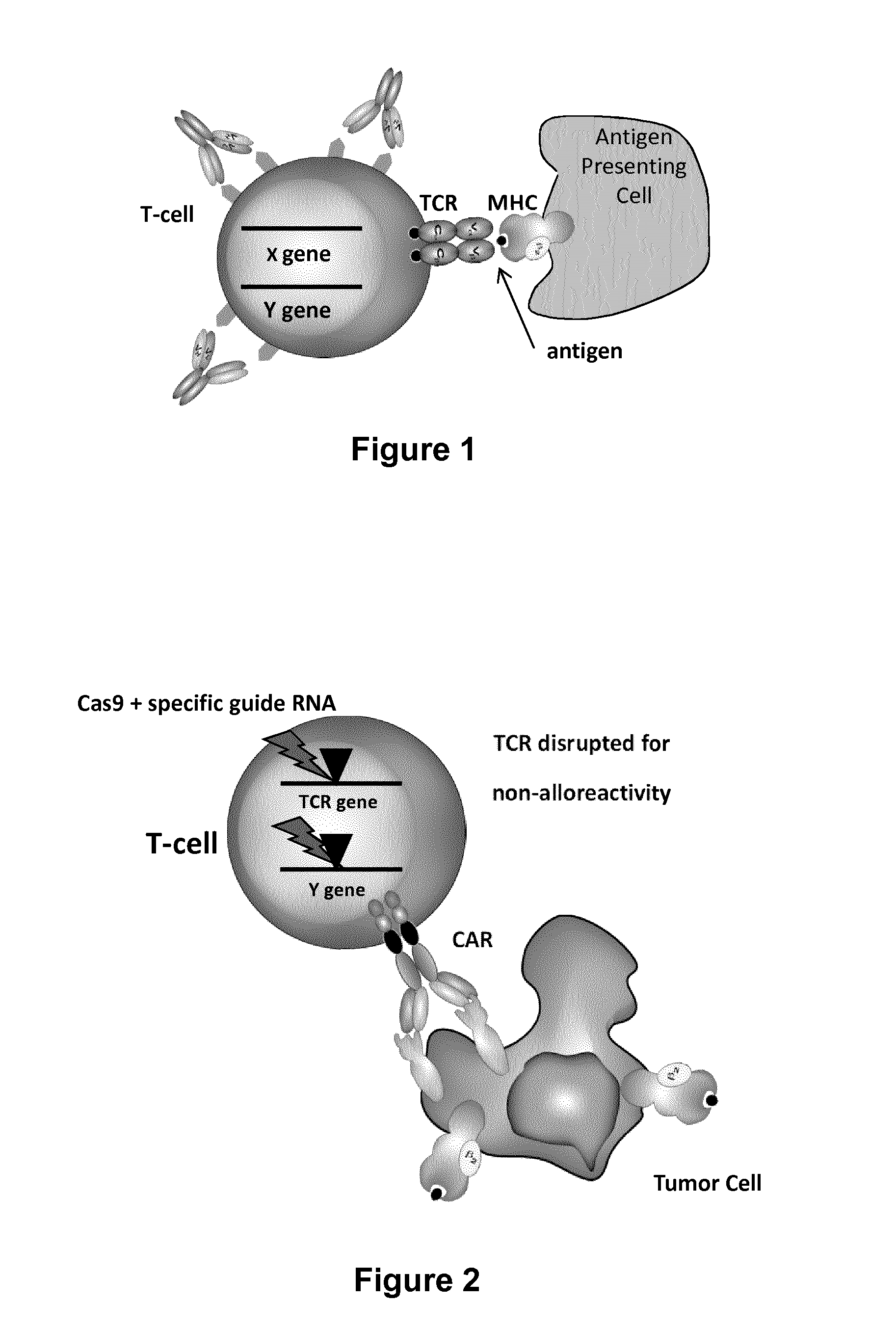

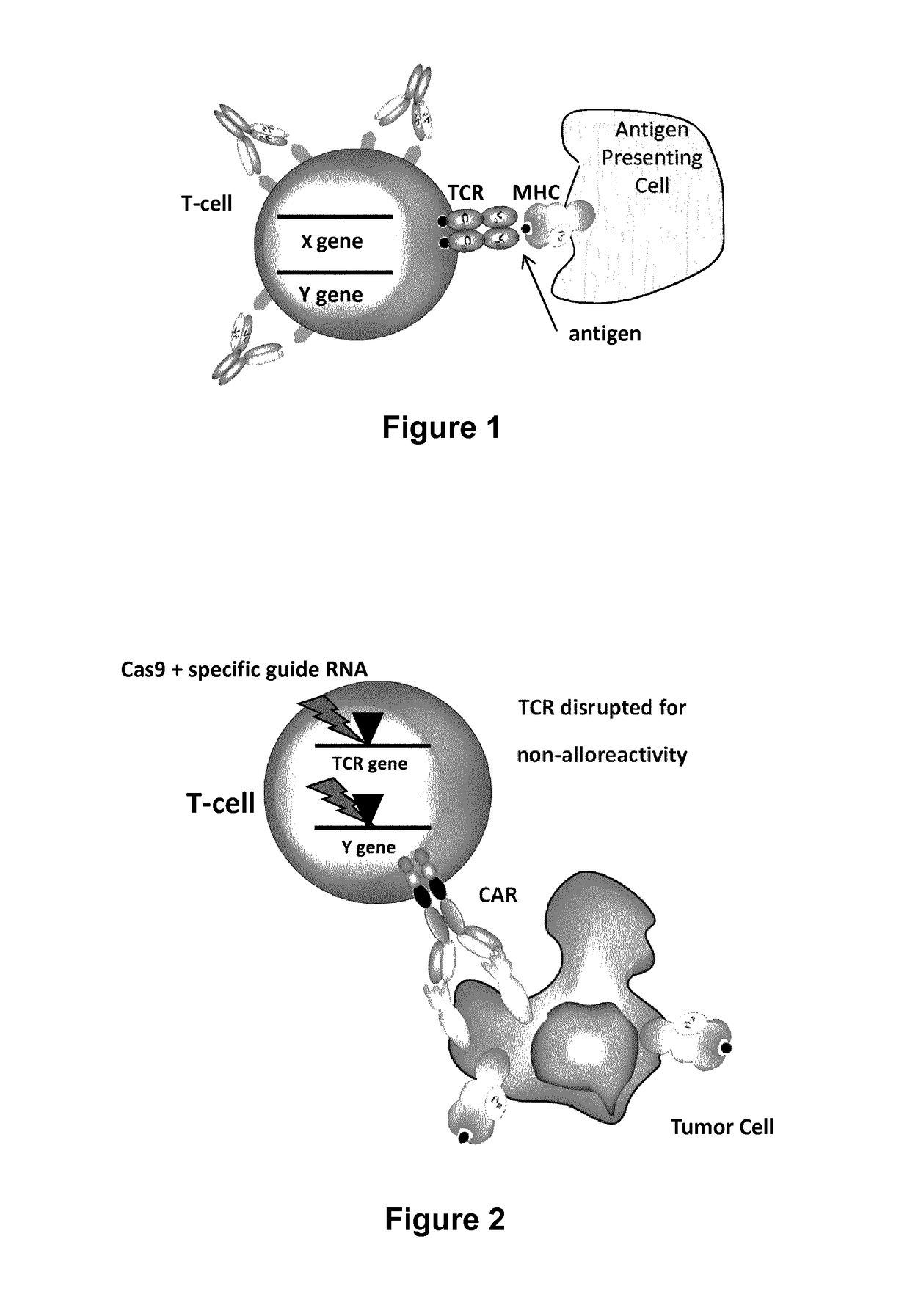

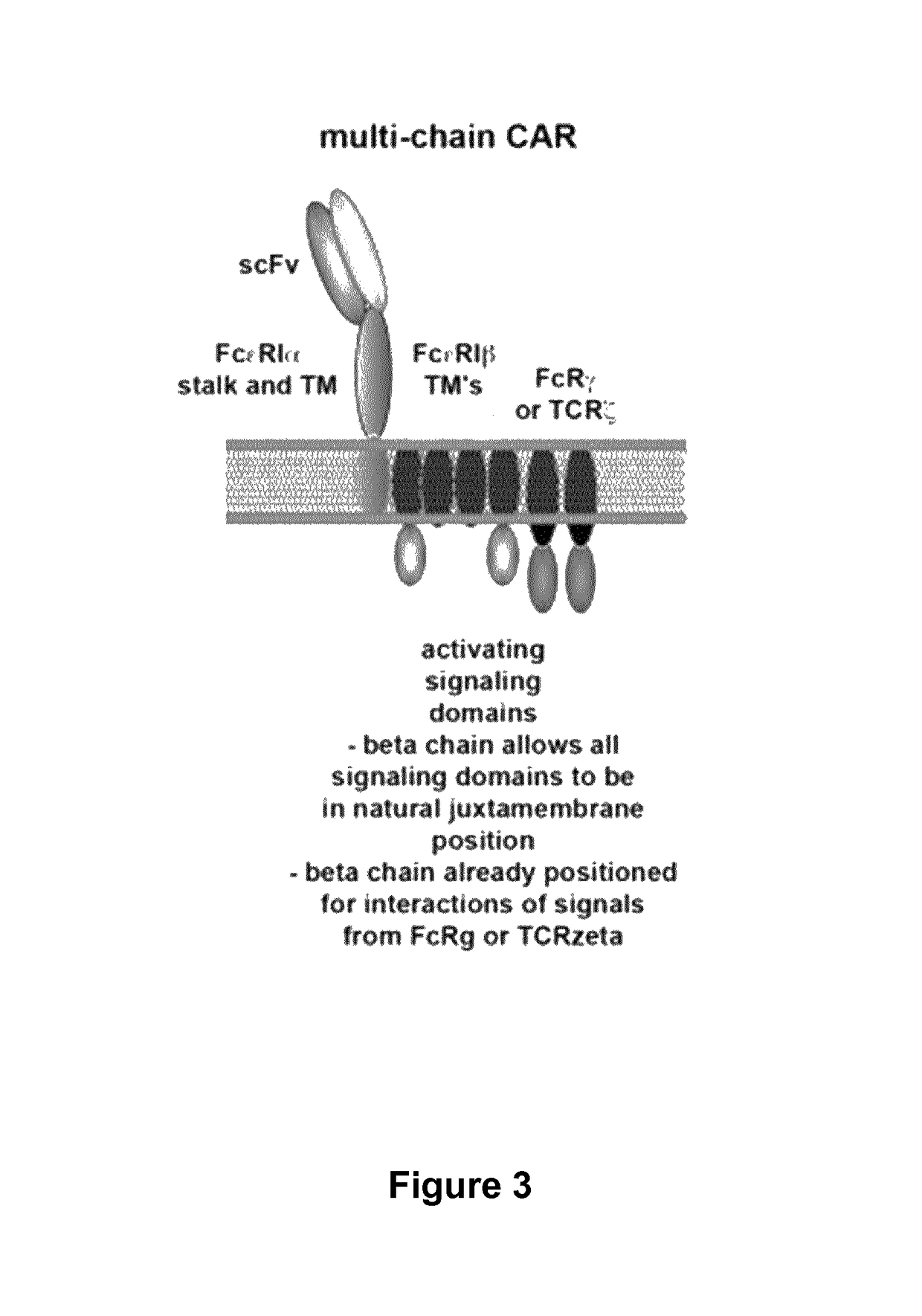

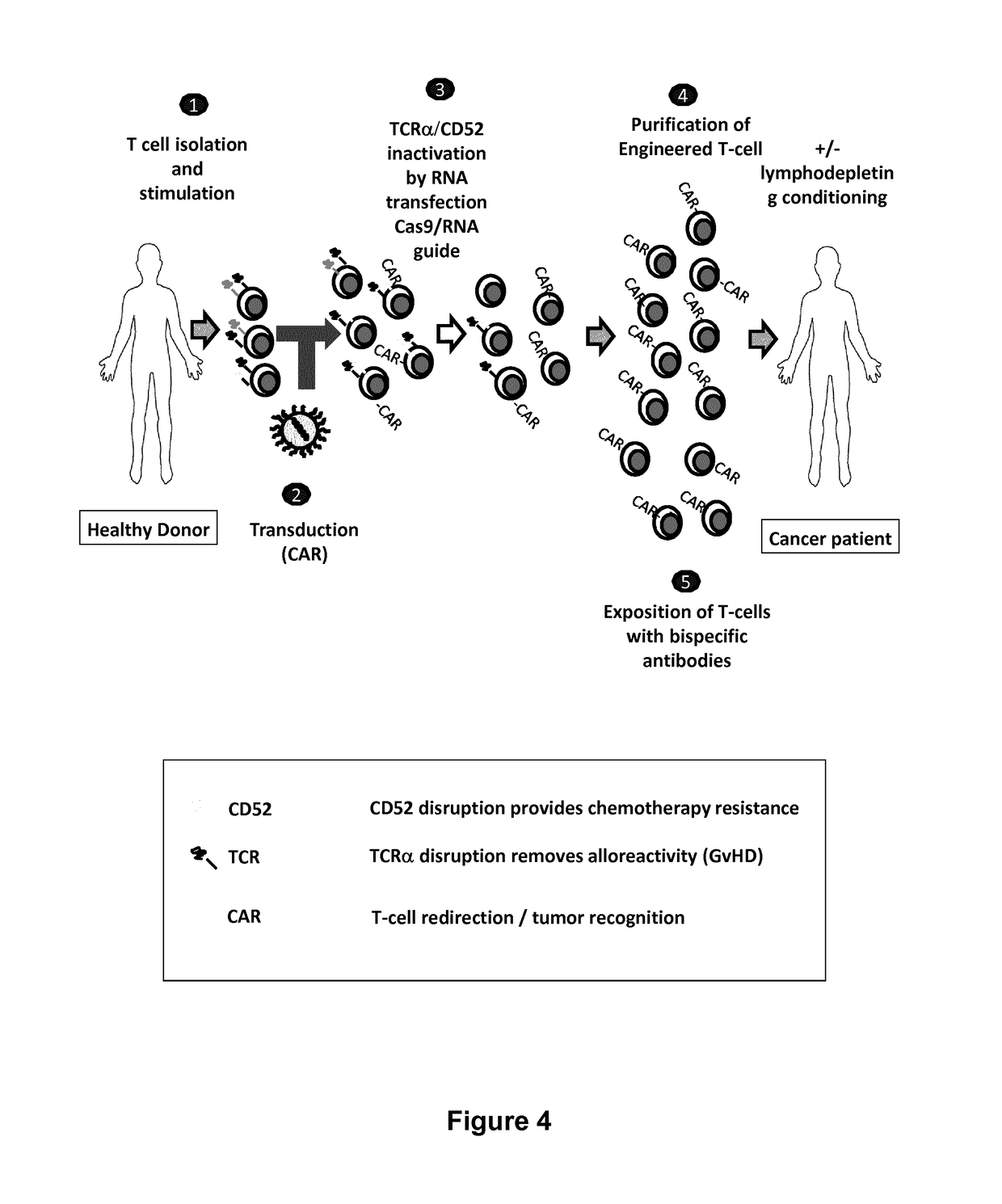

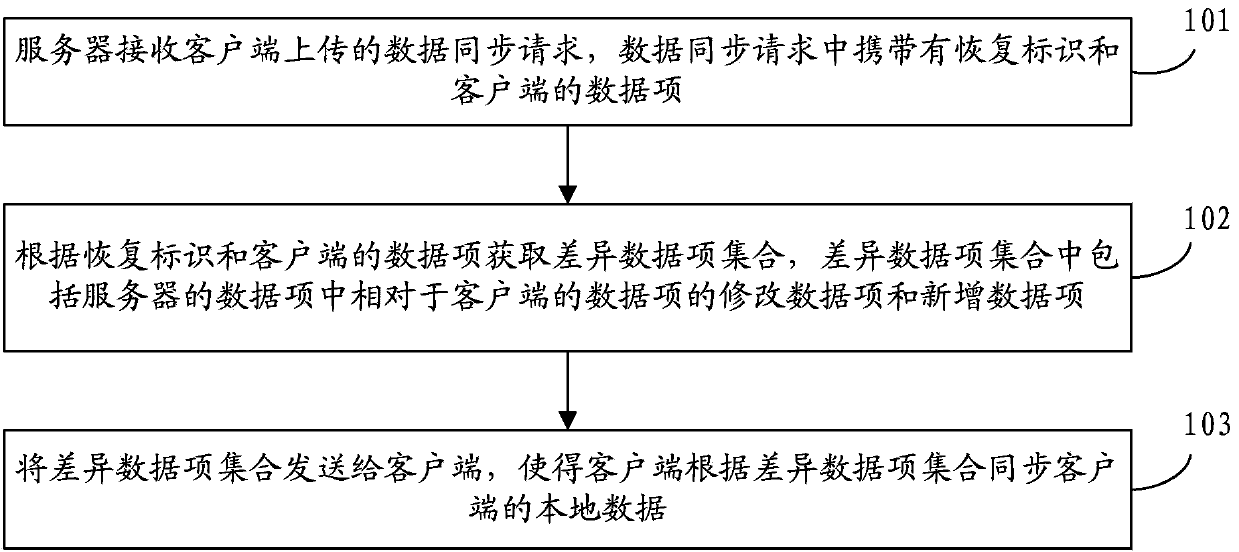

The present invention relates to methods of developing genetically engineered, preferably non-alloreactive T-cells for immunotherapy. This method involves the use of RNA-guided endonucleases, in particular Cas9 / CRISPR system, to specifically target a selection of key genes in T-cells. The engineered T-cells are also intended to express chimeric antigen receptors (CAR) to redirect their immune activity towards malignant or infected cells. The invention opens the way to standard and affordable adoptive immunotherapy strategies using T-Cells for treating cancer and viral infections.

Owner:CELLECTIS SA

Methods for engineering T cells for immunotherapy by using RNA-guided CAS nuclease system

ActiveUS9855297B2Accurate modificationHydrolasesGenetically modified cellsInfected cellAntigen receptors

The present invention relates to methods of developing genetically engineered, preferably non-alloreactive T-cells for immunotherapy. This method involves the use of RNA-guided endonucleases, in particular Cas9 / CRISPR system, to specifically target a selection of key genes in T-cells. The engineered T-cells are also intended to express chimeric antigen receptors (CAR) to redirect their immune activity towards malignant or infected cells. The invention opens the way to standard and affordable adoptive immunotherapy strategies using T-Cells for treating cancer and viral infections.

Owner:CELLECTIS SA

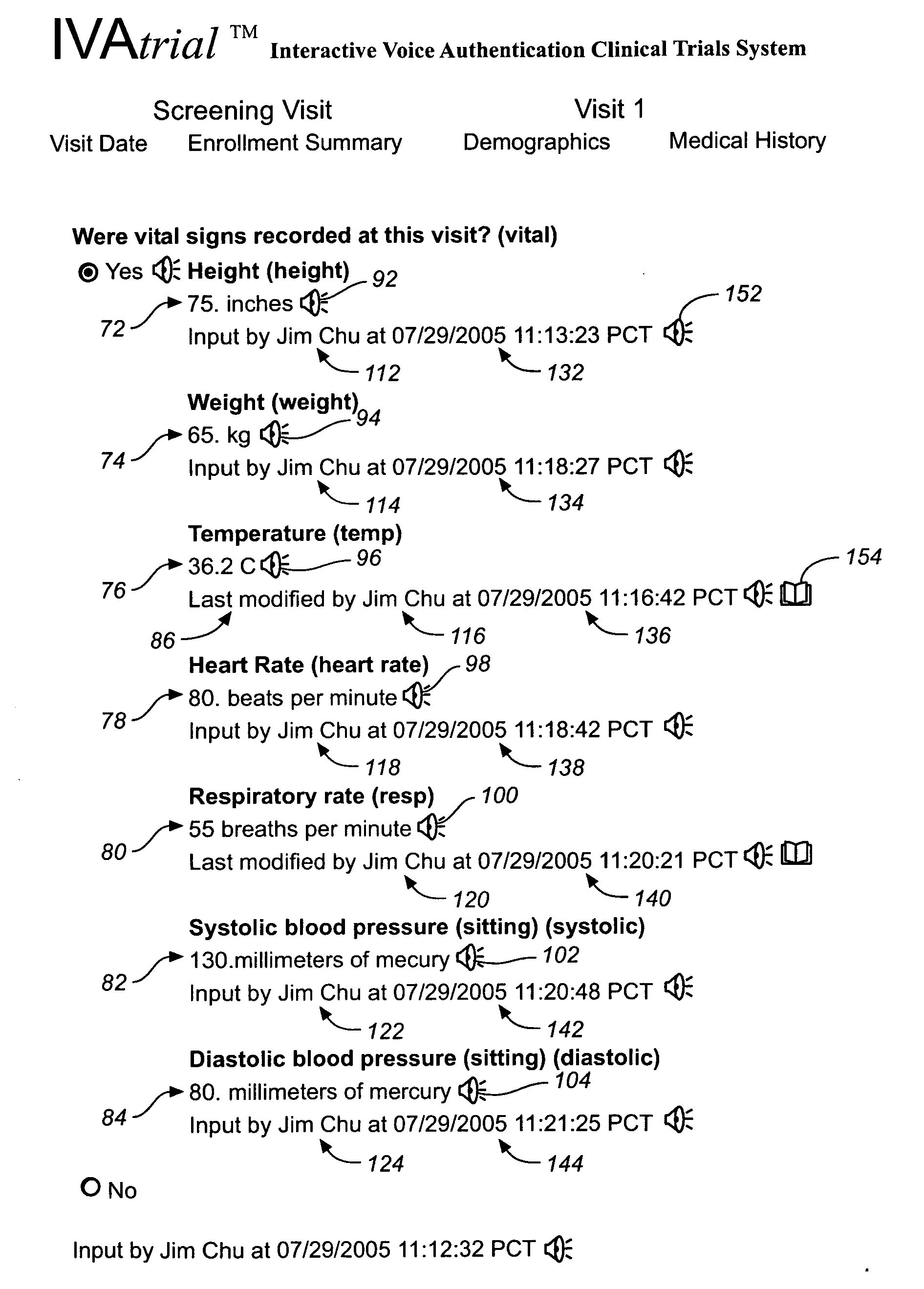

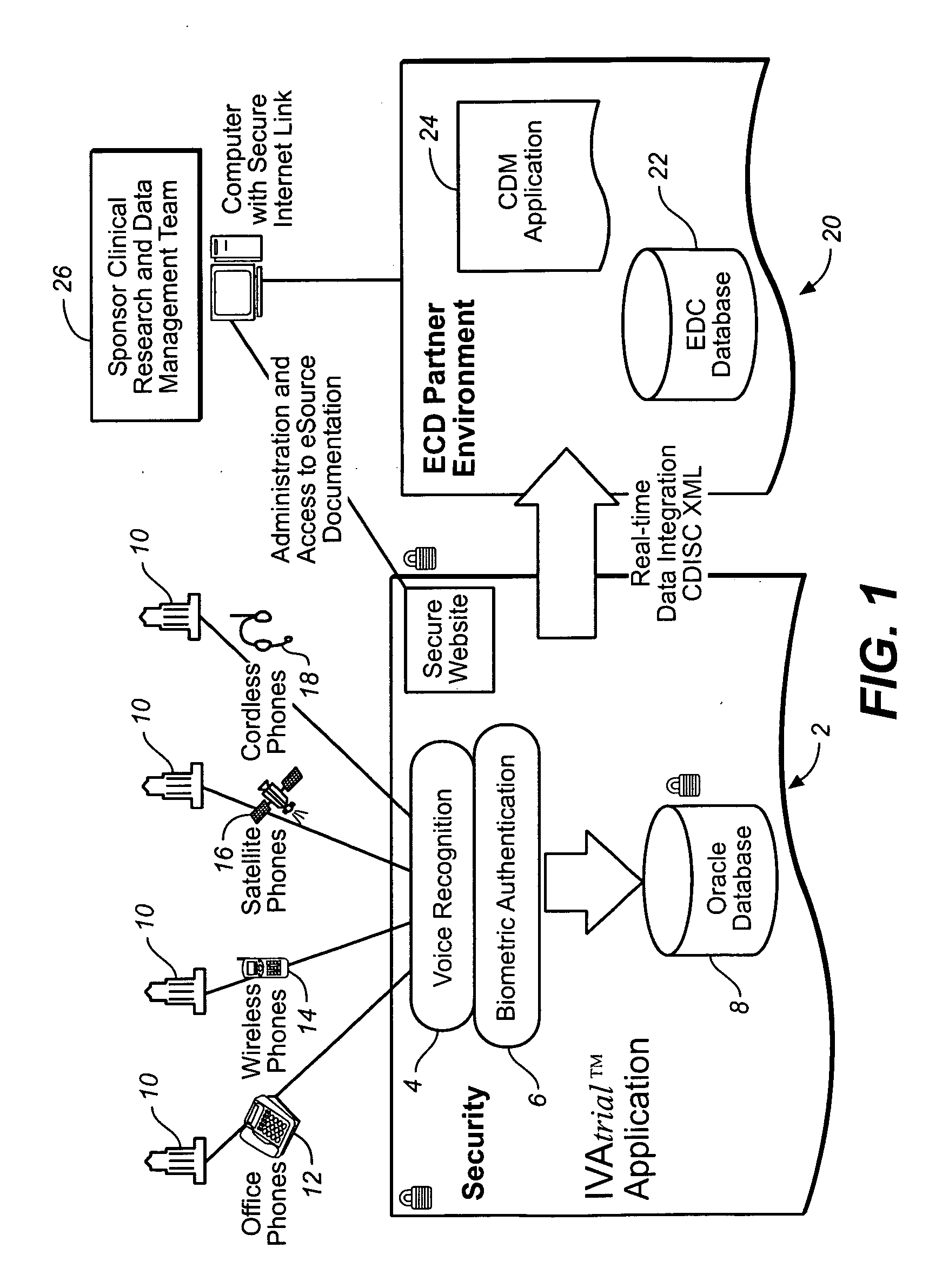

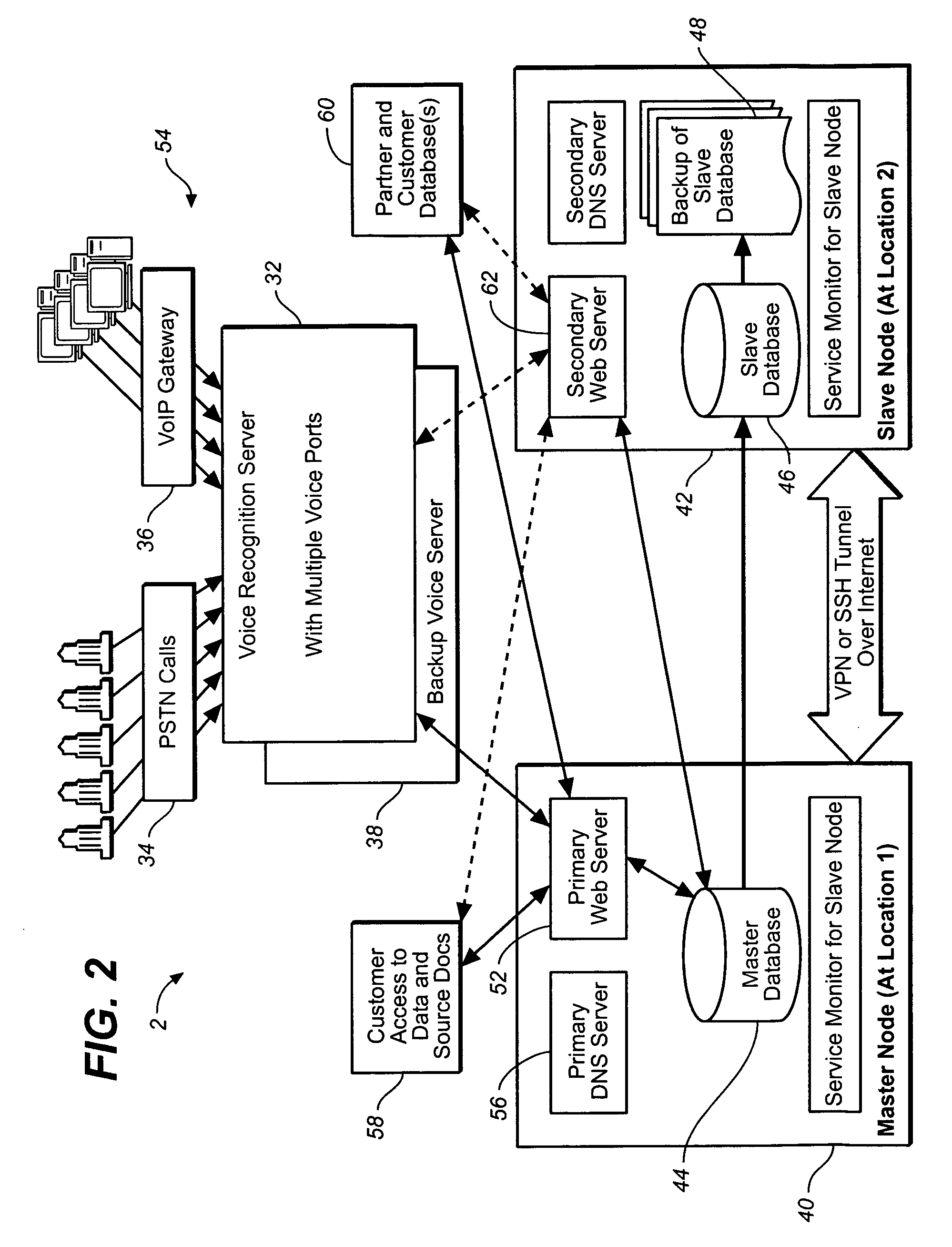

Voice based data capturing system

InactiveUS20070106510A1Improve accuracy reliabilityReliability of recorded dataData processing applicationsSpeech recognitionDigital recordingSpeech input

Methods and apparatuses for collecting data utilizing voice recognition and voice authentication technologies. In one variation, the method comprises recording a plurality of clinical data entries through voice inputs and verifying the identity of the user through voice authentication. The method can further include associating each of the recorded clinical data entries with the digital recording of a corresponding voice input. In another aspect, an apparatus is provided with voice authentication and voice recognition capabilities to record clinical data and verify user identity. In one variation, the apparatus is configured to assign an identity stamp and a time stamp to each of the clinical data entry stored in the database.

Owner:IVRAS

Methods for engineering T cells for immunotherapy by using RNA-guided CAS nuclease system

ActiveUS9890393B2Accurate modificationHydrolasesGenetically modified cellsInfected cellAntigen receptors

The present invention relates to methods of developing genetically engineered, preferably non-alloreactive T-cells for immunotherapy. This method involves the use of RNA-guided endonucleases, in particular Cas9 / CRISPR system, to specifically target a selection of key genes in T-cells. The engineered T-cells are also intended to express chimeric antigen receptors (CAR) to redirect their immune activity towards malignant or infected cells. The invention opens the way to standard and affordable adoptive immunotherapy strategies using T-Cells for treating cancer and viral infections.

Owner:CELLECTIS SA

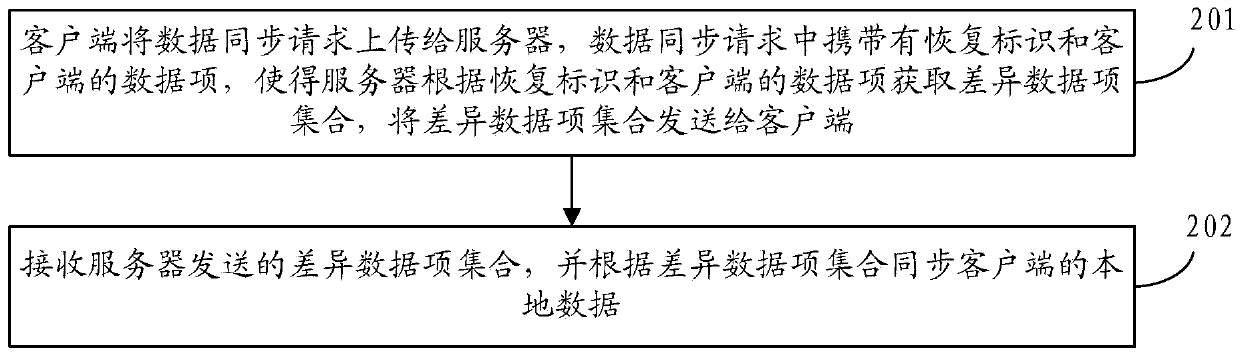

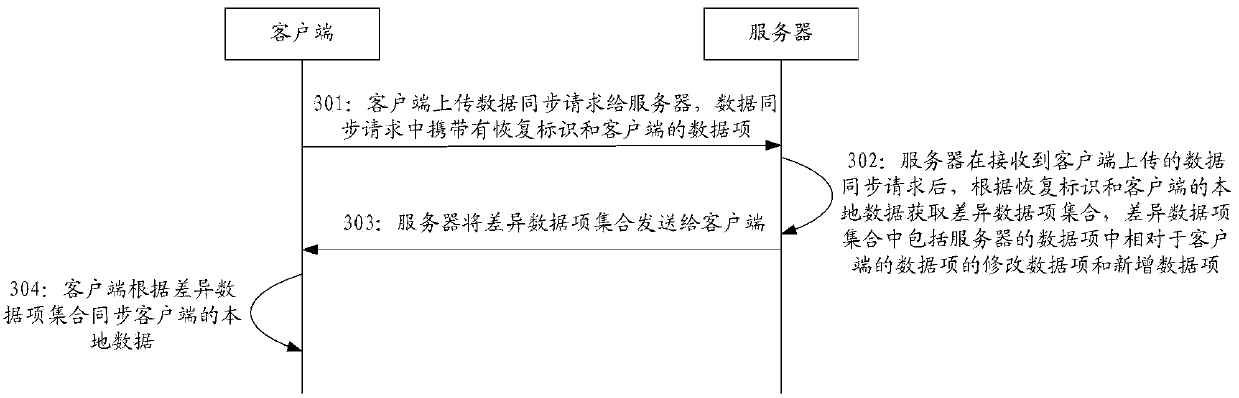

Data synchronization method, device and system

ActiveCN103428264AAccurate modificationHow to extend synchronizationTransmissionData synchronizationThe Internet

The invention discloses a data synchronization method, device and system and belongs to the field of internet. The method comprises that a server receives data synchronization requirements uploaded by a client, obtains a discrepant data item set according to restoring identifiers and data items of the client and sends the discrepant data item set to the client, so that the client can synchronize local data of the client according to the discrepant data item set. According to the data synchronization method, device and system, the server obtains the discrepant data item set including modified data items and newly added data items relative to data items of the client in data items of the server according to the restoring identifiers and the data items of the clients, and data of the server are not modified, so that the client synchronizes the local data of the client according to the discrepant data item set sent by the server, the data synchronization mode is expanded, data of the server are not modified during data synchronization, the local data of the client can be restored through the data of the server, and mistaken modification of the data of the server is prevented.

Owner:HUAWEI TECH CO LTD

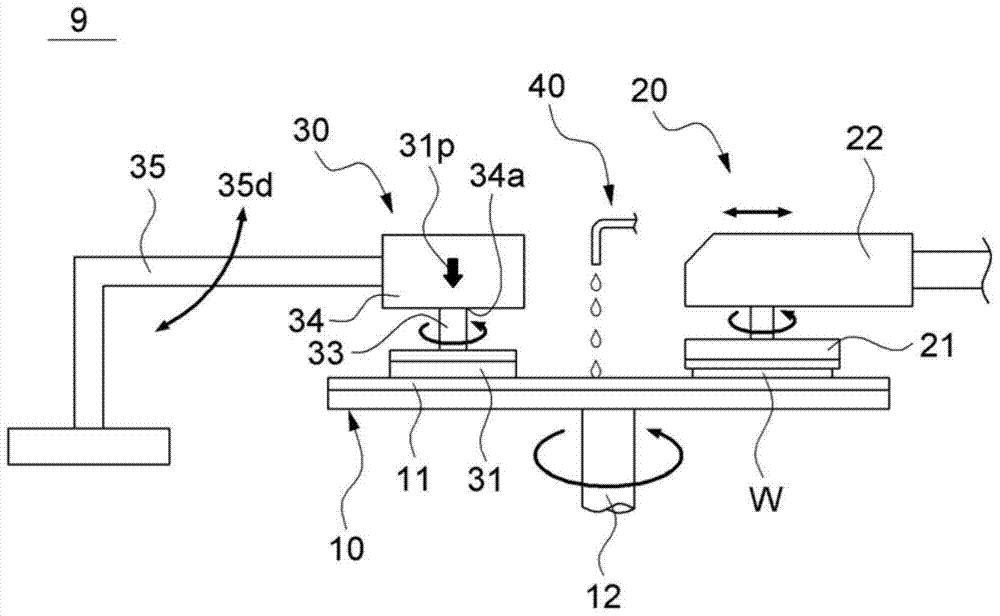

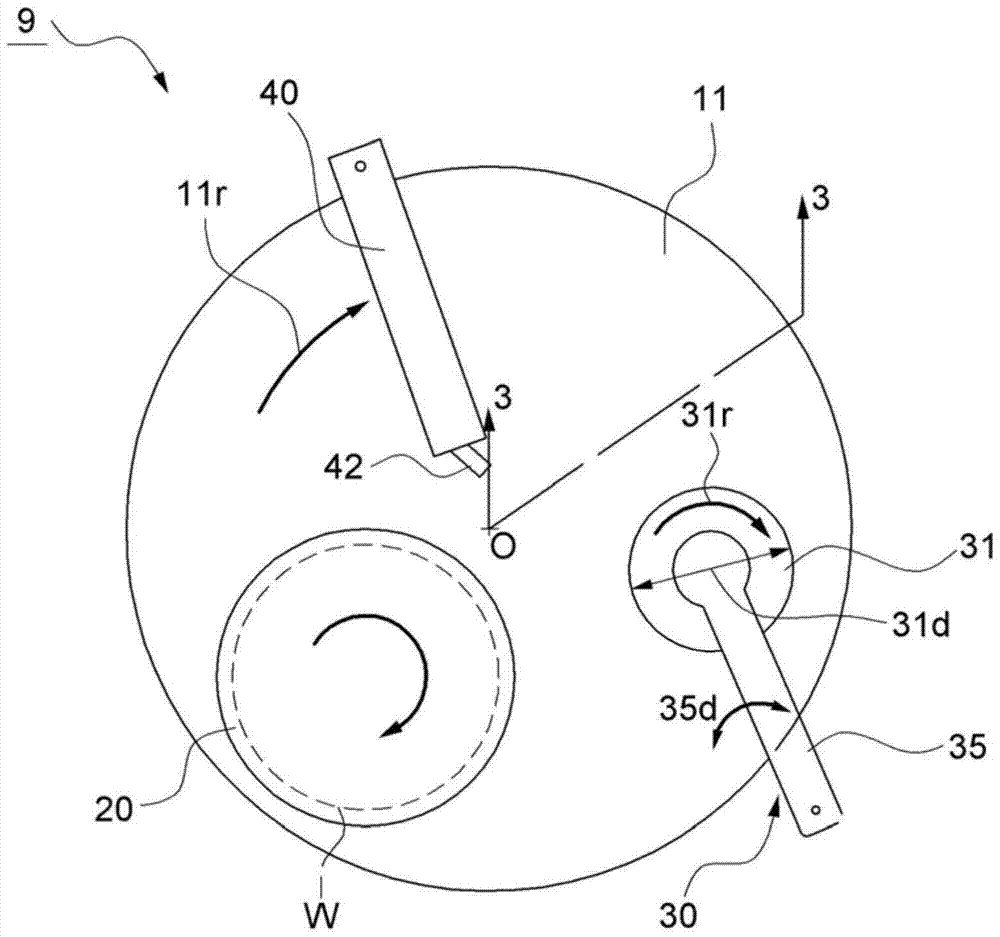

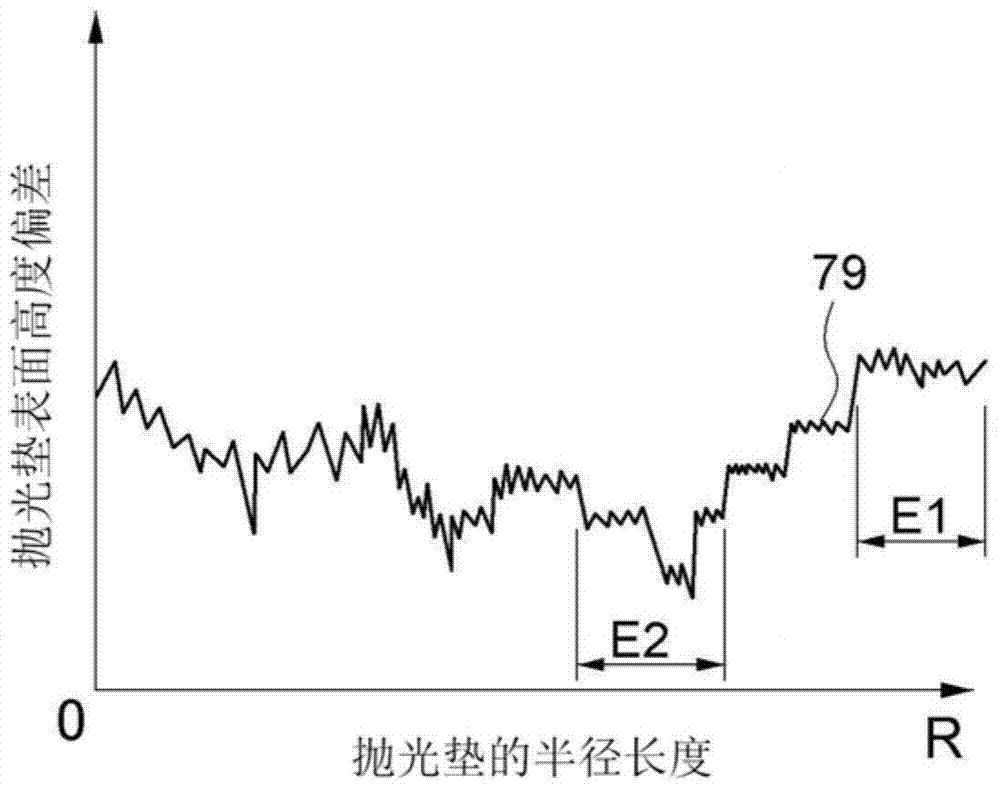

Chemical mechanical polishing apparatus and method thereof

The invention relates to a chemical mechanical polishing apparatus and a method thereof. The apparatus comprises a polishing head for pressing and rotating a wafer in a state where the wafer is on a lower side; a height measuring portion for obtaining a height deviation in the radial direction of a polishing pad during the chemical mechanical polishing; a regulating device having an arm portion and an adjusting disc, the arm being rotated about a hinge axis to rotate at a predetermined angle, and the adjusting disc pressing the polishing pad against the lower side of the arm portion and rotating; and a control portion for adjusting the rotational speed of the arm portion with a second rotation speed at a second position, the height of the polishing pad at the second position being higher than the height at the first position, and the second rotational speed being smaller than the first rotational speed, such that, by adjusting the rotational speed of the adjusting disc, it is possible to alleviate the height deviation of the polishing pad at different positions. Therefore, even if the same pressure is applied to the wafer, the friction amount is different depending on the height deviation of the polishing pad, so that the polishing amount per hour of the wafer can be adjusted in each region.

Owner:K C TECH

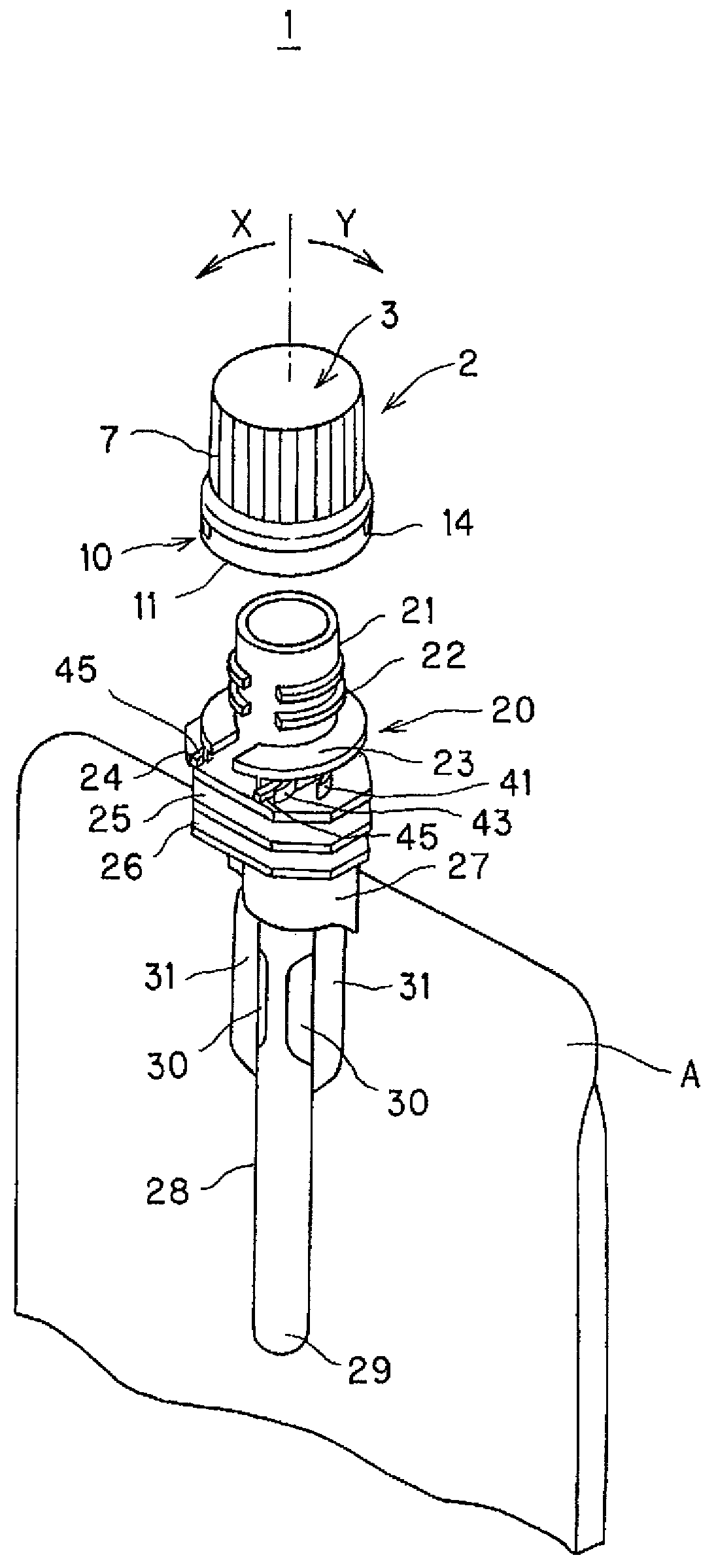

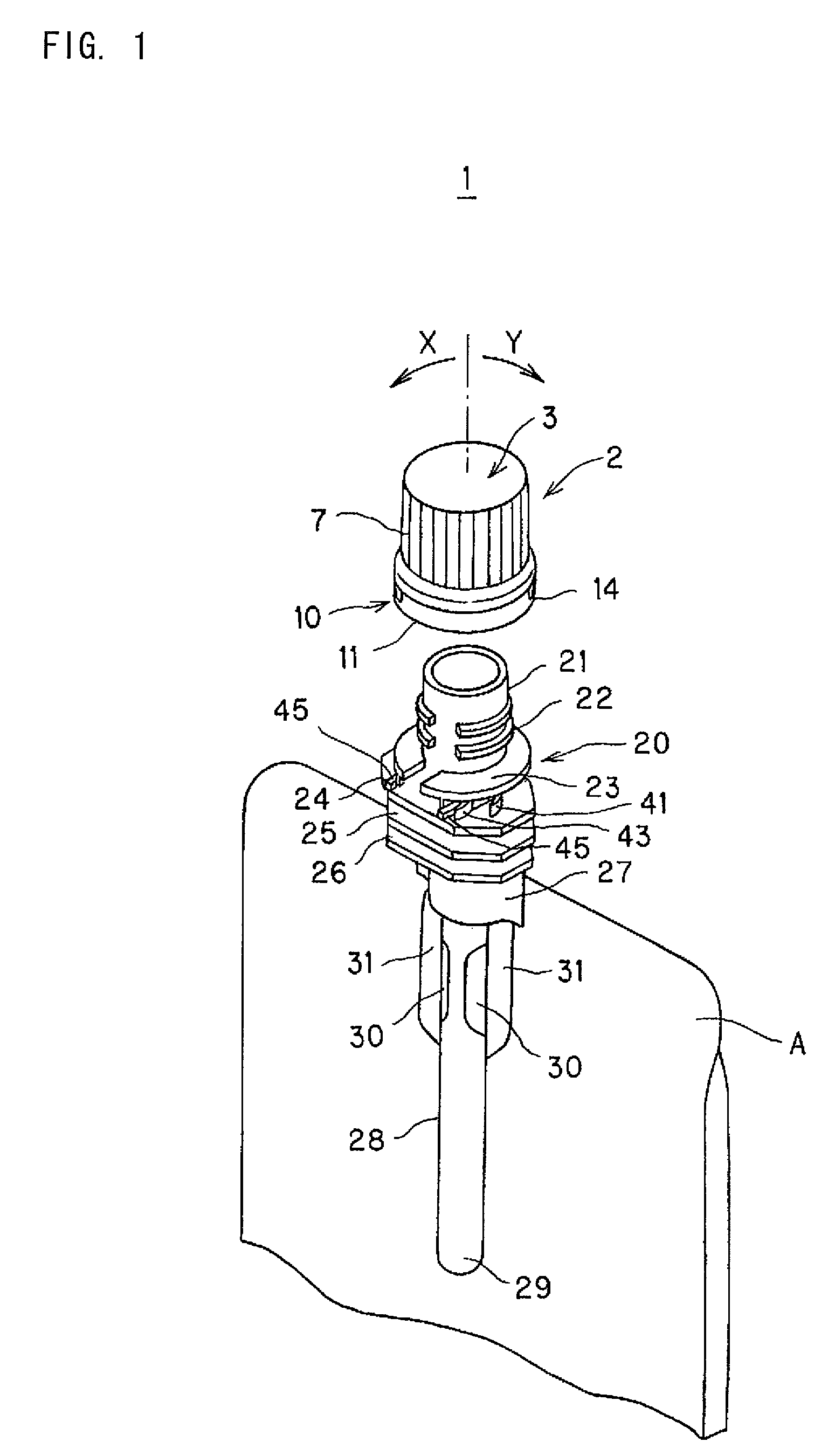

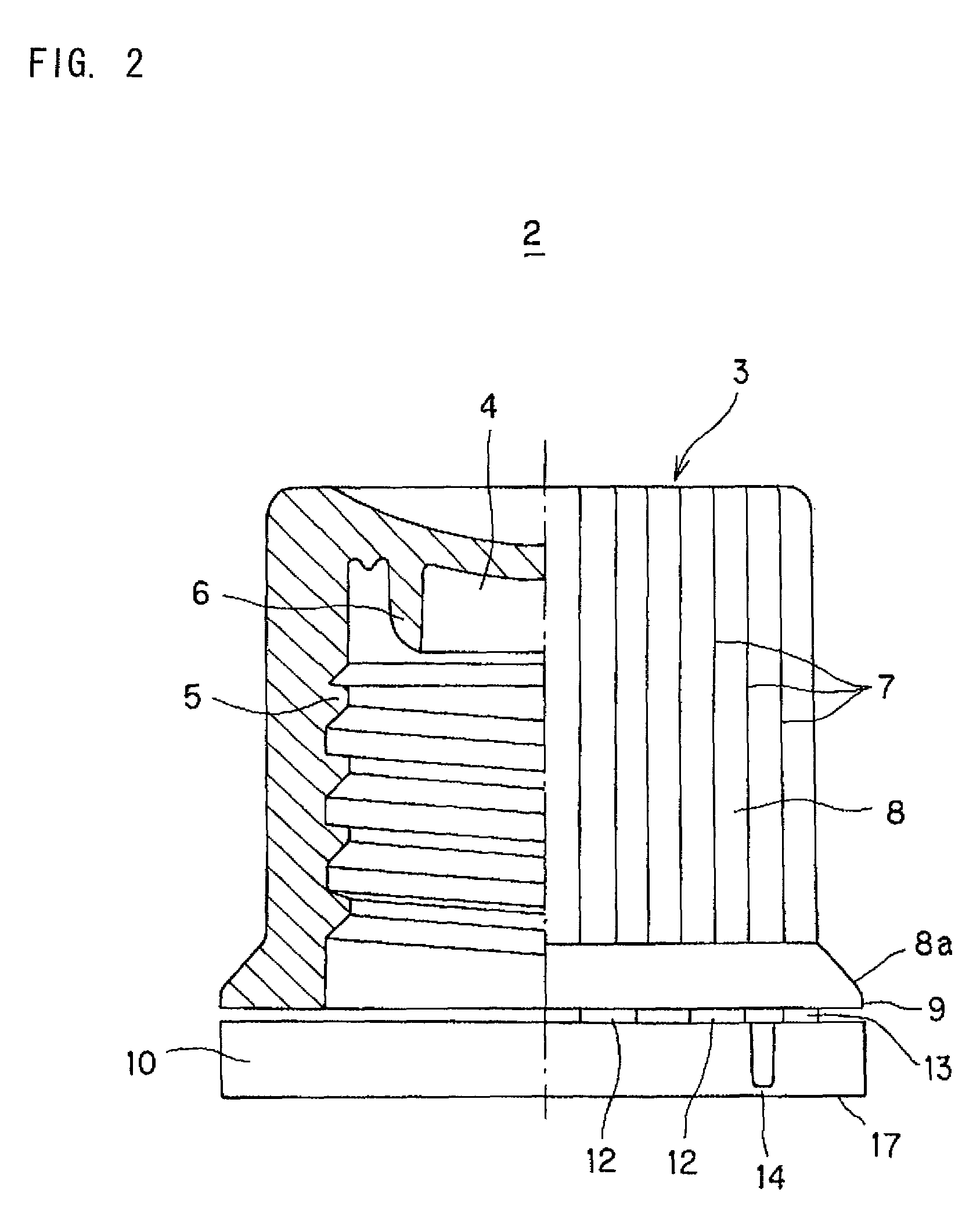

Spout unit and bag using the same

ActiveUS7753233B2Easy to judgeReduce resistanceCapsClosure using stoppersTamper resistanceEngineering

A spout unit having a tamper-evident function so that it is easy to determine visually that a sealed cap is opened when the cap is unsealed, wherein strong force is not needed to open while modification of moderate curve in convex from an easy-to-break portion of a tamper-proof ring is corrected when the spout is sealed with the cap, is provided. A spout unit comprising a spout20 having a cylindrical opening 21 and a cap 2 which seals the opening of the spout, wherein the cap 2 has a tamper-proof ring 10 connected to a lower end portion of the cap 2 via an easy-to-break linking piece; wherein the tamper-proof ring has an easy-to-break portion 14, which breaks by tension applied in the circumferential direction of the ring, and a claw part engageable with a ratchet provided at the spout side; and wherein a tamper-proof ring support 45 is provided at least at two points around the opening of the spout, in which the tamper-proof ring support is in partial contact with undersurface of the tamper-proof ring upon screwing the cap and has a height to maintain a position of the tamper-proof ring in horizontal direction at a constant level.

Owner:HOSOKAWA YOKO CO LTD

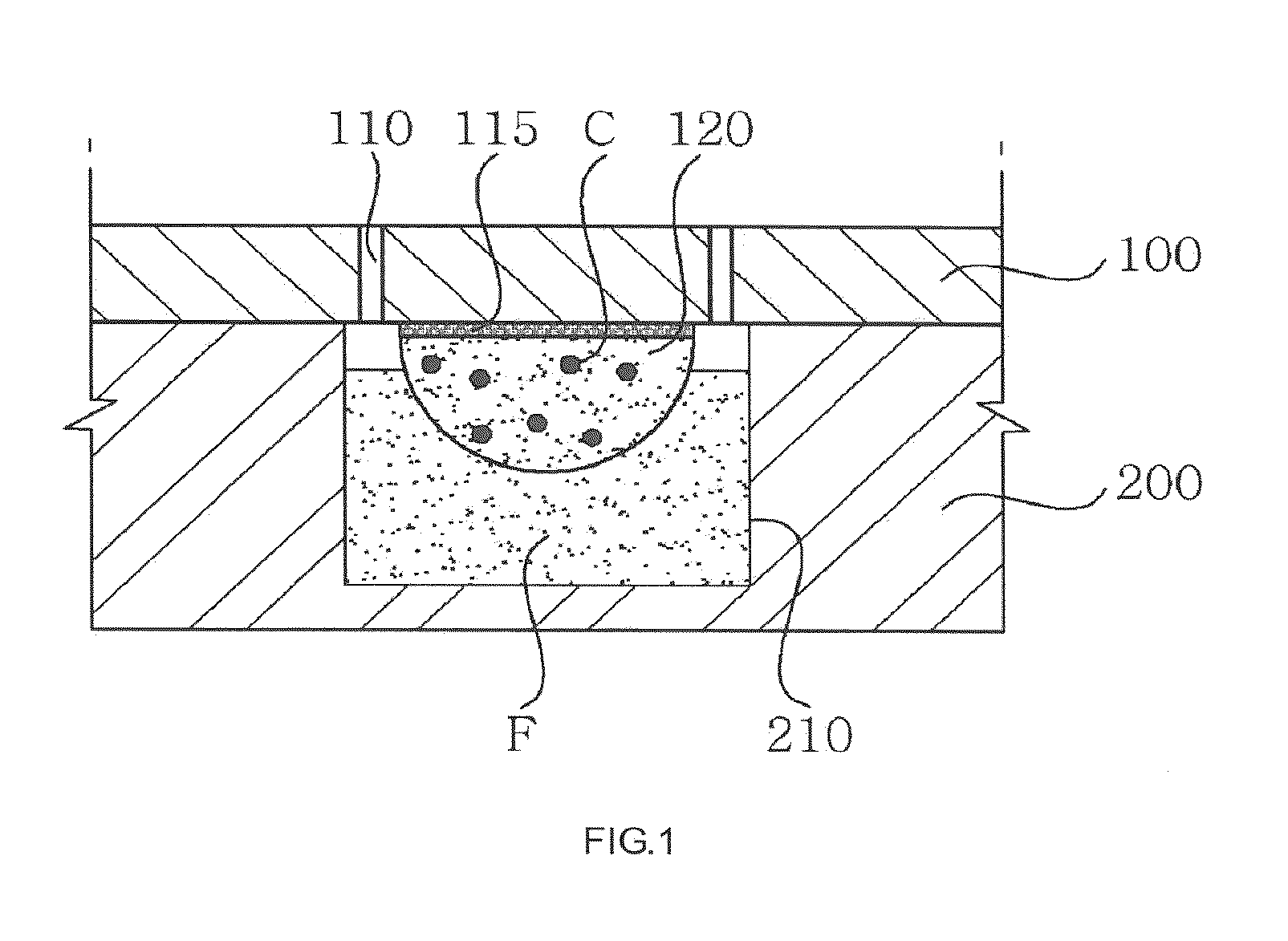

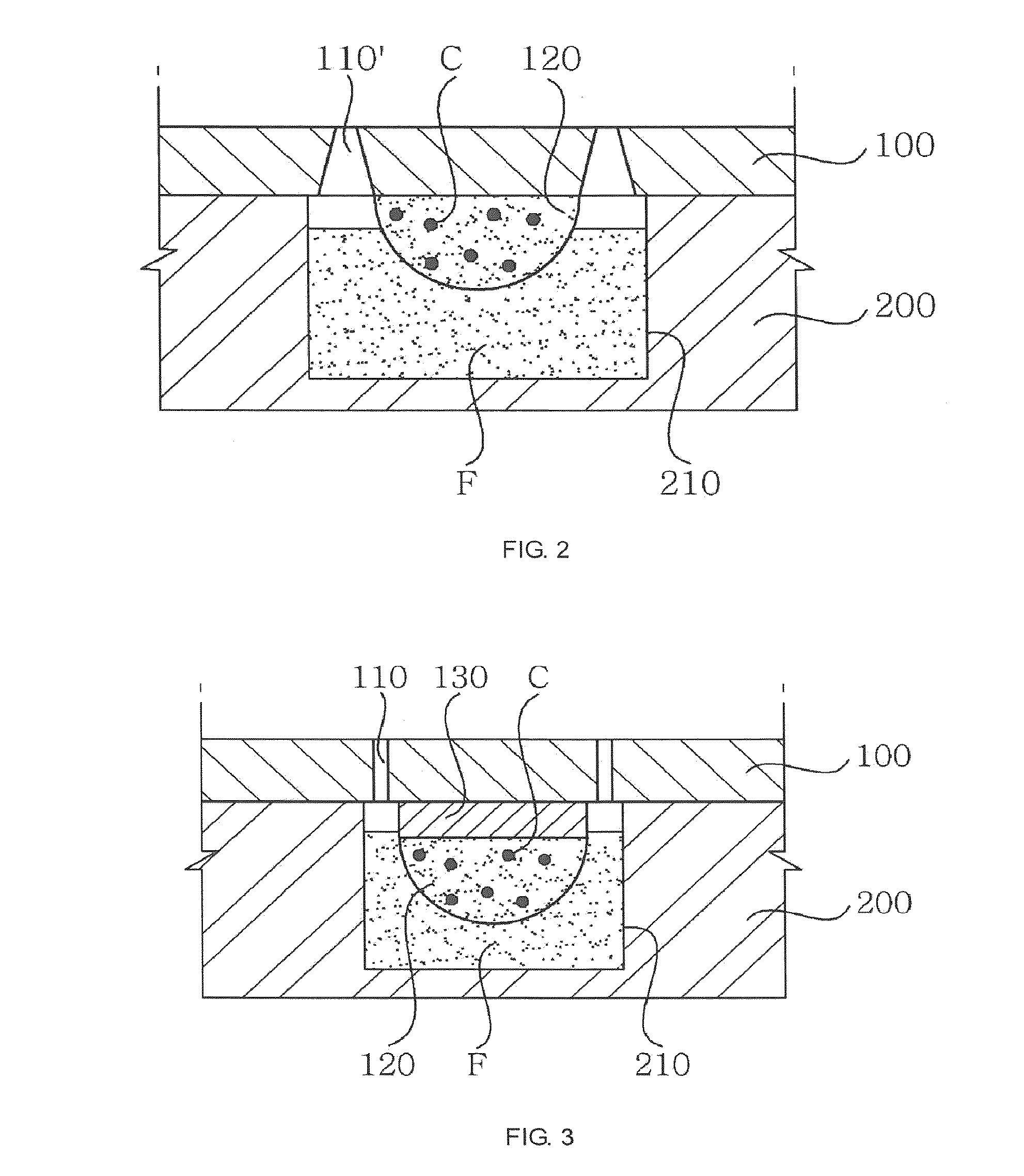

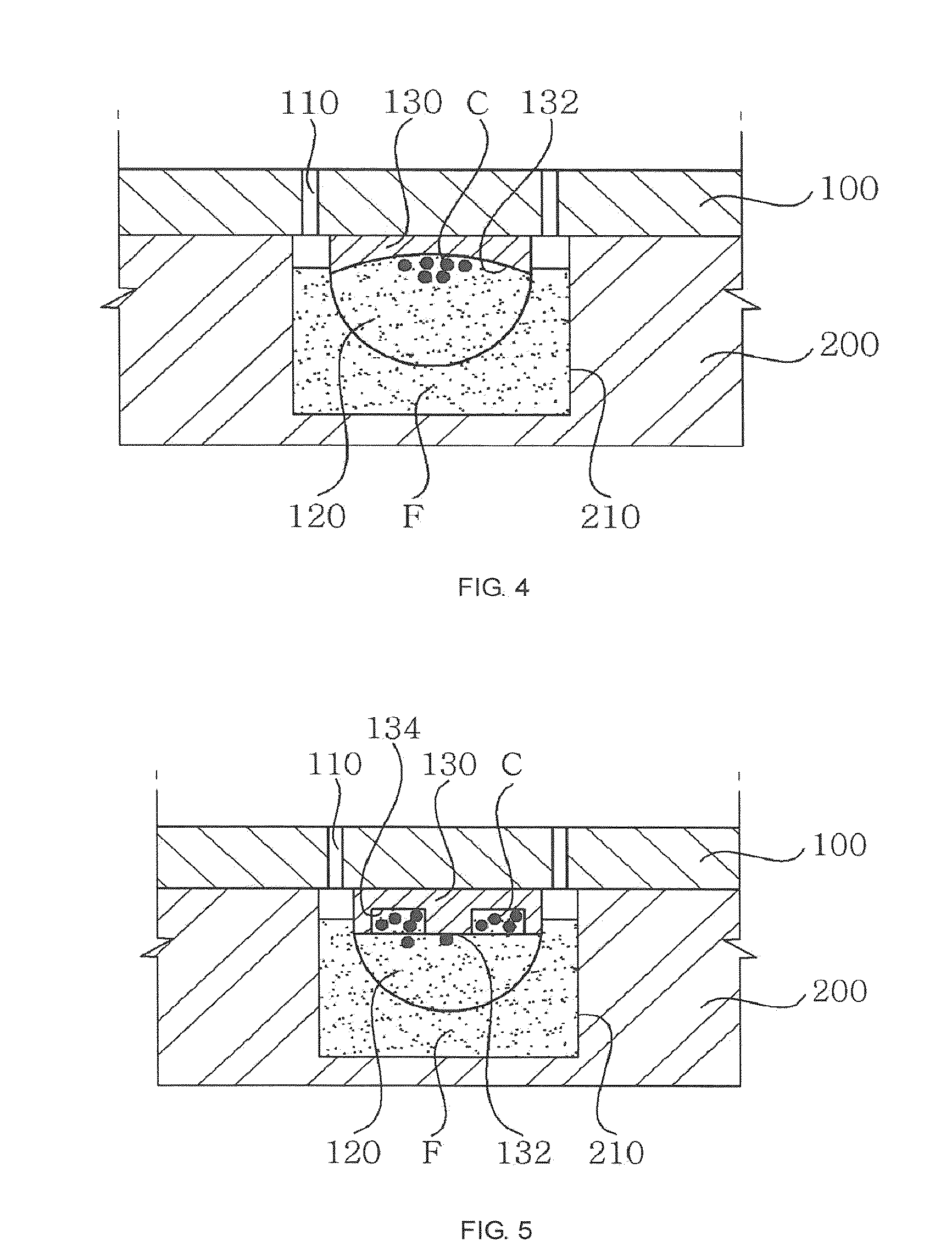

Microarray cell chip

InactiveUS20120088693A1Avoid cross contaminationEasy to implementMicrobiological testing/measurementLibrary screeningDiffusionBiological materials

Disclosed herein is a microarray cell chip. The microarray cell chip includes an upper substrate that has biomatrices encapsulating biomaterials formed on one surface thereof and through holes penetrating from one surface to the other surface thereof and a lower substrate that is coupled with the upper substrate and is provided with wells storing reagents supplied to the biomatrices. The microarray cell chip according to the present invention can smoothly transfer the culture media and the reagents to the biomaterials embedded in the biomatrices through the diffusion and simply separate the upper substrate from the lower substrate, thereby improving the easiness of washing. Therefore, the present invention provides an environment similar to the bio environment, thereby making it possible to increase accuracy of an experiment.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

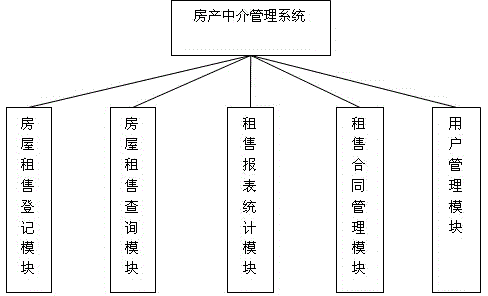

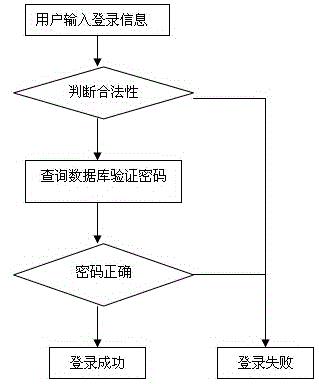

Real estate agent management system

InactiveCN104318387AHigh speedImprove accuracyBuying/selling/leasing transactionsResourcesInformation processingJava

The invention relates to a real estate agent management system and relates to a computer management system. According to the system, a house renting and selling registering module, a house renting and selling inquiry module, a house renting and selling report form statistic module, a house renting and selling contract management module and a user management module are set under the Browser / Server mode, a common sense information table, an agent information table, a user information table, a company information table, a house renting and selling contract table and a real estate agent contract table are built, the JDBC bridge data driving program is adopted, and the Java language is adopted connect a database. The system enables management work to be standardized, systematized and sequenced, avoids randomness, and improves information processing speed and accuracy. Property source basic information can be inquired and modified timely, accurately and effectively, and proper property sources can be found accurately and quickly. A manager can know the house renting and selling conditions in the current month quickly.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

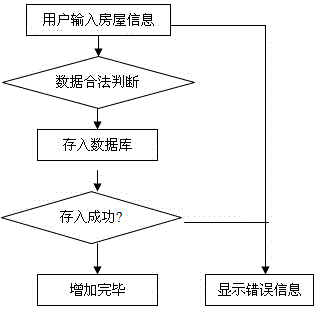

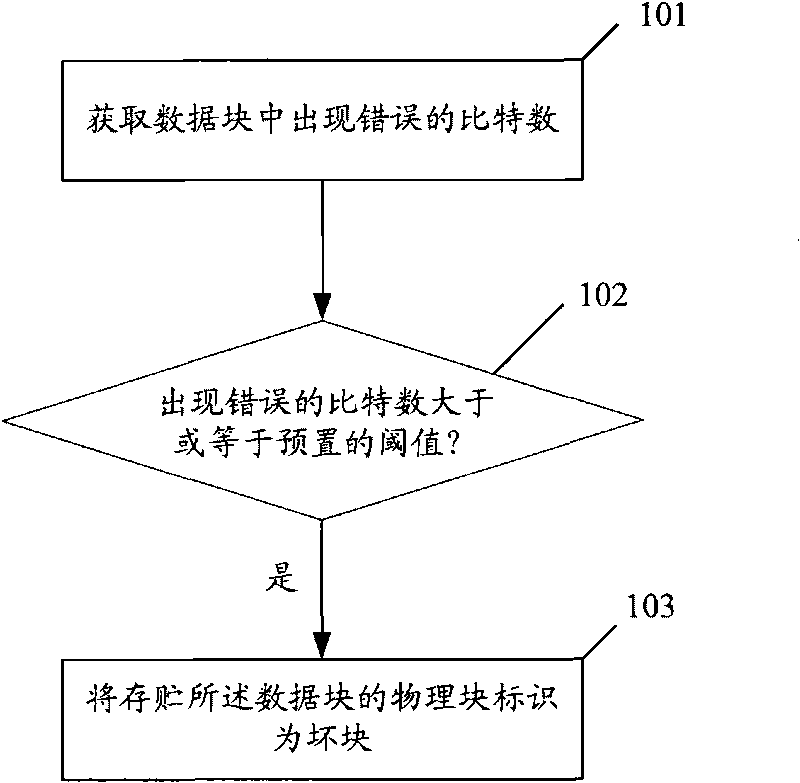

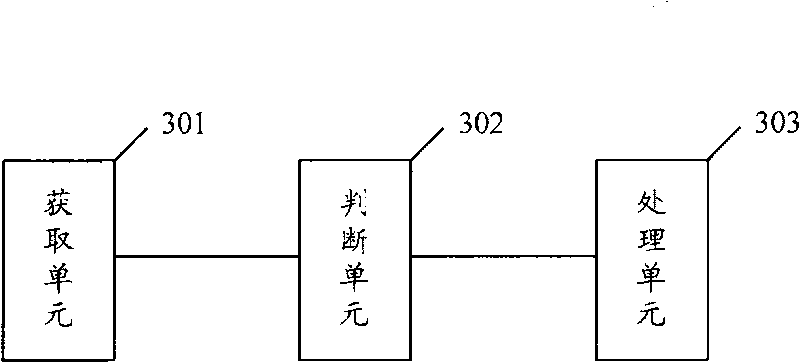

Method for processing data errors, and device and system for checking and correcting data errors

InactiveCN101739306AAvoid lossAccurate modificationRedundant data error correctionError checkingPosition Number

The embodiment of the invention discloses a method for processing data errors, and a device and a system for checking and correcting the data errors. The method for processing the data errors comprises the following steps of: acquiring a bit number with errors in a data block; judging whether the bit number with errors is greater than or equal to the preset threshold value which is smaller than a maximum bit position number corrected by the device for checking and correcting the data errors; and identifying a physical block which stores the data block as a bad block if the bit number with errors is grater than or equal to the preset threshold value. Because the physical block which stores the data block is identified as the bad block if the bit number with errors is judged to be greater than or equal to the preset threshold value which is smaller than the maximum bit position number corrected by the device for checking and correcting the data errors, the method for processing the data errors, and the device and the system for checking and correcting the data errors of the embodiment of the invention can effectively avoid the appearance of the errors which cannot be corrected so as to avoid the loss of the user data and prevent modifying the user data by mistake.

Owner:HUAWEI DIGITAL TECH (CHENGDU) CO LTD

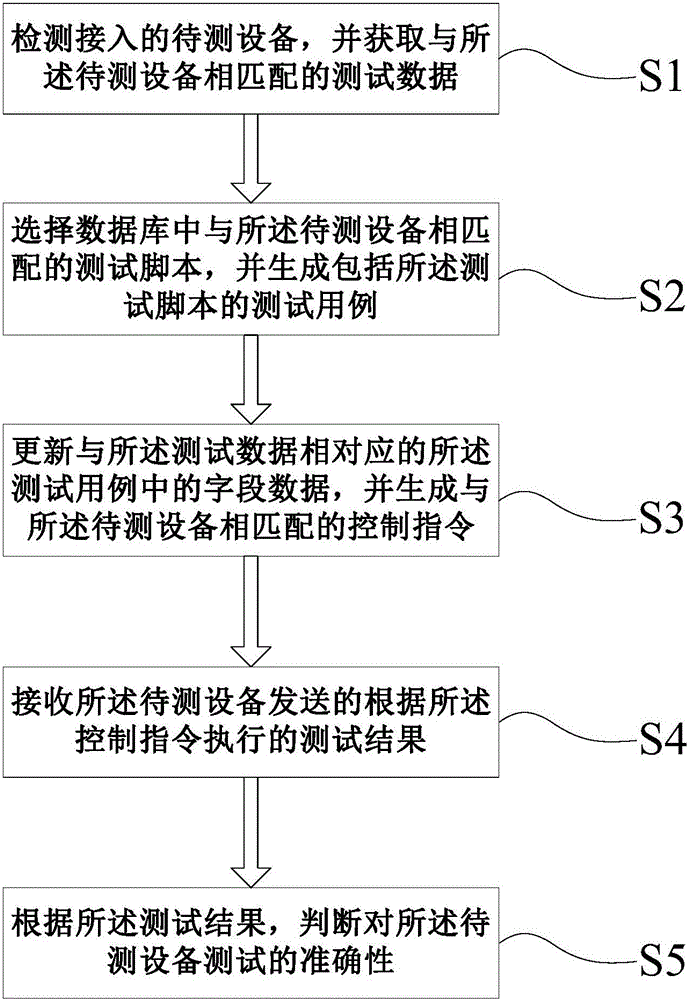

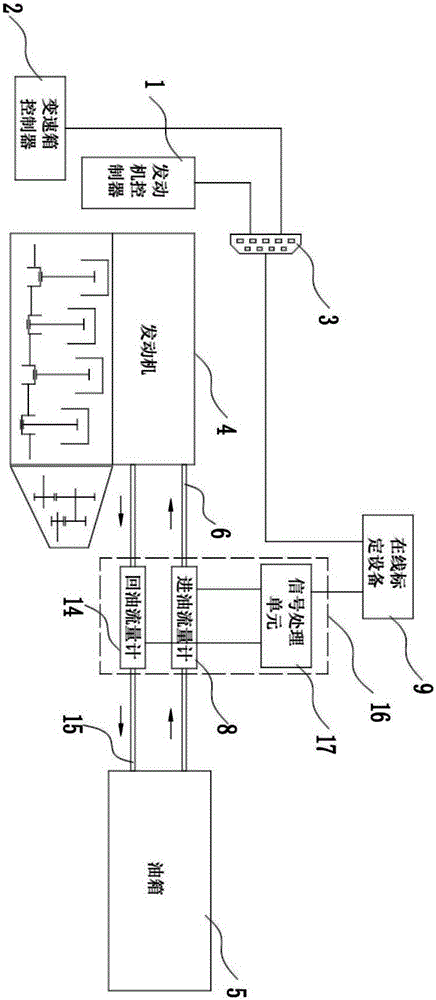

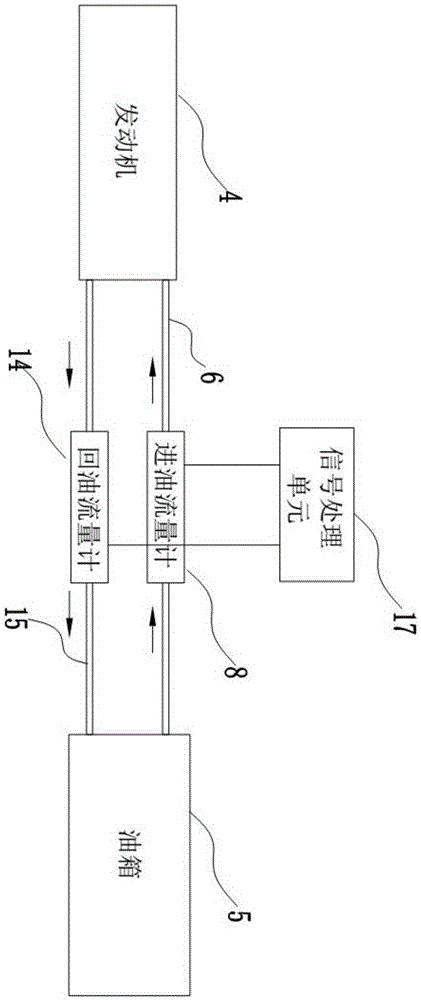

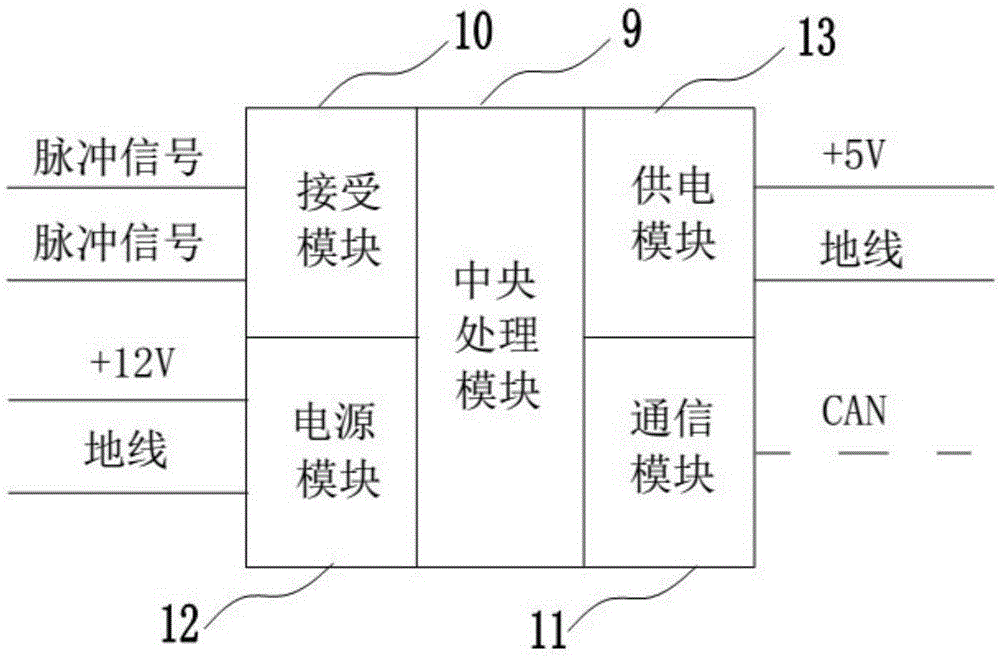

Full-automatic script test method based on intelligent substation

InactiveCN105760299ADynamically change test dataDynamically change functionSoftware testing/debuggingTest designTest efficiency

The invention provides a full-automatic script test method based on an intelligent substation.The method includes the following steps that in-access devices to be tested are detected, and test data matched with the devices to be tested is acquired; test scripts, matched with the devices to be tested, in a database are selected, and test cases are generated; field data in the test cases corresponding to the test data is updated, and control instructions are generated; test results which are sent by the devices to be tested and generated after execution according to the control instructions are received; the accuracy of testing the devices to be tested is judged according to the test results.The test data and functions can be dynamically changed through the automatic test scripts, the test results can be compared, it is not needed to reedit the whole test design, and the test scripts used last time can be accurately modified in time and updated into a state conforming to a test of this time when a tested system is changed.Thus, testing efficiency can be improved, and the problems that the test development cycle is long, the method is complex, and the requirement for the programming ability of personnel is high are solved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

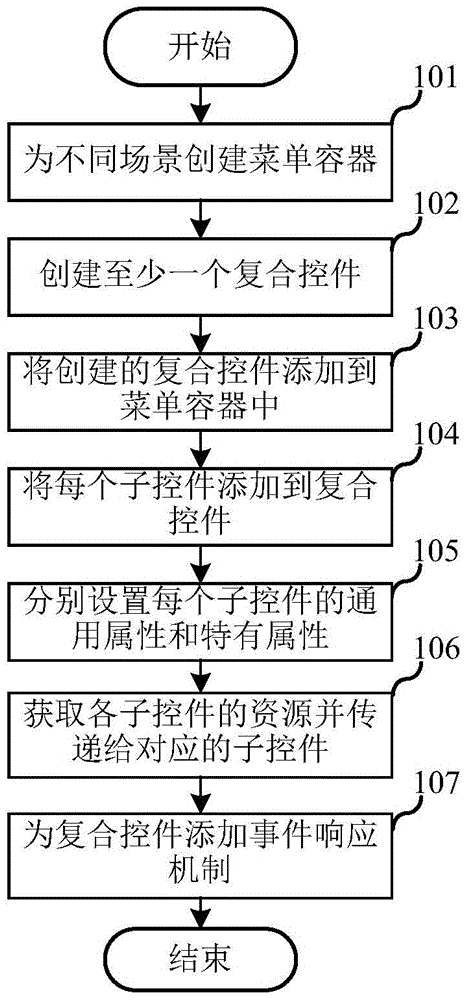

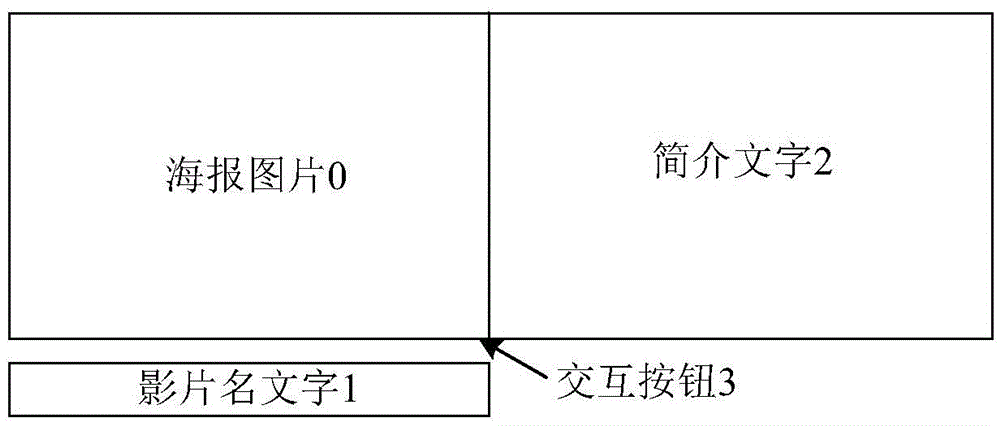

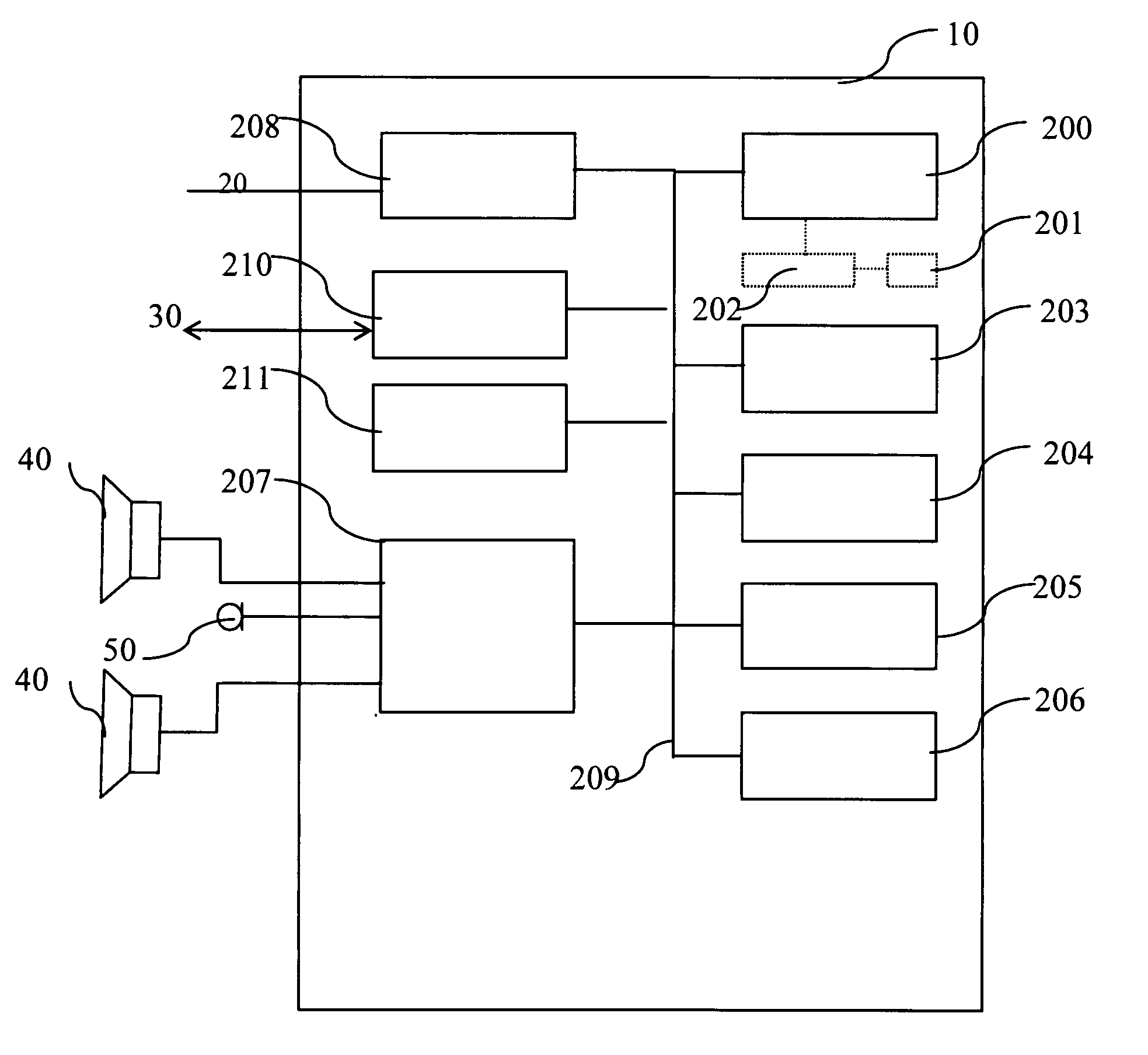

Production method and system of combined user interface control, and control method and system of combined user interface control

InactiveCN105893022AImprove experienceEasy to generateProgram loading/initiatingExecution for user interfacesHuman–computer interactionUser interface

The invention relates to the technical field of multimedia, and discloses a production method and system of a combined user interface control, and a control method and system of the combined user interface control. The production method of the combined user interface control comprises following steps of establishing at least one combined control, wherein the combined control comprises at least two sub-controls; adding each sub-control to the combined control; setting universal attribute and special attribute of each sub-control; obtaining the resource of each sub-control and transmitting the resources to corresponding sub-controls; and adding an event response mechanism to the combined control. According to the production method of the combined user interface control provided by the invention, the production method of the user interface control is relatively simple; and the method is beneficial for controlling and modifying the integral or single user interface control in a user interface. Because one set of user interface can be multiplexed in multiple scenes, the style of the whole application is unified in the user interface; the user experience is improved; and the errors resulting from repeatedly developing the user interface control can be avoided.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

Method for efficient transfer of human blastocyst-derived stem cells (hBS cells) from a feeder-supported to a feeder-free culture system, long-term propagation of hBS cells under feeder-free conditions and use of cultured hBS cells for applications in myocardial regeneration

InactiveUS7638328B2Efficiently attachedPromote rapid proliferationNervous disorderNervous system cellsStem cell lineCell culture media

A method for the transfer of human blastocyst-derived stem cells (hBS cells) to feeder-free culture system and propagation of the cells in such a feeder-free culture system, the method comprising the following steps of (a) transferring the balstocyst-derived stem cells from feeder to feeder free culture by mechanical treatment, (b) optionally, culturing the blastocyst-derived stem cells under feeder cell free growth conditions in a suitable growth medium and / or on a suitable support substrate, and (c) optionally passaging the blastocyst derived stem cell line every 3-10 days by enzymatic and / or mechanical treatment. The invention also relates to the application of hBS cells cultured under feeder free condition in medicine (e.g., myocardial regeneration) and screening and toxicity tests.

Owner:TAKARA BIO EURO

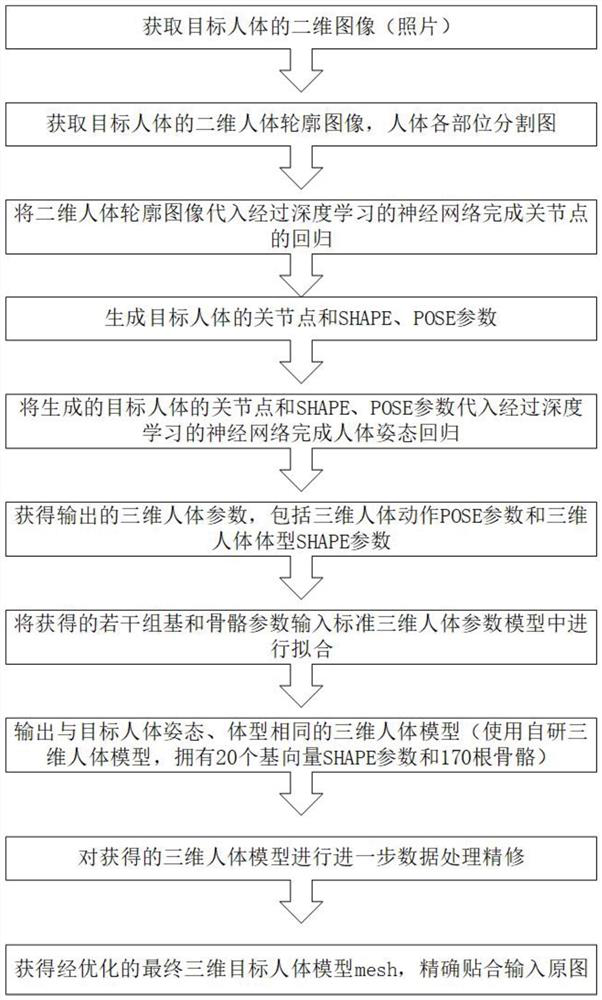

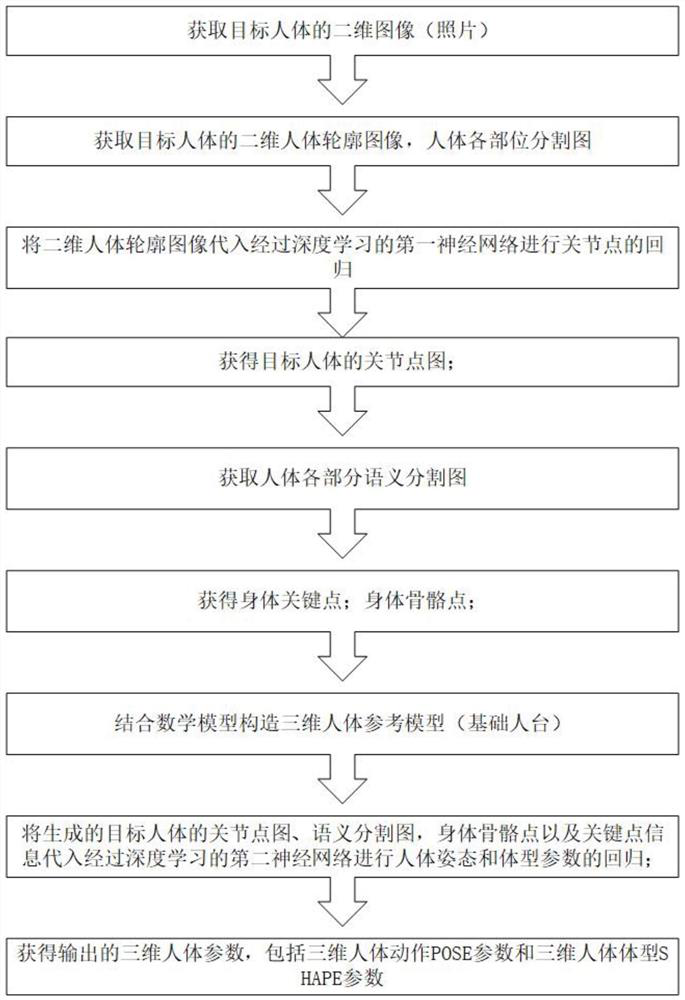

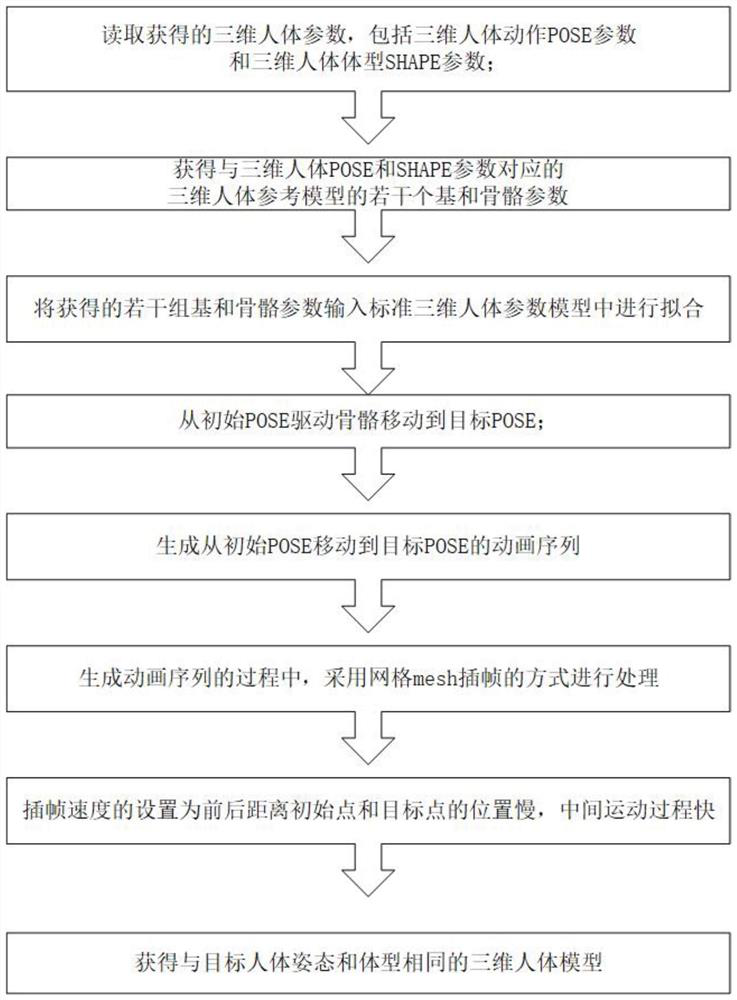

Human body model establishing method, system and equipment and storage medium

PendingCN114202629AEasy to operateImprove experienceBiometric pattern recognitionNeural learning methodsHuman bodyBody shape

The invention discloses a method for establishing a human body model, and the method comprises the steps: obtaining a two-dimensional image of a target human body; substituting the two-dimensional human body contour image into a first neural network subjected to deep learning to carry out regression of joint points; acquiring information such as a joint diagram of the target human body; substituting into a second neural network subjected to deep learning to carry out regression of human body posture and body shape parameters; obtaining three-dimensional human body parameters including three-dimensional human body action posture parameters and three-dimensional human body shape parameters; constructing a three-dimensional standard human body model, namely a basic mannequin, in combination with the mathematical model; inputting the plurality of groups of obtained basis and skeleton parameters into a standard three-dimensional standard human body model for fitting; and obtaining a three-dimensional human body model with the same posture and body shape as the target human body. According to the three-dimensional human body model generation method, the self-owned standard human body model is established, the body bases suitable for the body shape characteristics of the Asian human body are selected, and the parameters corresponding to the 20 body bases and the 170 bones are used, so that the three-dimensional human body model which is closer to the body shape of the Asian human body than a Mapp human body SMPL model and is better in independent operation and controllability is generated.

Owner:北京陌陌信息技术有限公司

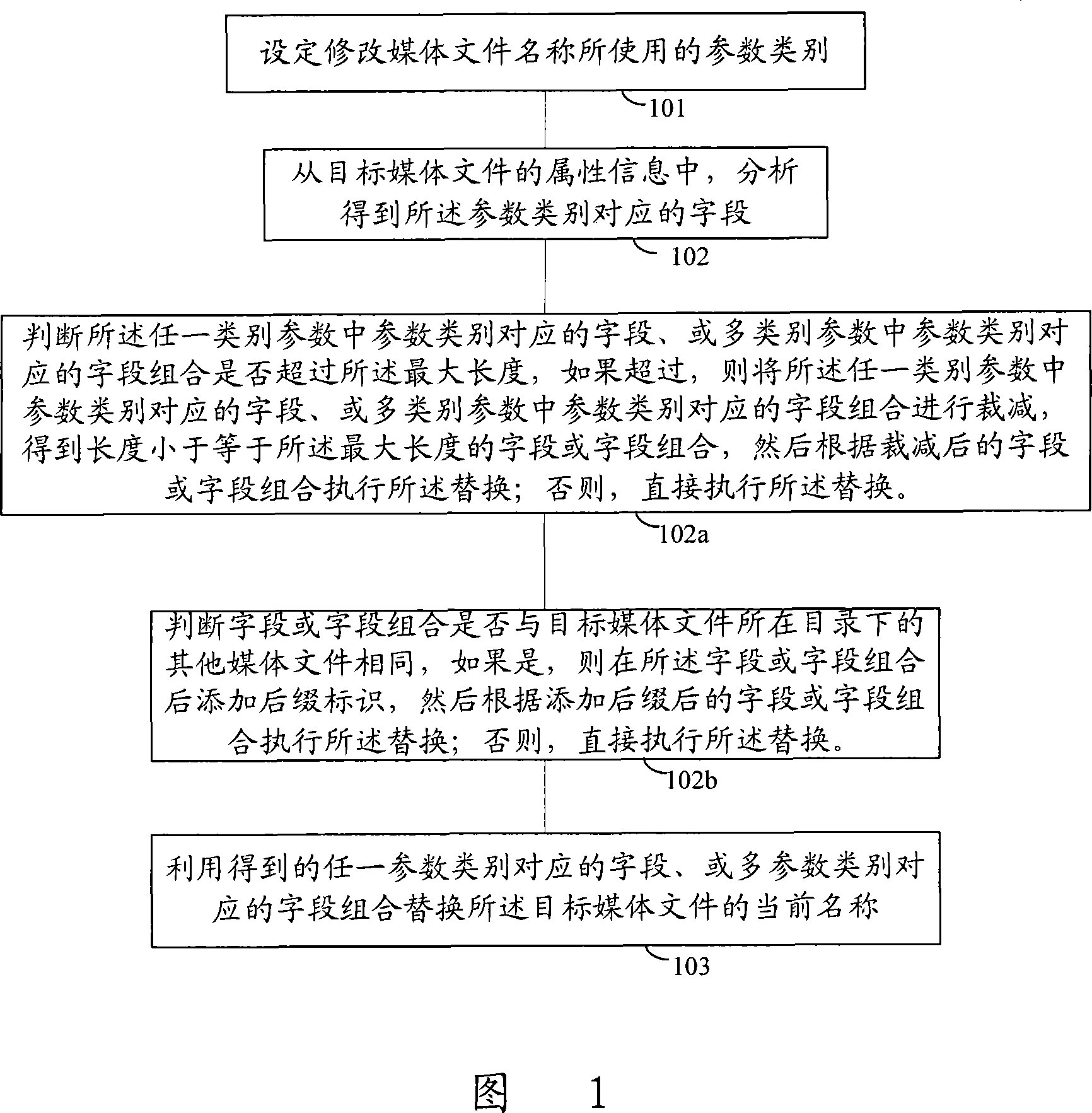

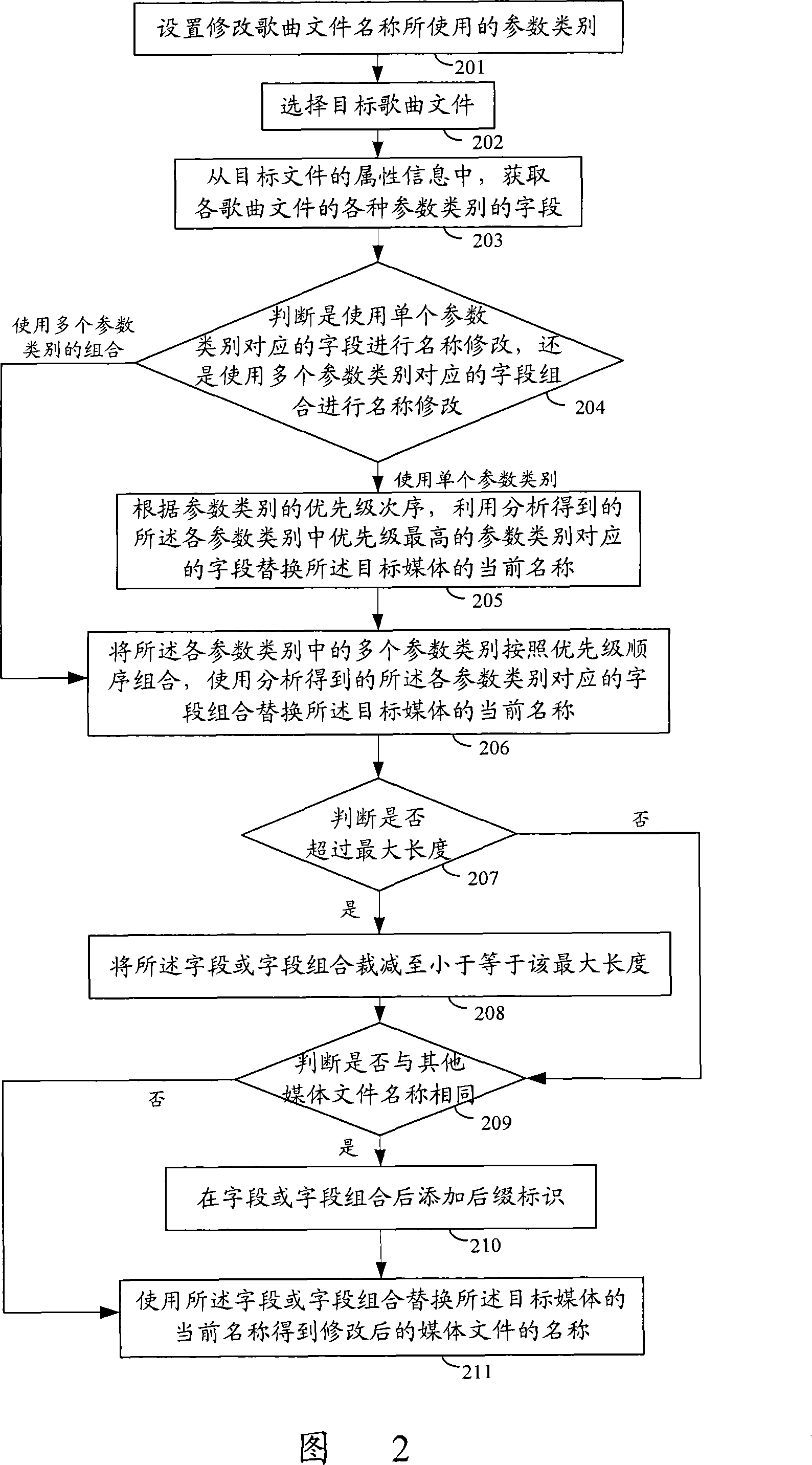

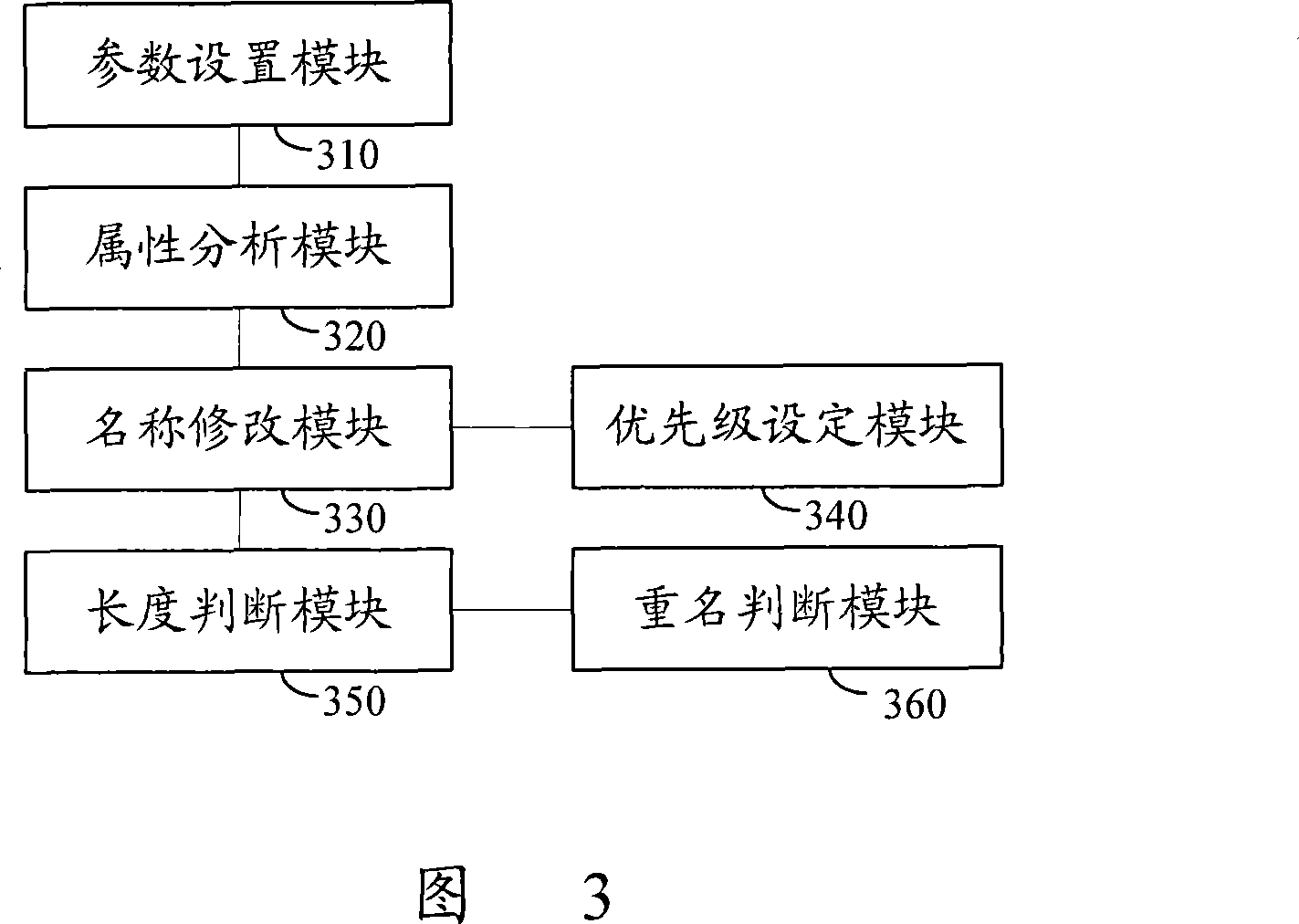

Method and device for modifying media file name

InactiveCN101216848AModify batchAccurate modificationSpecial data processing applicationsComputer science

Owner:VIMICRO CORP

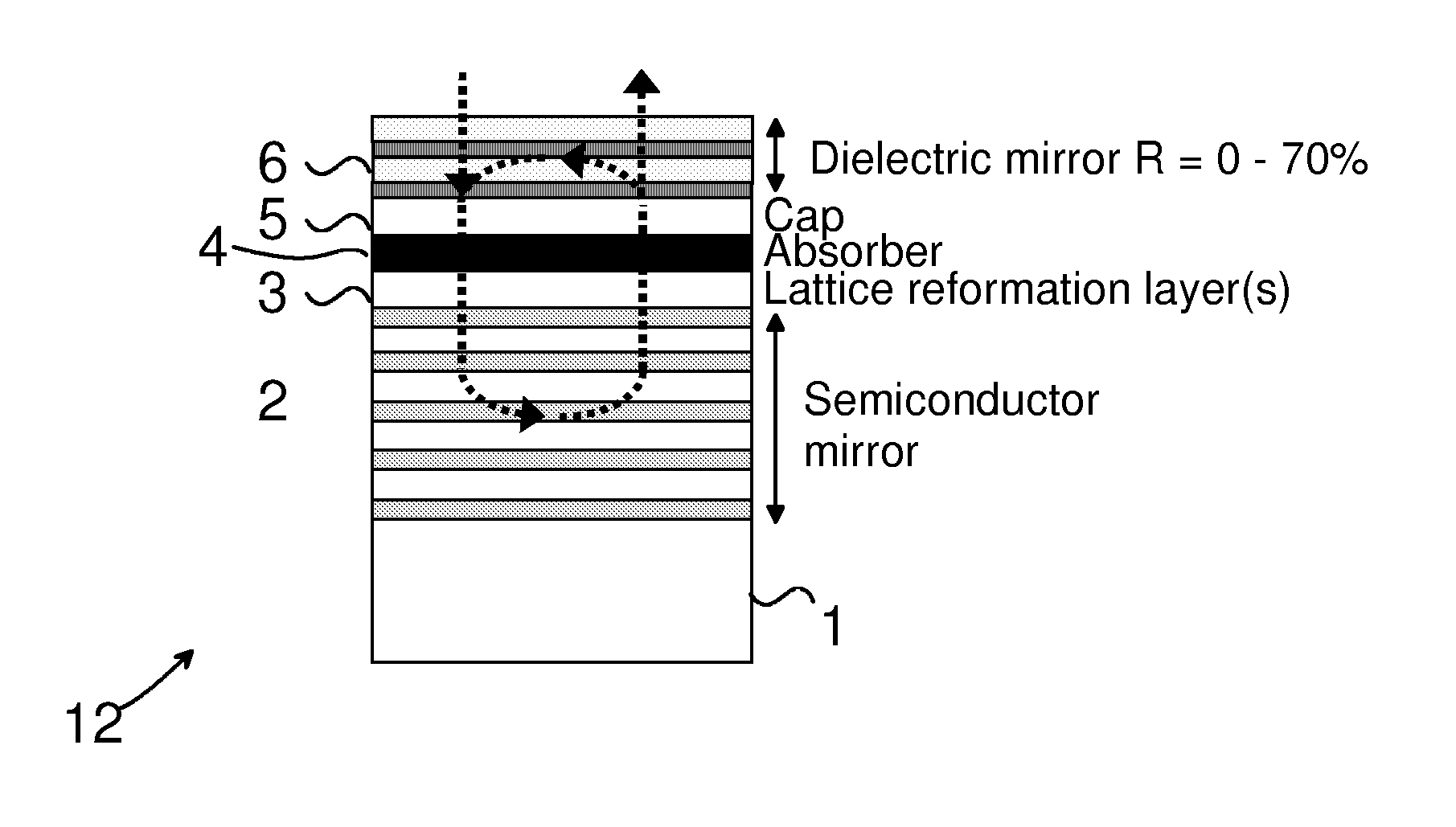

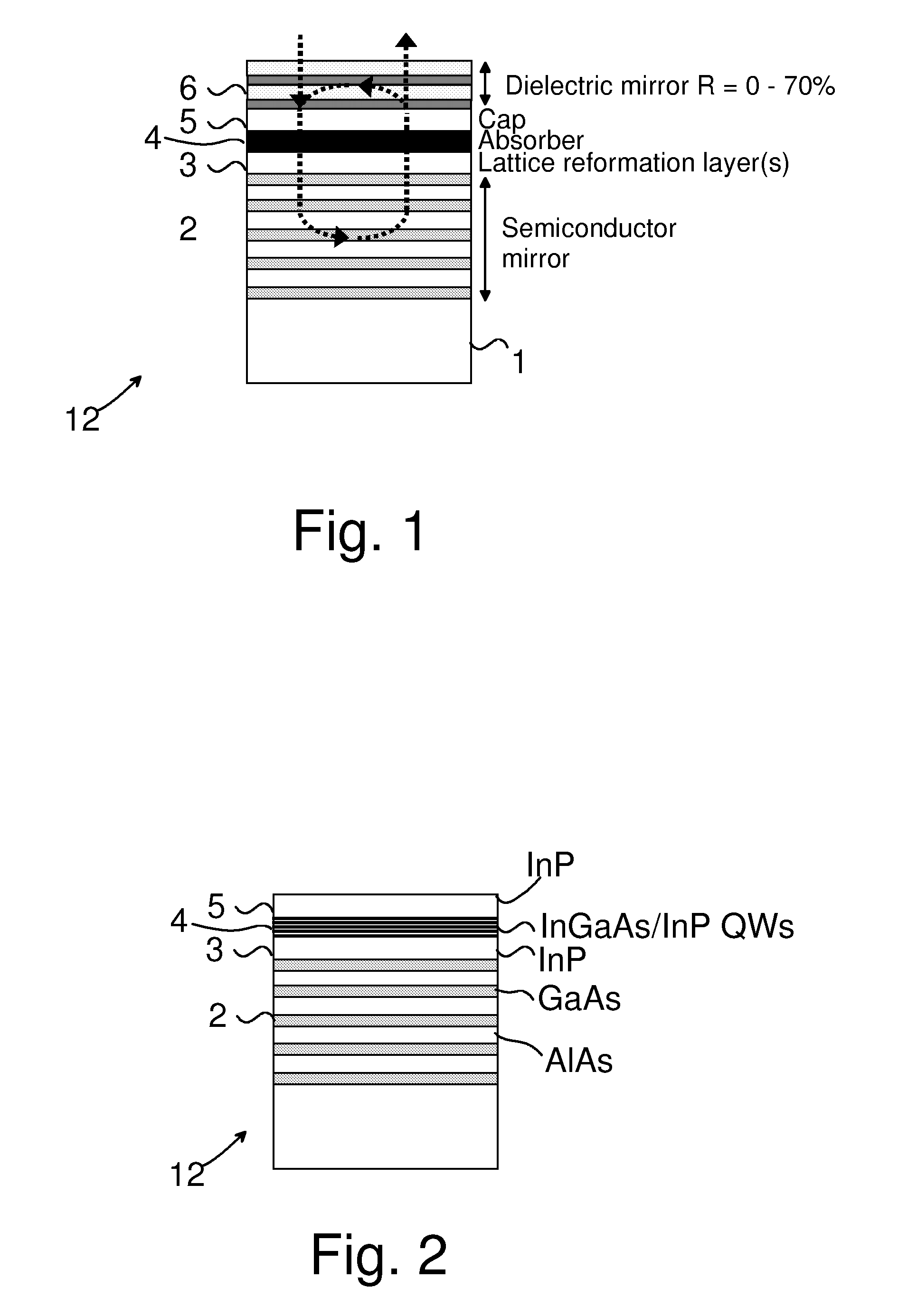

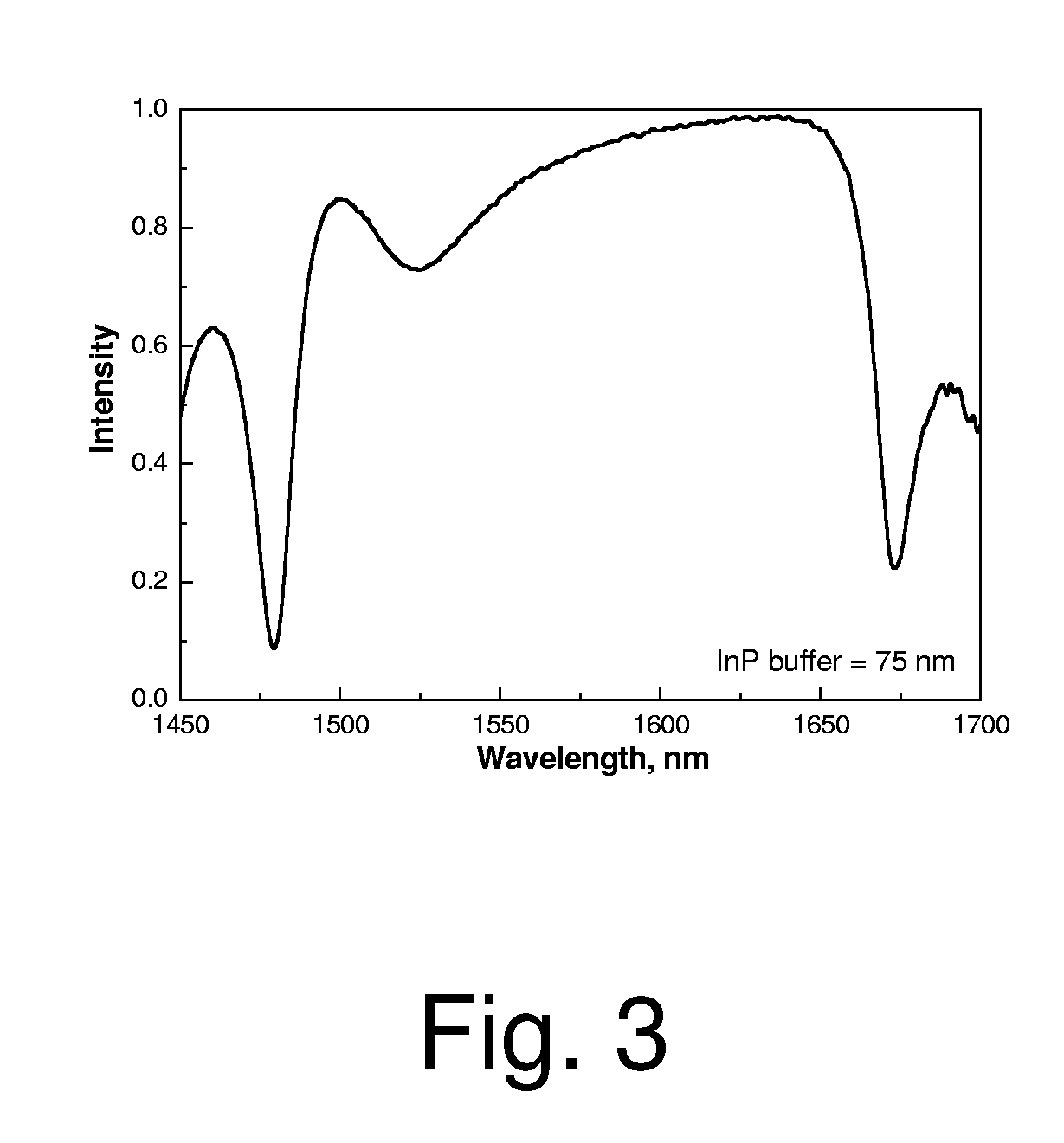

Semiconductor Saturable Absorber Reflector and Method to Fabricate Thereof

ActiveUS20090296767A1Accurate modificationLimit recovery timeLaser detailsNanoinformaticsSemiconductor materialsLattice mismatch

A design of a semiconductor saturable absorber that offers a convenient and reliable way to control / decrease the recovery time of the absorption. The absorption recovery time is controlled during the epitaxial growth by using lattice-mismatched layer(s) to induce dislocations, and implicitly non-radiative recombination centers within the nonlinear absorbing region. These lattice reformation layer(s) are interposed between the distributed Bragg reflector and the nonlinear absorption region, containing quantum-wells, quantum-dots or bulk semiconductor material. The thickness and composition of the lattice reformation layer(s) is an instrumental to control the amount of non-radiative recombination centers used to trap the optically excited carriers generated in the absorption region.

Owner:OPTOELECTRONICS RES CENT

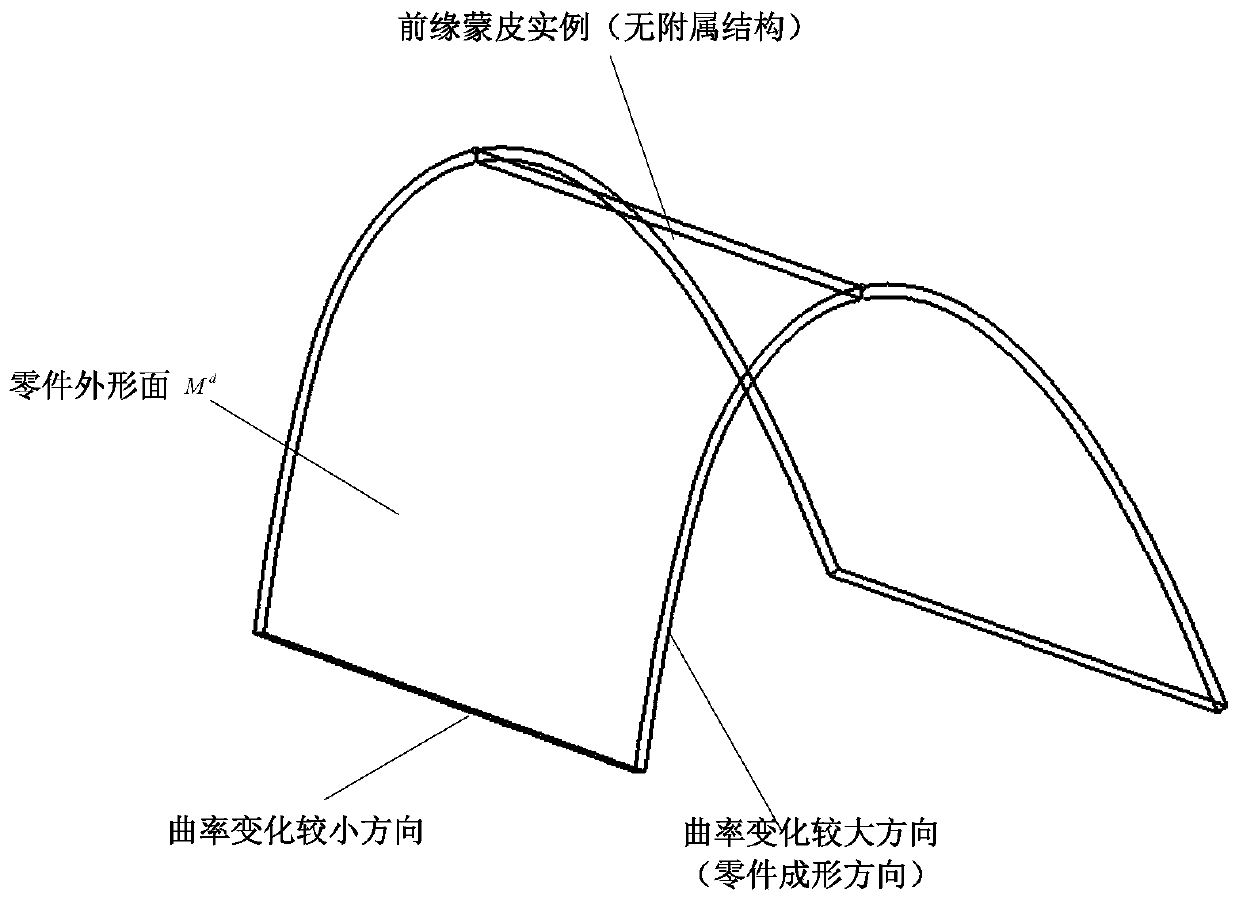

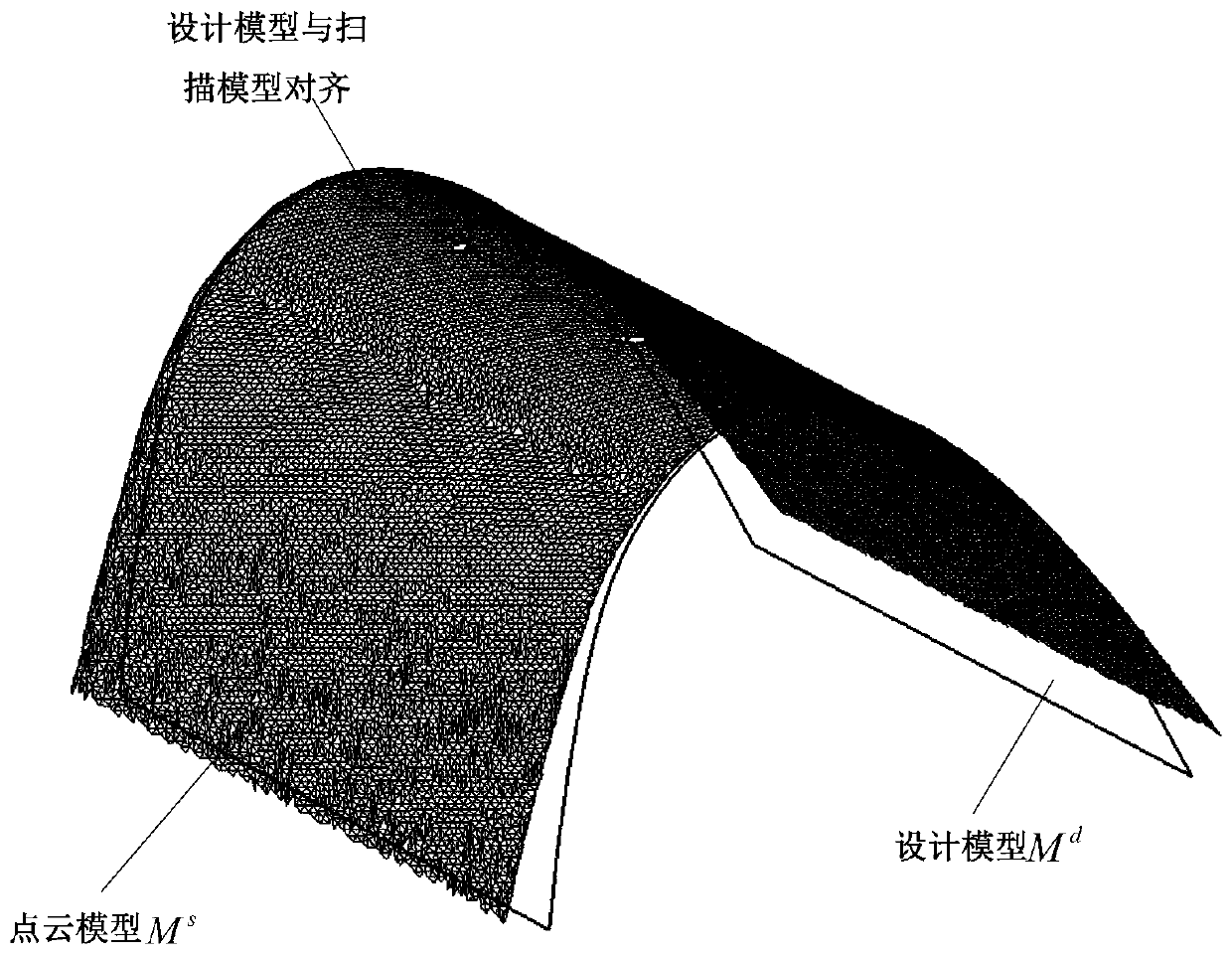

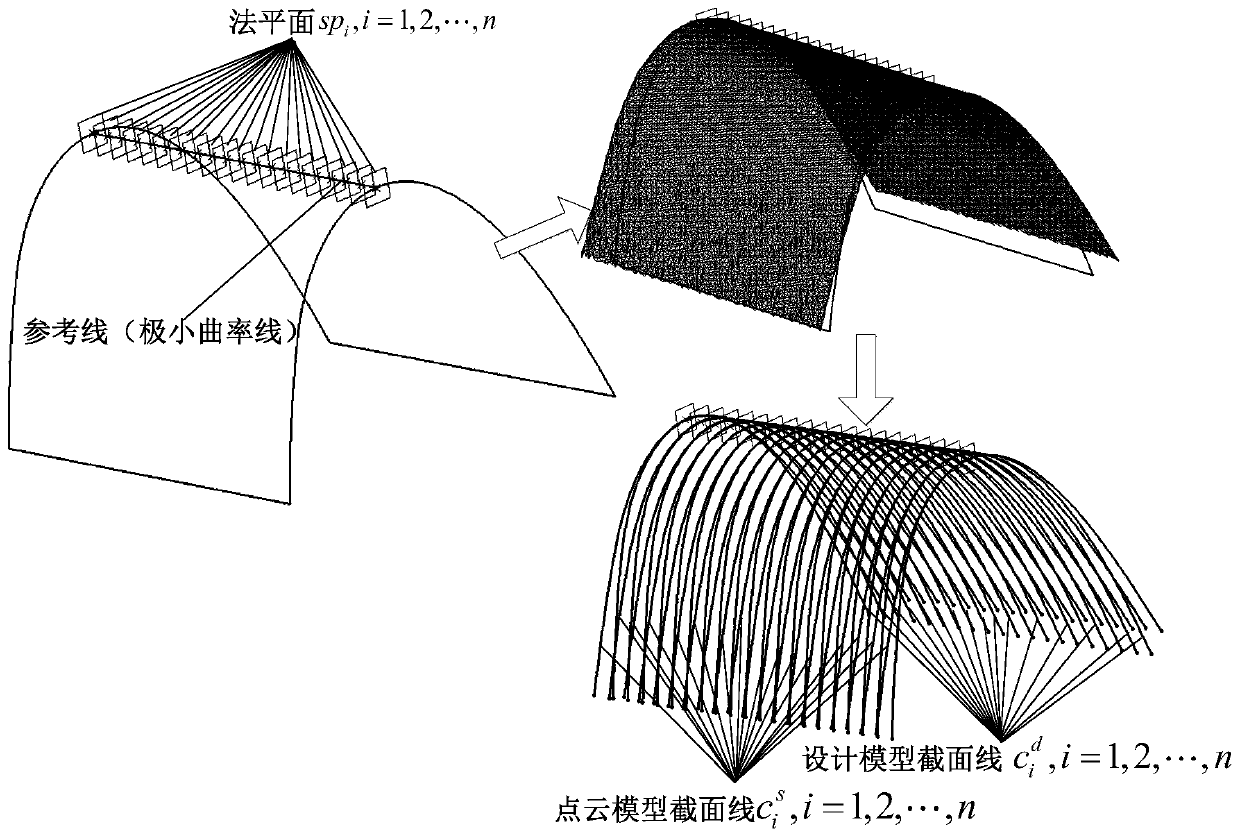

Skin process model correction method based on workpart point cloud model

ActiveCN110688709AAvoid fit biasAccurate modificationGeometric CADImage enhancementComputational scienceAlgorithm

The invention provides a skin process model correction method based on a workpart point cloud model. And performing point cloud processing on the workpart, performing equal-length cutting by referringto the design model, and aligning with the design model. Creating a reference line and a reference plane group, the reference plane group is intersected with the point cloud model and the design model of the workpart to obtain a section line group, then the section line group is discretized to obtain discrete point groups corresponding in pairs, a discrete curvature calculation formula is established, the discrete curvature of each discrete point is calculated, and the discrete curvature value of the compensated point is calculated through a compensation formula. And the positions of the compensated discrete points are obtained by utilizing the positions of the discrete points of the section line of the design model and the discrete curvature values of the discrete points of the section line of the process model, and the compensated section line is obtained through fitting. Finally, a curved surface based on the compensated section line set is generated, and a corrected process modelis obtained. According to the method, secondary correction can be carried out on the inaccurate skin process model, and the process model of the skin part can be quickly and accurately modified.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

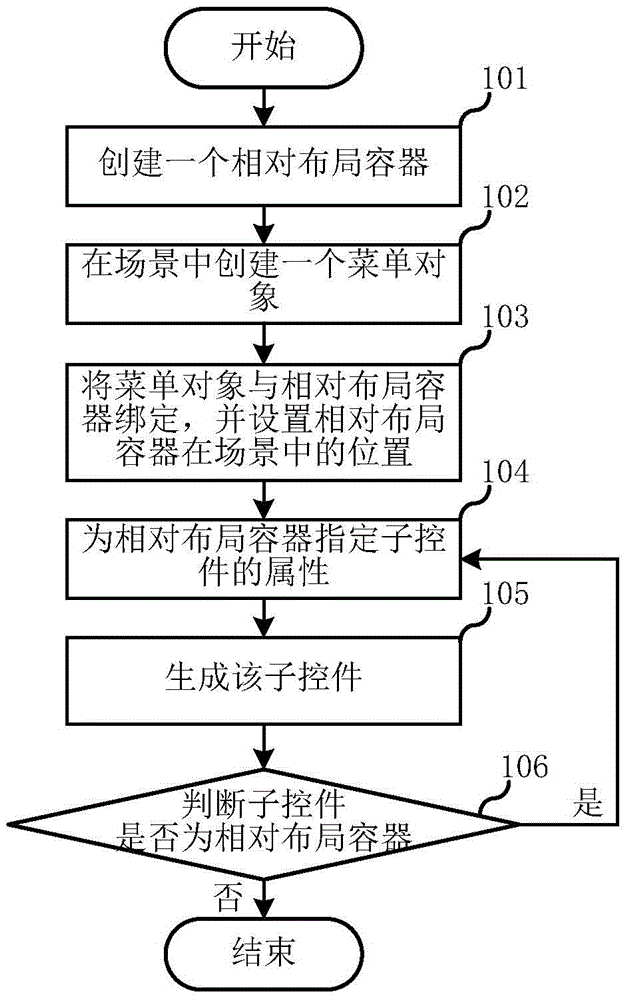

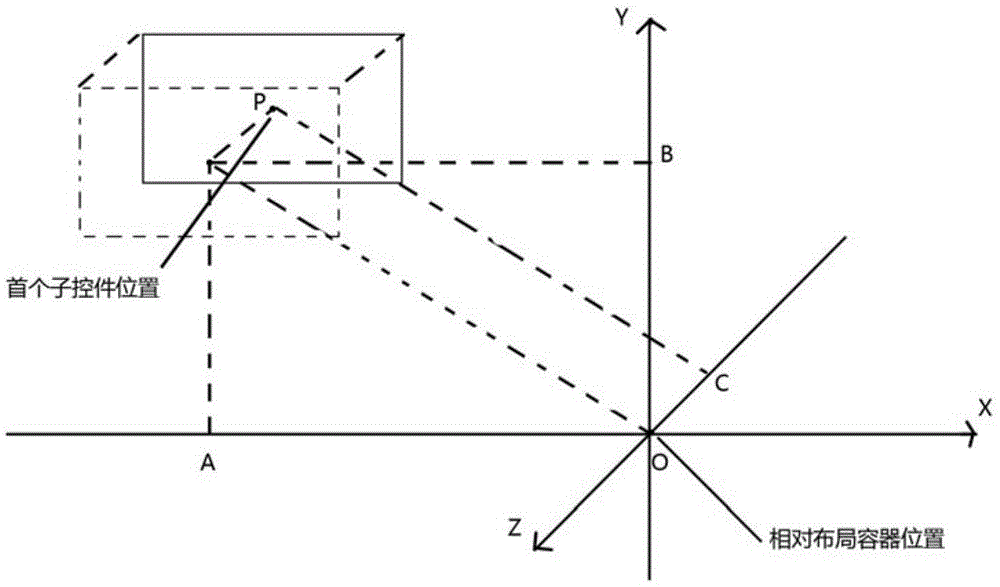

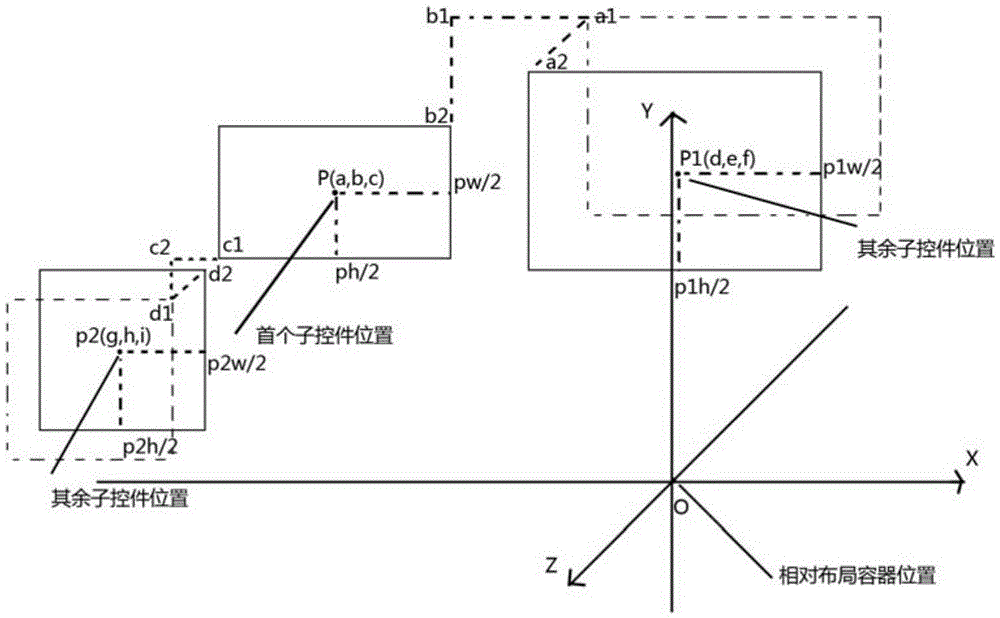

Layout method and system for user interface control, and control method and system for user interface control

InactiveCN105912314AEasy to generateEasy to controlExecution for user interfacesSimulationUser interface

The invention relates to the technical field of multimedia, and discloses a layout method and a system for user interface controls, and a control method and a system for user interface controls. The layout method for user interface controls comprises the following steps: establishing a relative layout container, the relative layout container being used to hold child controls, the child controls being relative layout containers or common controls; assigning the attributes of the child controls for the relative layout container; generating child controls; if the child controls being the relative layout containers, repeating the above steps, until all child controls in the relative layout container are common controls. The method can generate UI controls in a plurality of different sizes or types through layout arrangement, and the UI controls in the plurality of different sizes or types can be nested with each other, so as to rapidly realize UI interfaces in different rules, and satisfy different requirements of various products on UI control arrangement.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

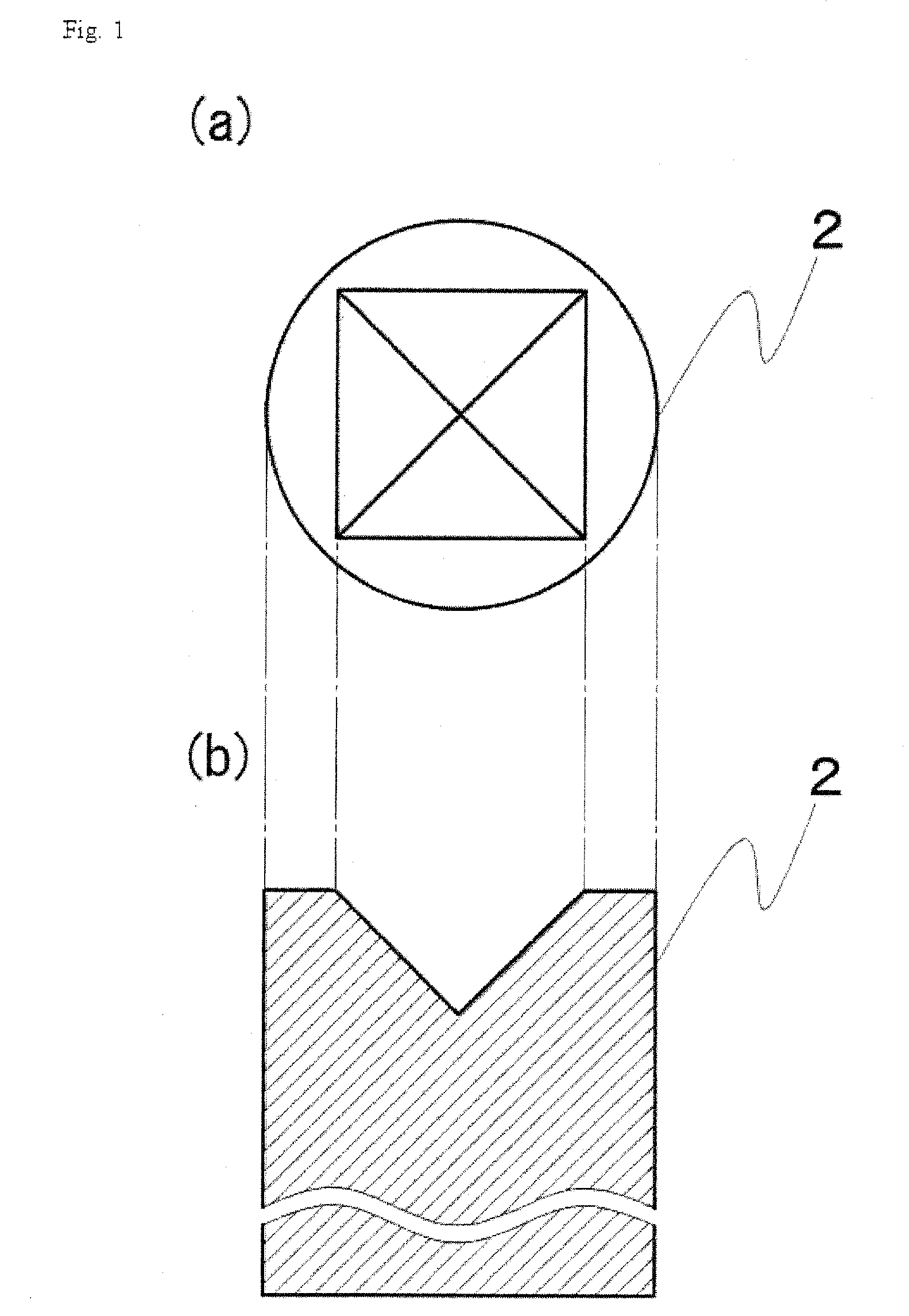

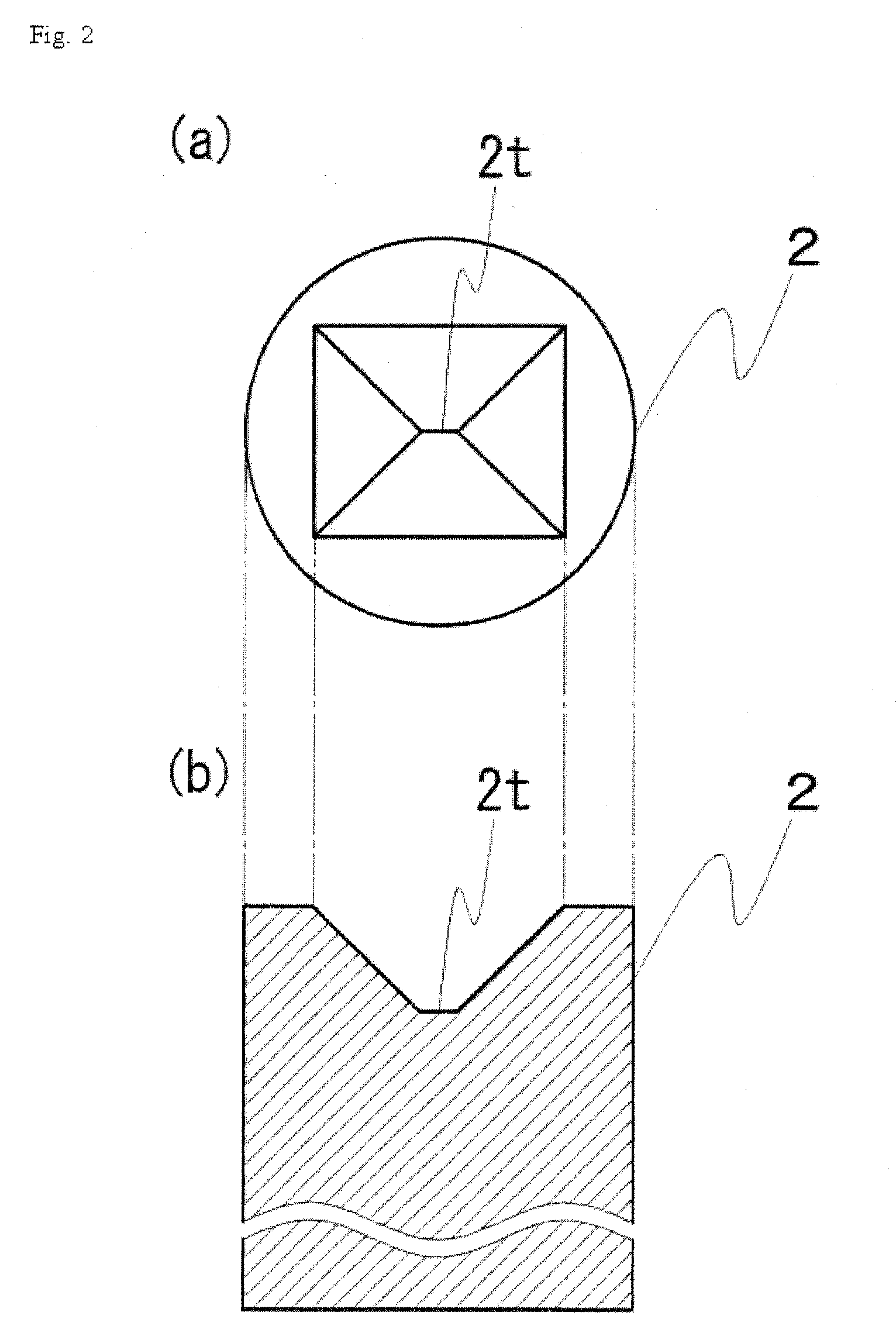

Shank and diamond scriber assembled therewith

InactiveUS20090183617A1Improve wear resistanceHighly preferable fixationWing handlesWing knobsSingle crystalScriber

A shank of a diamond scriber suitable for substantially flat-surfaced materials that is to be scribed with particularly high loads. The shank includes a blind hole for retaining a diamond single crystal. The blind hole includes a rectangular mouth and four triangular sidewalls, each of which includes one edge of the rectangular mouth and meets the other three.

Owner:NAMIKI PRECISION JEWEL CO LTD

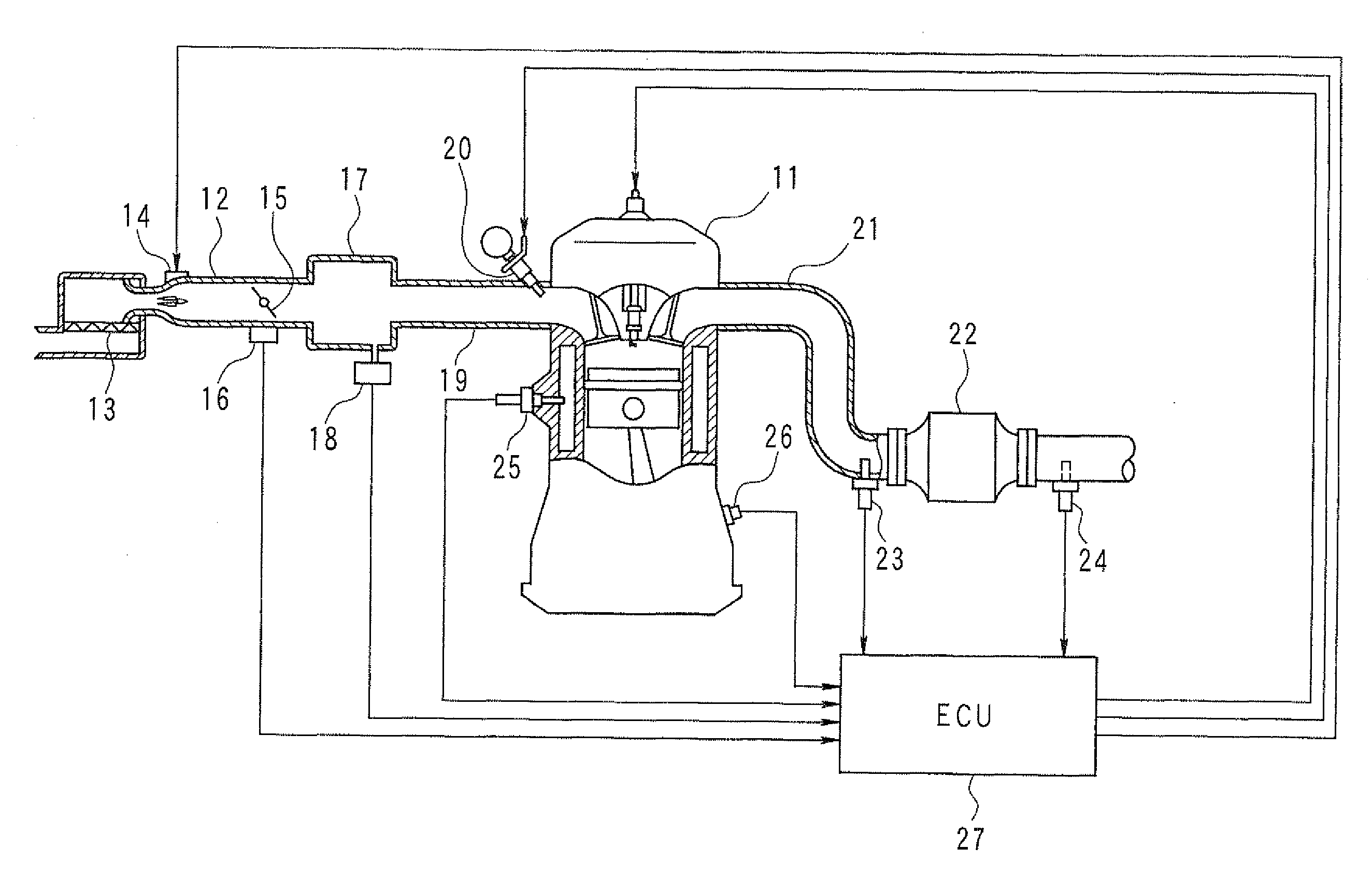

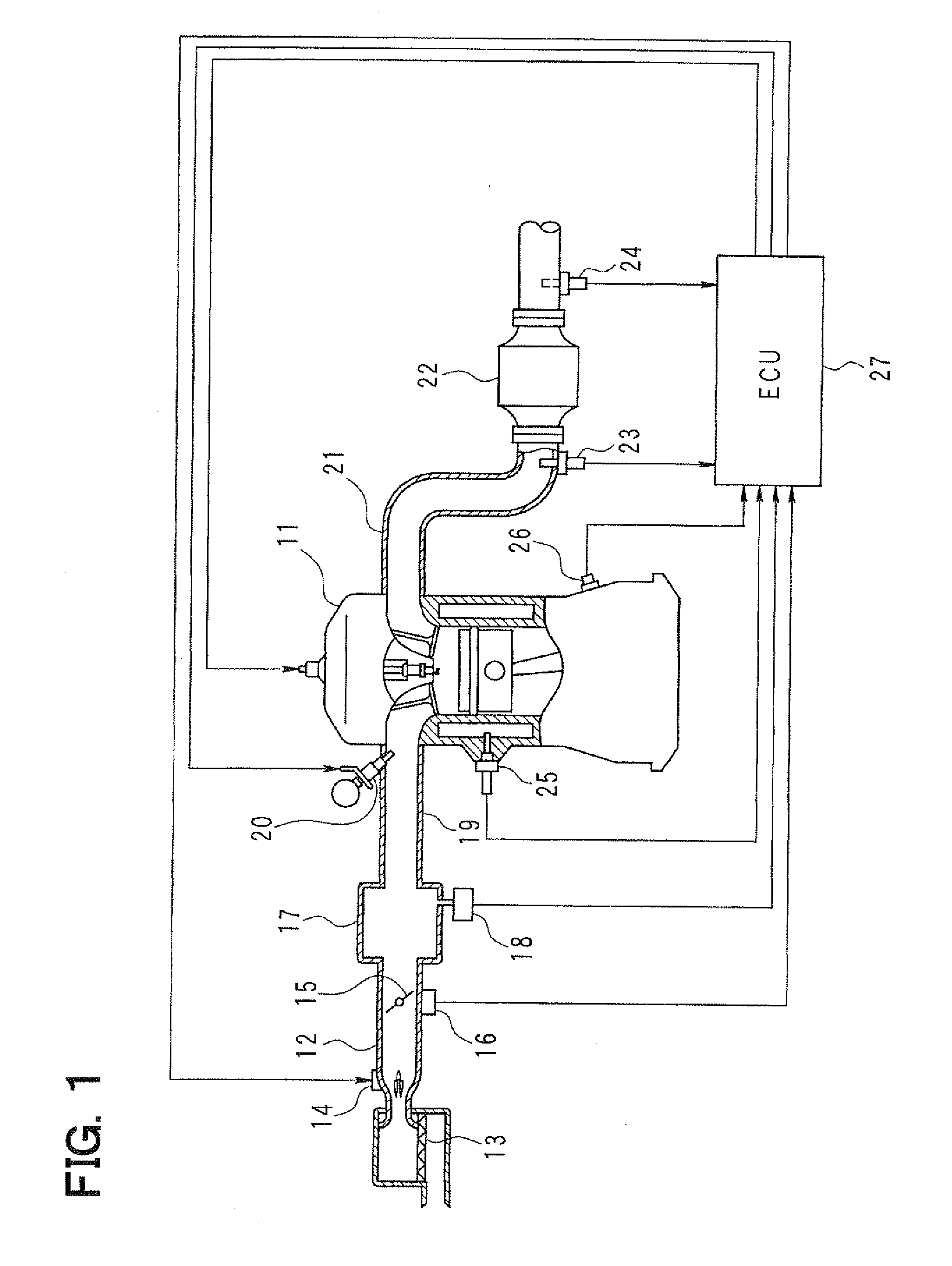

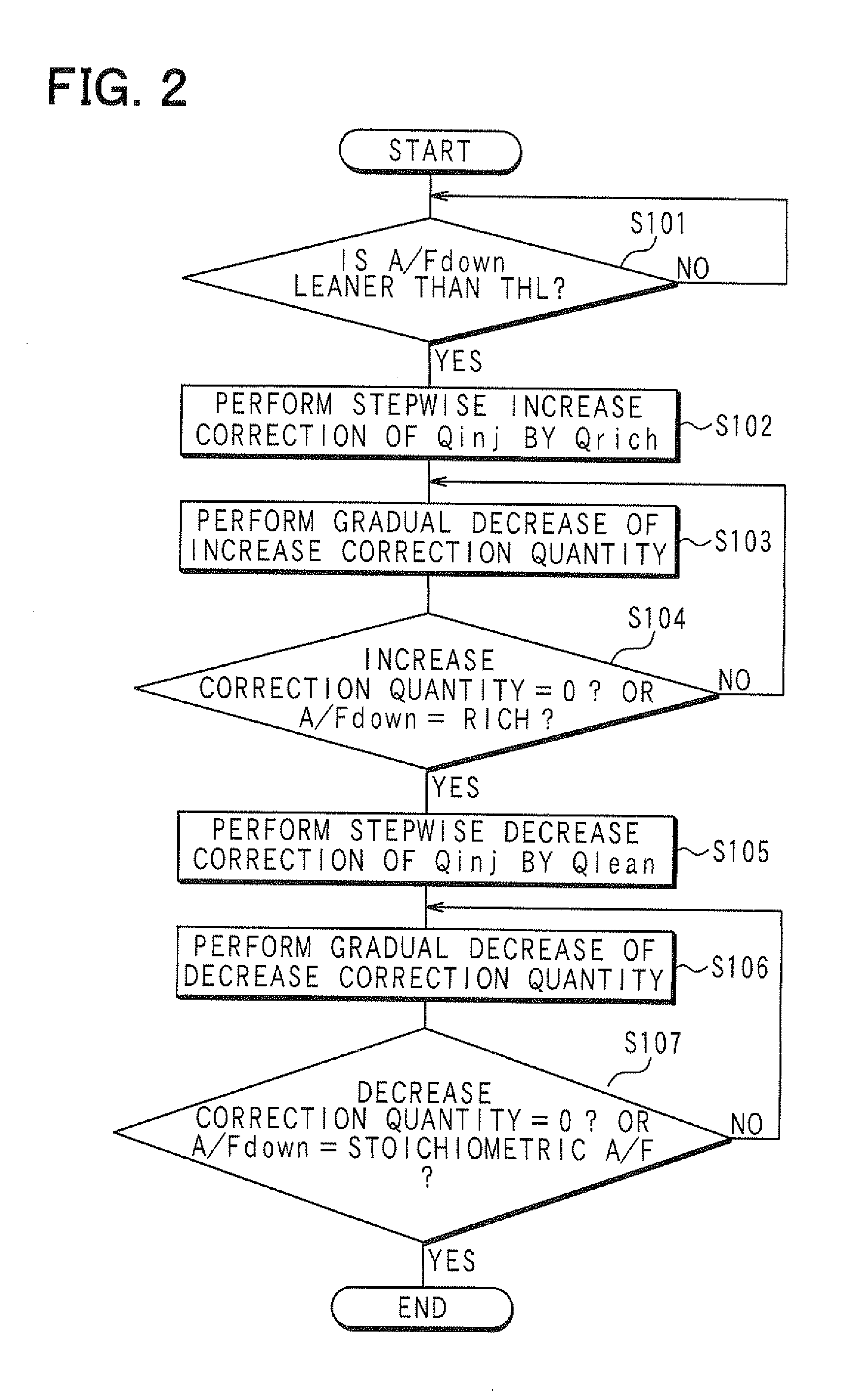

Air-fuel ratio control device of internal combustion engine

InactiveUS20100078000A1Reduce in quantityComponents is relatively effectiveElectrical controlExhaust apparatusEngineeringOxygen

When an output of a downstream sensor provided downstream of a catalyst for exhaust gas purification becomes a leaner value than a leanness determination value, an air-fuel ratio control device supplies a rich component to the catalyst by performing rich input processing, in which increase correction for increasing fuel injection quantity stepwise is performed and then increase correction quantity of the fuel injection quantity is decreased gradually. When the increase correction quantity of the fuel injection quantity defined by the rich input processing becomes zero or when oxygen occlusion quantity of the catalyst becomes zero, the control device supplies a lean component to the catalyst by performing lean input processing, in which decrease correction for decreasing the fuel injection quantity stepwise is performed and then decrease correction quantity of the fuel injection quantity is decreased gradually.

Owner:DENSO CORP

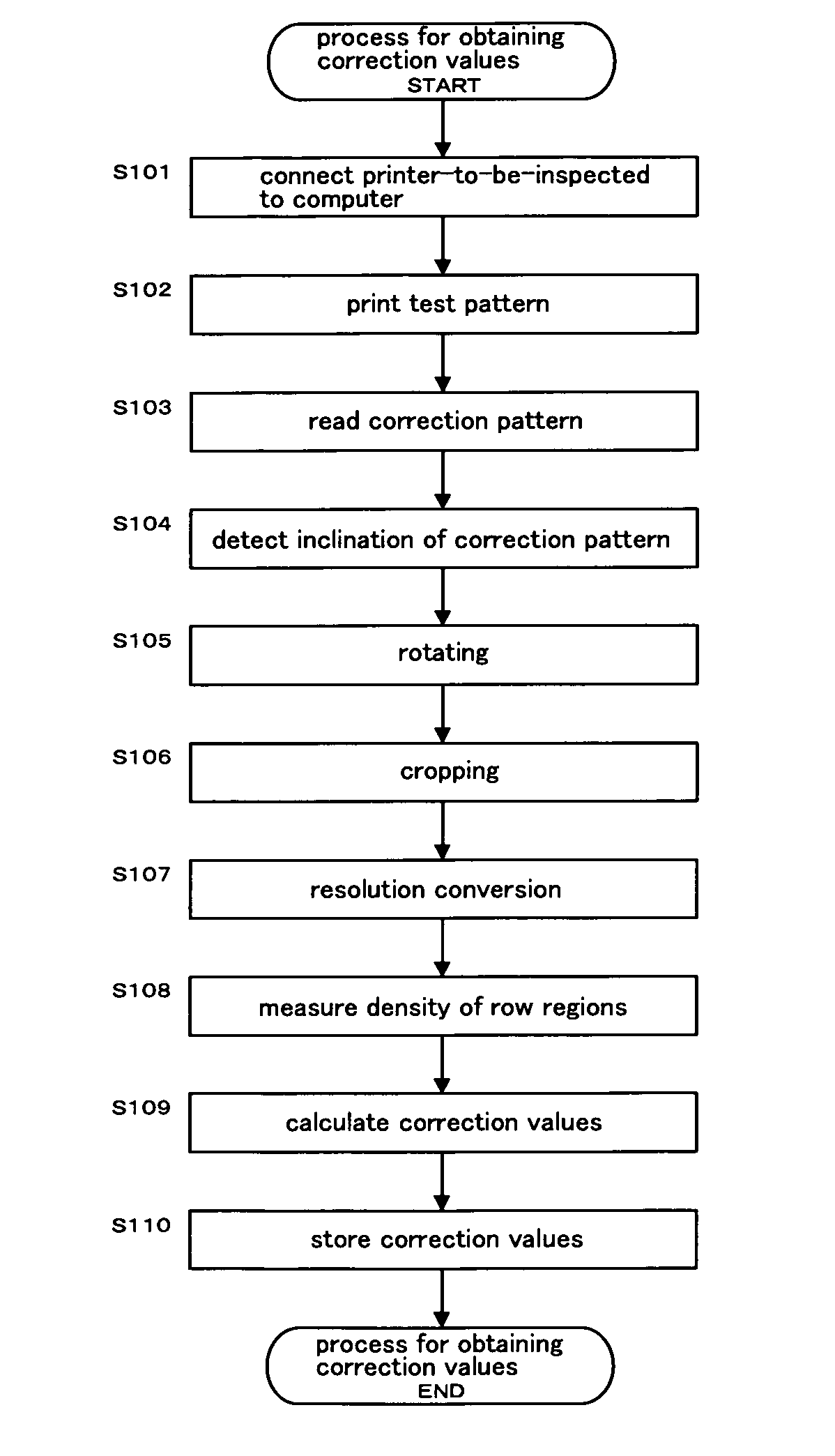

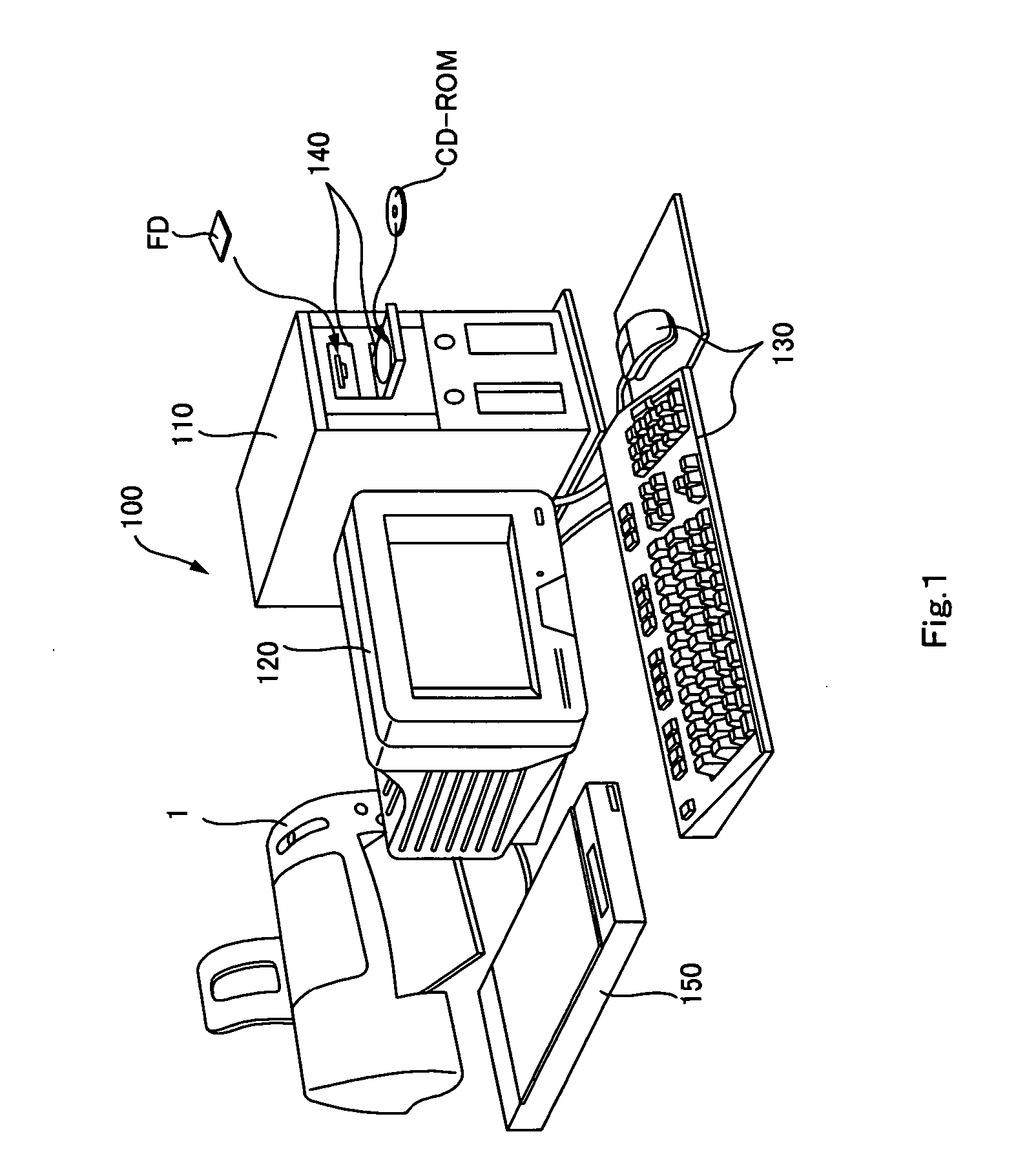

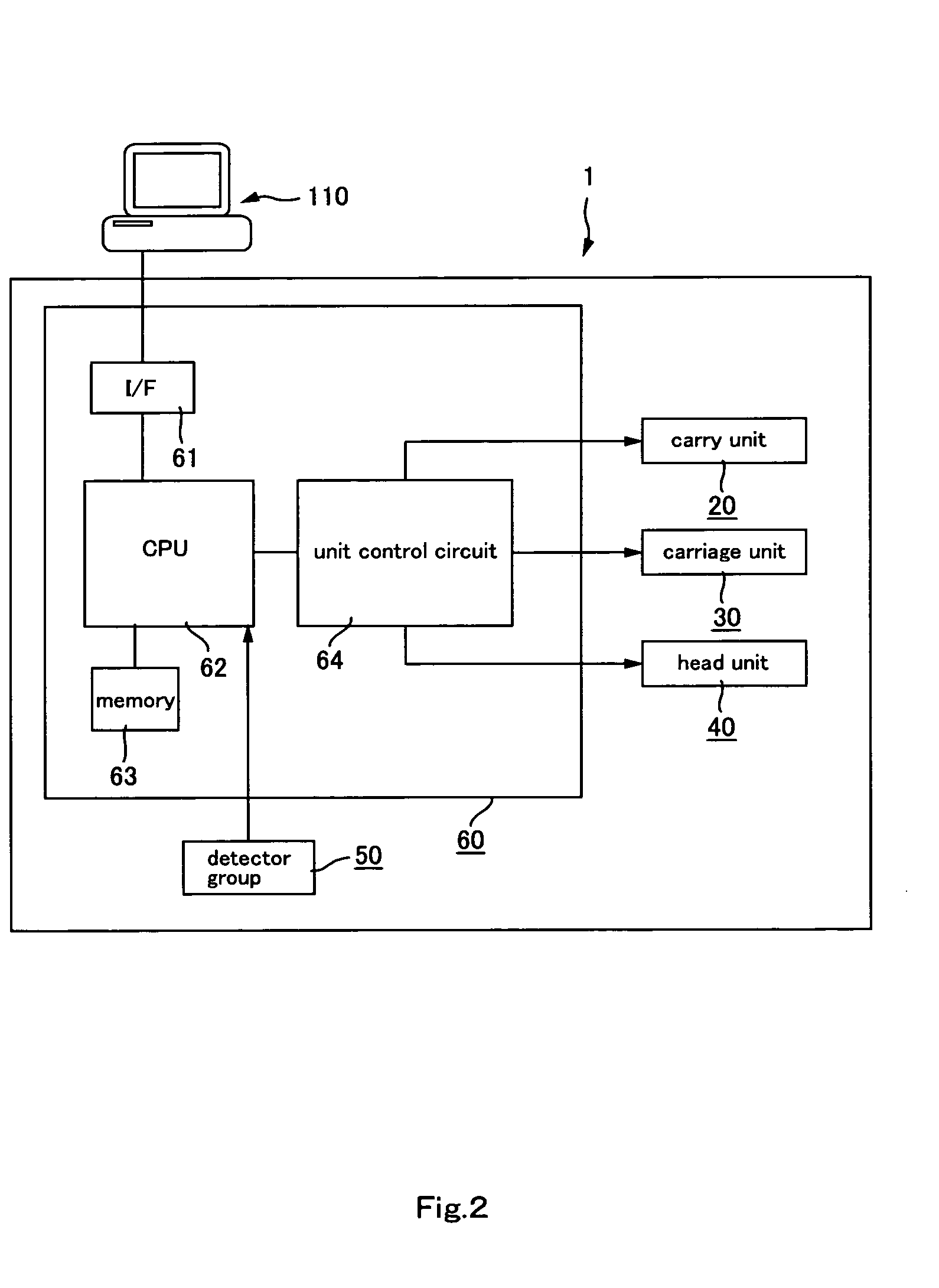

Method for measuring density, printing method, method of calculating correction value, method of manufacturing printing apparatus and method for obtaining correction value

InactiveUS20060262361A1Uneven inhibitory concentrationDensity unevennessOther printing apparatusColour-separation/tonal-correctionEngineeringVolumetric Mass Density

A method for measuring density, includes: forming on a medium a pattern that consists of a plurality of dot rows formed respectively in a plurality of row regions lined up in a direction intersecting a movement direction in which a plurality of nozzles move, by forming each of the dot rows in the row region arranged in the movement direction by ejecting ink from the nozzles; reading the pattern by a scanner; measuring density of each of the row regions of the read pattern; calculating respective modification values corresponding to each of the row regions, based on at least a part of a measurement result of the density of the plurality of the row regions; and modifying respective measured values of the density of each of the row regions based on the respective modification values corresponding to each of the row regions.

Owner:SEIKO EPSON CORP

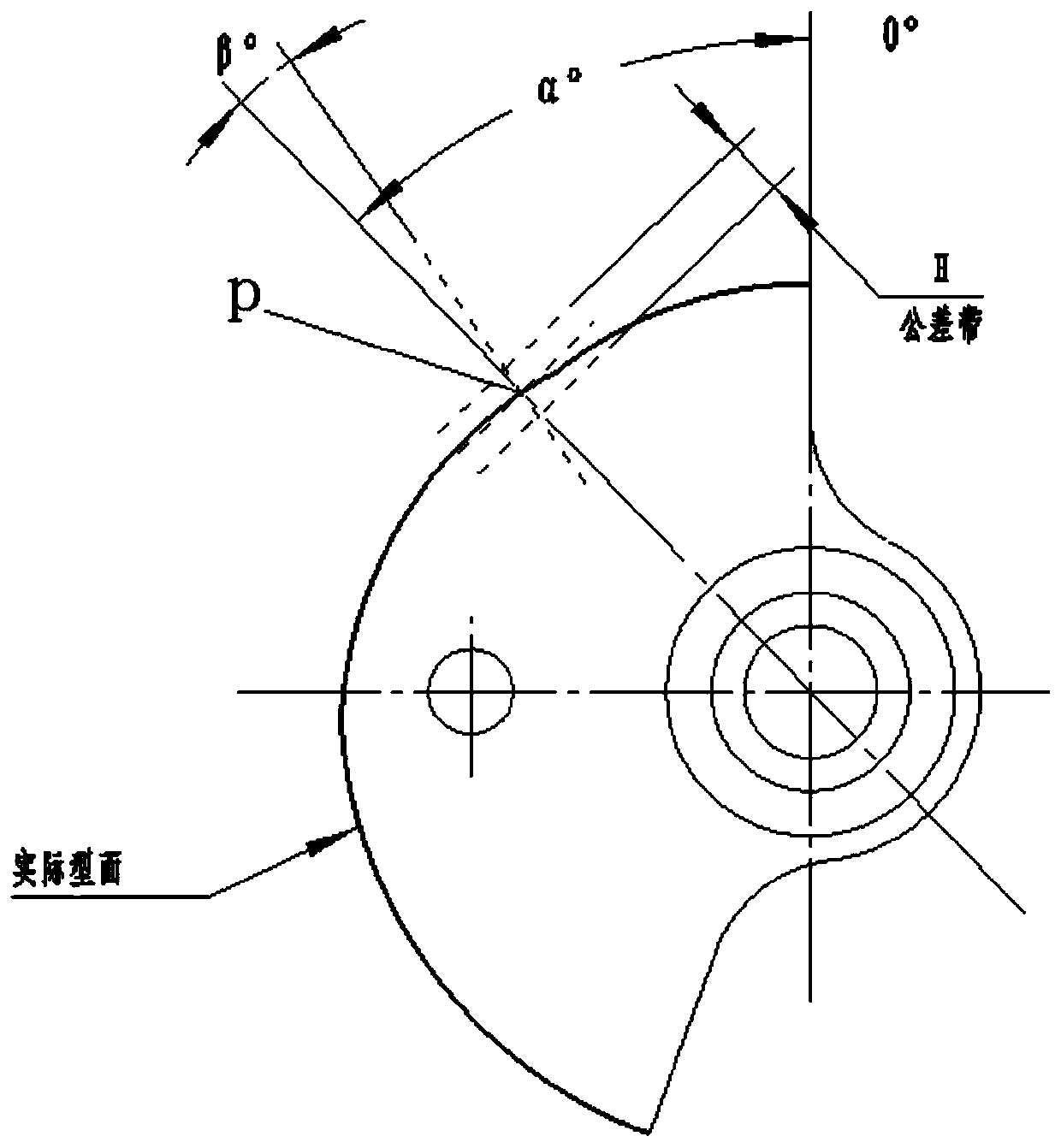

Two-dimensional cam part shape digital measurement method based on profile

The invention belongs to the field of measurement, and relates to a two-dimensional cam part shape digital measurement method based on profile. The method includes the following steps: (1) establishing a two-dimensional cam part shape digital measurement model; (2) calculating the profile tolerance of the actual surface curve of the shape of the model according to the two-dimensional cam part shape digital measurement model; (3) obtaining a profile measurement result of the actual surface curve of a two-dimensional cam part; and (4) comparing the obtained profile measurement result with the profile tolerance, determining that the two-dimensional cam part product is qualified if the profile measurement result is within the profile tolerance range, and determining that the two-dimensional cam part product is unqualified if the profile measurement result is out of the profile tolerance range. The invention provides a two-dimensional cam part shape digital measurement method based on profile which can improve the measurement efficiency of cam shapes, make the measurement conclusion conform to the real allowance of cam profiles and facilitate rapid and accurate modification of processing procedures.

Owner:XIAN AERO ENGINE CONTROLS

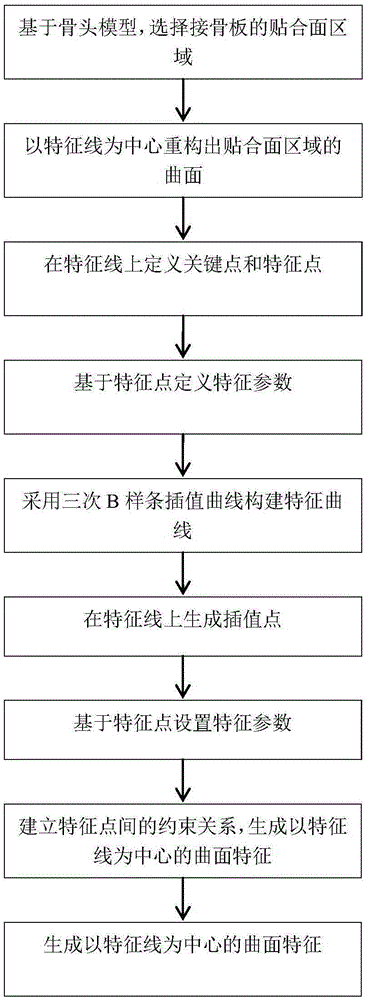

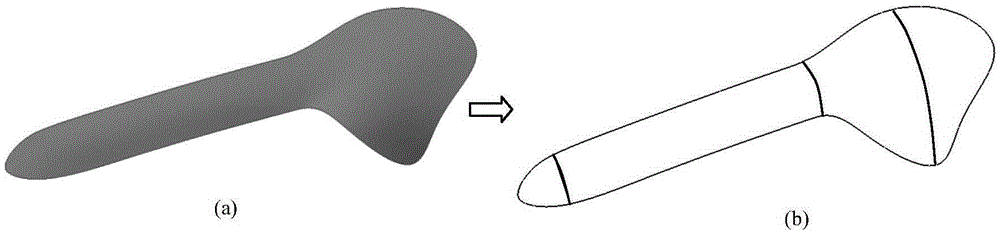

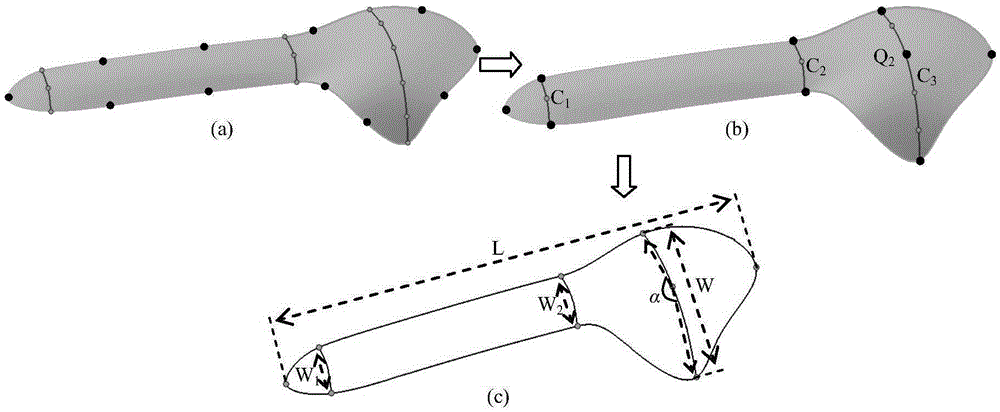

Characteristic line-based parametric design method for bone fracture plate abutment surface

InactiveCN105243227AVisual modificationAccurate modificationSpecial data processing applicationsAbutmentEngineering

The invention discloses a characteristic line-based parametric design method for a bone fracture plate abutment surface. The characteristic line-based parametric design method comprises the following steps: (1) on the basis of a bone model, selecting an abutment surface region of a related bone fracture plate, and reconstructing curved surface characteristics of the selected region on the basis of a characteristic line; (2) defining key points and characteristic points on the characteristic line, wherein the characteristic points are one part of the key points; the key points are used for determining the basic shape of the characteristic line; and the characteristic points are used for defining characteristic parameters; (3) building the characteristic line by a cubic B spline interpolation curve, wherein the characteristic line comprises interpolating points, and defining a few of interpolating points to be the key points by a user; and (4) setting semantic parameters on the basis of the characteristic points, building a constrained relationship between the characteristic points and generating the curved surface characteristics employing the characteristic line as the center. According to the characteristic line-based parametric design method, the bone fracture plate form can be intuitively modified through high-level parameters; a series of diversified bone fracture plates can be generated; the method is of great significance in a bone fracture plate design of a patient in an orthopedic surgery; and the development cycle of a product can be effectively shortened; and the production efficiency can be improved.

Owner:HOHAI UNIV CHANGZHOU

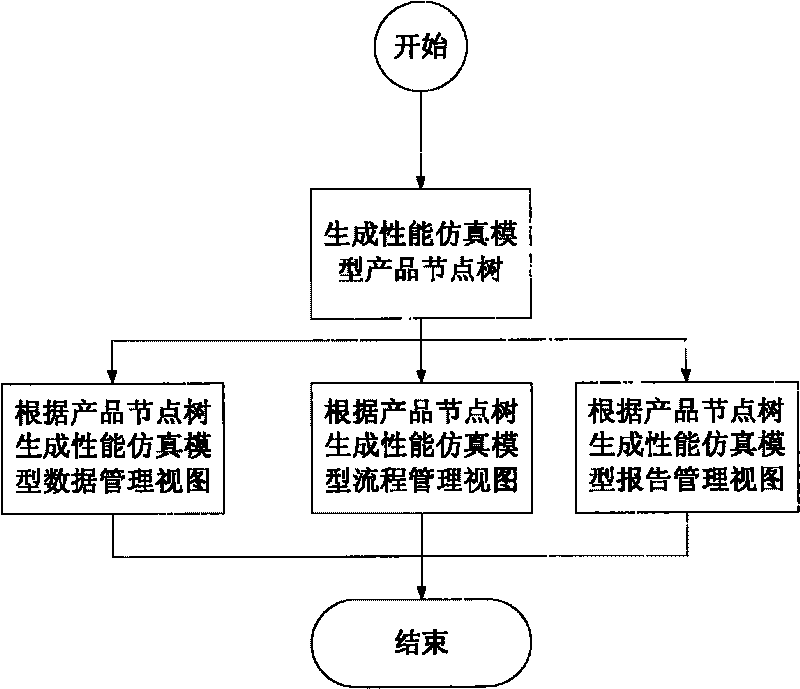

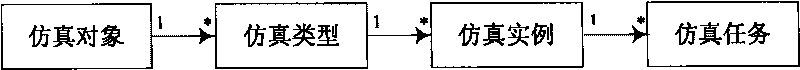

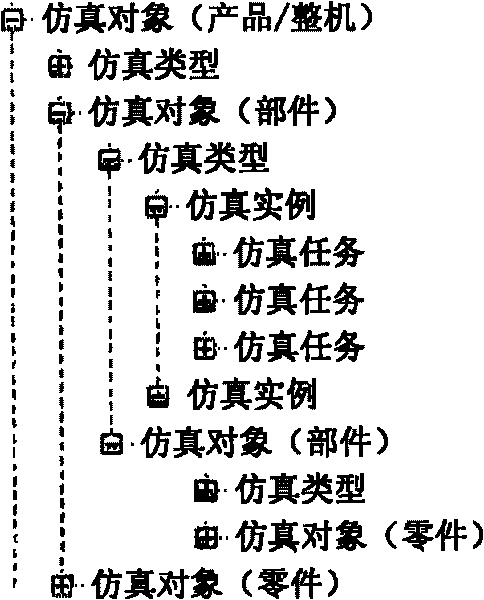

Product node tree based presentation method of product performance simulation information

InactiveCN101706840AEasy to manageConvenient querySpecial data processing applicationsState of artData management

The invention provides a product node tree based presentation method of product performance simulation information, belonging to the technical field of information integration. The method mainly comprises the following steps: 1) generating the product node tree of a performance simulation model; 2) generating a data management page of the performance simulation model; 3) generating a report management page of the performance simulation model; and 4) generating a flow management page of the performance simulation model. The method solves the problem that such cross information as simulation process, tasks, report data and the like can not be expressed in an omnidirectional manner in the prior art, and has the advantages of convenience for managing the performance simulation process and convenience for inquiring the flow execution process at all times, etc.

Owner:XIAN YISHENG INFORMATION TECH

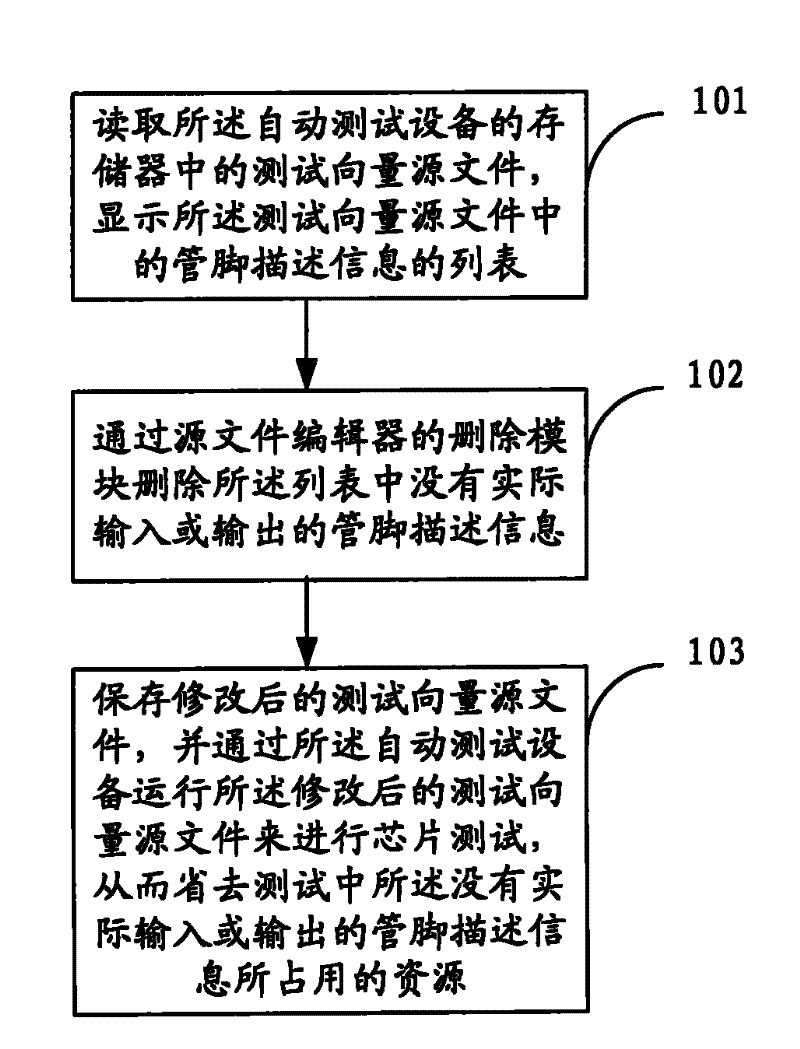

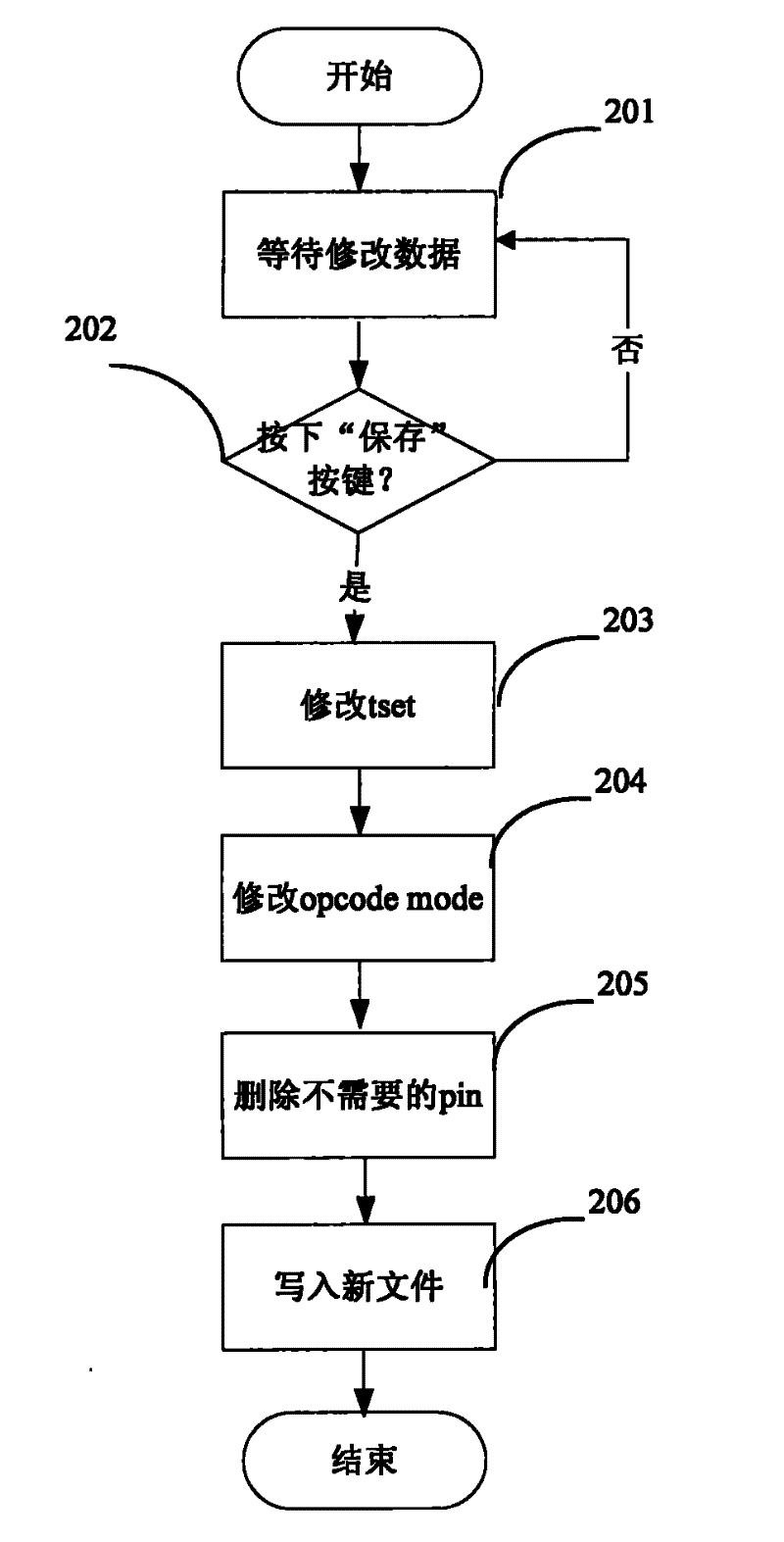

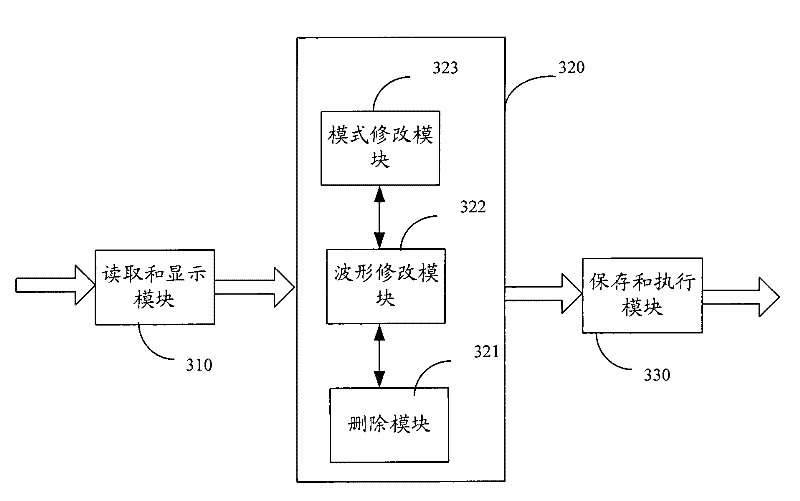

Method and device for testing chip

ActiveCN102236068AMany test resourcesImprove test efficiencyElectronic circuit testingTest efficiencyAutomatic test equipment

The invention provides a method and a device for testing a chip. The method is used for automatic test equipment (ATE) and comprises the following steps of: reading a test vector source file in a memory of the ATE, and displaying a list of pin description information in the test vector source file; deleting pin description information, which is not actually input or output, in the list by using a deletion module of a source file editor; storing the modified test vector source file; and operating the modified test vector source file by using the ATE to test the chip, so that resources occupied by the pin description information which is not actually actual input or output in the test are saved. By the method and the device, the resources of the ATE can be saved, test efficiency is improved, and the technical problems that the test vector source file consumes a large quantity of time and resources and the test efficiency is low in the prior art are solved.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

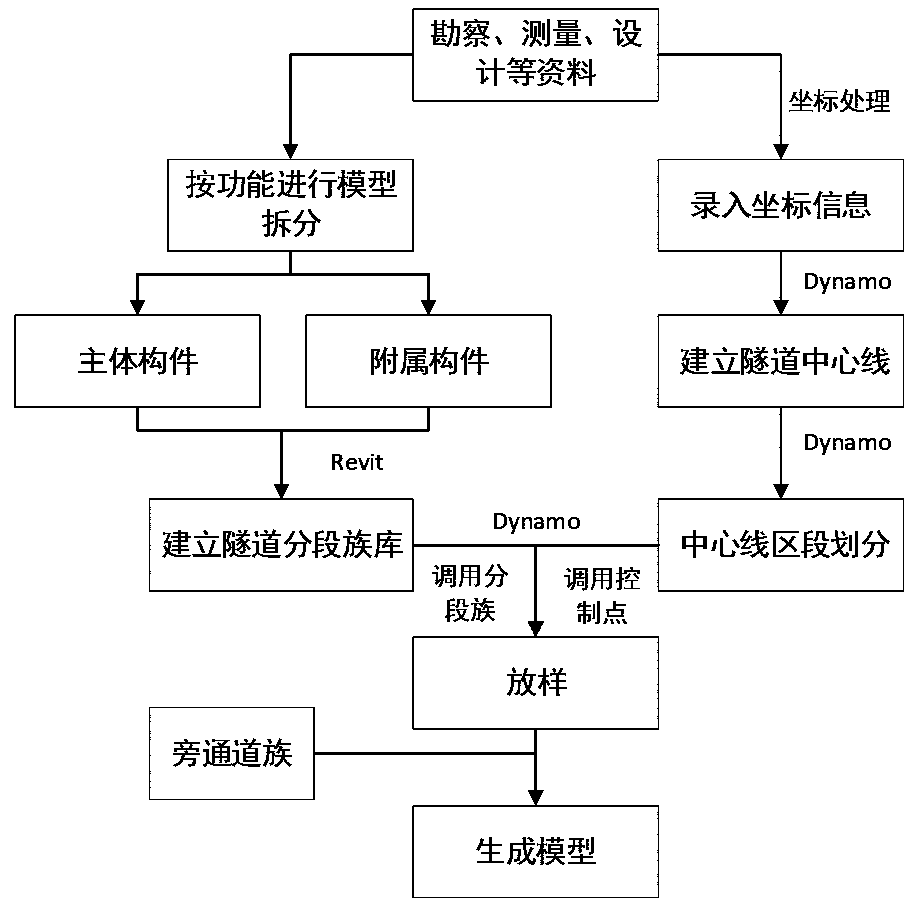

Tunnel structure model modeling method based on Dynamo

The invention discloses a tunnel structure model modeling method based on Dynamo. The method comprises the following steps of obtaining coordinates of center points on a center line of a to-be-built tunnel; opening Revit software, programming by using Dynamo, and reading coordinates of each center point to establish a tunnel center line; dividing the center line of the tunnel into a plurality of sections at equal intervals; according to the segment length and the cross section form of the to-be-built tunnel, building a segment family of the to-be-built tunnel; programming by using Dynamo, andaccording to the tunnel center line and the separation control points on the segments, calling a segment family to instantiate to given separation control point coordinates to generate a tunnel main body structure model; and constructing a bypass channel segment family of the tunnel to be built and instantiating the bypass channel segment family to a control point of a bypass channel to complete the whole tunnel structure model. The method has the advantages that the tunnel structure model is quickly and accurately established on the Revit platform on the basis of the Dynamo visual programmingtool in combination with the structural characteristics of tunnel engineering, the modeling steps of the tunnel structure model are simplified, and the modeling efficiency is improved.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

Method and device for generating multi-level vector diagram

ActiveCN106296773AErasure implementationAchieve the effect of erasingFilling planer surface with attributesBoundary contourVector diagram

The invention provides a method for generating a multi-level vector diagram. The method comprises the steps of: determining a boundary contour of a color filling area of an image; storing the boundary contour and an image attribute of the color filling area, wherein the image attribute is used for determining pixels in the boundary contour. By adopting the method, the pixels within the contour range can be reduced via the contour of the color filling area, so that the effect of modifying the pixels is achieved and the image can be modified more accurately; and because the pixels can be directly operated, processing of complex topological structures can be supported.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

On-line detection and calibration apparatus for oil consumption of automobile

InactiveCN105388026AAccurate modificationReduce consumptionVehicle testingRelative volume flow measurementsControl systemMeasuring instrument

The invention discloses an on-line detection and calibration apparatus for oil consumption of an automobile. The on-line detection and calibration apparatus comprises an on-line calibration device, an automobile diagnosis interface, an oil consumption measuring instrument and a data processing unit. A gear value, engine rotating speed data, throttle data and speed data are read from en engine controller and a gearbox controller by means of an automobile diagnosis interface. Gasoline consumption information is read from the oil consumption measuring instrument. The above read information can be simultaneously transmitted to a laptop through the on-line calibration device, an automobile engineer calculates current gasoline consumption through a logic way according to all the read information in the laptop, and then a parameter correction instruction is emitted. In this way, the engineer obtains current oil consumption in real time from an automobile, updates corrected control parameters in a control system for an engine or a gearbox, also obtains running information of the automobile, and corrects the parameters more accurately. Furthermore, on-line repeatedly debugging can be conducted quickly, and the work efficiency can be effectively improved.

Owner:SHENGRUI TRANSMISSION

Echo processing method and device

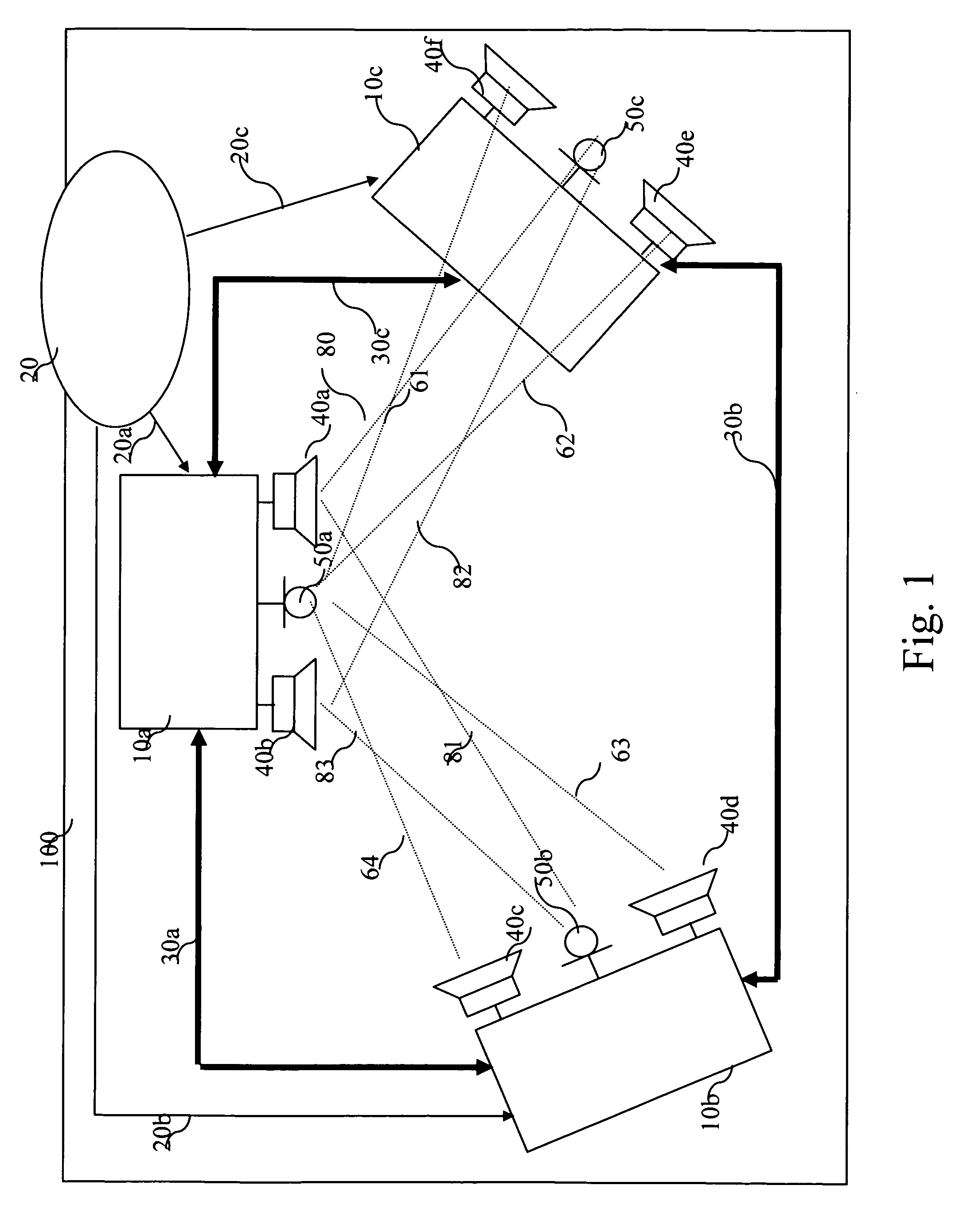

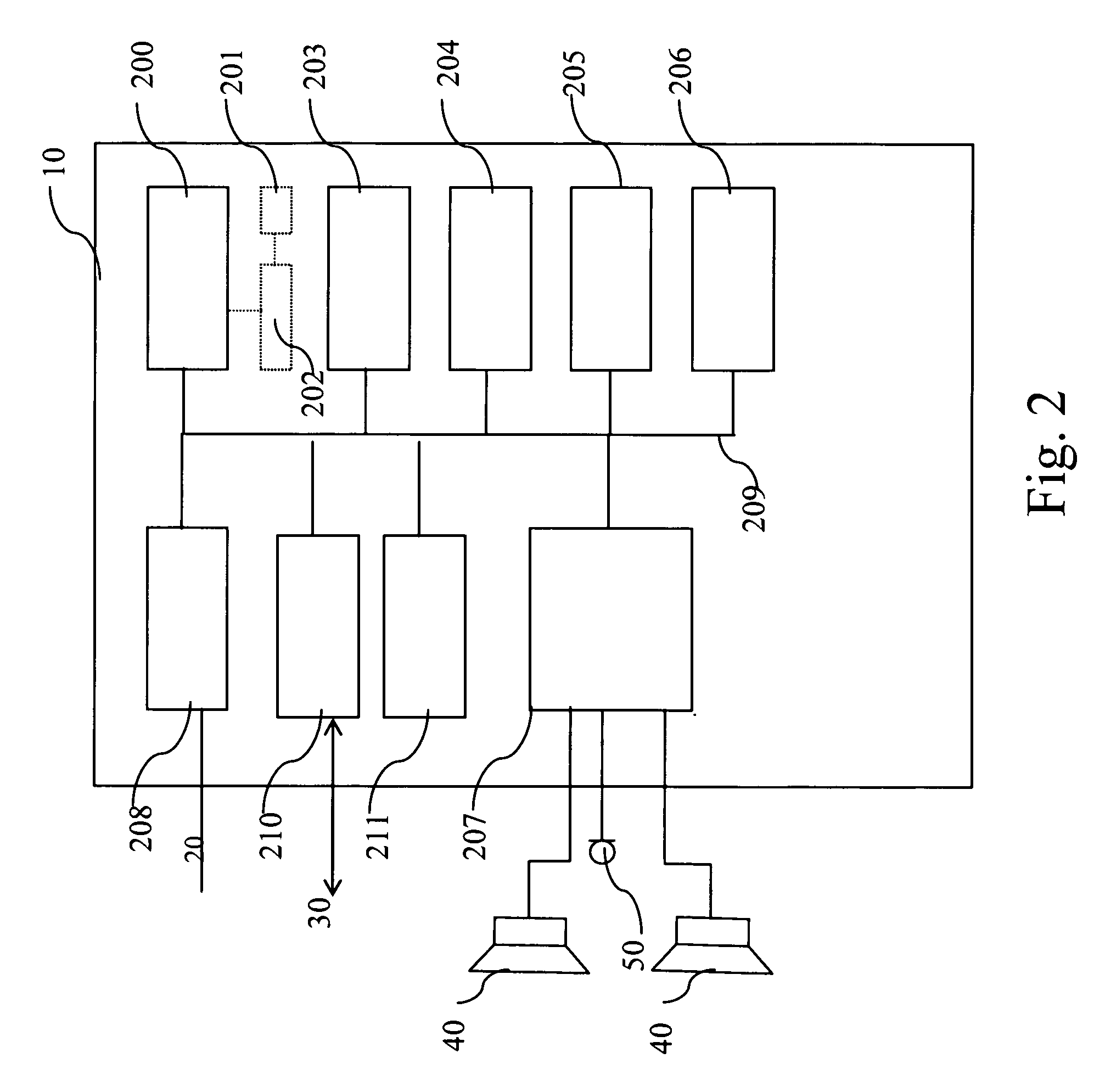

InactiveUS20060177045A1Great energySimple and effective modificationTwo-way loud-speaking telephone systemsEar treatmentLoudspeakerMicrophone

Owner:FRANCE TELECOM SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com