Skin process model correction method based on workpart point cloud model

A technology of point cloud model and process model, which is applied in the field of aircraft manufacturing, can solve the problems of large springback, large deviation and difficulty in meeting precision requirements of skin parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

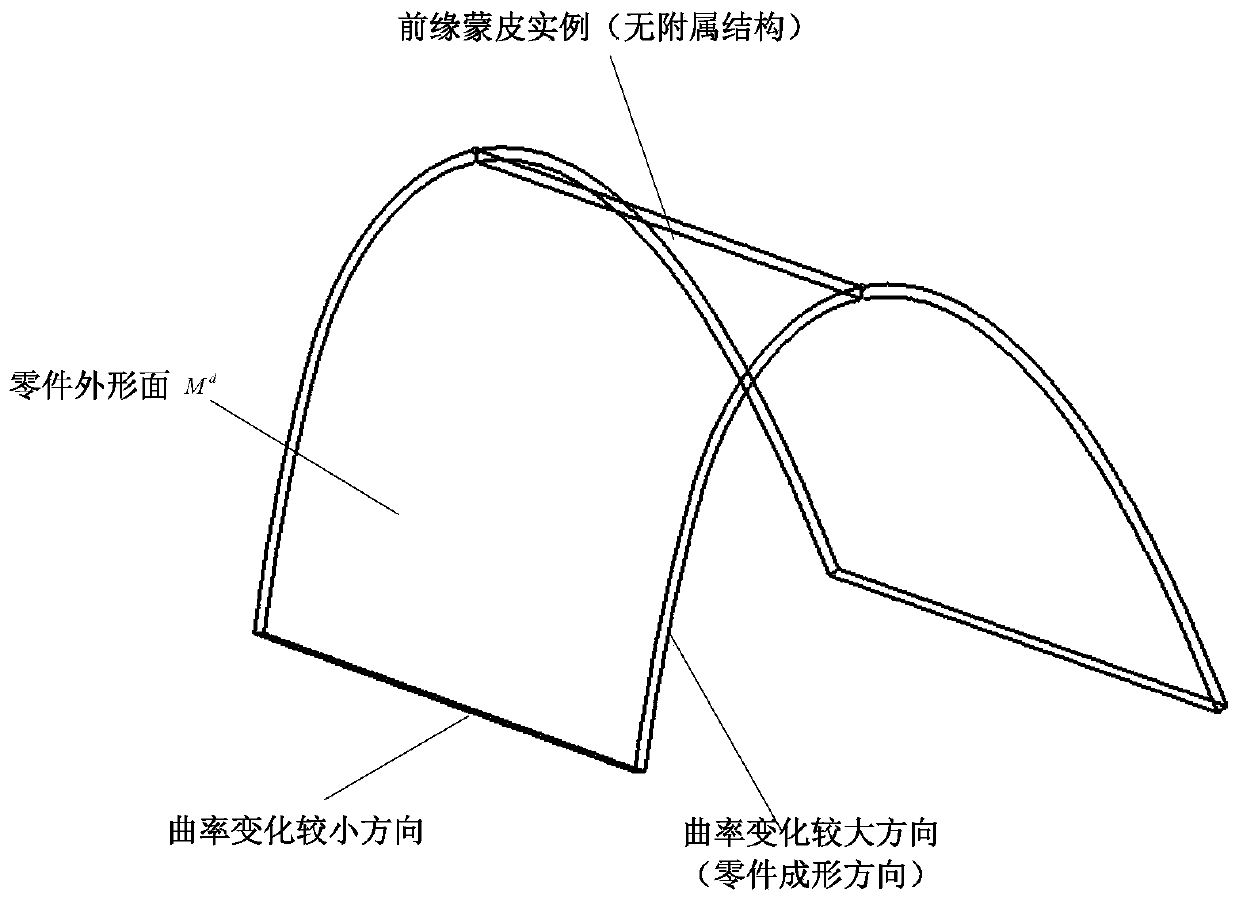

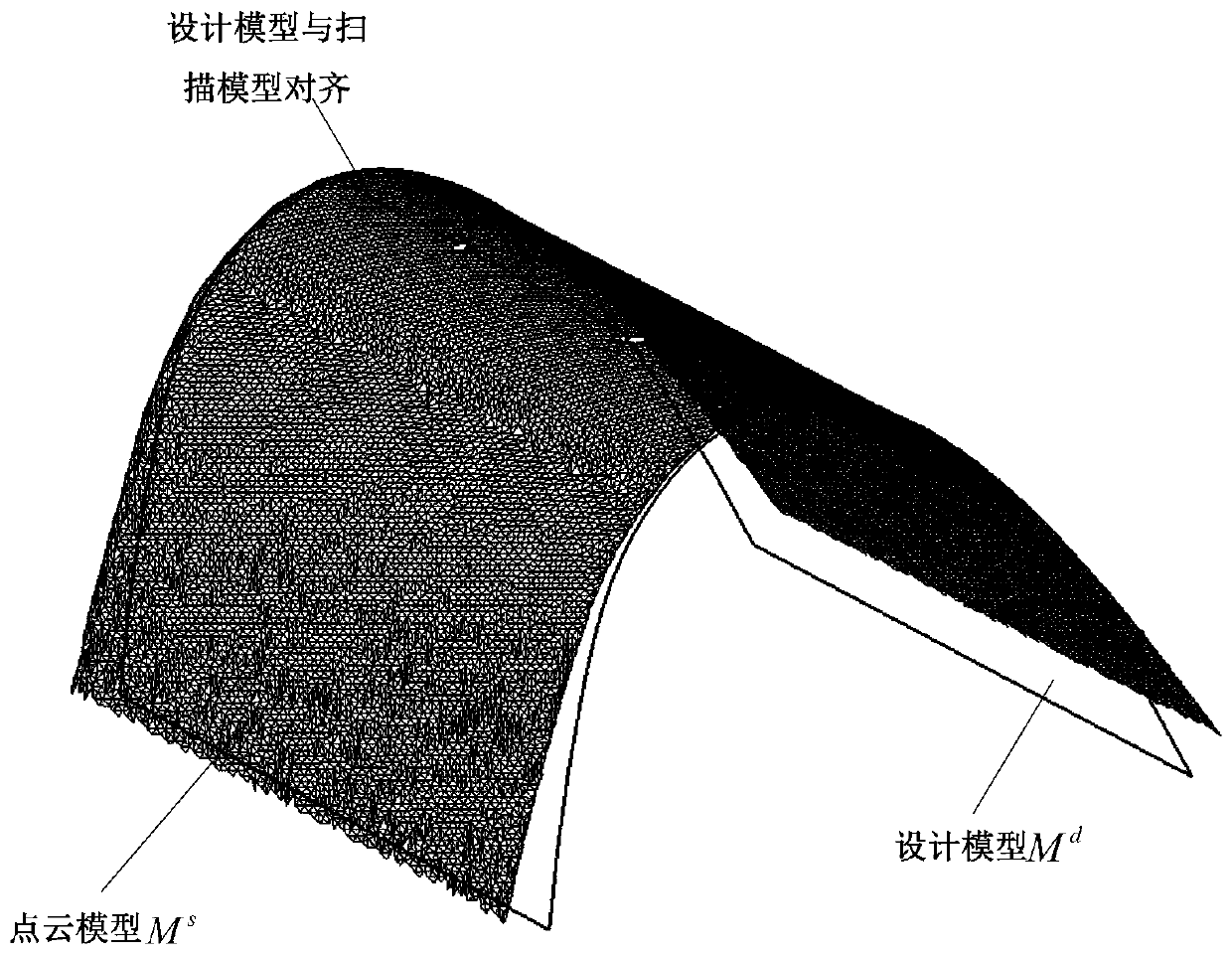

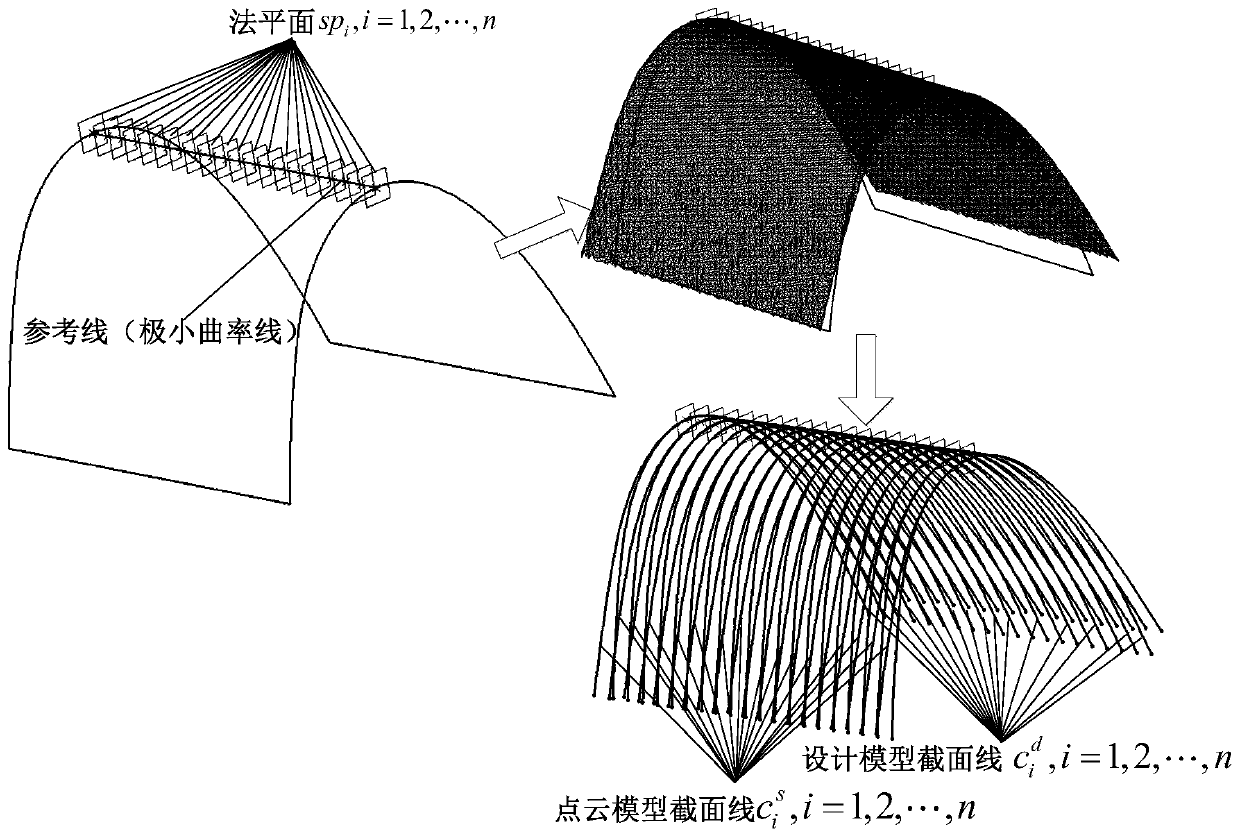

[0055] In order to realize the precise forming of the skin part, the invention proposes a method for correcting the skin process model based on the three-dimensional scanning of the workpiece. This method processes the workpiece point cloud and refers to the design model for equal-length cutting, then aligns it with the design model. Create a reference line and a reference plane group, intersect the reference plane group with the point cloud model of the workpiece and the design model to obtain a cross-section line group, and then discretize the cross-section line group to obtain two corresponding discrete point groups, and establish a calculation formula for discrete curvature, using The formula calculates the discrete curvature of each discrete point, and calculates the discrete curvature value of the compensated point through the compensation formula. Using the position of the discrete point of the design model section line and the discrete curvature value of the discrete p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com