Characteristic line-based parametric design method for bone fracture plate abutment surface

A parametric design and feature line technology, applied in special data processing applications, calculations, electrical digital data processing, etc., can solve the problems of low efficiency, time-consuming and laborious operation, and unsatisfactory operation, so as to improve the surgical effect and improve the design efficiency. and the effect of diverse designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

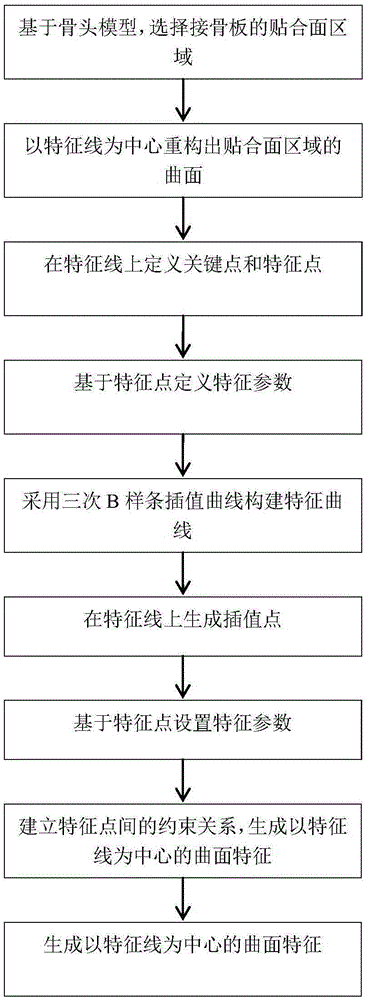

[0028] refer to figure 1 As shown, the parametric design method of bone plate fitting surface based on feature lines includes the following steps:

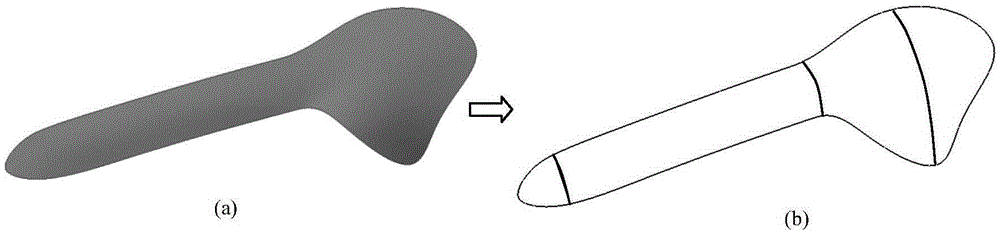

[0029] Step 1: Based on the bone model, select the fitting surface area of the involved bone plate, and reconstruct the surface features of the selected area based on the feature line.

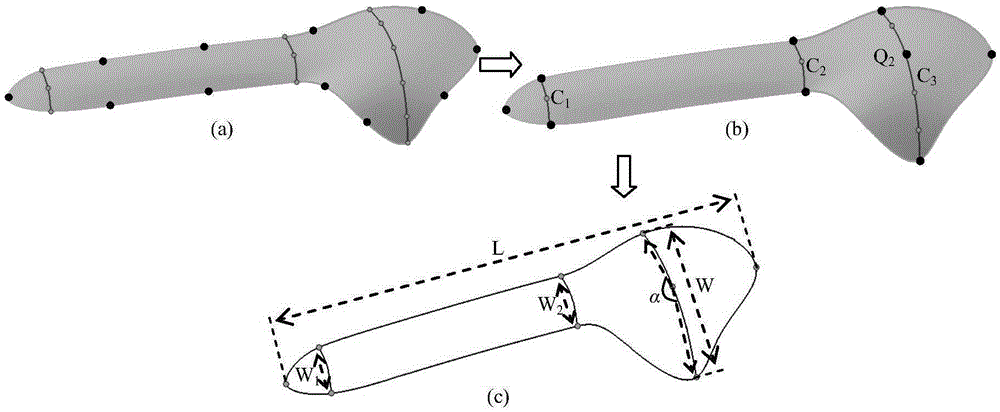

[0030] Step 1a: Select the bone plate fitting surface area, define the interpolation points on the boundary to enclose the contour shape of the area boundary, and use the B-spline interpolation curve to generate the boundary curve;

[0031] The bonding surface area includes: boundary feature lines and internal constraint feature lines; the boundary feature lines determine the area range and size of the bonding surface, and the internal constraint lines affect the internal local detail shape of the curved s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com