Two-dimensional cam part shape digital measurement method based on profile

A measurement method and profile technology, applied in the field of measurement, can solve the problems of production cost and long cycle, little reference value, and low measurement efficiency, and achieve the effect of reducing the machining adjustment cycle, improving measurement efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

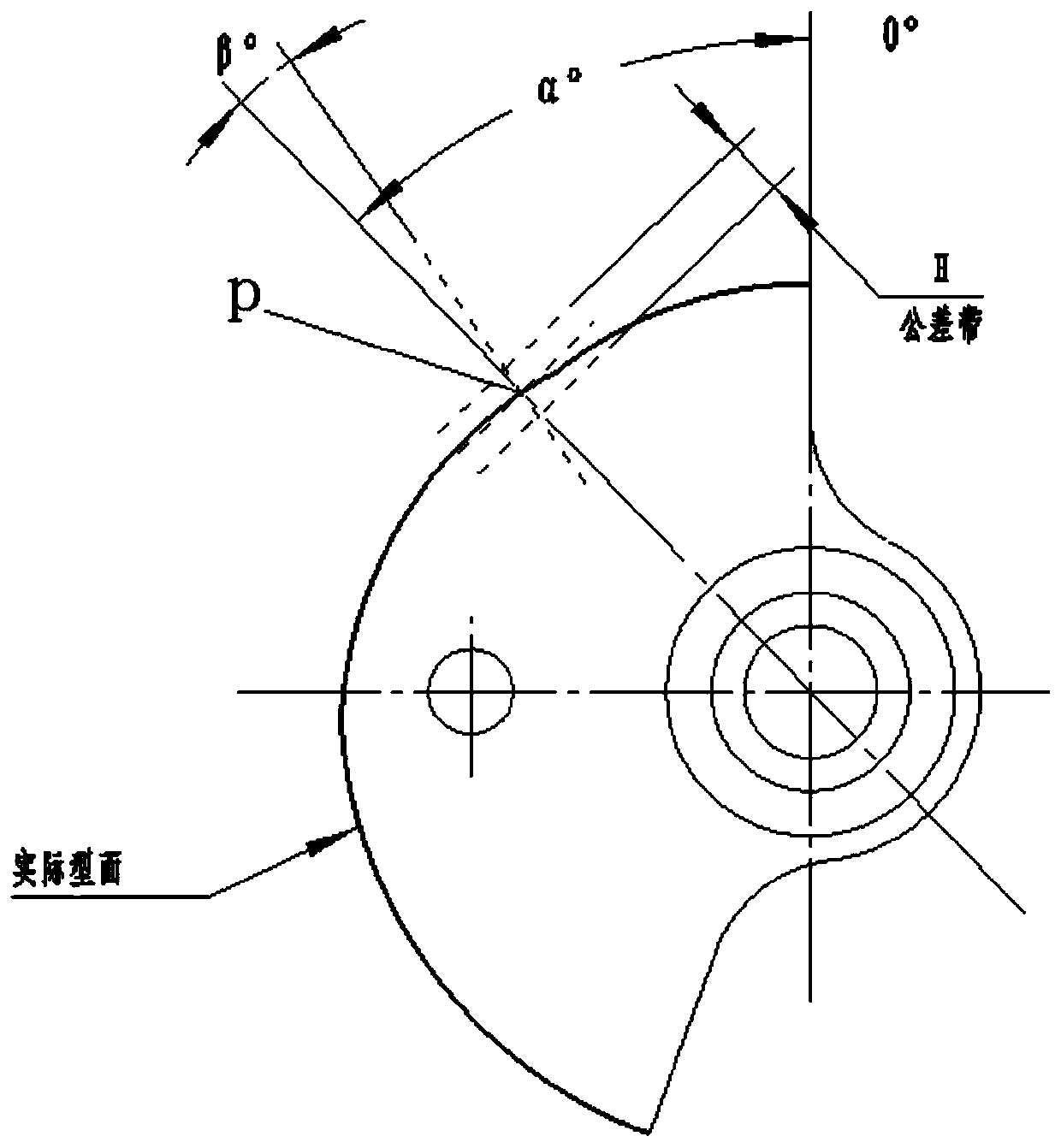

[0028] The present invention establishes a high-precision cam mathematical model, reasonably converts the polar radius measurement tolerance zone into a contour tolerance zone, and uses digital technology to measure the cam profile by using a three-coordinate measuring machine through off-line measurement program + on-line detection. Points to measure the vector direction deviation, so that the measurement conclusion conforms to the real margin of the cam profile, improves the measurement efficiency of the cam profile, reduces the machining adjustment cycle, and achieves the purpose of reducing production costs.

[0029] The technical scheme provided by the present invention will be described in detail below in conjunction with embodiment:

[0030] The contour-based two-dimensional cam type part profile digital measurement method provided by the present invention comprises the following steps:

[0031] 1) Establish a digital measurement model of the two-dimensional cam part pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com