Real-time liquid level meter capable of automatically recording highest position and lowest position of past floating

An automatic recording and highest level technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of no recording function and inability to check the equipment, etc., to achieve the effect of complete functions, fast reset and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

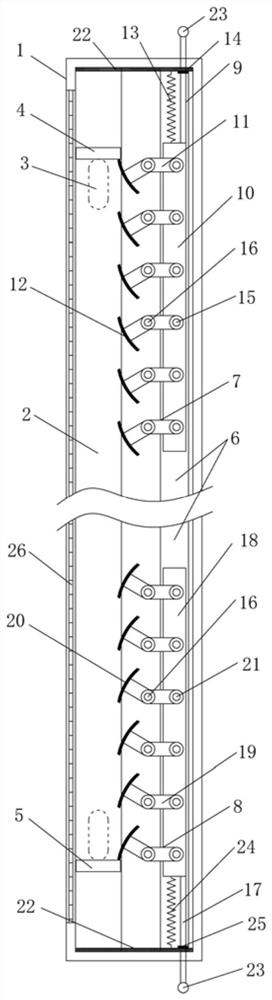

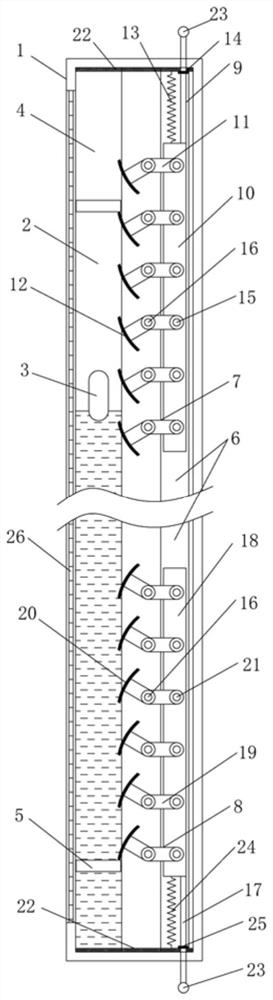

[0039] Embodiment 1-record liquid level change: After installing and connecting the real-time liquid level gauge of the present invention, which automatically records the highest and lowest floating positions in the past, to the monitored equipment, turn on the starting equipment, and the present invention begins to record the working liquid level of the equipment ,Such as Figure 2-3 As shown, when the liquid level of the equipment rises, the float 3 rises with the liquid level, and the float 3 drives the high-level recording part 4 to move upward along the floating tank 2, and the high-level recording part 4 pushes against the upper end of the float 3 and moves together. Floating up, when the rear end of the high-position recording part 4 passes the high-position limit block 12, the upward force of the float 3 makes the high-position recording part 4 slide and move upward along the front end surface of the high-position limit block 12, due to the high-position limit block Th...

Embodiment 2

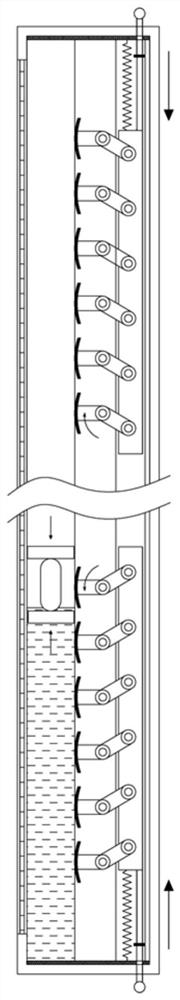

[0043] Embodiment 2 - Operation of resetting the liquid level gauge: when the liquid level data record of the equipment is obtained, a reset operation is required.

[0044] First reset the high limit mechanism, such as Figure 6 As shown, the high position reset connecting rod 9 is pressed down through the grip part 23, so that the high position reset guide plate 10 slides down and moves along the sliding groove 6, and the rear end of the high position limit connecting rod 11 is driven to rotate along the first movable moving pin 15, and at the same time The high position limit connecting rod 11 lifts upwards along the fixed movable bolt 16 in the center, lifts the high position limit retainer 12 until the inner wall of the floating groove 2 is flush, because there is no blocking of the high position limit retainer 12, the high position recording part 4 It falls to the top of the float 3 under the action of gravity, and the reset of the high-level recording part 4 is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com