Liquid crystal diaphragm cutting method and finished liquid crystal diaphragm

A cutting method and technology of liquid crystal film, applied in nonlinear optics, instruments, optics, etc., can solve the problems of easy bursting and short circuit of liquid crystal film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

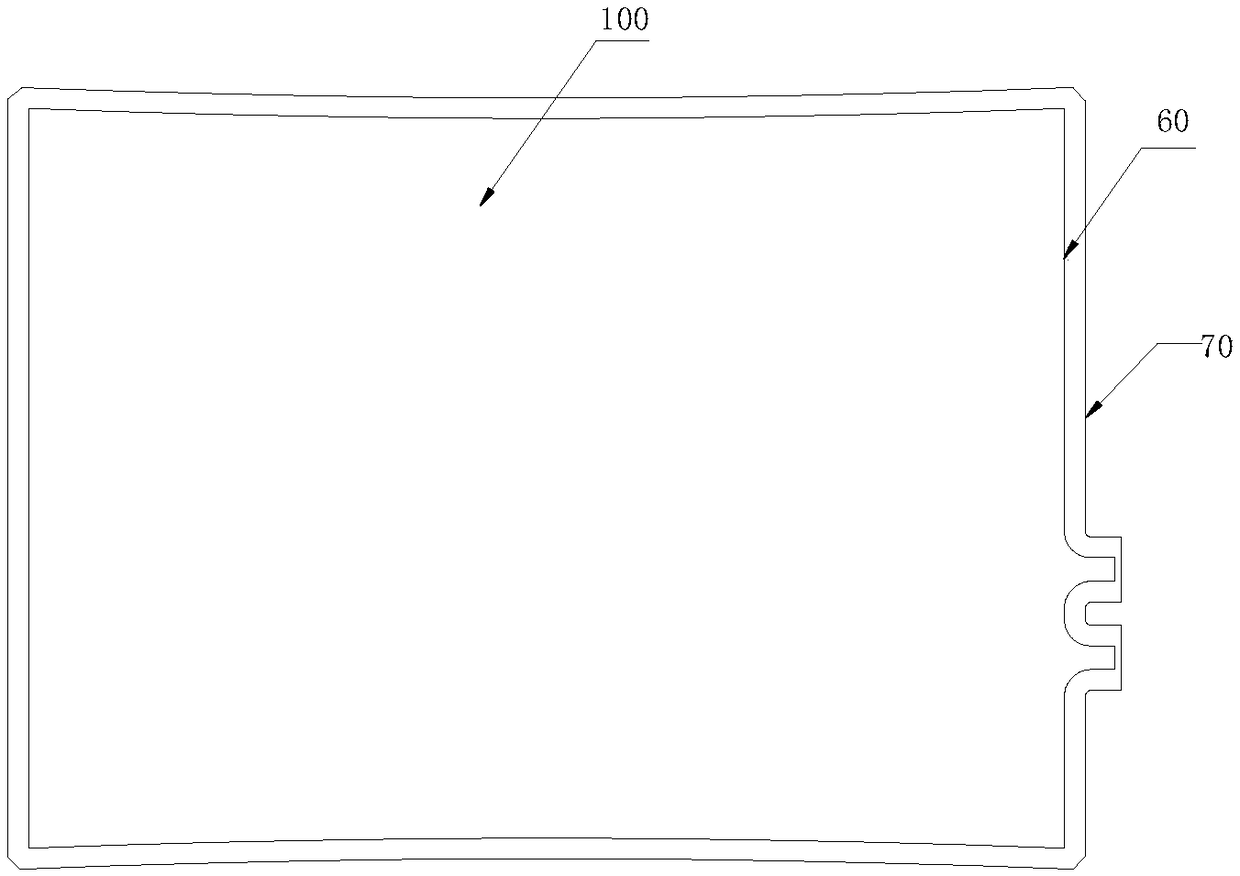

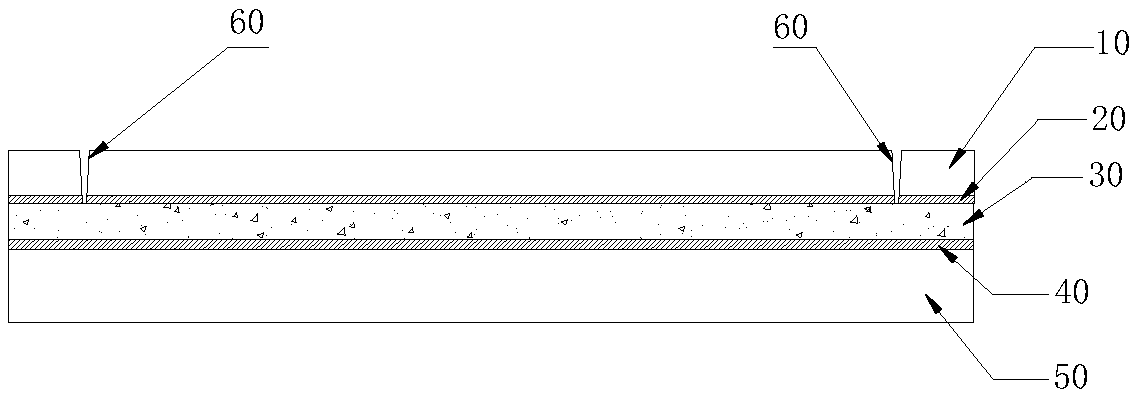

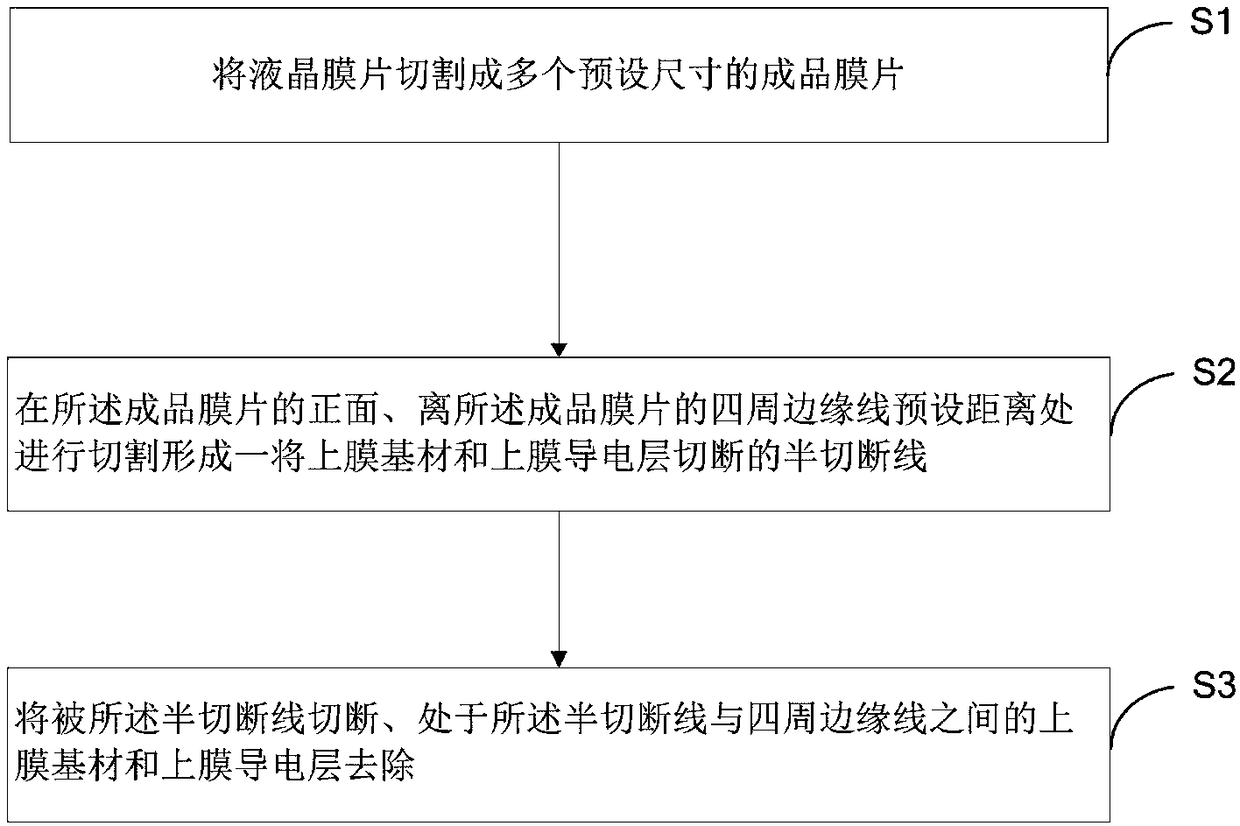

[0024] Such as figure 1 and figure 2 As shown, in one embodiment of the present invention, the finished liquid crystal diaphragm includes a diaphragm body 100, and the diaphragm body 100 includes an upper film base material 10, an upper film conductive layer, and an upper film conductive layer arranged sequentially from top to bottom. 20. The liquid crystal layer 30, the lower film conductive layer 40 and the lower film substrate 50. On the front of the diaphragm body 100, an upper film substrate is formed at a predetermined distance from the peripheral edge line 70 of the diaphragm body 100. 10 and the half-cut line 60 cut off by the upper film conductive layer 20. The upper conductive layer 20 and the lower con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com