High-strength low-crack sensitive slab and manufacture method thereof

A manufacturing method and a sensitive technology, applied in the field of high-strength structural steel and its preparation, can solve the problems of adverse effects on the welding performance of steel plates, high production process costs, and affecting production rhythms, and achieve less precious elements, high production efficiency, and high production efficiency. The effect of process reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The components contained in the high-strength and low-crack-sensitivity thick plate and their weight percentages are: C 0.06%, Si0.24%, Mn 1.42%, P 0.016%, S 0.0013%, Cr 0.11%, Ni 0.18%, Al 0.04 %, Cu 0.19%, Nb 0.03%, Ti 0.015%, V 0.03%, N 0.0033, and the balance is iron and unavoidable impurity elements.

[0050] The production process of the high strength and low crack sensitivity thick plate is as follows:

[0051] The smelting raw materials are configured according to the chemical composition of the above-mentioned thick plates, followed by converter smelting-LF refining-RH vacuum degassing-continuous casting-continuous casting billet (thickness 220mm)-heating (insulation treatment)-high pressure water descaling-controlled rolling, controlled Cold - straightened - air cooled to room temperature - finished product.

[0052] Further speaking, the specific processes of the above heat preservation treatment, controlled rolling and controlled cooling stages are as follo...

Embodiment 2

[0056] The components contained in the high-strength and low-crack-sensitivity thick plate and their weight percentages are: C 0.06%, Si0.19%, Mn 1.47%, P 0.008%, S 0.0023%, Cr 0.11%, Ni 0.18%, Al 0.04 %, Cu 0.18%, Nb 0.03%, Ti 0.013%, V 0.03%, N 0.0044, and the balance is iron and unavoidable impurity elements.

[0057] The production process of the 420MPa grade low crack sensitivity thick plate is basically the same as that of Example 1, but there are differences in the processes of the controlled rolling and controlled cooling stages, as follows:

[0058] In the two-stage rolling process, the starting temperature of the first-stage rough rolling is 1016°C, and the thickness of the intermediate billet is 120mm; the starting temperature of the second-stage finish rolling is 859°C, and the final plate thickness is 50mm; Speed cooling to a temperature of 521°C and then air cooling.

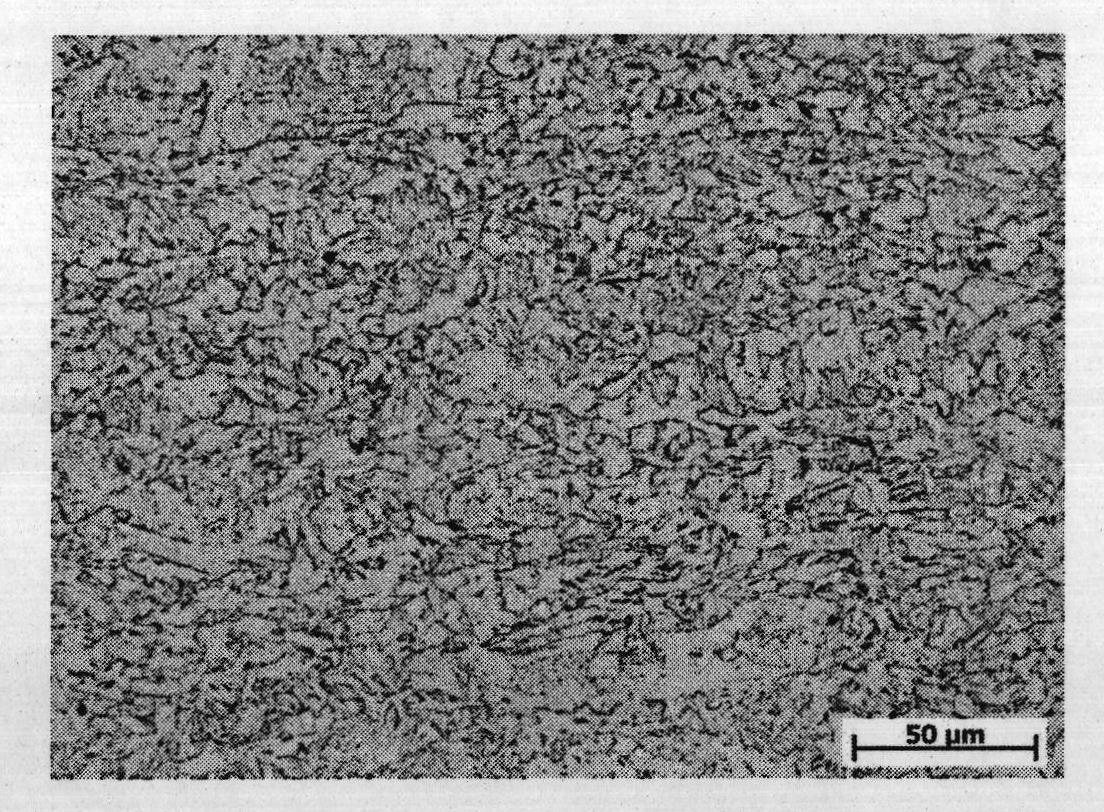

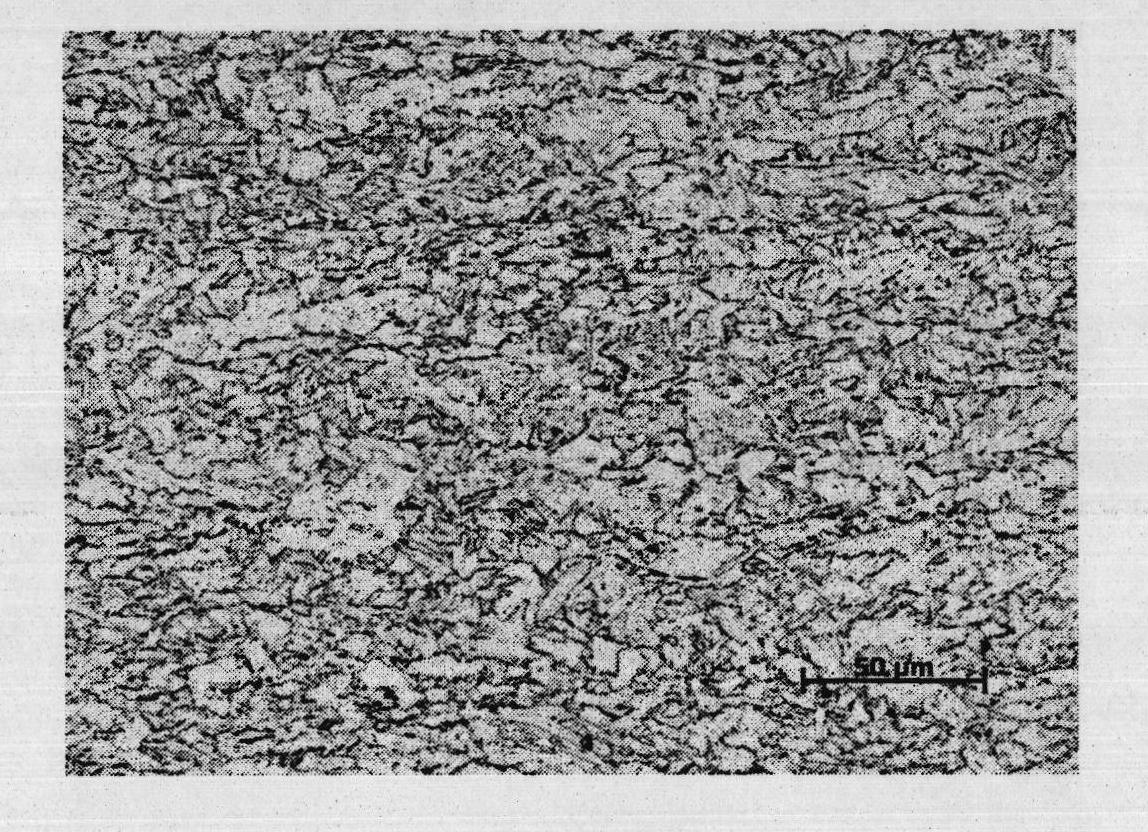

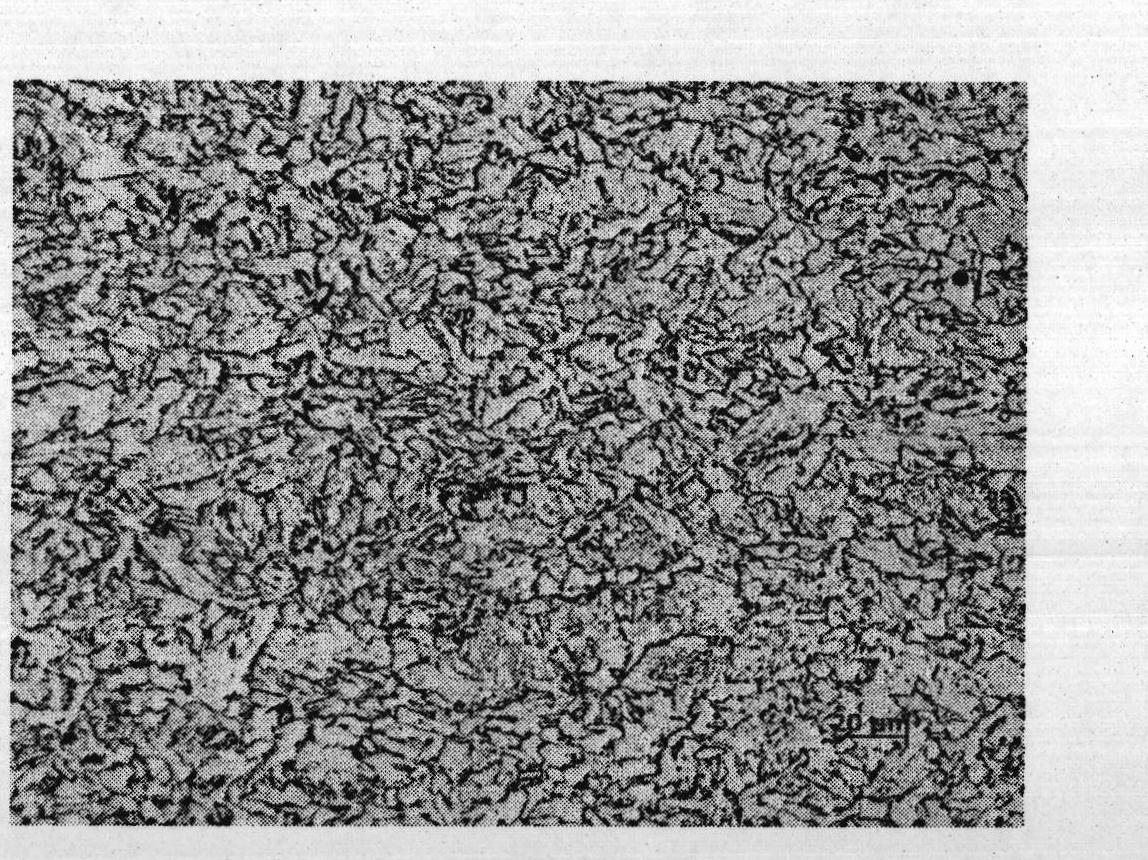

[0059] The metallographic structure of the finished product formed through the above-mention...

Embodiment 3

[0061] The components contained in the high-strength and low-crack-sensitivity thick plate and their weight percentages are: C 0.07%, Si0.21%, Mn 1.35%, P 0.016%, S 0.0018%, Cr 0.14%, Ni 0.18%, Al 0.04 %, Cu 0.18%, Nb 0.03%, Ti 0.015%, V 0.03%, N 0.0027, and the balance is iron and unavoidable impurity elements.

[0062] The production process of the high strength and low crack sensitivity thick plate is as follows:

[0063] The smelting raw materials are configured according to the chemical composition of the above-mentioned thick plates, followed by converter smelting-LF refining-RH vacuum degassing-continuous casting-continuous casting billet (thickness 320mm)-heating (insulation treatment)-high pressure water descaling-controlled rolling, controlled Cold - straightened - air cooled to room temperature - finished product.

[0064] Further speaking, the specific processes of the above heat preservation treatment, controlled rolling and controlled cooling stages are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com