Patents

Literature

82results about How to "Not easy to grow up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-sintering catalyst for preparing low-carbon olefin by low-carbon alkane dehydrogenation and preparation method thereof

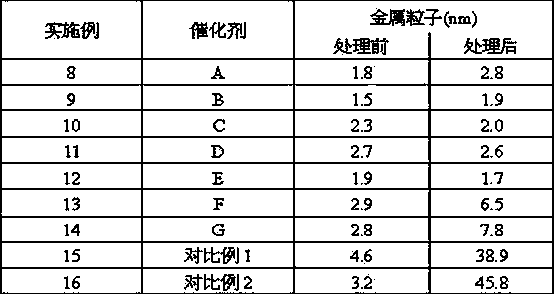

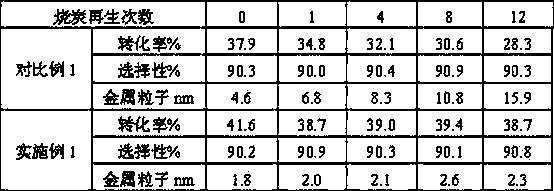

ActiveCN103418376AReduce aggregationImprove anti-coking performanceHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneWater vapor

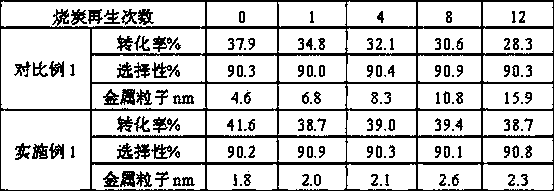

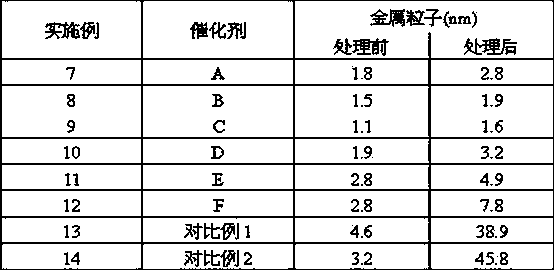

The invention relates to a platinum-tin catalyst of low-carbon alkane dehydrogenation and a preparation method thereof, and mainly solves the problem that in the prior art, in high temperature and carbon burning processes of a catalyst, metal platinum particles are easy to coalesce to grow up to affect the stability of the catalyst. According to the platinum-tin catalyst of low-carbon alkane dehydrogenation and the preparation method thereof, a technical scheme is adopted to well solve the problem, the technical scheme is shown as follows: first introducing assistants of alkalinous metals such as calcium, magnesium and the like into an alumina carrier by a coprecipitation method to get a compound metal oxide carrier, then using a dipping method to load tin and platinum components, namely dipping an aqueous solution of soluble salts of the platinum and tin components, and thus obtaining the platinum-tin catalyst by drying, roasting and water vapor treatment. The platinum-tin catalyst of low-carbon alkane dehydrogenation and the preparation method thereof can be used in industrial preparation of the catalyst for preparing low-carbon olefin by low-carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

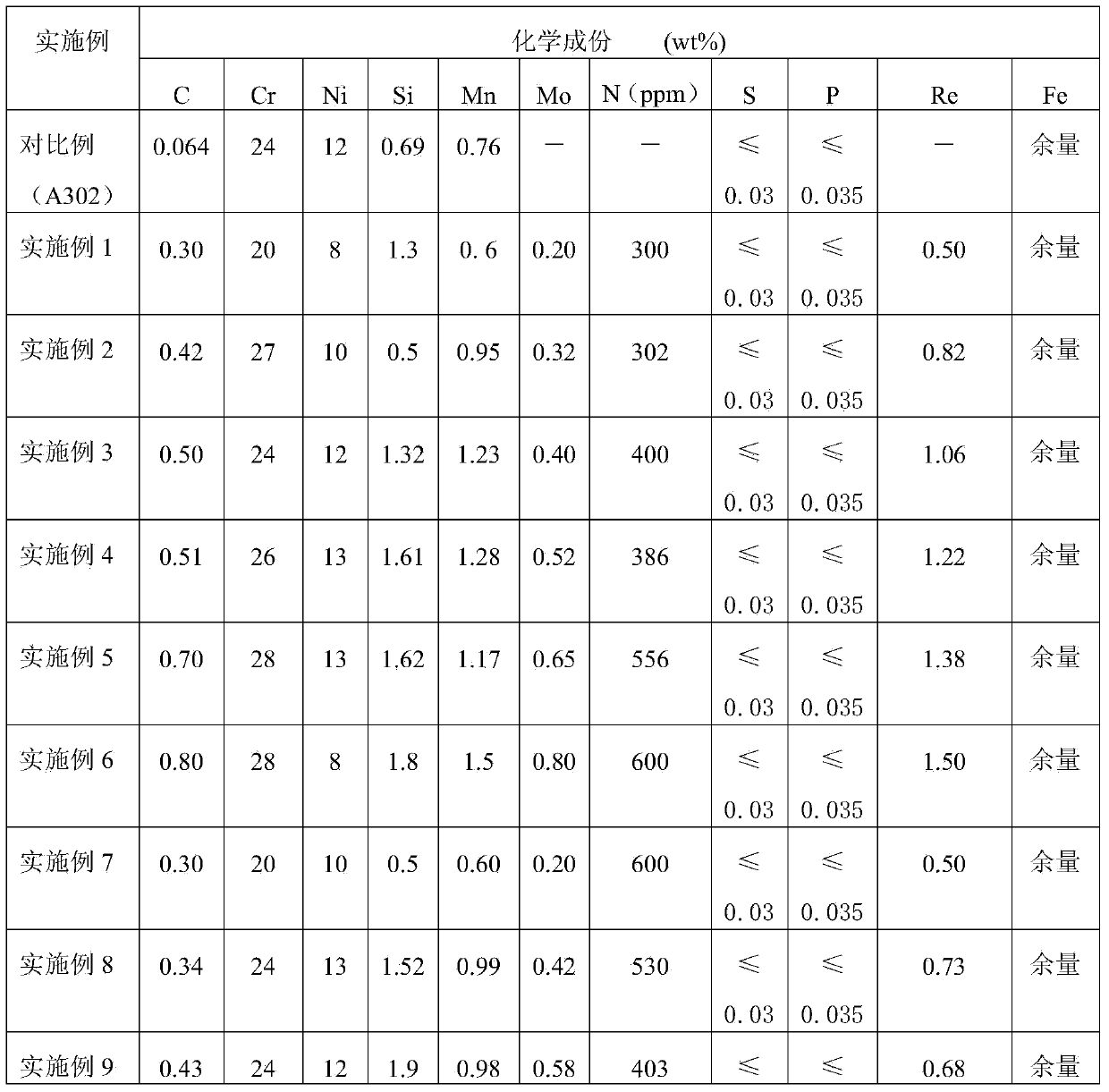

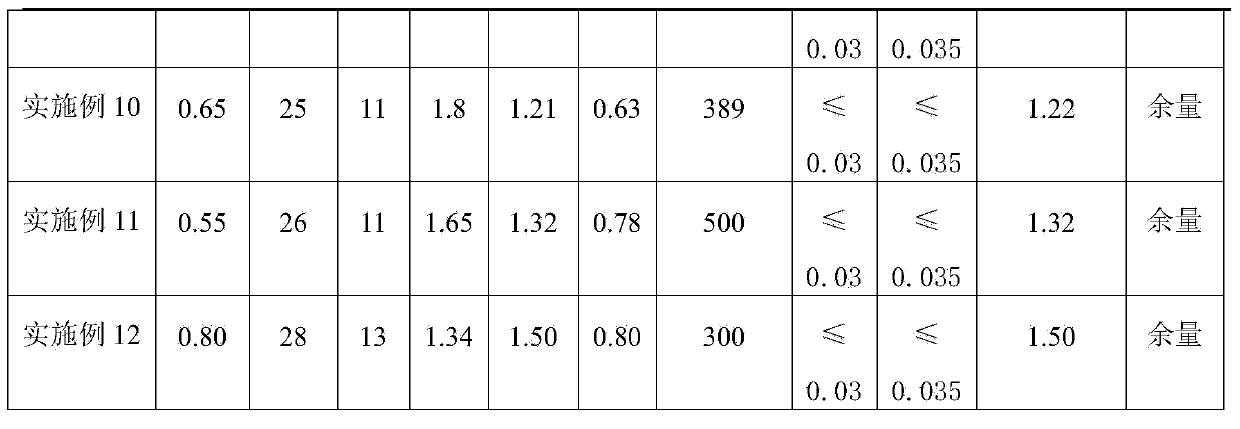

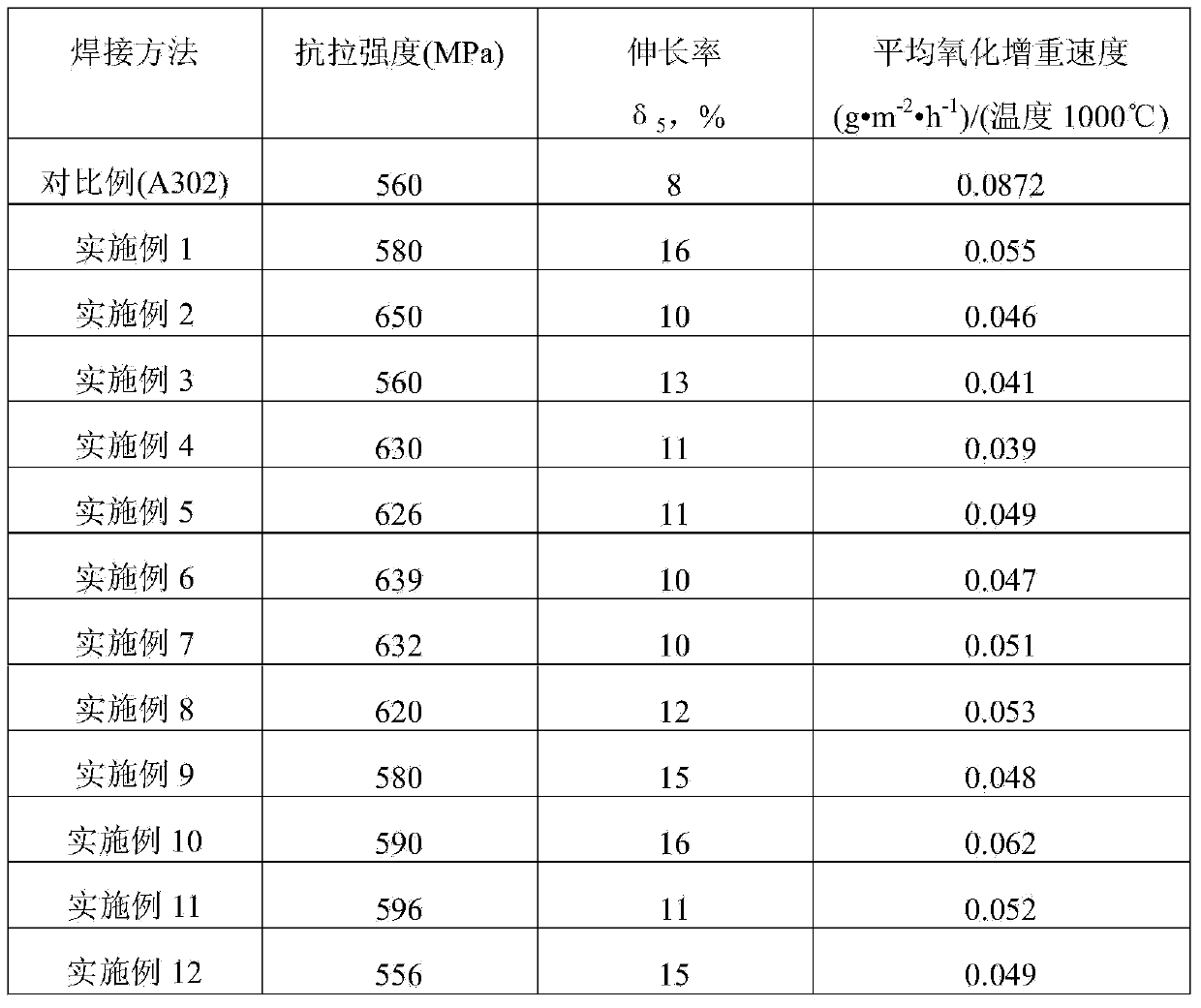

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

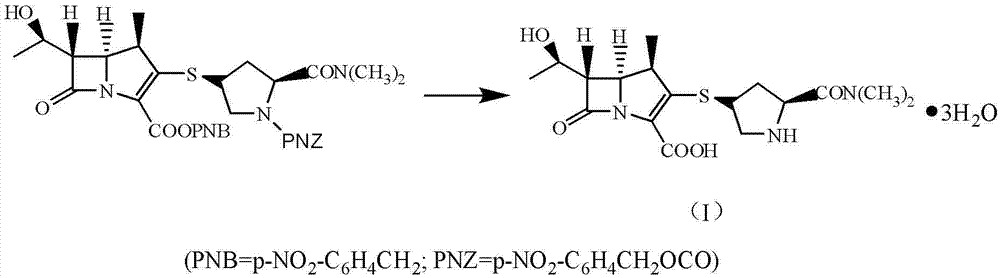

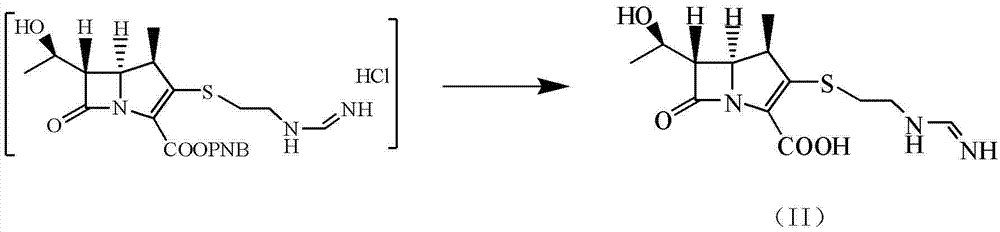

Preparation method of high-activity palladium-carbon catalyst for synthesis of imipenem antibiotics

InactiveCN103041805AImprove effective utilizationLarge diameterOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActivated carbonActive component

The invention relates to a preparation method of a high-activity palladium-carbon catalyst for synthesis of imipenem antibiotics. According to the preparation method of the high-activity palladium-carbon catalyst for the synthesis of the imipenem antibiotics, ammonium chloropalladite and salts thereof are taken as precursor compounds of an active component, namely palladium, powdered activated carbon is taken as a carrier, additives such as sodium citrate are added into Pd impregnation liquid, and then the Pd impregnation liquid is absorbed onto the activated carbon in a segmenting manner and subjected to wet chemical reduction to obtain the high-activity palladium-carbon catalyst; and the catalyst is used for industrial production of the synthesis of the imipenem antibiotics.

Owner:SINO PLATINUM METALS CO LTD

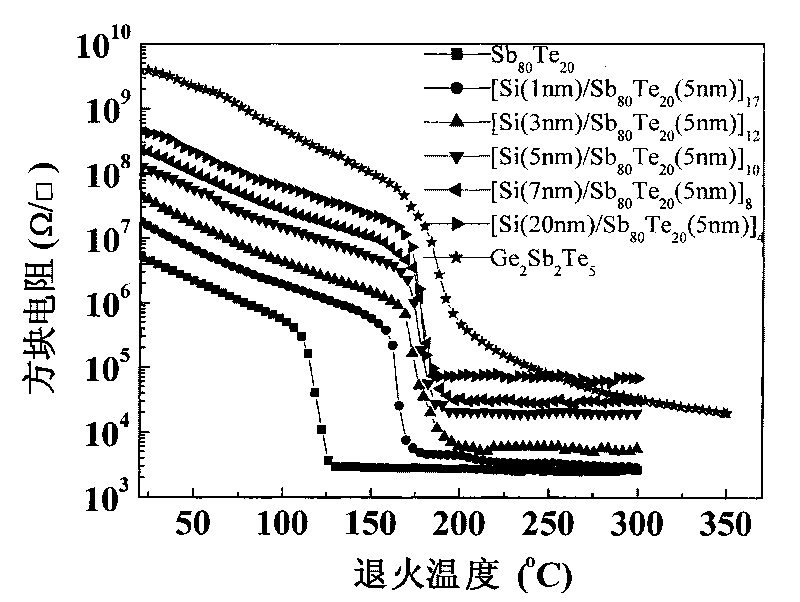

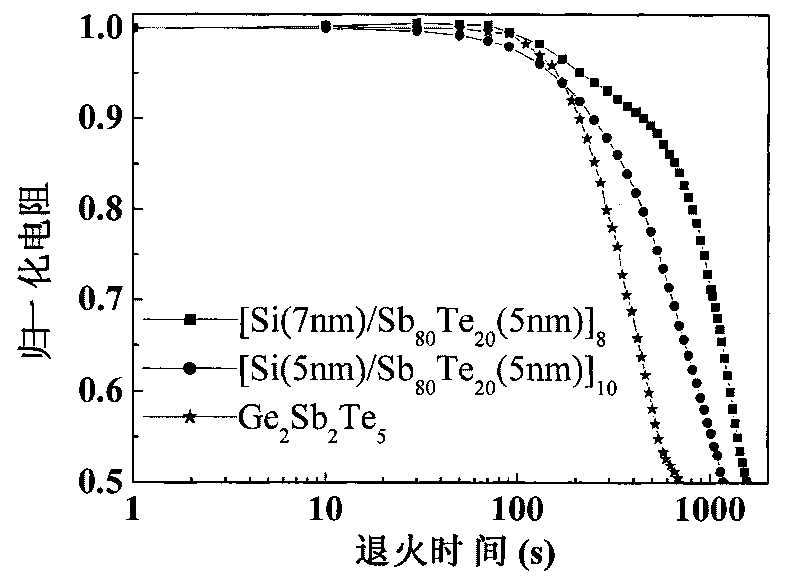

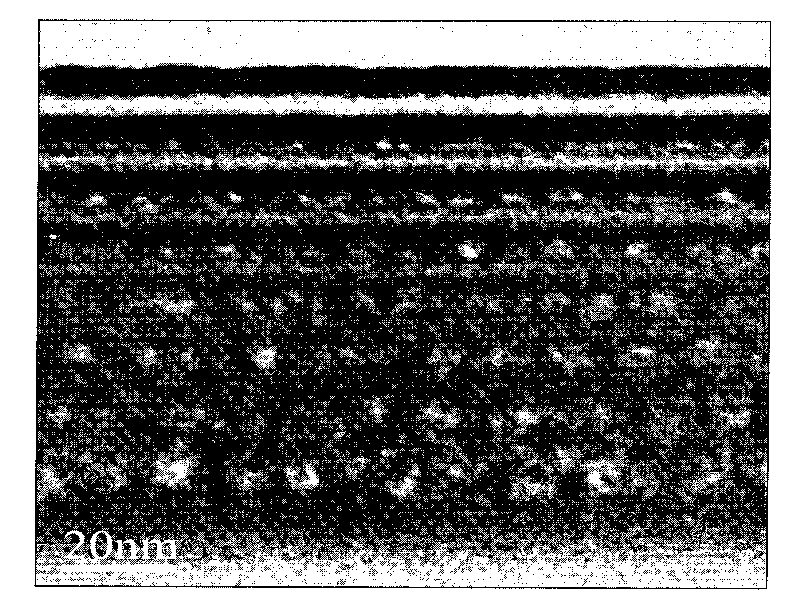

Si/Sb80Te20 nanometer compound multi-layer phase change film and method for preparing same

InactiveCN101714610ATake advantage of thermal stabilityImprove thermal stabilityElectrical apparatusCrystallization temperaturePhase change

The invention relates to a Si / Sb80Te20 nanometer compound multi-layer phase change film and a method for preparing the same. The phase change film is prepared by alternately arranging and compounding Si films and Sb80Te20 films in nanometer scale, wherein the Si films separates all layers of the Sb80Te20 films to form a multi-layer film structure. The phase change film has the advantages that: (1) the crystallization temperature of the phase change film rises with the increase of the thickness of the Si film, and when the thickness of the Si film is over 5nm, the crystallization temperature of the phase change film is basically constant; (2) the separation action of the Si films on the Sb80Te20 films improves the thermal stability of the phase change film, and the temperature area where the phase change film is crystallized is very narrow, which shows that the phase change speed is very high; and (3) the crystalline state resistance of the phase change film increases with the increase of the thickness of the Si film, which facilitates the reduction of the operational power consumption in a programming process of a PCRAM device.

Owner:TONGJI UNIV

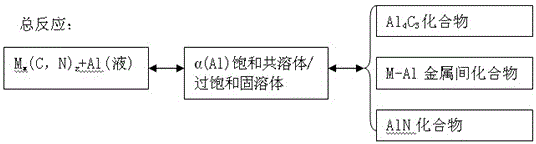

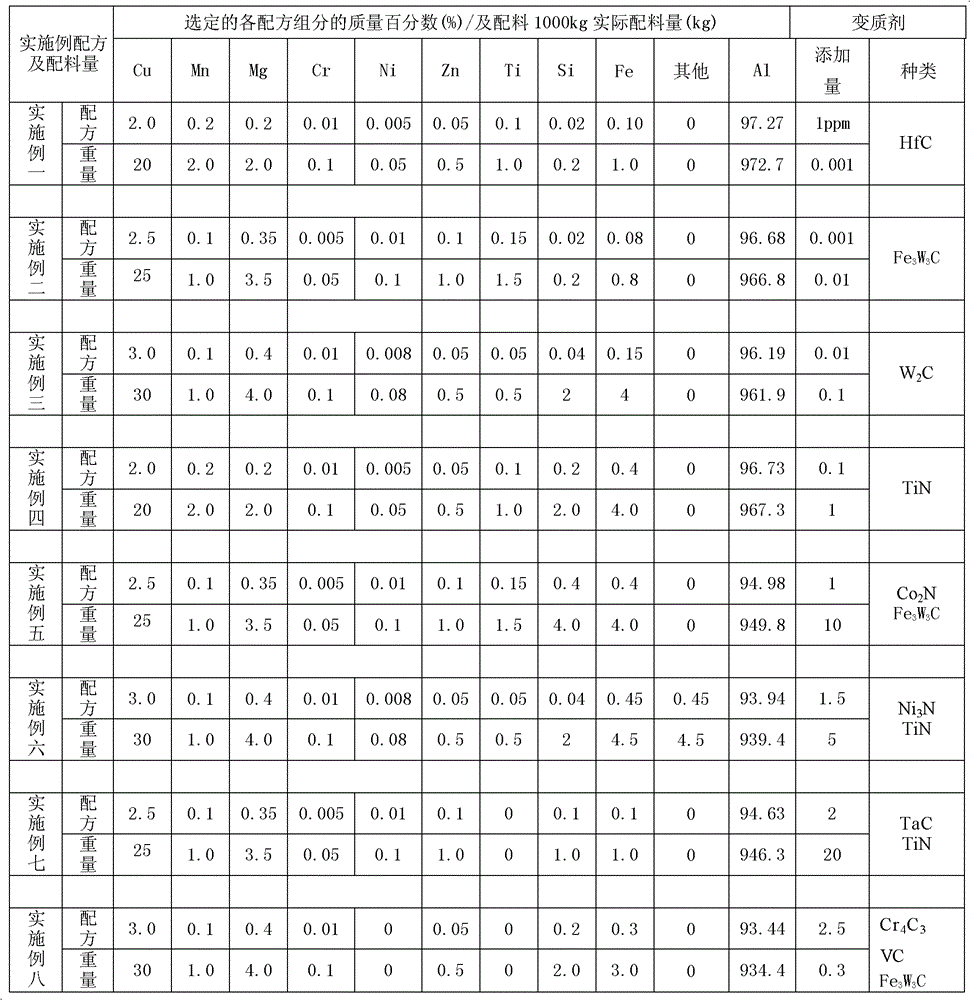

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

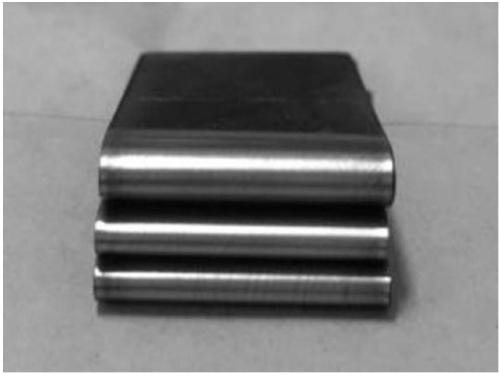

Heat treatment process for water pump shaft connecting bearings

InactiveCN101445866AImprove performanceResolve the breakFurnace typesHeat treatment furnacesIntermediate frequencyQuenching

The invention relates to a heat treatment process for water pump shaft connecting bearings, which includes a quenching and tempering treatment and an intermediate-frequency inductive heat treatment, wherein, the quenching and tempering treatment comprises the steps that an inner shaft of a water pump shaft connecting bearing is positioned in a resistance furnace to have integral heat treatment at a heating temperature being 820 DEG C to 830 DEG C; then oil quenching is performed; and the water pump shaft connecting bearing after oil quenching is tempered at a temperature as high as 480 DEG C to 520 DEG C, kept for 2 hours, and then cooled quickly. The intermediate-frequency inductive heat treatment includes the following steps that the surface heat treatment of the inner shaft of the water pump shaft connecting bearing is performed after the quenching and tempering treatment is performed, the heating temperature is 880 DEG C to 900 DEG C, then water-quenched quenching is performed, the inner shaft of the water pump shaft connecting bearing is heated up to 160 DEG C to 180 DEG C and cooled at a normal temperature, the intermediate-frequency induction heating is performed at a high speed, austenite grains are difficult to grow, the martensite structure after quenching is also extremely tiny, the surface hardness is high, fine-granular carbide is distributed on the matrix of a rope prime body after the quenching and tempering treatment in a dispersion manner, and the hardness of the core thereof is HRC35-45; therefore, the strength and the toughness are good.

Owner:SHENGRUI TRANSMISSION

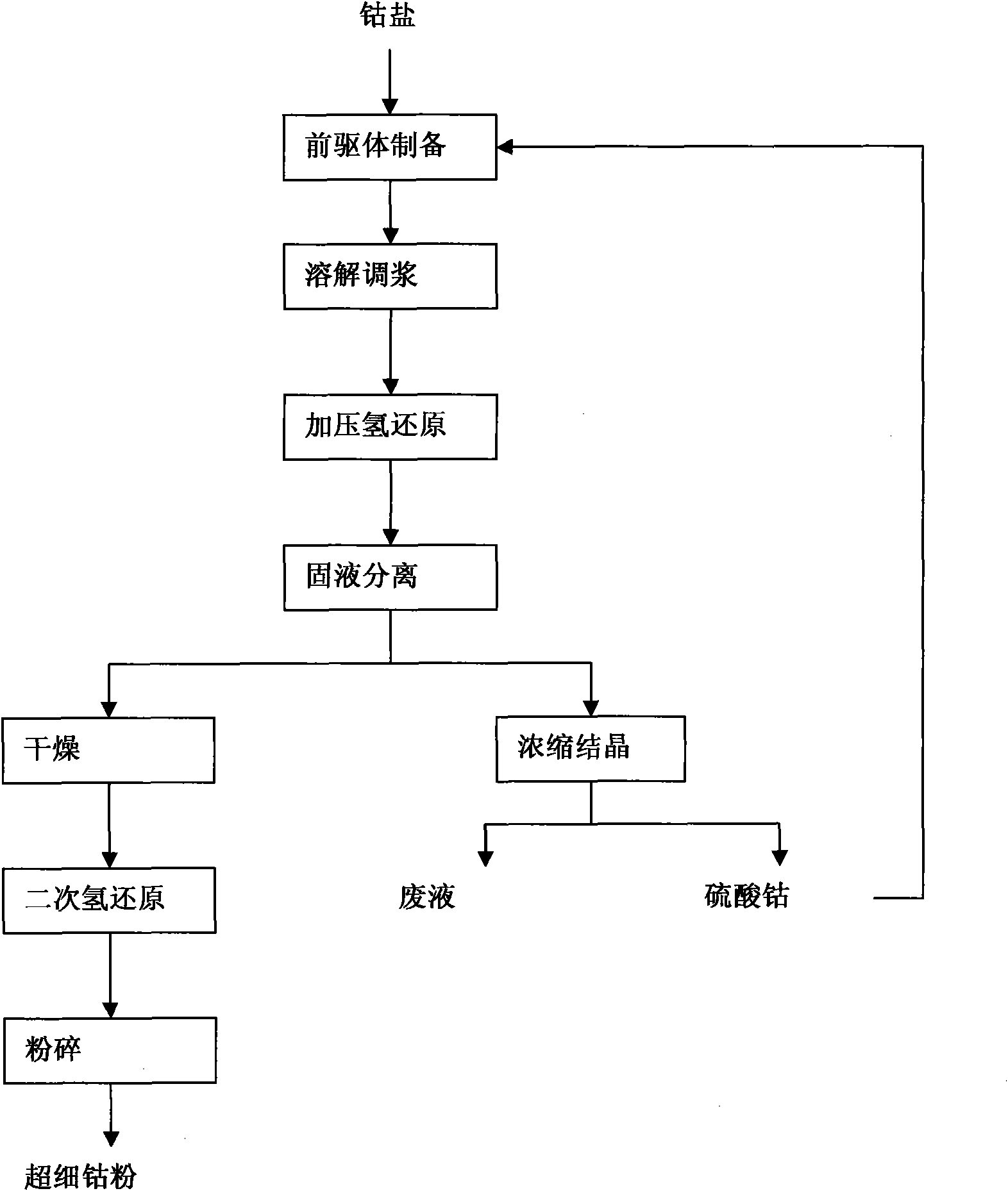

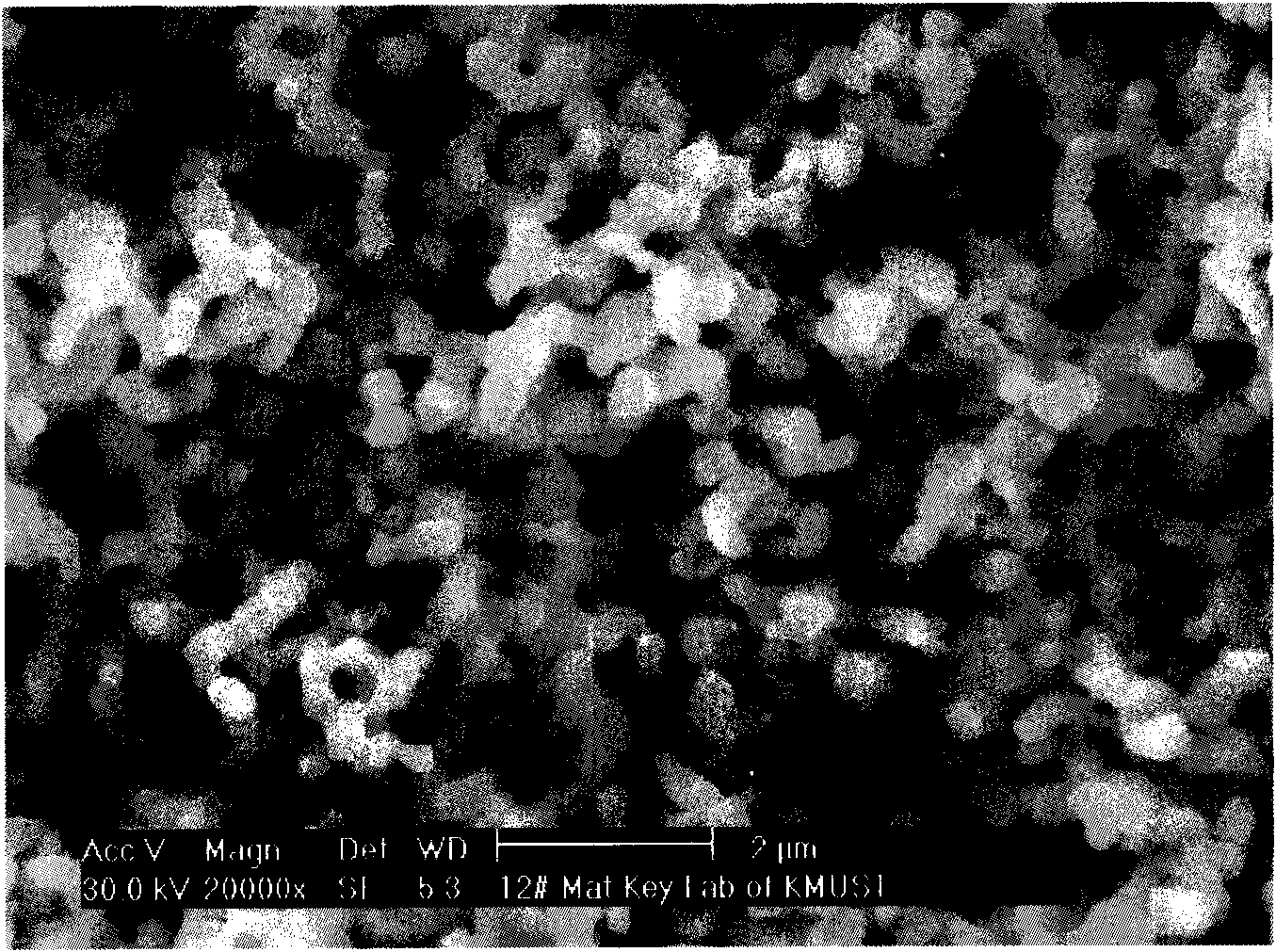

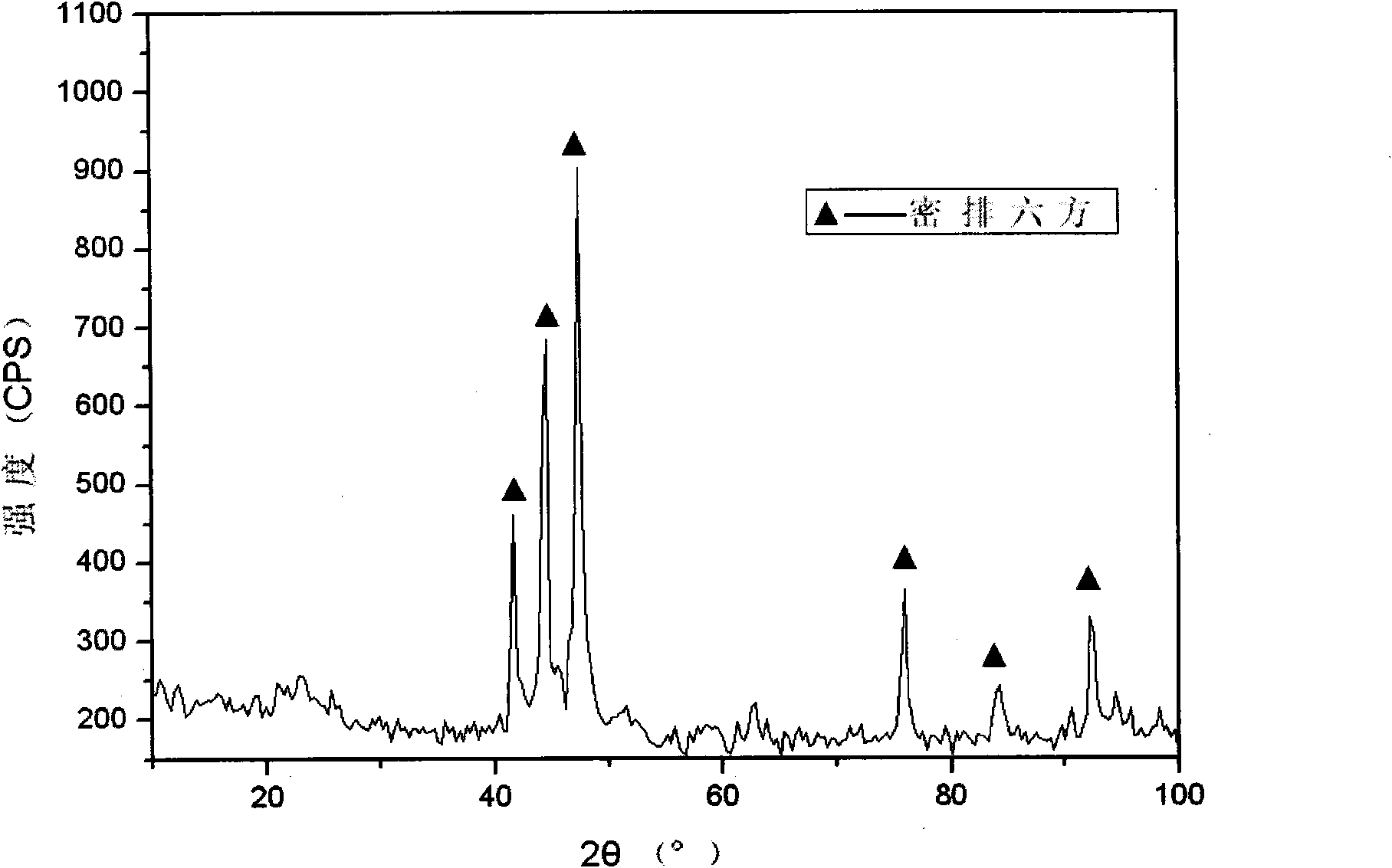

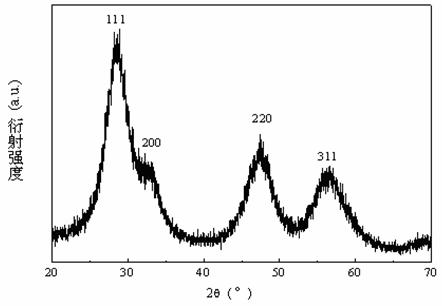

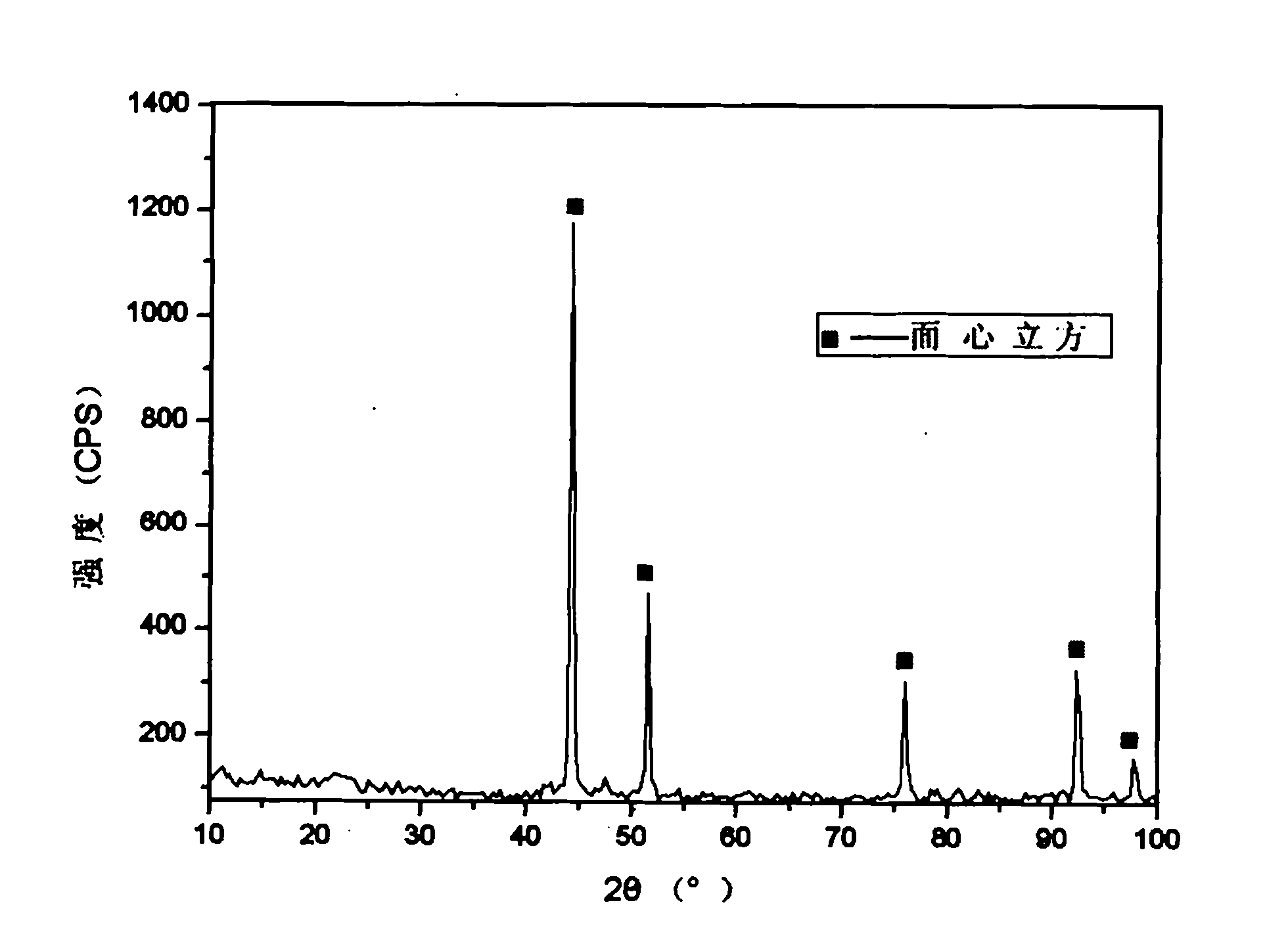

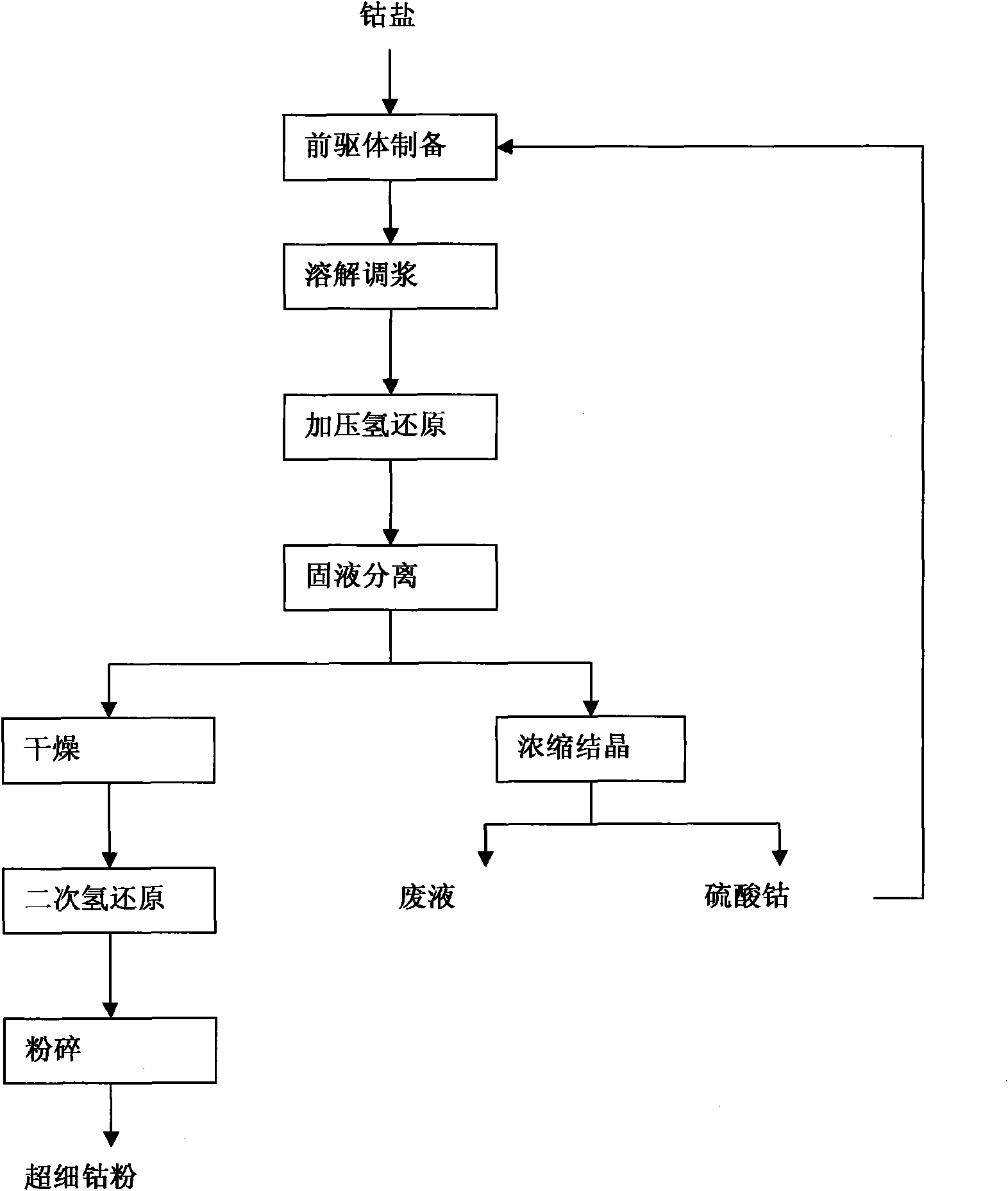

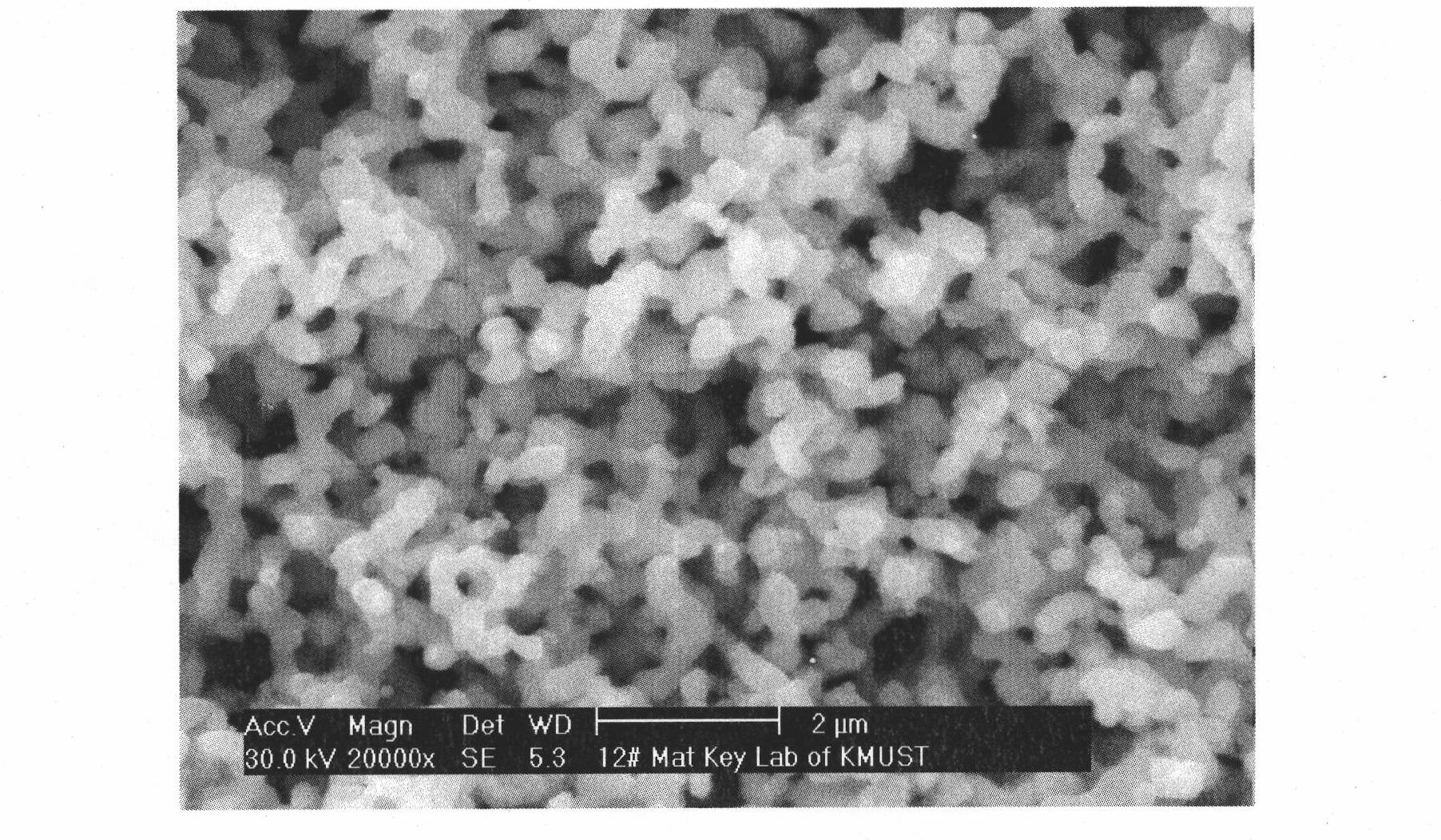

Method for preparing superfine cobalt powder in close-packed hexagonal structure or face-centered cubic structure by hydrogen reduction

The invention discloses a technical method for preparing superfine cobalt powder in a close-packed hexagonal structure or a face-centered cubic structure by hydrogen reduction, and belongs to the technical field of the preparation of metal powdered material. The invention comprises the following steps: excessive alkali is added into the water soluble salt of cobalt which is used as a raw material,obtained precipitation of hydroxide of the cobalt is directly transferred into a high-pressure autoclave without filtration and reduced under the catalysis of a small quantity of palladium chloride below 180 DEG C in poor hydrogen (<1MPa), the reduzate is reduced by secondary consolidation hydrogen in a hydrogen reducing furnace after being filtered, washed and dried and then crashed under the protection of inert gas, and finally, the superfine cobalt powder which has the granularity of less than 0.5um, big specific surface, even distribution and single close-packed hexagonal structure or face-centered cubic structure is produced.

Owner:KUNMING INST OF PRECIOUS METALS

High-end bearing steel material for machine tool and production process thereof

ActiveCN110257716AImprove purityEvenly distributedProcess efficiency improvementElectric furnaceRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool and a production process of the high-end bearing steel material, and belongs to the technical field of special steel smelting. The high-end bearing steel material for the machine tool and the production process of the high-end bearing steel material aim to solve the problem that the properties such as wear resistance and contact fatigue strength of an existing bearing steel material cannot meet the requirements of a high-end numerical control machine tool, and the production process comprises electric furnace treatment, LF refining and VD process, die casting, hot delivery / cover cooling, primary heating rolling cogging, slow cooling, secondary heating rolling and spheroidizing annealing. Ni, Mo and rare earth elements are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for steel materials, and the produced bearing steel material has high elasticity limit, tensile strength, contact fatigue strength and wear resistance, can effectively reduce the phenomena of material fatigue flaking, clamping and the like and is applicable to manufacturing a bearing ring and a rolling body and needle with the wide size range for the machine tool.

Owner:建龙北满特殊钢有限责任公司

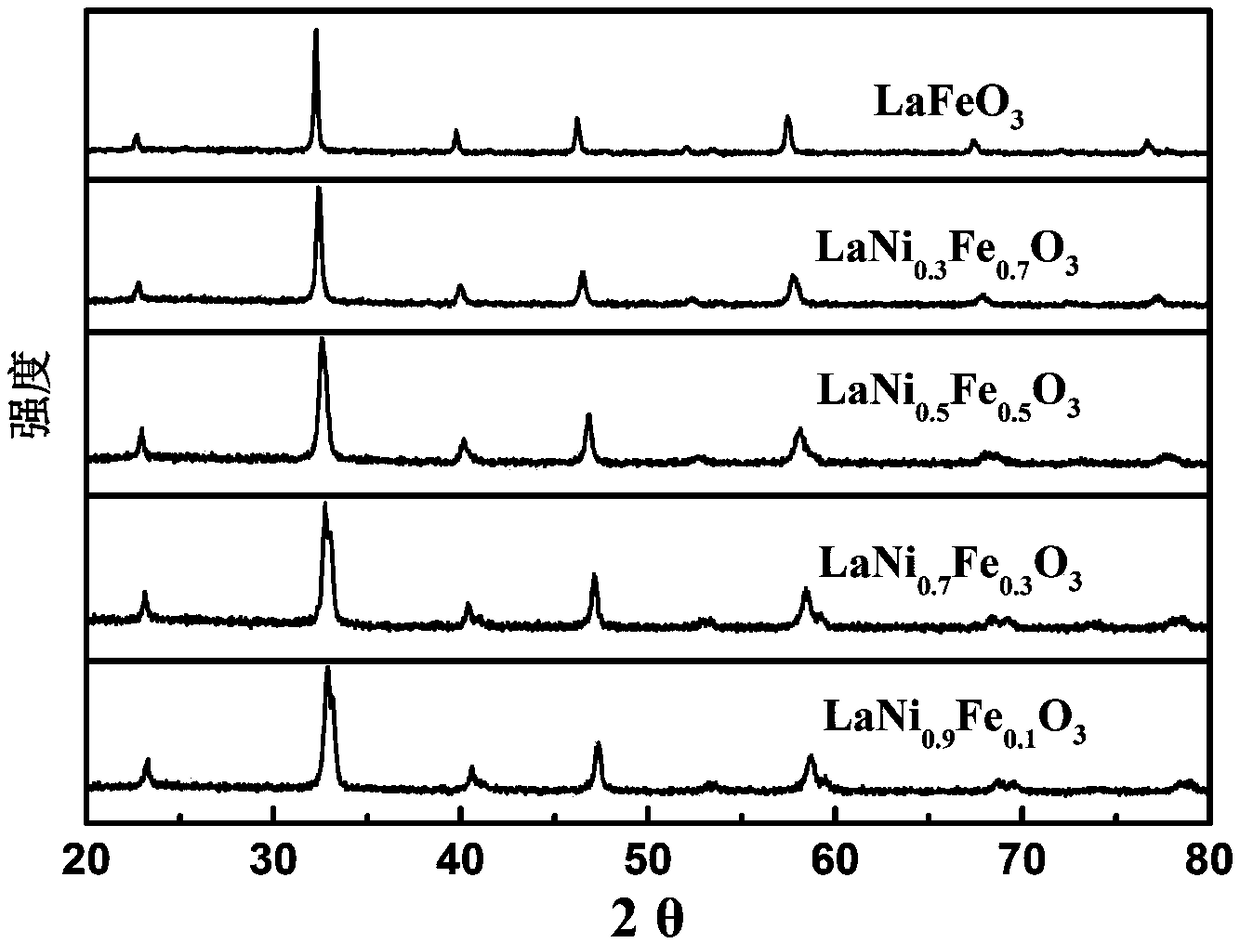

Preparation method and application of bifunctional perovskite type oxide oxygen electrode catalyst

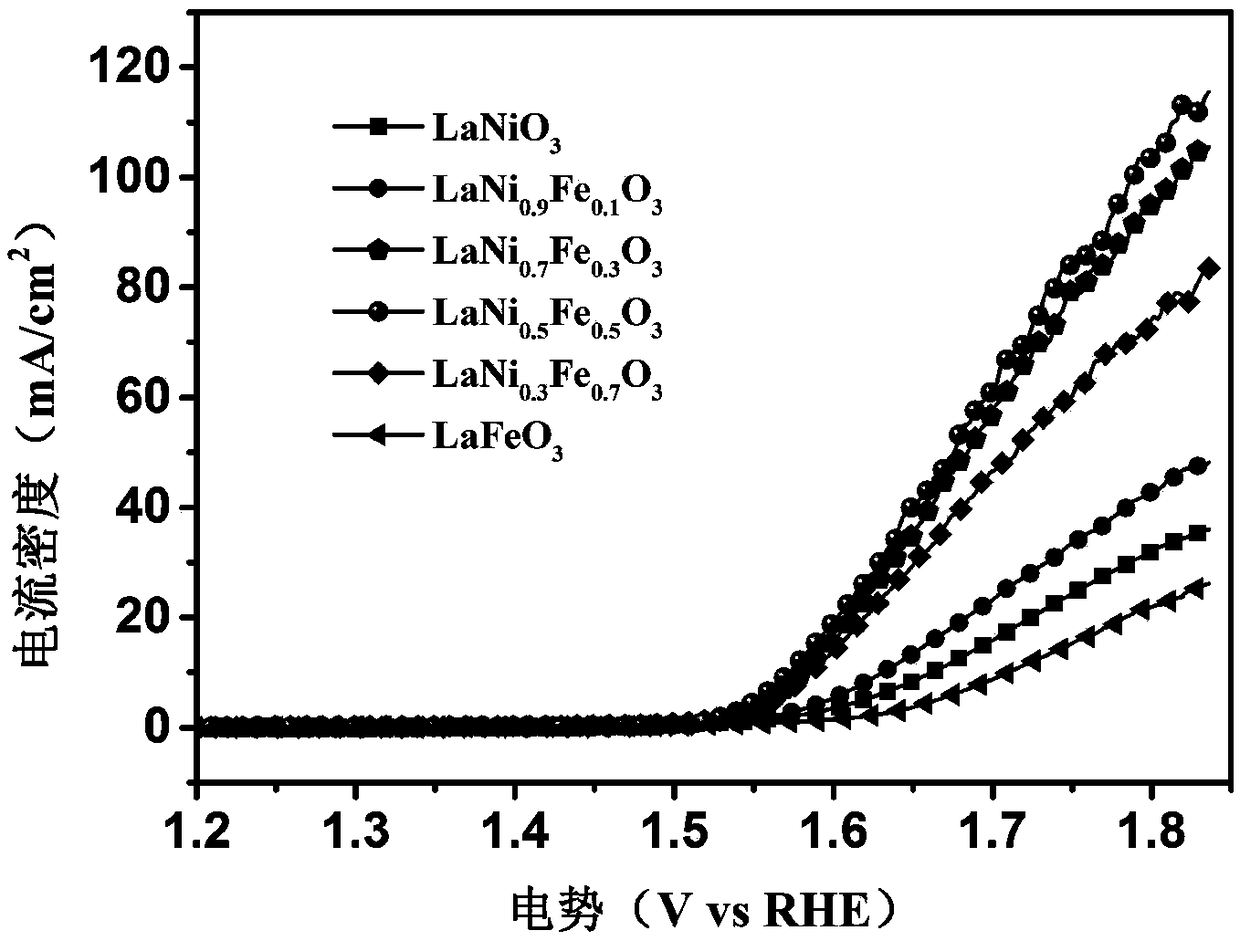

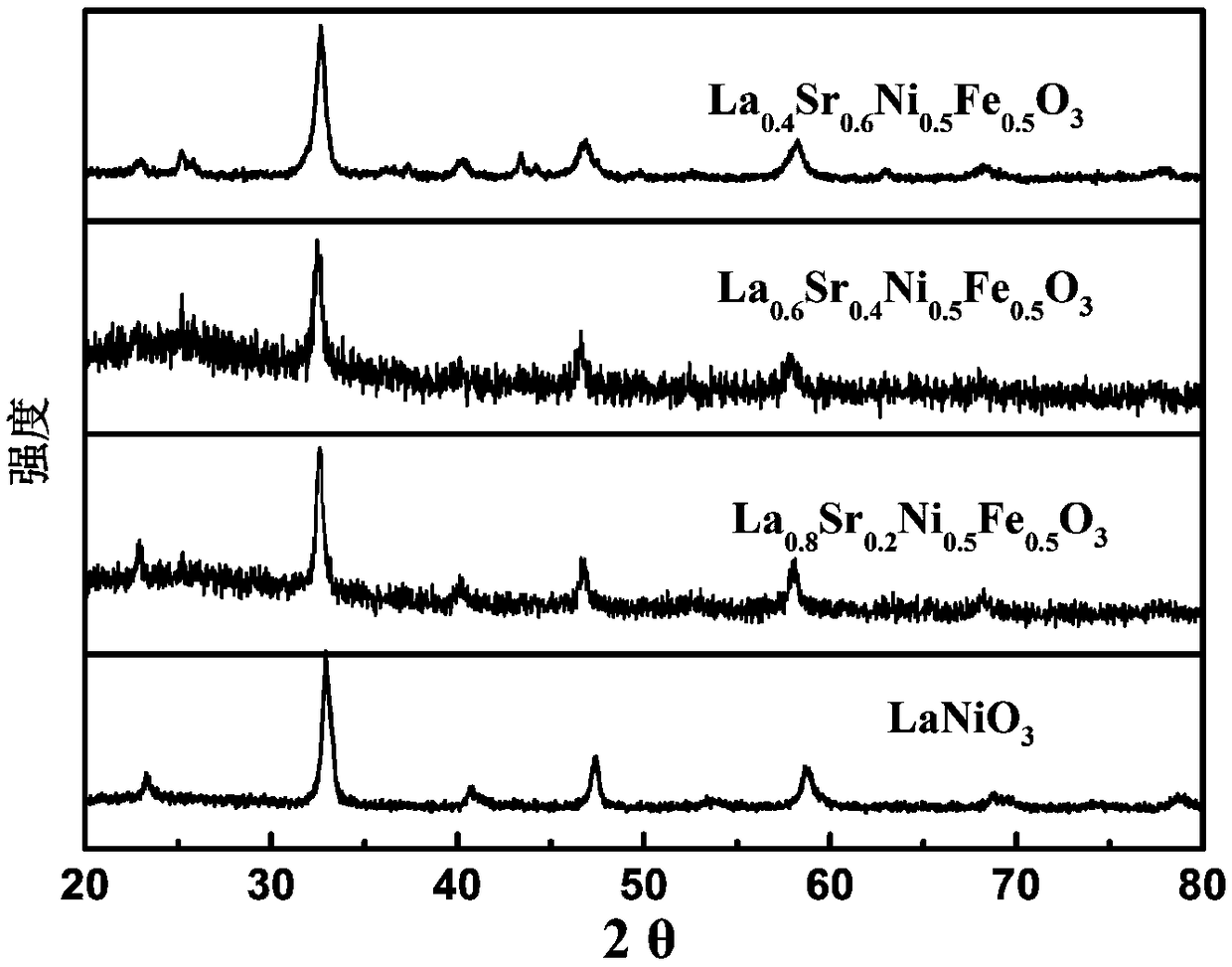

InactiveCN109390598ABifunctional electrocatalytic performance is goodImproved Oxygen Reduction (ORR) Catalytic PerformanceCell electrodesWater bathsOxygen

The invention relates to a preparation method and an application of a bifunctional perovskite type oxide oxygen electrode catalyst. The method comprises the following steps: mixing aqueous solutions of lanthanum nitrate, strontium nitrate, nickel nitrate and ferric nitrate, then adding ethanediol, adding the mixture into a citric acid solution, heating a water bath to 70-90 DEG C until a gel is formed; finally raising the temperature of the gel to 650-800 DEG C, preserving heat for 6-9 hours; finally obtaining a La(1-x)SrxNi(1-y)FeyO3 powder, namely the bifunctional perovskite type oxide oxygen electrode catalyst. The catalyst is used for catalyzing the oxygen evolution reaction (OER) and the oxygen reduction reaction (ORR) of a fuel cell and an electrolytic tank. The main ingredients of the bifunctional perovskite type oxide oxygen electrode catalyst are from rich transition metal materials, and the cost is low.

Owner:HEBEI UNIV OF TECH

Stainless steel seamless steel tube for sulfuric acid waste heat recovery device

ActiveCN103710644AImprove hardenabilityImprove corrosion resistanceUltimate tensile strengthMaterials science

The invention relates to a stainless steel seamless steel tube for a sulfuric acid waste heat recovery device. The stainless steel seamless steel tube comprises the following components: 0.05-0.06 percent of C, 1.5-2.0 percent of Mn, 19.0-22.0 percent of Ni, 24.0-26.0 percent of Cr, 0.45-0.60 percent of Nb, 0.4-0.6 percent of Si, 0.1-0.15 percent of N, less than or equal to 0.2 percent of Cu, less than or equal to 0.015 percent of s, less than or equal to 0.025 percent of p, 0.3-0.5 percent of Mo, 2-4 percent of Al, 0.4-0.6 percent of Ti, 0.0018-00022 percent of v, 0.5-0.8 percent of composite rare earth and the balance of Fe. According to the operations of limiting the components and technological parameters, adding the composite rare earth and performing bright heat treatment on pure nitrogen protective gas, the stainless steel tube has excellent corrosion resistance, low roughness of inner and outer surfaces, high yield strength and high tensile strength.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Preparation method of precious metal-containing low-carbon alkane dehydrogenation catalyst carrier

The invention relates to a preparation method of a precious metal-containing low-carbon alkane dehydrogenation platinum-tin catalyst carrier, and mainly solves the problem that in the prior art in high temperature and carbon burning processes of a catalyst, metal platinum particles are easy to coalesce to grow up to affect the stability of the catalyst. According to the preparation method, first a technical scheme is adopted to well solve the problem, the technical scheme is shown as follows: alkalinous metal assistants of calcium, magnesium and the like are introduced into an alumina carrier by a coprecipitation method to get a compound metal oxide carrier, and the preparation method can be used in industrial preparation of the catalyst for preparation of low carbon olefins by low-carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

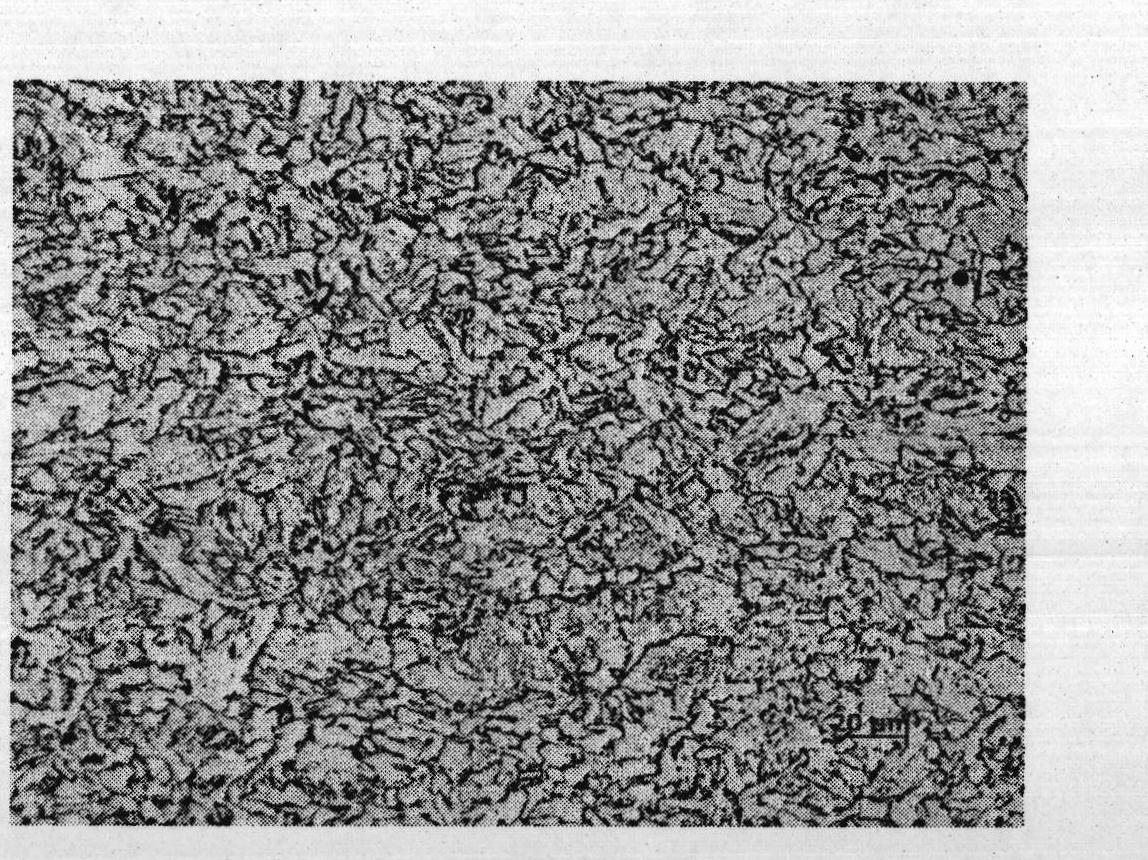

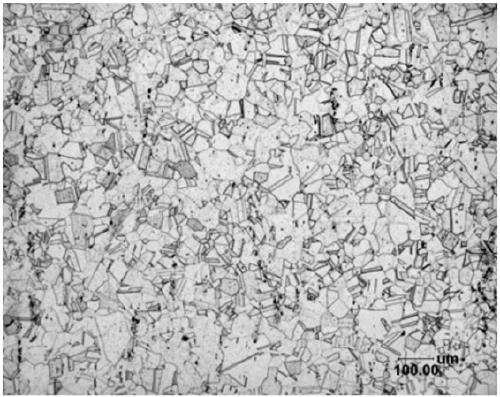

High-end bearing steel material for machine tool bearing ring and manufacturing method of high-end bearing steel material for machine tool bearing ring

ActiveCN110257717AImprove mechanical propertiesImprove purityElectric furnaceProcess efficiency improvementRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool bearing ring and a manufacturing method of the high-end bearing steel material for the machine tool bearing ring, and belongs to the technical field of special steel smelting forging. The high-end bearing steel material aims to solve the problem that the performance of the steel material cannot meet the requirement of a high-end numerical control machine tool due to the fact that the carbide inside the steel material for the bearing ring is segregated and distributed in a mesh mode, the steel material is caused not to meet the requirement of the high-end numerical control machine tool, the invention provides the high-end bearing steel material for the machine tool bearing ring and the manufacturing method of the high-end bearing steel material for the machine tool bearing ring, and comprises the following steps of electric furnace, LF refining and VD process, die casting, hot charging / cover cooling, heating rolling, slow cooling, and spheroidizing annealing. According to the steel material and the method, Ni, Mo and rare earth element are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for the steel material; the carbide in the manufacturing process is effectively diffused, the carbide level of the steel material is improved, the steel material for the bearing ring of the machine tool has a high elastic limit, tensile strength, contact fatigue strength and wear resistance, and can effectively reduce the phenomena of fatigue peeling, blocking and the like.

Owner:建龙北满特殊钢有限责任公司

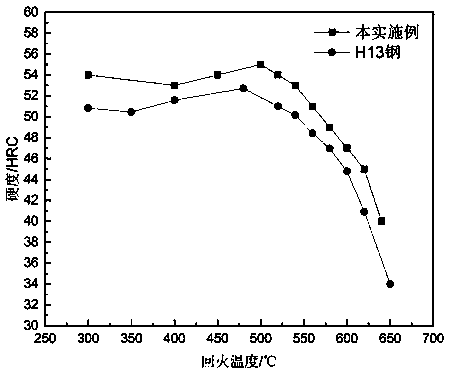

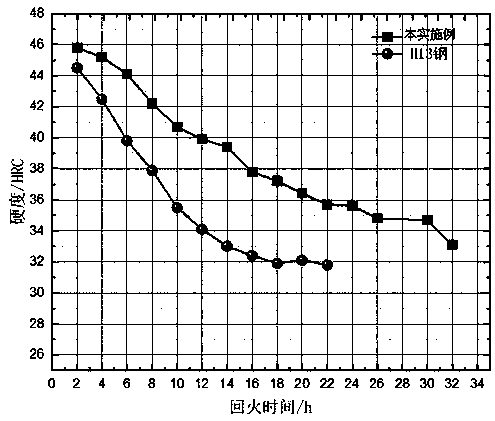

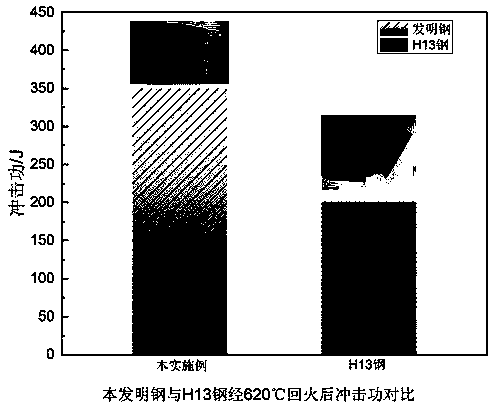

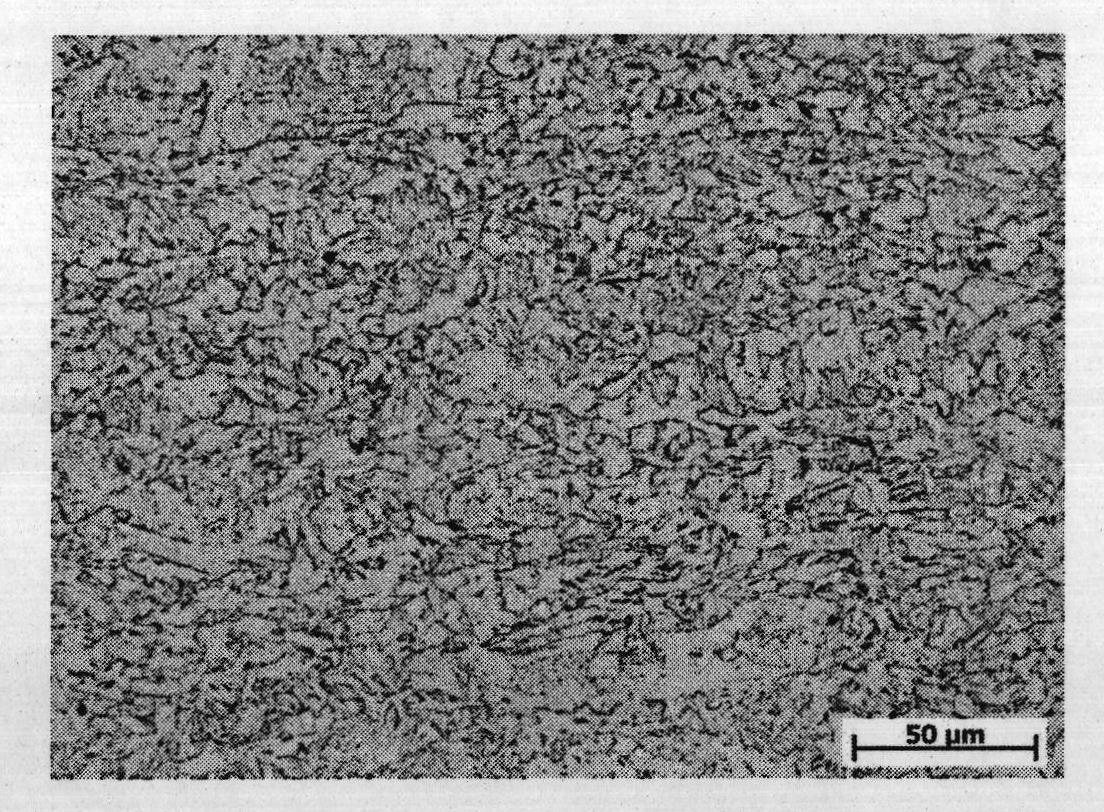

High-manganese low-chromium type hot work die steel and preparation method thereof

The invention relates to high-manganese low-chromium type hot work die steel and a preparation method of the high-manganese low-chromium type hot work die steel, and belongs to the technical field ofhot work die steel. The high-manganese low-chromium type hot work die steel is prepared from, by mass, 0.35-0.45% of C, 0.50-1.20% of Si, 0.60-1.20% of Mn, 3.75-4.50% of Cr, 0.80-1.20% of Mo, 0.30-0.60% of V, 0.50-5.50% of Co, 0.80-3.00% of Ni, less than 0.02% of P, less than 0.02% of S and the balance Fe and inevitable impurities. The high-manganese low-chromium type hot work die steel is prepared through the processes of material preparation, smelting, casting, electroslag remelting, high temperature homogenization treatment, forging, annealing and heat treatment. Compared with existing H13hot work die steel, the high-manganese low-chromium type hot work die steel has higher toughness and higher heat stability.

Owner:KUNMING UNIV OF SCI & TECH

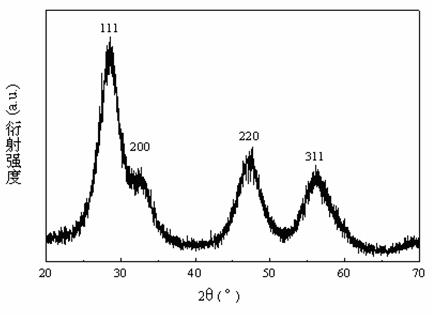

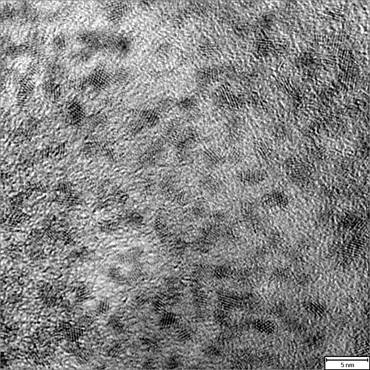

Nano-quantum-dot-level fuel borne catalyst for diesel vehicle as well as preparation method and application thereof

InactiveCN102125845AHigh yieldNot easy to gatherDispersed particle separationNanotechnologyPtru catalystPhysical chemistry

The invention discloses a nano-quantum-dot-level fuel borne catalyst for a diesel vehicle as well as a preparation method and an application thereof, and the preparation method comprises the following steps: adding a trivalent cerium metal salt or a mixture of trivalent cerium and a trivalent iron metal salt into alcohol ether, and preparing a solution enabling the total concentration of cations to be 0.001-0.04mol / L; and adopting the two-section heating method to perform a heating reaction on the solution, firstly heating to 100 DEG C, condensing, refluxing till the solution is uniformly mixed, then heating to 160-200 DEG C, performing the reaction till the color of the solution changes, and finally getting a cerium oxide catalyst or a cerium-iron composite oxide catalyst. In the preparation method, pH does not need to be regulated, the reaction is performed at normal temperature and normal pressure, the reaction is simple and can be controlled through the temperature, the operation is convenient, the appearance of the catalyst can achieve 100%, the yield is high, and the catalyst can be applied in diesel engineering machinery, diesel trucks, diesel passenger vehicles, diesel urban buses and other tools in a large-scale manner.

Owner:UNIV OF JINAN

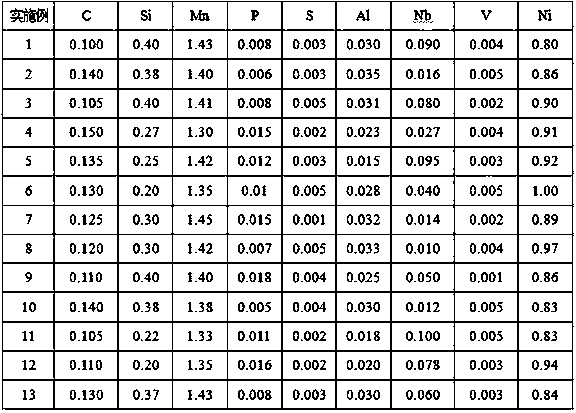

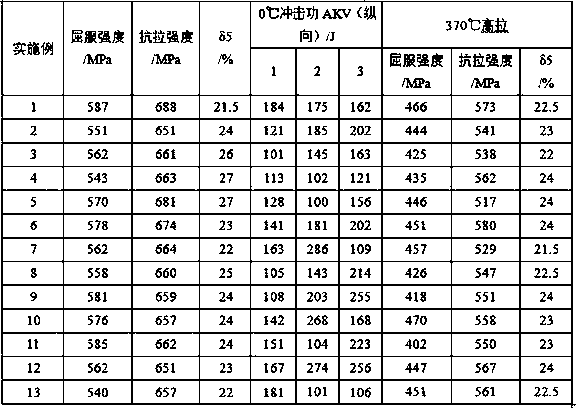

High-strength low-crack sensitive slab and manufacture method thereof

The invention relates to a high-strength low-crack sensitive slab and a manufacture method thereof. The slab is prepared from the following chemical components in percentage by weight: 0.06-0.09 percent of C, 0.1-0.3 percent of Si, 1.35-1.55 percent of Mn, 0.02-0.04 percent of Nb, 0.02-0.04 percent of V, 0.01-0.02 percent of Ti, 0.15-0.25 percent of Ni, 0.1-0.2 percent of Cr, 0.15-0.25 percent of Cu, 0.02-0.04 percent of Al, not more than 0.006 percent of N, not more than 0.016 percent of P, less than 0.004 percent of S and the balance of Fe and impurities. The manufacture method of the high-strength low-crack sensitive slab comprises the following sequential steps of: heating a casting blank; descaling; controlling rolling; controlling cooling, straightening, and the like. The slab of the invention can reach the thickness of 80 mm, and the yield strength over 420 MPa and has excellent comprehensive mechanical performance, simple and convenient production process and low cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

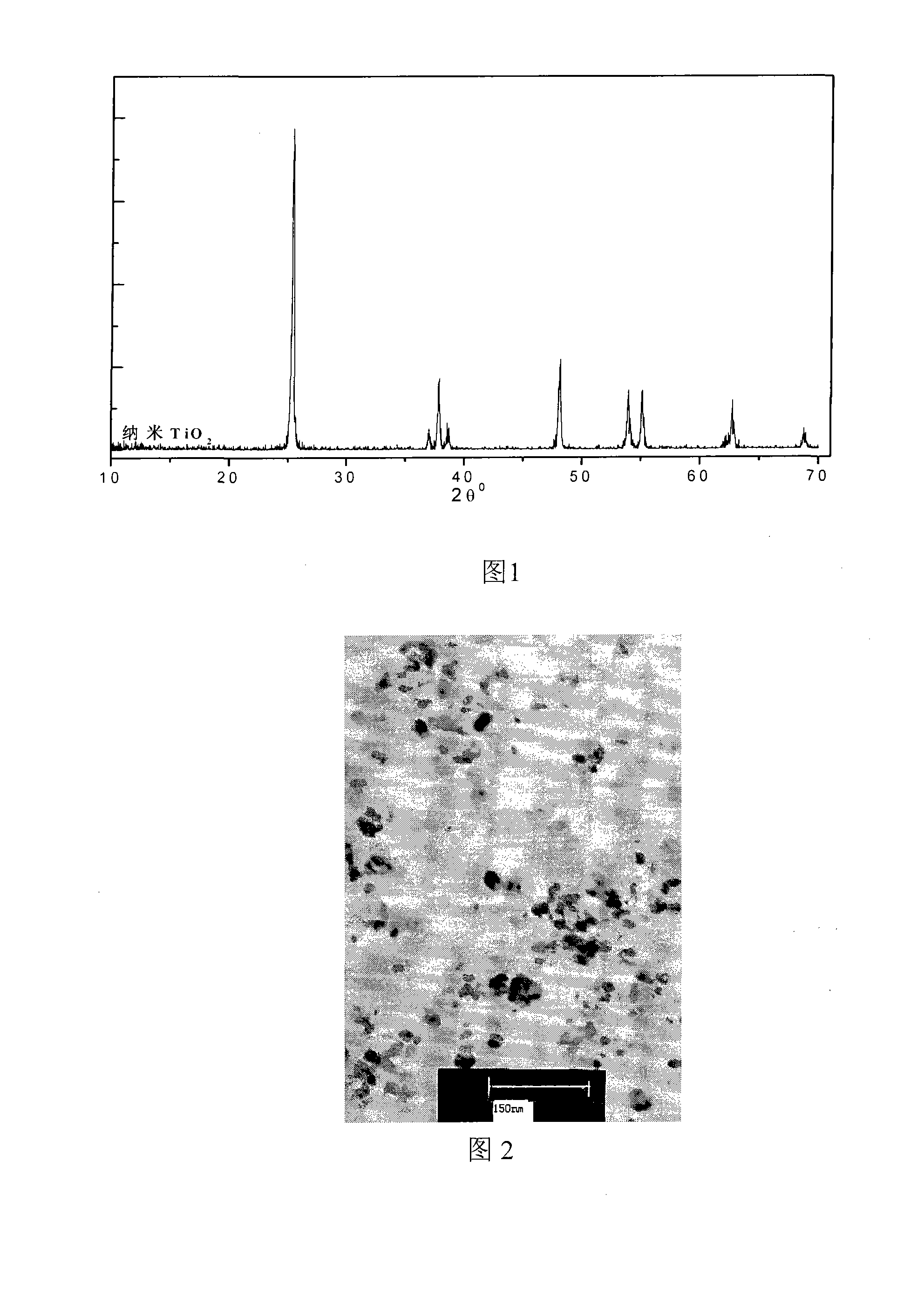

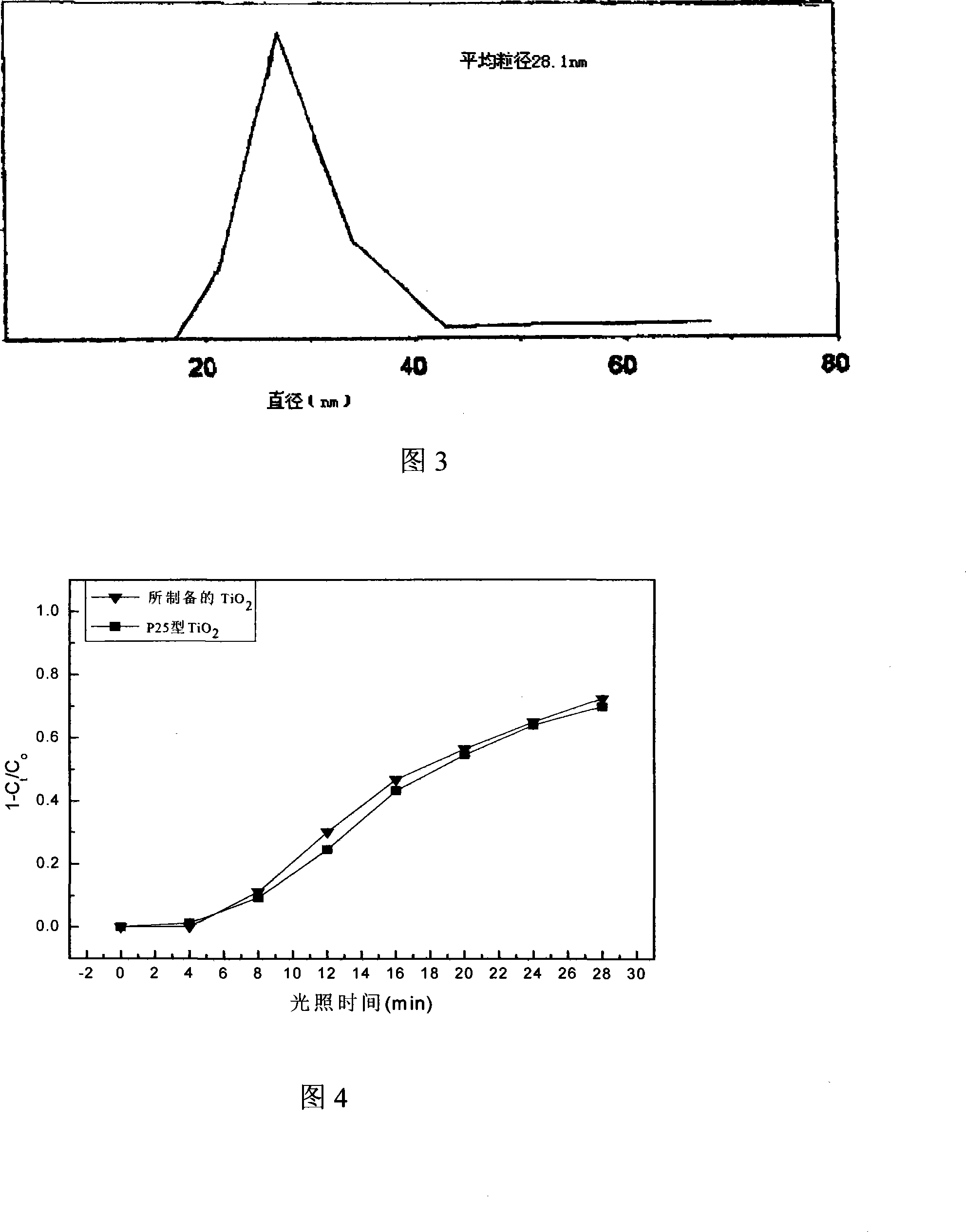

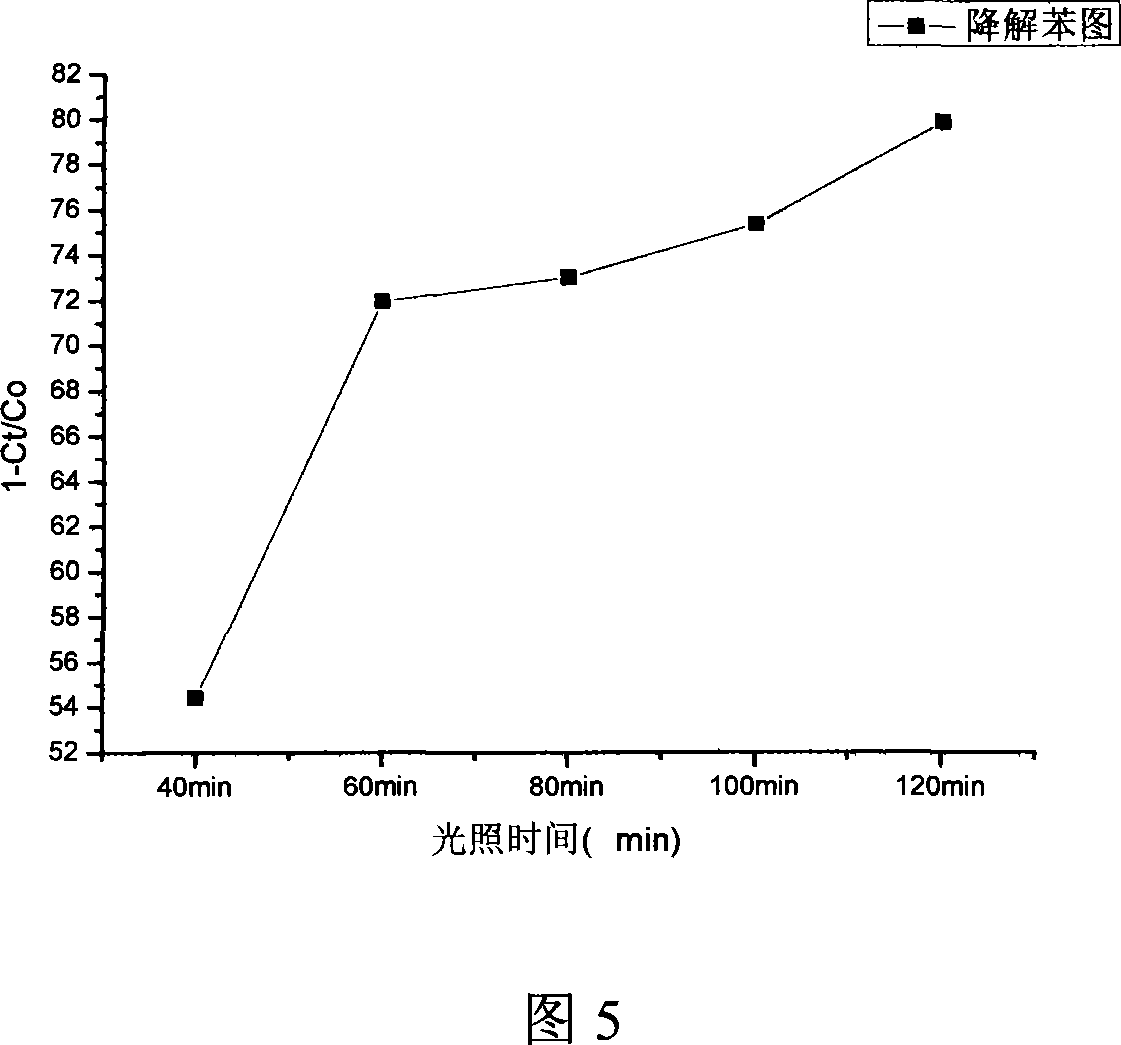

Method for preparing nano titanium dioxide by using surfactant peptization method

InactiveCN101234783AWide variety of sourcesLow costNanostructure manufactureTitanium dioxideWater bathsPolyvinyl alcohol

The invention belongs to a field for preparing nano titanium dioxide, which discloses a method for preparing the nano titanium dioxide by using a surfactant colloidal chemical method with simple process and low cost. The method adopts meta-titanic acid as raw material; acetate, oxalate, citric acid, tween 20, span 40, polyethylene glycol 2,000 and polyvinyl alcohol 2,000 are added to be carried out peptization reaction under water bath temperature of 30-90 DEG C to obtain nano meta-titanic acid colloidal solution; then precursor of titanium dioxide nano-particle is prepared by drying; the precursor is calcinated and heat preserved to obtain nano titanium dioxide powder. The method for preparing the nano titanium dioxide has wide material source, low cost and simple preparation process; furthermore, the method does not need to update and transform the device and has no special production devices and low cost; the method has low cost of the titanium material and little environment pollution; the nano titanium dioxide is prepared by three steps.

Owner:胡晓洪

Aluminum alloy capable of digesting high-hardness compounds and smelting method of aluminum alloy

The invention discloses an aluminum alloy capable of digesting high-hardness compounds and a smelting method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Cu, Mn, Mg, Cr, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding LaH3 powder into the alloy melt in a fluidized form together with the gas; stirring to make the LaH3 distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU ALUMINUM MATERIALS ENG TECHRES CENT

Method for preparing superfine cobalt powder in close-packed hexagonal structure or face-centered cubic structure by hydrogen reduction

The invention discloses a technical method for preparing superfine cobalt powder in a close-packed hexagonal structure or a face-centered cubic structure by hydrogen reduction, and belongs to the technical field of the preparation of metal powdered material. The invention comprises the following steps: excessive alkali is added into the water soluble salt of cobalt which is used as a raw material, obtained precipitation of hydroxide of the cobalt is directly transferred into a high-pressure autoclave without filtration and reduced under the catalysis of a small quantity of palladium chloride below 180 DEG C in poor hydrogen (<1MPa), the reduzate is reduced by secondary consolidation hydrogen in a hydrogen reducing furnace after being filtered, washed and dried and then crashed under the protection of inert gas, and finally, the superfine cobalt powder which has the granularity of less than 0.5um, big specific surface, even distribution and single close-packed hexagonal structure or face-centered cubic structure is produced.

Owner:KUNMING INST OF PRECIOUS METALS

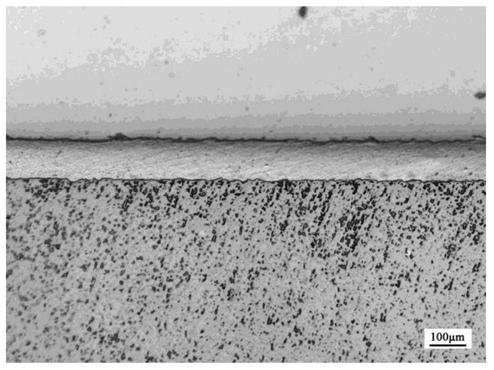

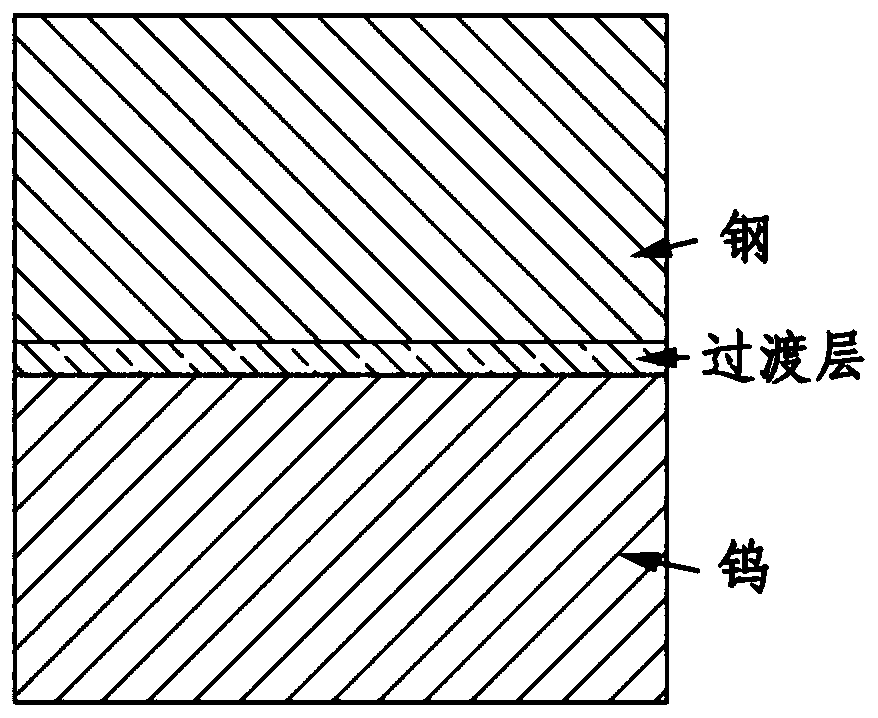

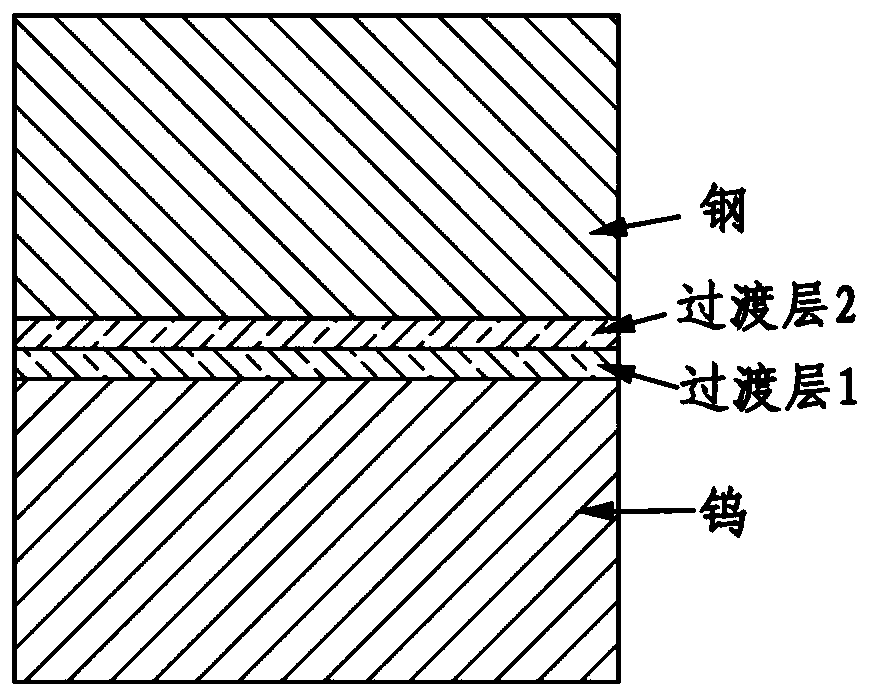

Hot isostatic pressure diffusion connection method for tungsten or tungsten alloy and high-strength steel

InactiveCN110303236AFully deformedFully deformed fullyWelding/soldering/cutting articlesPressure inorganic powder coatingSputteringHigh intensity

The invention discloses a hot isostatic pressure diffusion connection method for tungsten or tungsten alloy and high-strength steel. The method mainly comprises the following steps of cleaning beforewelding operation, transition layer preparation and hot isostatic pressure diffusion connection, wherein a cold spraying treatment mode is adopted for the transition layer preparation. The connectionmethod can realize the hot isostatic pressure diffusion connection of samples with special-shaped curved surfaces of an arc surface, a U-shaped surface and the like, can realize the preparation of themultiple layers of transition layers, the bonding performance is good, the connection strength is high, and compared with magnetron sputtering, the method is simpler, more practical and more economical. In addition, by adopting the hot isostatic pressure diffusion connection method, the defects of air holes and the like are overcome, batch production can be realized, the production efficiency ishigh, and the yield is high.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

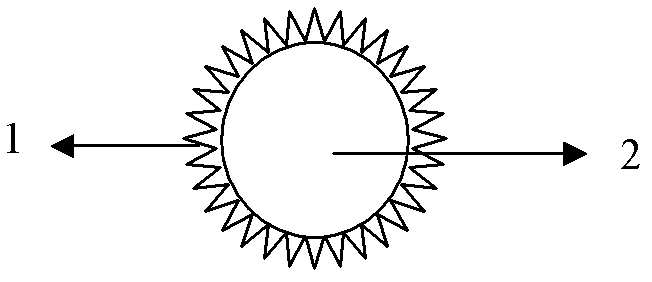

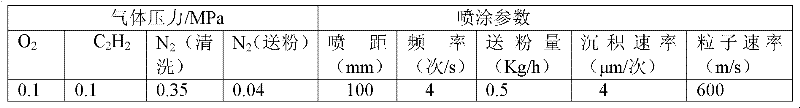

Novel ice-covering-proof coating and preparation method thereof

InactiveCN102443326AIncrease surface areaInhibition of icingOther chemical processesCoatingsGas explosionTransmission line

The invention relates to a novel ice-covering-proof coating and a preparation method thereof, belonging to the technical field of power transmission line protection. The ice-covering-proof coating is prepared from a composite material which has a particle size of 10-50 mu m and contains glass powder and polytetrafluoroethylene, wherein the mass percent of the glass powder is 50-90%, and the mass percent of the polytetrafluoroethylene is 10-50%; the thickness of the sprayed coating is 15-25 mu m, the coating with thickness of 5-10 mu m is in a small bulge structure, and a micro nanometer structure is formed on the surface of the small bulge structure; and the spraying method can be gas explosion spraying or supersonic flame spray coating. The surface of the coating has fine hydrophobicity, and can effectively inhibit the ice covering phenomenon of the power transmission line, thereby ensuring the stable operation of the power transmission line; the coating material has the characteristics of persistent low temperature resistance, high heat radiation performance, high ageing resistance and the like; and the preparation method based on gas explosion spraying or supersonic flame spray coating ensures the high bonding strength between the coating and a matrix and the low surface temperature and large surface roughness of the workpiece, thereby effectively avoiding the covering of ice and water.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

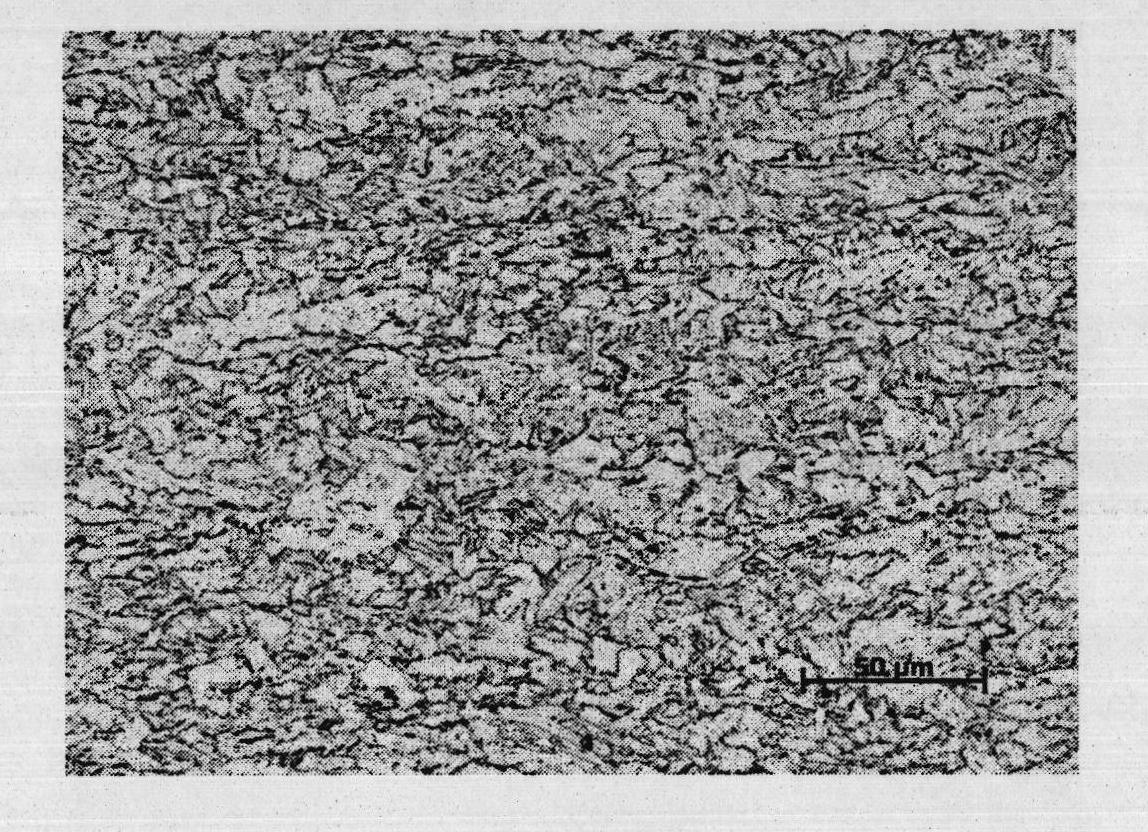

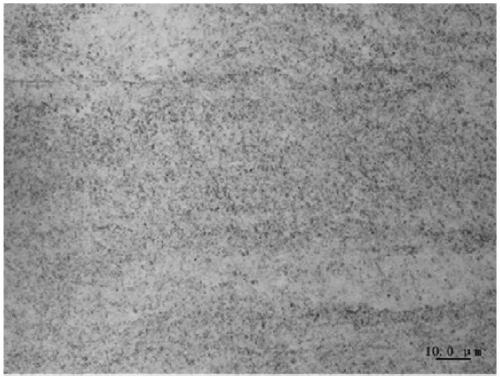

High-strength nitrogen-containing economical austenite stainless steel and manufacturing method thereof

The invention relates to a high-strength nitrogen-containing economical austenite stainless steel and a manufacturing method thereof. The chemical components of the stainless steel, by weight, of 0.05-0.15% of C, 0.3-1% of Si, 8.5-11.0% of Mn, 14.0-16.0% of Cr, 1.0-2.5% of Ni, 0.10-0.25% of N, less than 0.08% of P, less than 0.01% of S, 0.5-2.0% of Cu, 0.1-0.5% of Mo, and the balance Fe and inevitable impurities, wherein Md <30 / 50> is greater than or equal to 20 DEG C. In the manufacturing process of the high-strength nitrogen-containing economical austenite stainless steel, through cold rolling twice and flexible annealing, crystal grains are refined through production and inversion of deformation martensites, and finally, the crystal grains of which the dimension is smaller than 500nm are obtained, so that the intensity of materials is greatly improved; and the obtained high-strength nitrogen-containing economical austenite stainless steel has the following specific properties that the yield strength is greater than or equal to 650MPa, the tensile strength is greater than or equal to 1000MPa, and the elongation rate is greater than or equal to 35%, and the high-strength nitrogen-containing economical austenite stainless steel is suitable for preparation of high-strength fine-specification precision strip steels.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

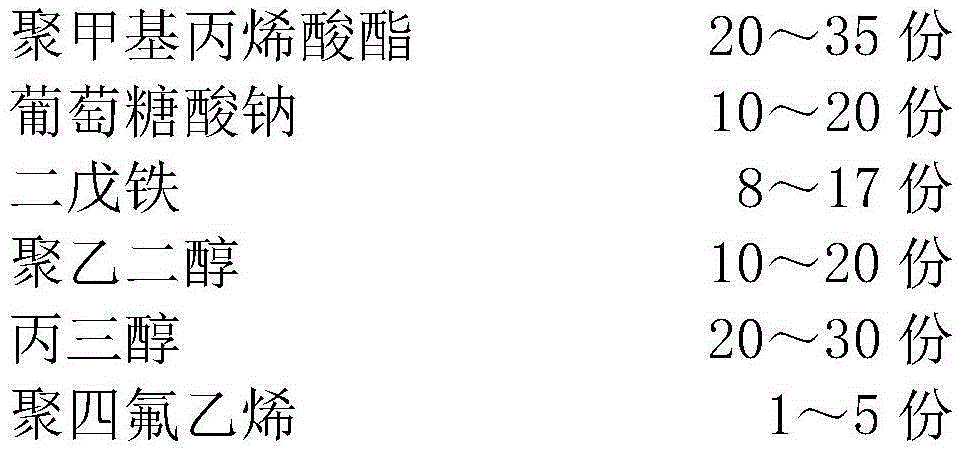

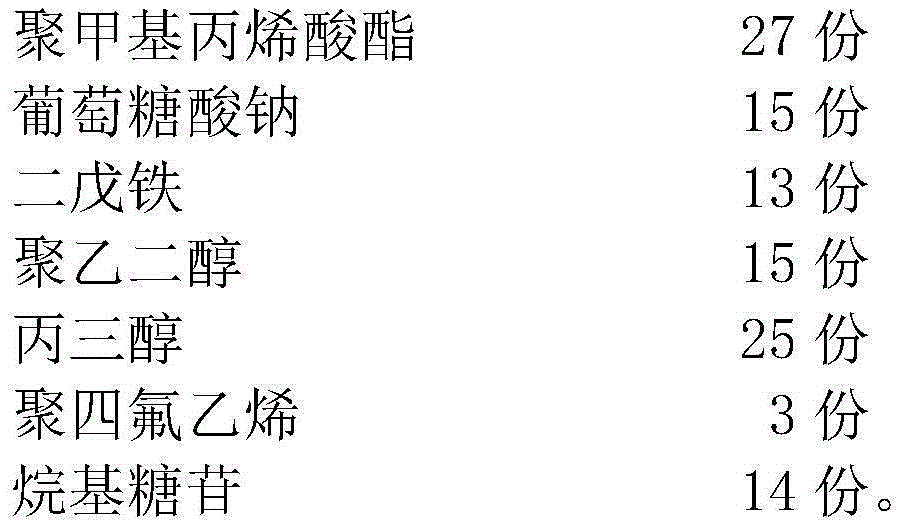

Smoke-eliminating antifreezing agent for diesel oil

InactiveCN104910978ANot easy to grow upInhibit growthLiquid carbonaceous fuelsFuel additivesPolyethylene glycolGlycerol

The invention relates to the technical field of petrochemical engineering, and particularly relates to a smoke-eliminating antifreezing agent for diesel oil. The antifreezing agent is prepared from the following raw materials in parts by weight: 20-35 parts of polymethacrylate, 10-20 parts of sodium gluconate, 8-17 parts of Fe(C5H5)2, 10-20 parts of polyethylene glycol, 20-30 parts of glycerol, 1-5 parts of polytetrafluoroethylene, and 10-18 parts of alkyl glycoside. The smoke-eliminating antifreezing agent for diesel oil disclosed by the invention can keep continuously supplemental firing, and can significantly reduce the condensation point and cold filter plugging point of diesel oil, prevent the diesel oil from being frozen at low temperature, clean parts, improve the effect of smoke elimination, and reduce the emission of exhaust gas.

Owner:ZHONGZHOU UNIV

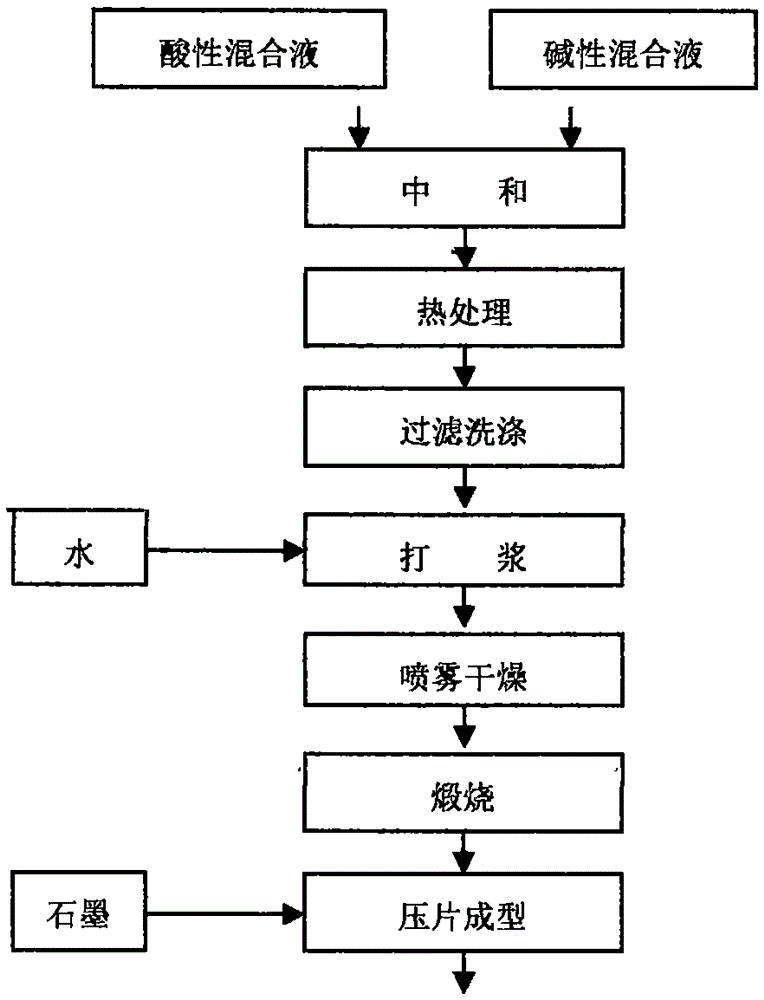

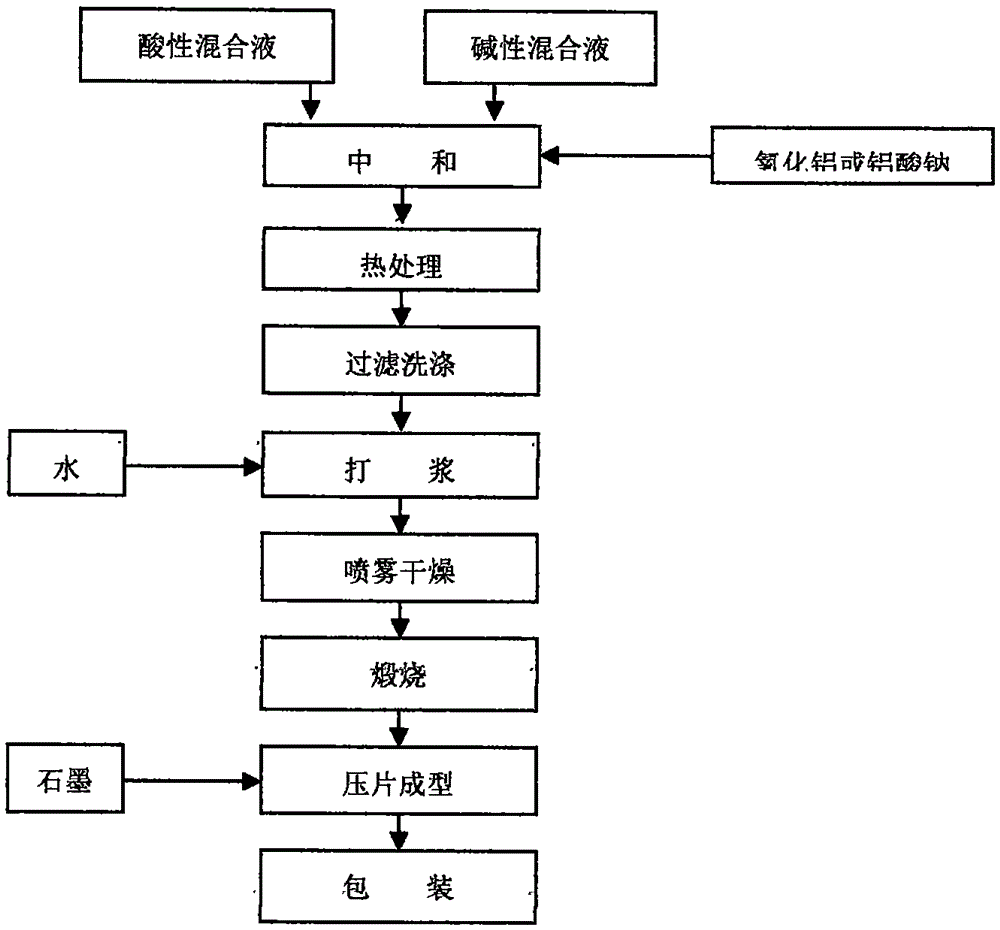

Copper-filled carbon monoxide medium temperature shift catalyst and preparation method thereof

InactiveCN105536803ANot easy to grow upHigh copper surface areaHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to a copper-filled carbon monoxide medium temperature shift catalyst and a preparation method thereof. The catalyst is prepared by the following steps of adopting a sandwich type composition with the chemical formula as Cu3Zn3Al2(OH)164H2O; adopting copper salt, zinc salt and aluminum salt as active components; comprising 25 percent to 50 percent of CuO, 30 percent to 50 percent of ZnO and 10 percent to 40 percent of Al2O3; neutralizing; heat treating; filtration washing; pulping; spray drying; forging; pressing and forming; packaging; and the like. According to the copper-filled carbon monoxide medium temperature shift catalyst and the preparation method thereof provided by the invention, a coprecipitation technique and special equipment are adopted, and the active components are dispersed highly and identical completely, so that the only uniform composite Cu3Zn3Al2(OH)164H2O instead of a mixture of various structure compounds is really formed, and the catalyst has the advantages of high activity and high heat stability; effective copper crystals are dispersed highly, so that the copper crystals are ensured to be small, and the copper surface area is high; in addition, due to the height interval of other active auxiliaries and the structures, the copper crystals of the catalyst are not easy to grow, and have higher heat stability.

Owner:PANJIN DIBAO CATALYST TECH CO LTD

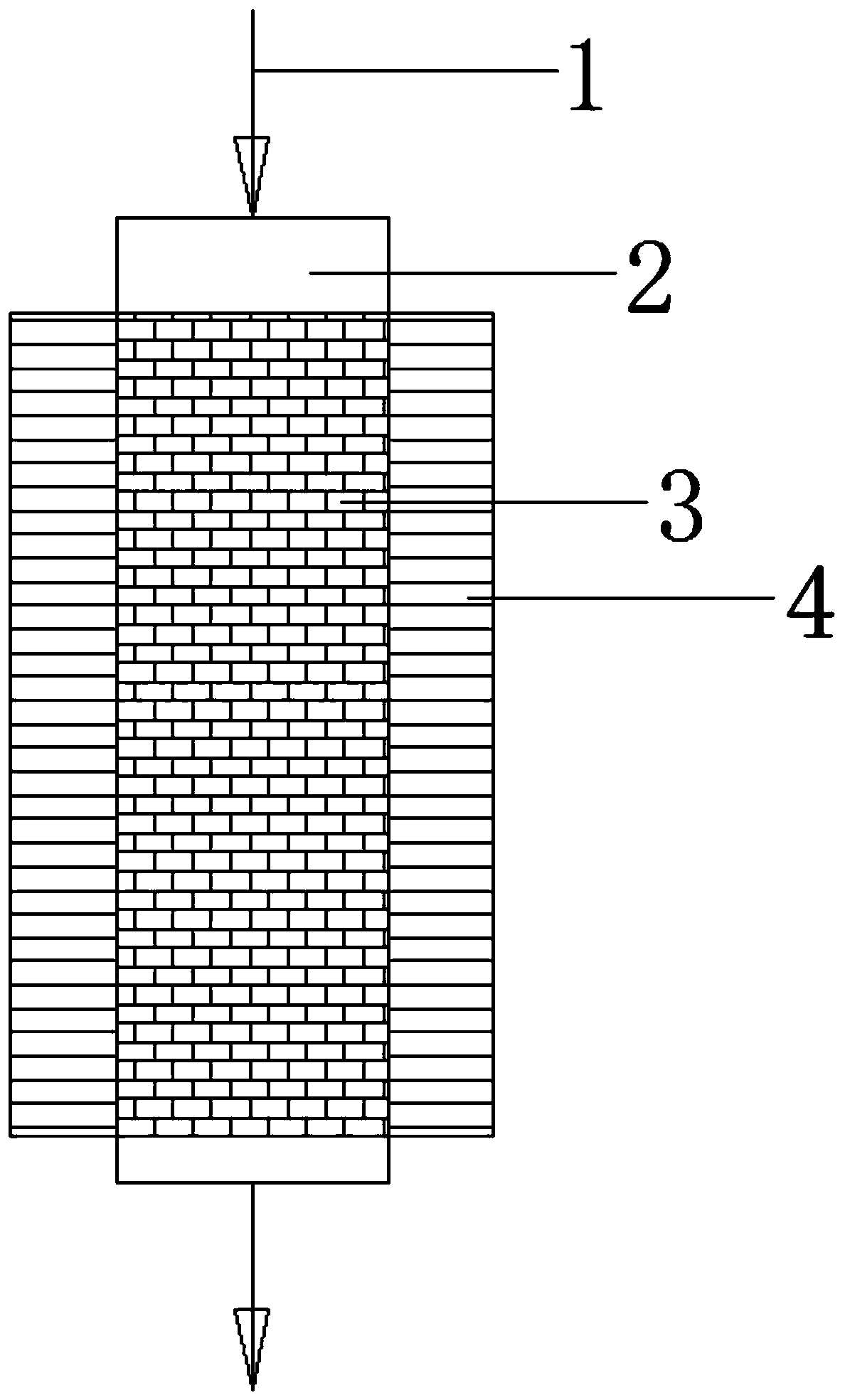

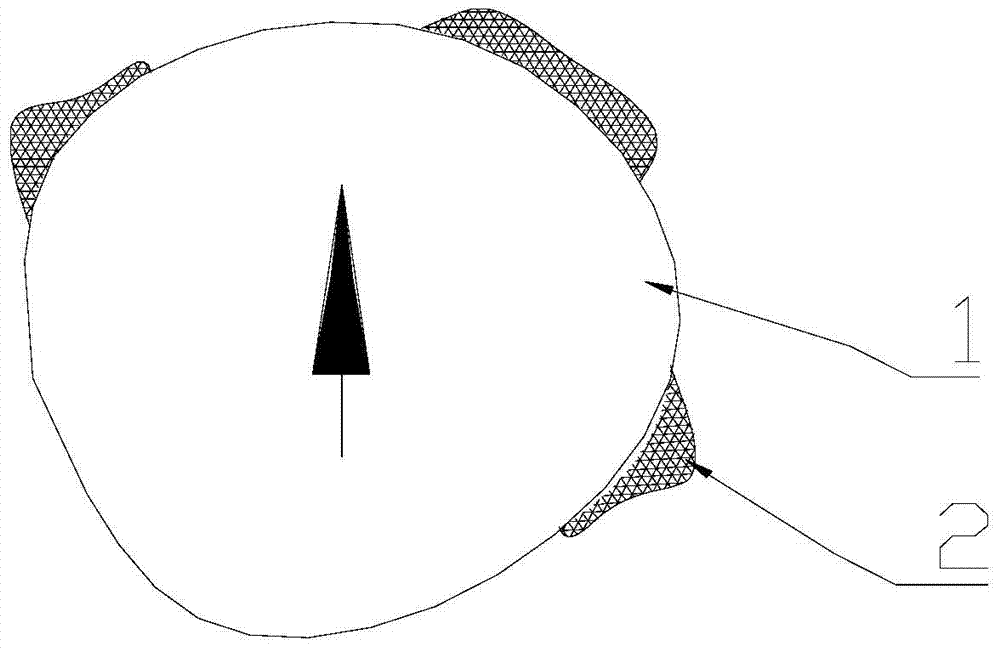

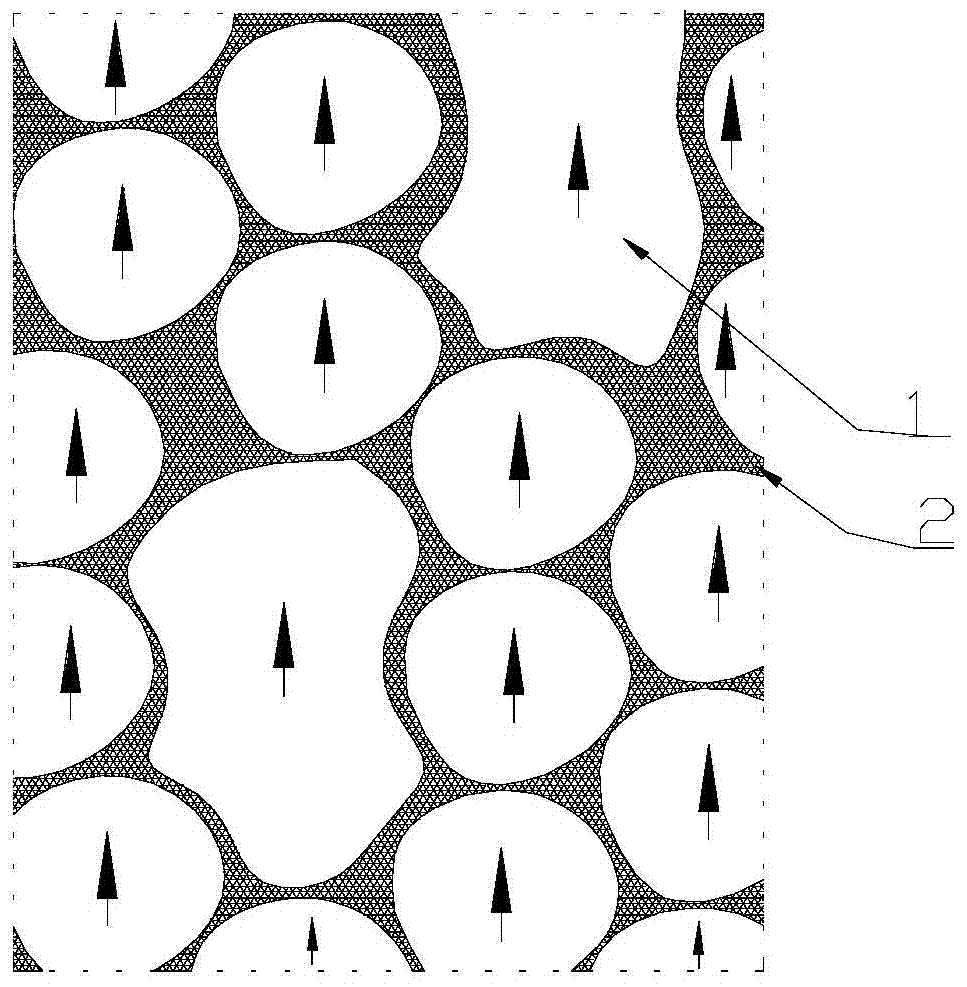

Catalyst carrier with three-dimensional mesh inert skeleton structure and preparation method of catalyst carrier

ActiveCN110368921ANot easy to collapseHigh mechanical strengthCatalyst carriersCatalyst protectionPore diameterCatalyst support

The invention provides a catalyst carrier with a three-dimensional mesh inert skeleton structure and a preparation method of the catalyst carrier. The carrier comprises a three-dimensional mesh (dense) ceramic skeleton with densely distributed large-pore-diameter pore channels, and large pore diameters of the three-dimensional mesh ceramic skeleton are filled with porous catalytic materials; and the size of the large pore diameters is greater than 50 nm, and the size of porous pore diameters is 0.3-20 nm. The catalyst carrier with the three-dimensional mesh inert skeleton structure and the preparation method of the catalyst carrier have the advantage that the morphology structures and physico-chemical properties of the catalyst are effectively adjusted and controller to improve catalytic performance.

Owner:姚光纯

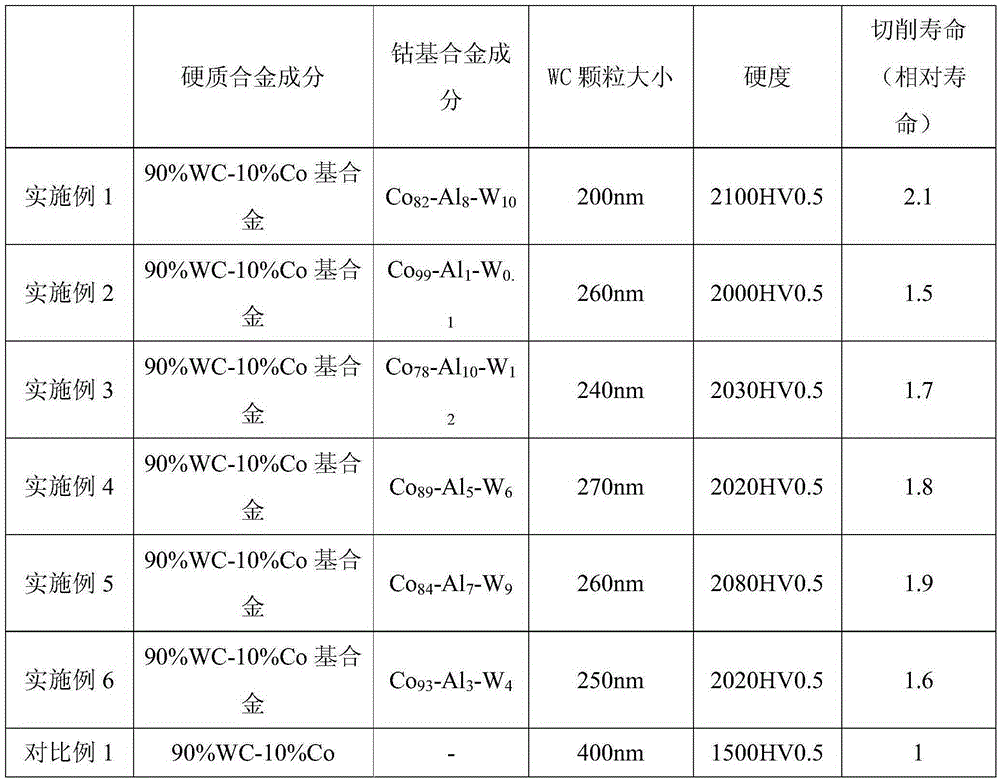

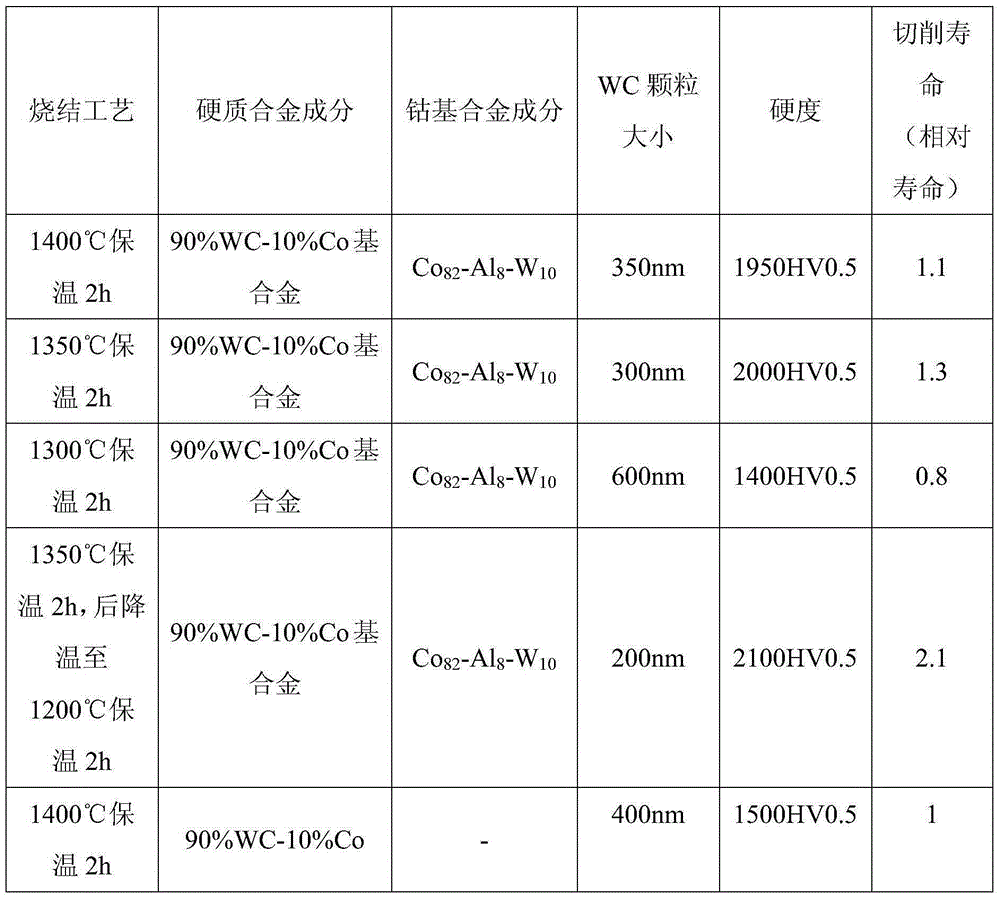

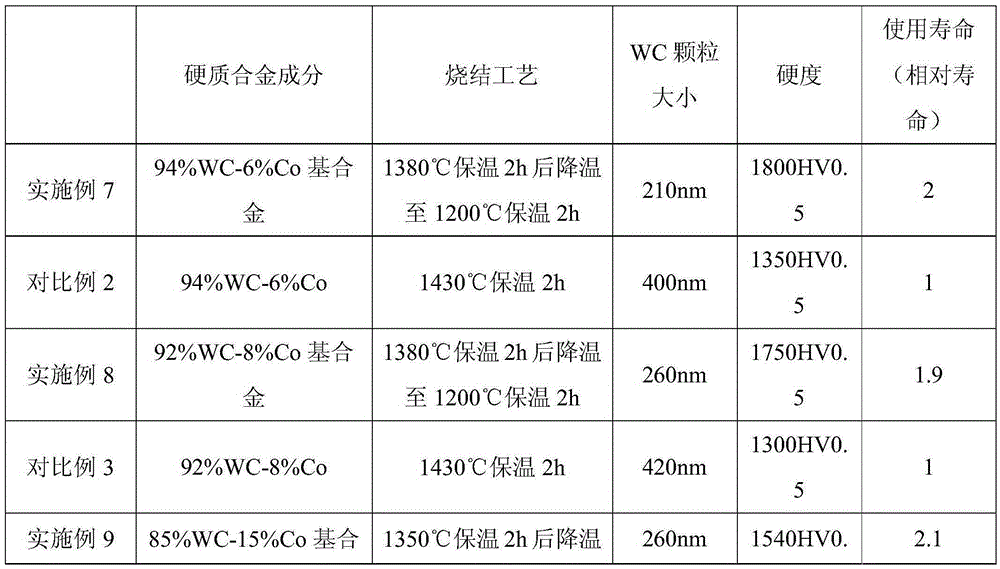

High-performance hard alloy with cobalt-based alloy as binding phase

The invention discloses a high-performance hard alloy and a preparation method thereof. The high-performance hard alloy is prepared with a cobalt-based alloy as a binding phase, and the cobalt-based alloy is composed of, by mole percentage, 78%-99% of Co, 1%-10% of Al and 0.1%-12% of W. According to the hard alloy prepared through the method, the size D of each WC particle is less than 300 nm; the hardness reaches 2100 HV at a maximum; the sintering temperature is lowered by 50 DEG C; and the service life reaches 2.1 times that of a standard hard alloy composed of the same constituents at a maximum.

Owner:NANJING UNIV OF SCI & TECH

Production method for big-thickness ultrawide DIWA353 steel plates

InactiveCN110499458AImprove low temperature toughnessGuaranteed StrengthSheet steelTreatments procedures

The invention discloses a production method for big-thickness ultrawide DIWA353 steel plates, and belongs to the technical field of metallurgy. The production method comprises the procedures of smelting, casting, heating, rolling, water cooling and heat treatment. The smelting procedure comprises electric furnace initial smelting, LF furnace refining and VD furnace vacuum treatment; the heat treatment procedure adopts normalization and tempering treatment processes; the normalization temperature is 950+-10 DEG C; the heating time is 4.5-5 h; the insulation time is 0.8-1 min / mm; the furnace iscooled to 910+-10 DEG C; the insulation time is 1.2-1.5 min / mm; the water cooling is performed by 6-8 min after normalization; and the red returning temperature of steel plates is not higher than 600DEG C. The produced steel plates are higher in purity, uniform in component, compact in internal, smooth in surface, free of recess and excellent in mechanical performance, and can be used for manufacturing high-pressure boiler drums, nuclear energy containers and other high-pressure resisting containers.

Owner:WUYANG IRON & STEEL

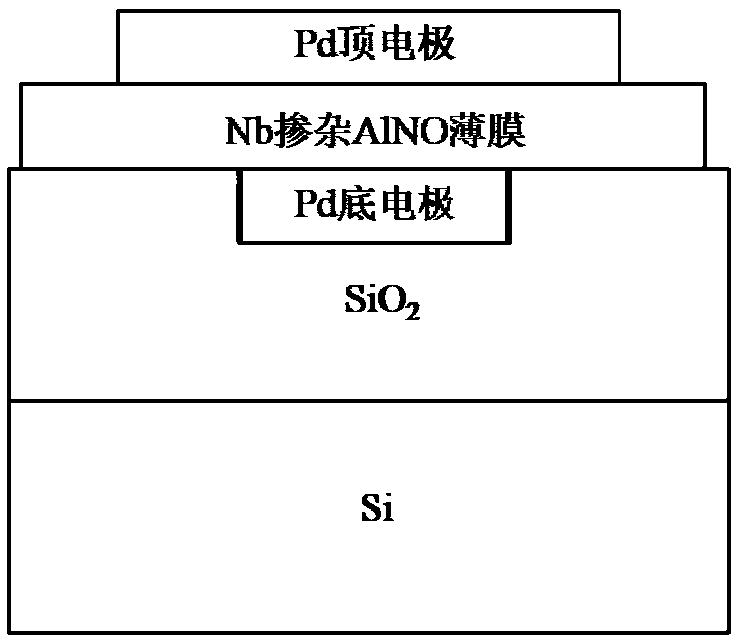

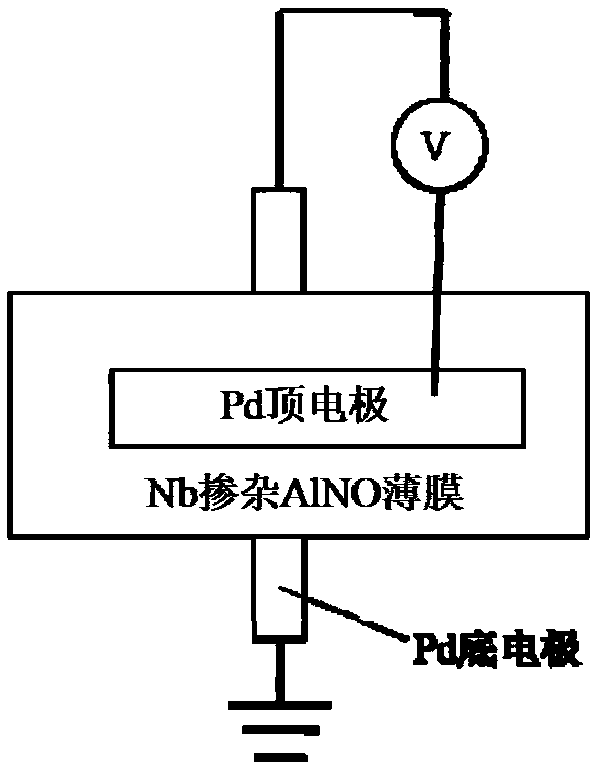

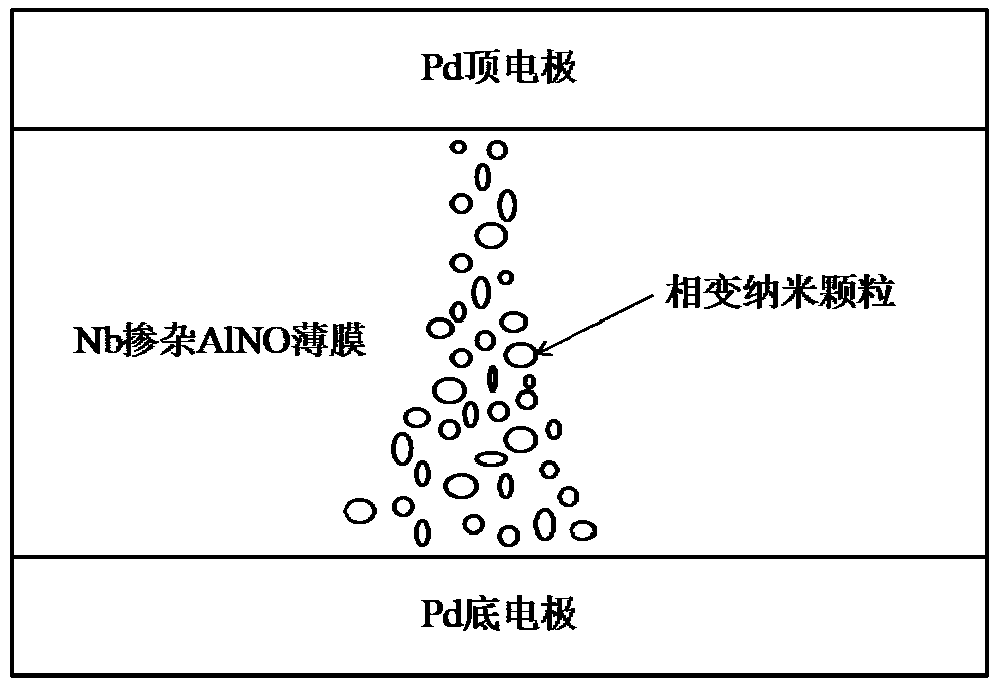

Phase-changing nanoparticle-embedded nitride memristor and fabrication method thereof

ActiveCN109449286AInhibitory connectivityNot easy to grow upMaterial nanotechnologyElectrical apparatusSynapseNanoparticle

The invention discloses a phase-changing nanoparticle-embedded nitride memristor and a fabrication method thereof. The memristor comprises a bottom electrode, a dielectric layer and a top electrode which are sequentially arranged, wherein the dielectric layer is a nitride or nitrogen oxide thin film, and the nitride or nitrogen oxide thin film is arranged on a surface of the bottom electrode and is doped with transition metal. The fabrication method comprises the following steps of depositing inert metal on a substrate as the bottom electrode; depositing a layer of nitride or nitrogen oxide thin film on the bottom electrode, and simultaneously depositing a few amount of transition metal into the nitride or nitrogen oxide thin film; adding a mask plate onto the dielectric layer, and depositing the inert metal on the mask plate as the top electrode, and then removing the mask plate; and employing negative bias between the top electrode and the bottom electrode so that phase-changing nanoparticle is formed in the dielectric layer, penetrates through the dielectric layer and is gathered to form beams. The memristor has a coding function under a periodic and strong input pulse effect and has functions of memory and learning after the strong input pulse is ended, and the calculation and learning function of synapse can be simulated very well.

Owner:TSINGHUA UNIV

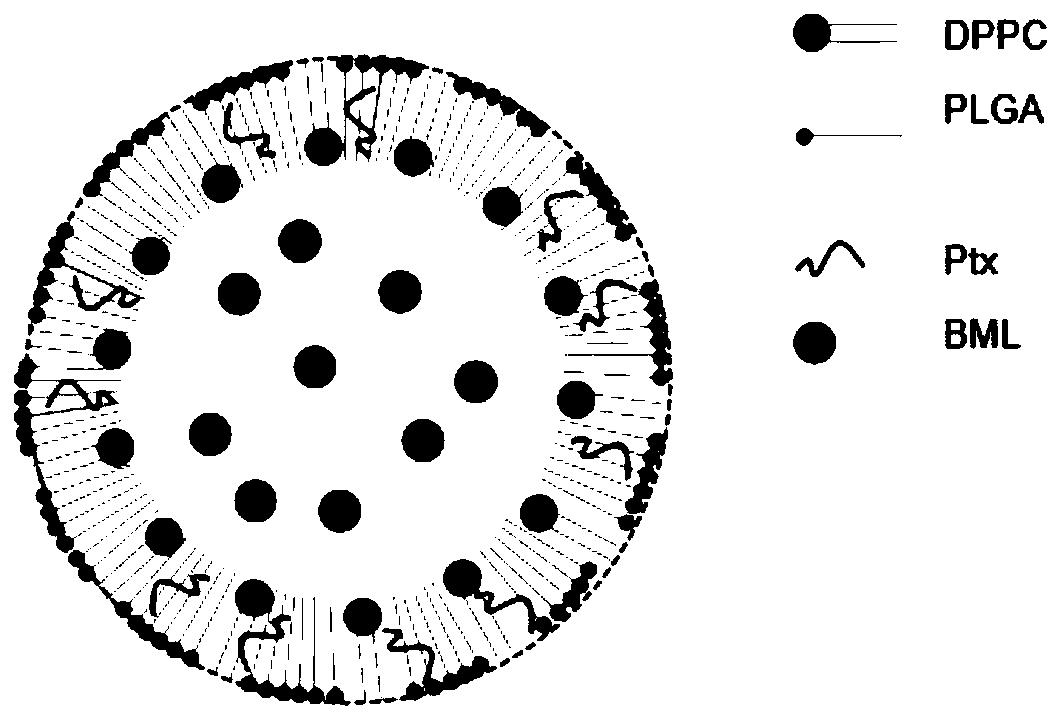

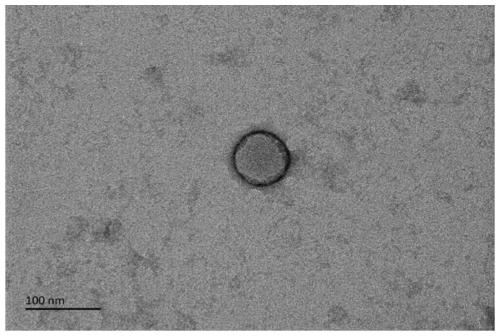

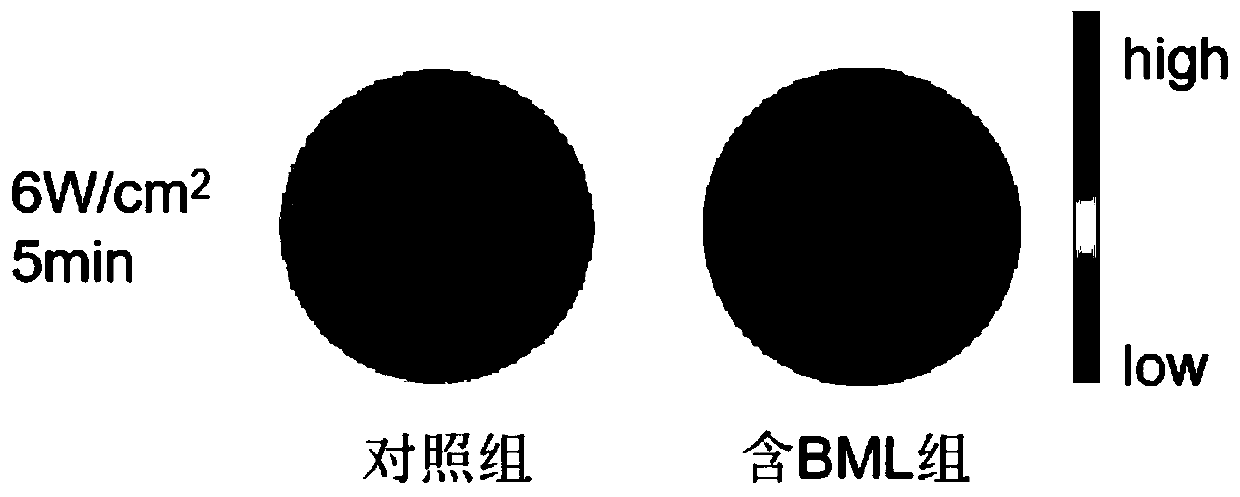

Nanoparticle for microwave touch release of PLGA shell, and preparation method and application of nanoparticle

PendingCN111420056AEfficient releaseLow mechanical strengthOrganic active ingredientsPharmaceutical non-active ingredientsPhysicsChemistry

The invention provides a nanoparticle for microwave touch release of a PLGA shell, and a preparation method and application thereof, and relates to the technical field of nanoparticle drug carriers. The nanoparticle at least takes PLGA as a shell, and at least an ionic liquid microwave sensitizer is wrapped in the nanoparticle. Under action of a microwave field, when the prepared nanoparticle formicrowave touch release of the PLGA shell reaches a target tissue, local irradiation is performed on the tissue by using a microwave therapeutic instrument, and the microwave sensitizer in the nanoparticle generates a large amount of heat energy after being irradiated, so that local release of drugs by the nano material is promoted.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Production method for sintered neodymium-iron-boron permanent magnets

ActiveCN104752048ANot easy to grow upNot easy to grow up fastInductances/transformers/magnets manufactureMagnetic materialsRare earthAlloy

Disclosed is a production method for sintered neodymium-iron-boron permanent magnets. The method is a dual-alloy method using master alloy and auxiliary alloy and is characterized in that the grain size of the auxiliary alloy ranges from 0.01 micrometers to 0.1 micrometers. The method includes that quenching auxiliary neodymium-iron-boron powder with total rare earth content obviously lower than master alloy powder and the grain size far less than particle size is added to sintered master neodymium-iron-boron alloy powder with the total rare earth content ranging from 28wt.% to 35wt.% and the average particle size and grain size ranging from 3.0 micrometers to 5.0 micrometers. Grains of Neodymium-iron-boron compact is prevented from growing rapidly, generation of bulk-shaped rich rare earth phase on the boundary of neodymium-iron-boron main phase is reduced, and the neodymium-iron-boron permanent magnets low in production cost and high in performance are obtained.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

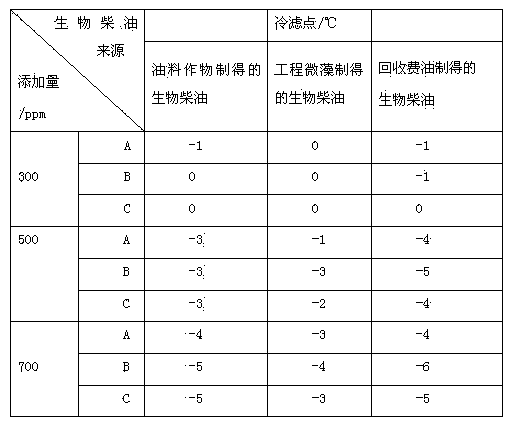

Preparation method of biodiesel composite additive

ActiveCN103642543ALower freezing temperatureGood fluidity at low temperatureLiquid carbonaceous fuelsBiodieselOil additive

The invention belongs to the field of fuel oil additives and in particular relates to a preparation method of a biodiesel composite additive. The preparation method of the biodiesel composite additive comprises the following steps: adding dodecyl methacrylate, steary methacrylate, isooctyl nitrate and dicthyl ortho-phthalate into a raw material mixing tank and stirring evenly; adding maleic anhydride and isooctanol and stirring evenly; and then adding tert-butylamine and double hexadecyl dimethyl ammonium chloride and stirring for 30-35 minutes; adding polyoxyethylene hexadecy phenolic ether and phenyl propargyl ether into a solution, heating to 45-50 DEG C, stirring for 20-30 minutes at 0.5-1.0MP, standing for 24 hours and filtering to remove sediment. The biodiesel composite additive prepared by the preparation method is good in cold filtering point reducing effect; and meanwhile, the problem of reversion of the cold filtering point can be avoided; the effects of other diesel additives are not influenced; and the biodiesel composite additive is efficient and stable in dispersion capability and good in oil solubility.

Owner:临沂星火知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com