Patents

Literature

46 results about "Local irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable-spectrum solar simulator

InactiveUS20120057324A1Facilitating characterisation of photovoltaicImprove versatilityElectrical apparatusElectric lighting sourcesControl systemLight beam

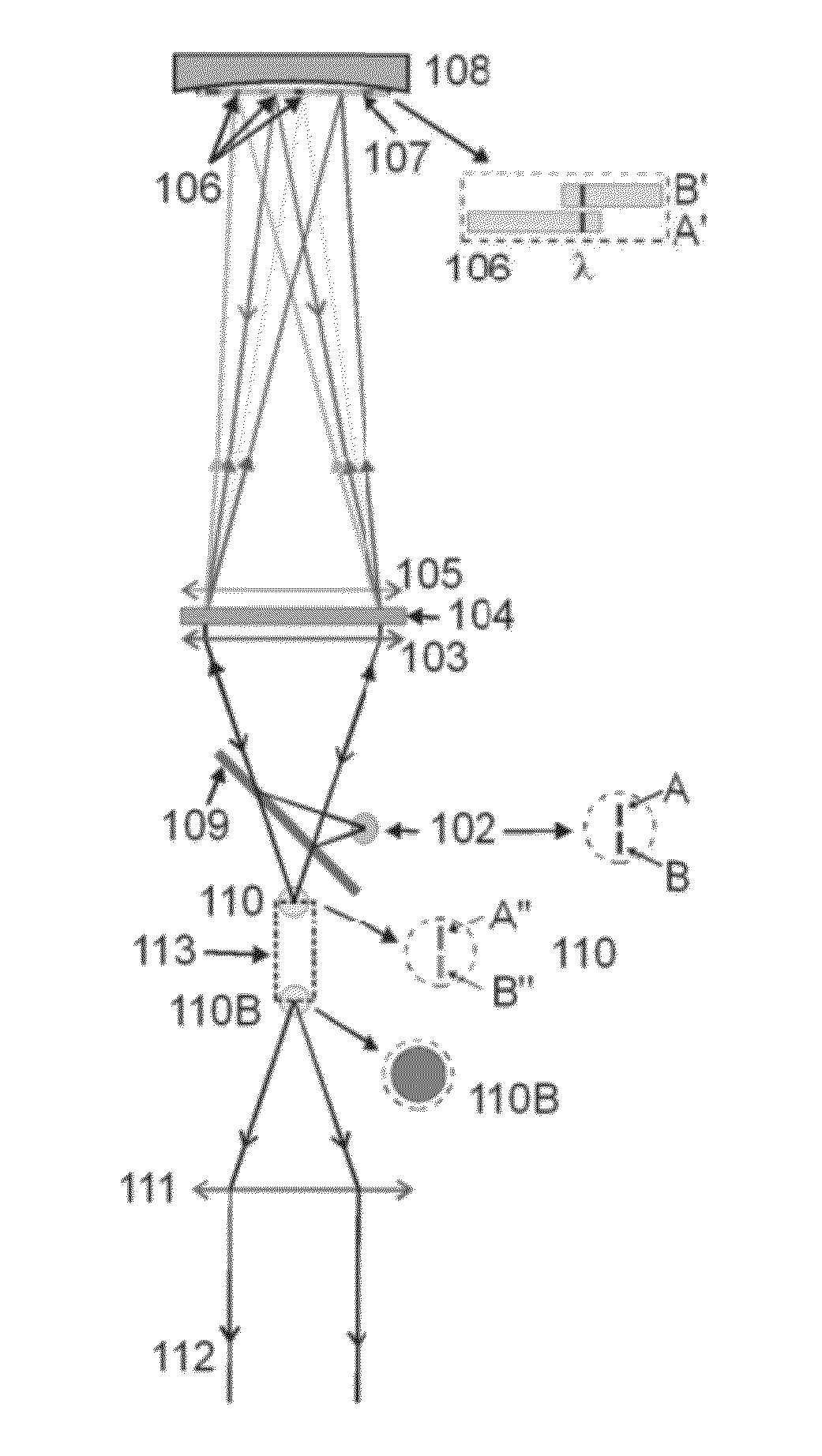

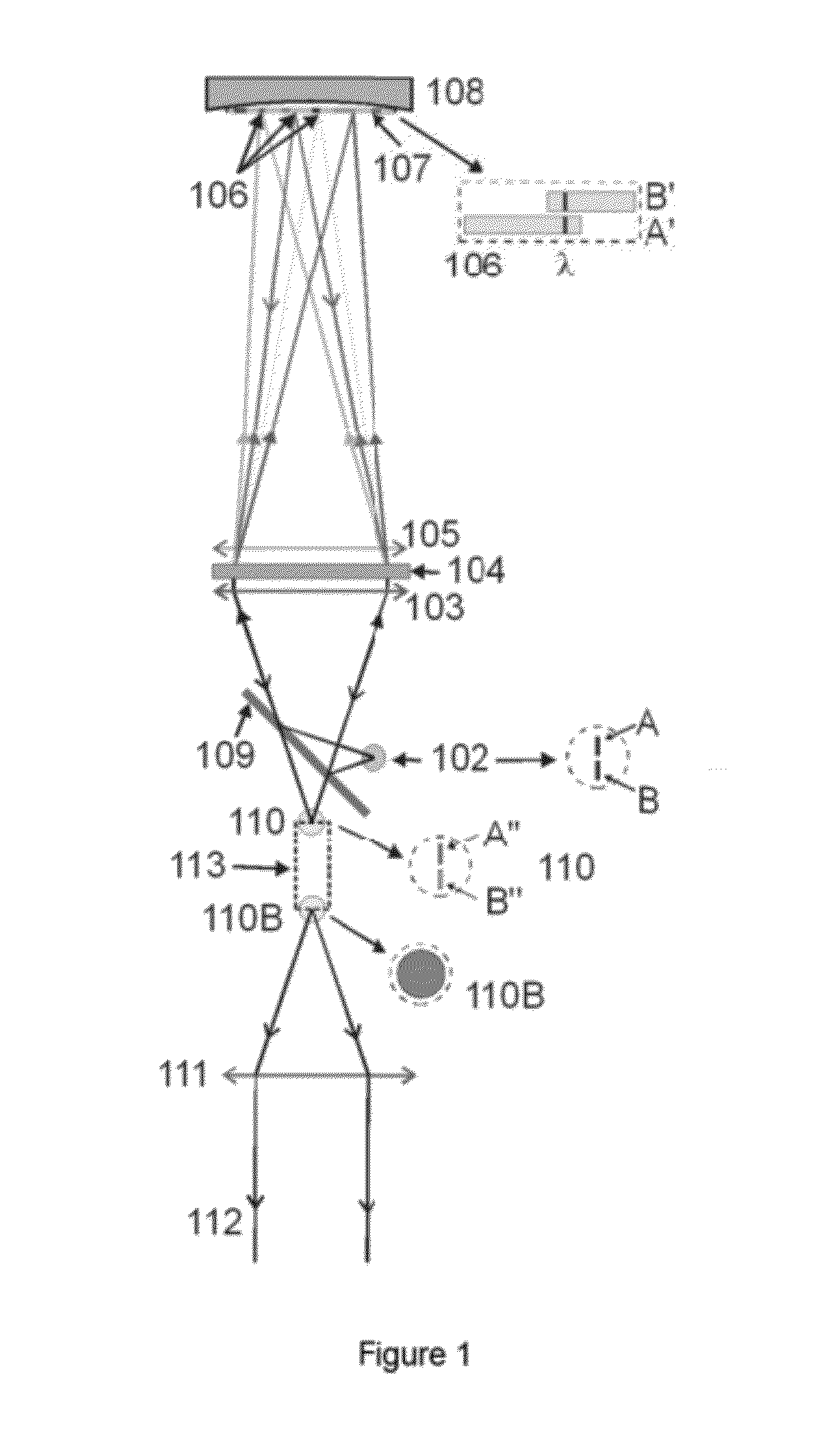

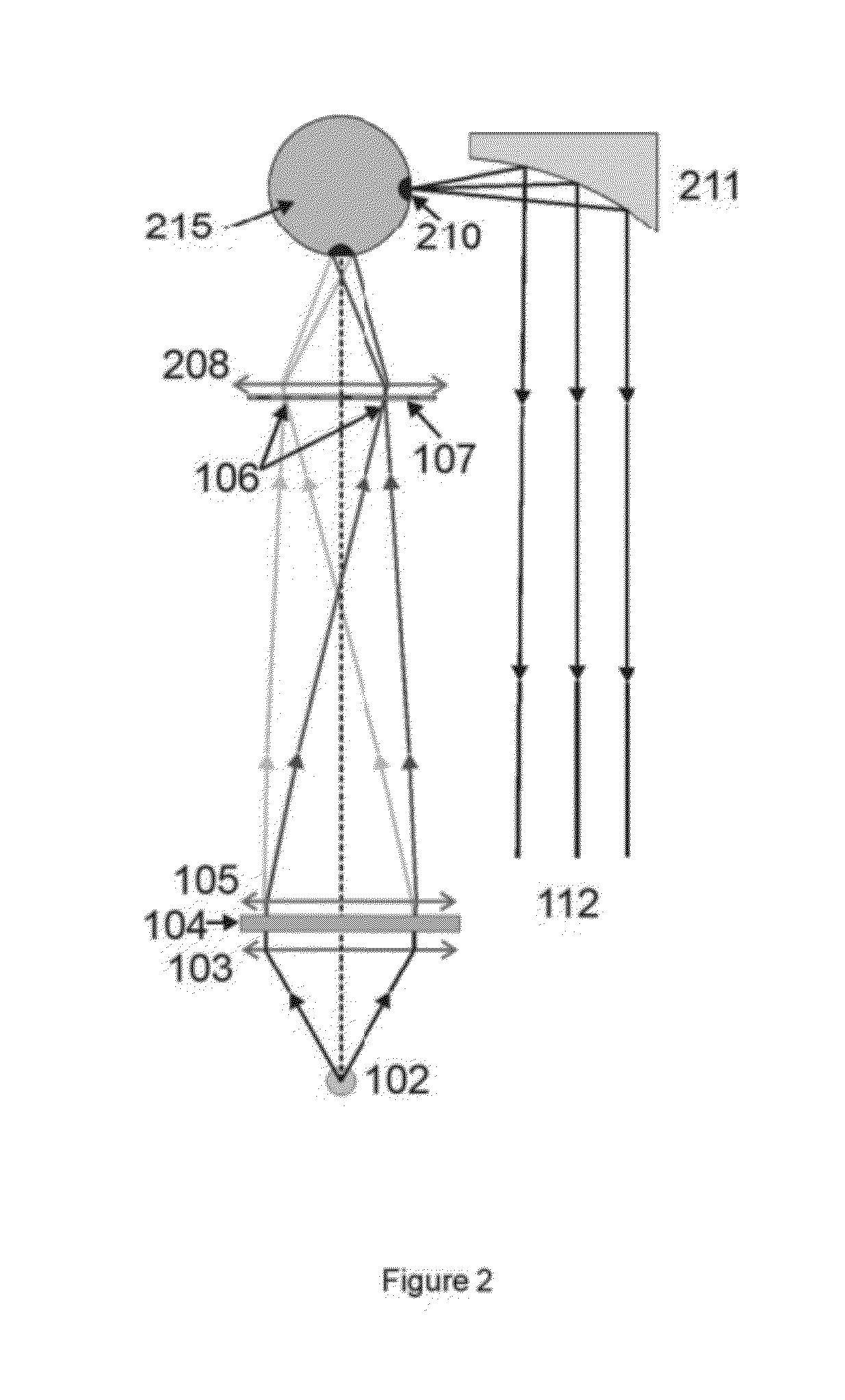

The invention relates to a variable-spectrum solar simulator for characterising photovoltaic systems. The simulator can be used to obtain a spectrum adjusted to the solar spectrum, both for a standard spectrum or a real spectrum adjusted to local irradiation conditions. The simulator also allows the spatial-angular characteristics of the sun to be reproduced. The invention comprises: a broad-spectrum light source, the flux from which is emitted through an aperture; an optical system which collimates the primary source; a system which disperses the beam chromatically; an optical system which forms an image of the dispersed primary source at a given position, at which a spatial mask is placed in order to filter the received irradiance spectrally; an optical system which captures the filtered spectrum and returns, mixes and concentrates same in a secondary source with the desired spectral, angular, and spatial characteristics; an optical system which collimates the secondary source such that it reproduces the angular characteristics of the sun; and a control system.

Owner:ABENGOA SOLAR NEW TECH SA

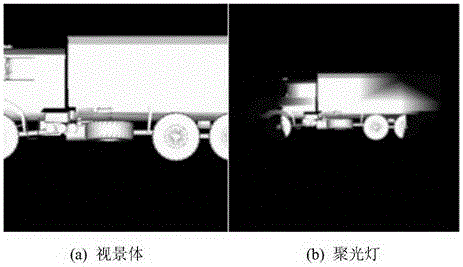

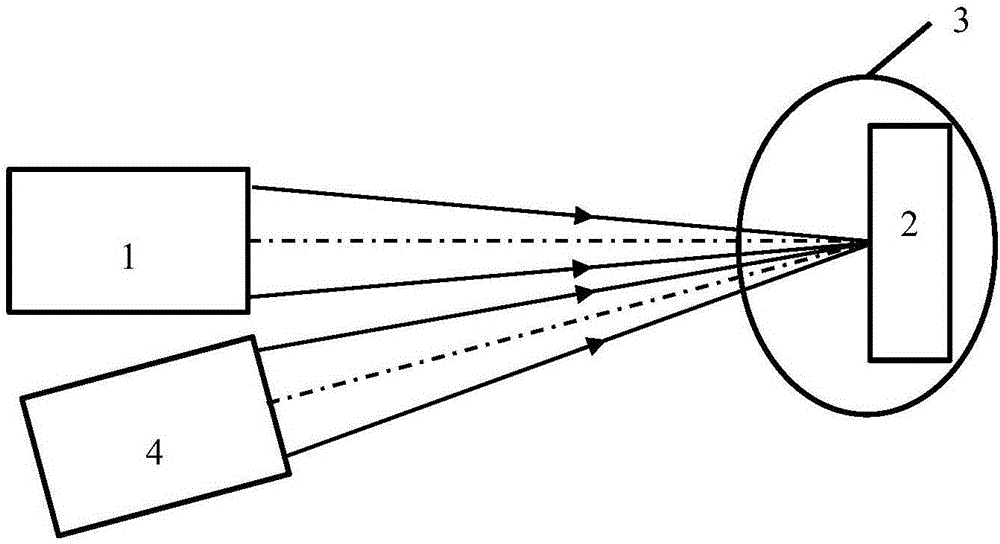

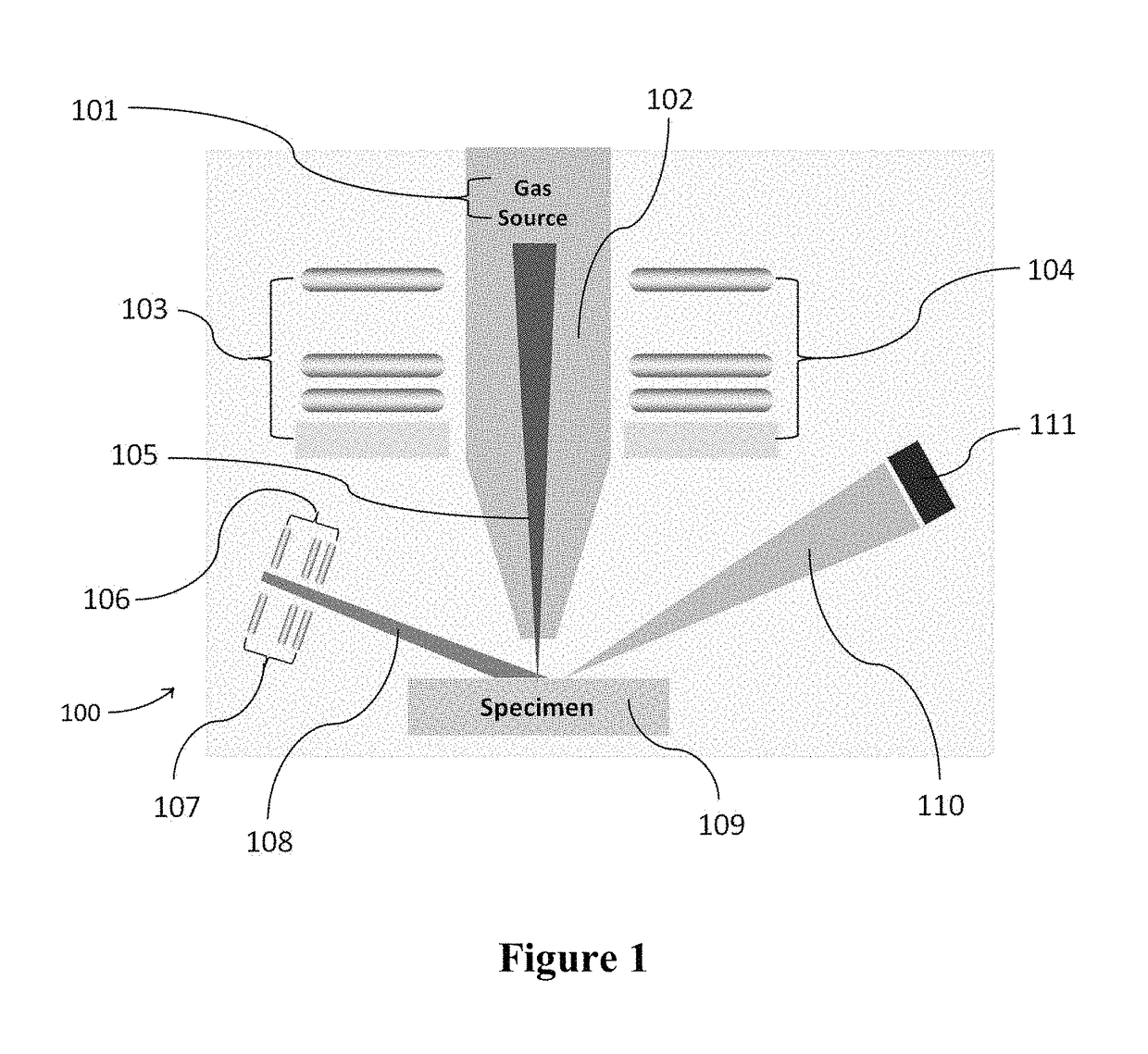

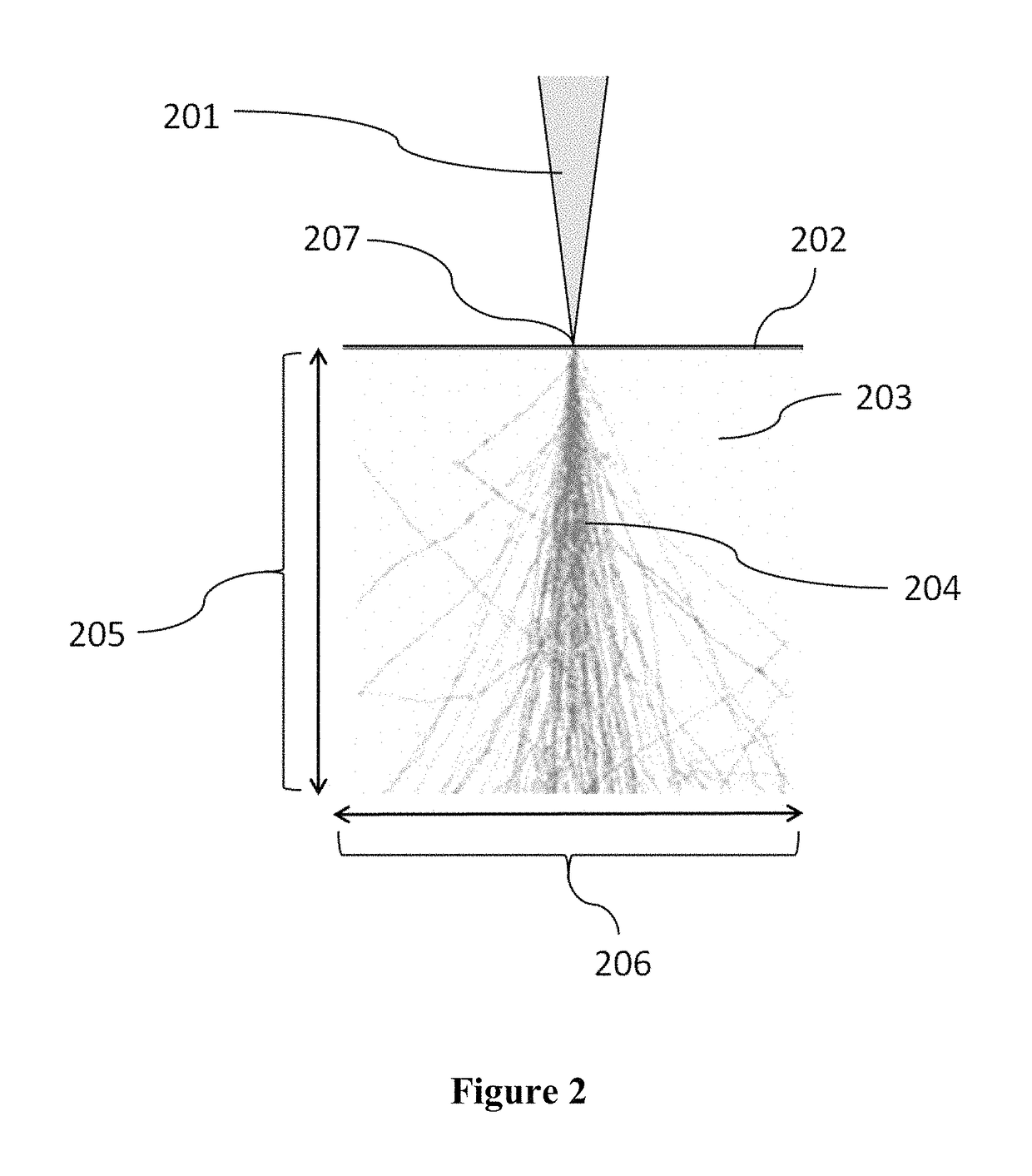

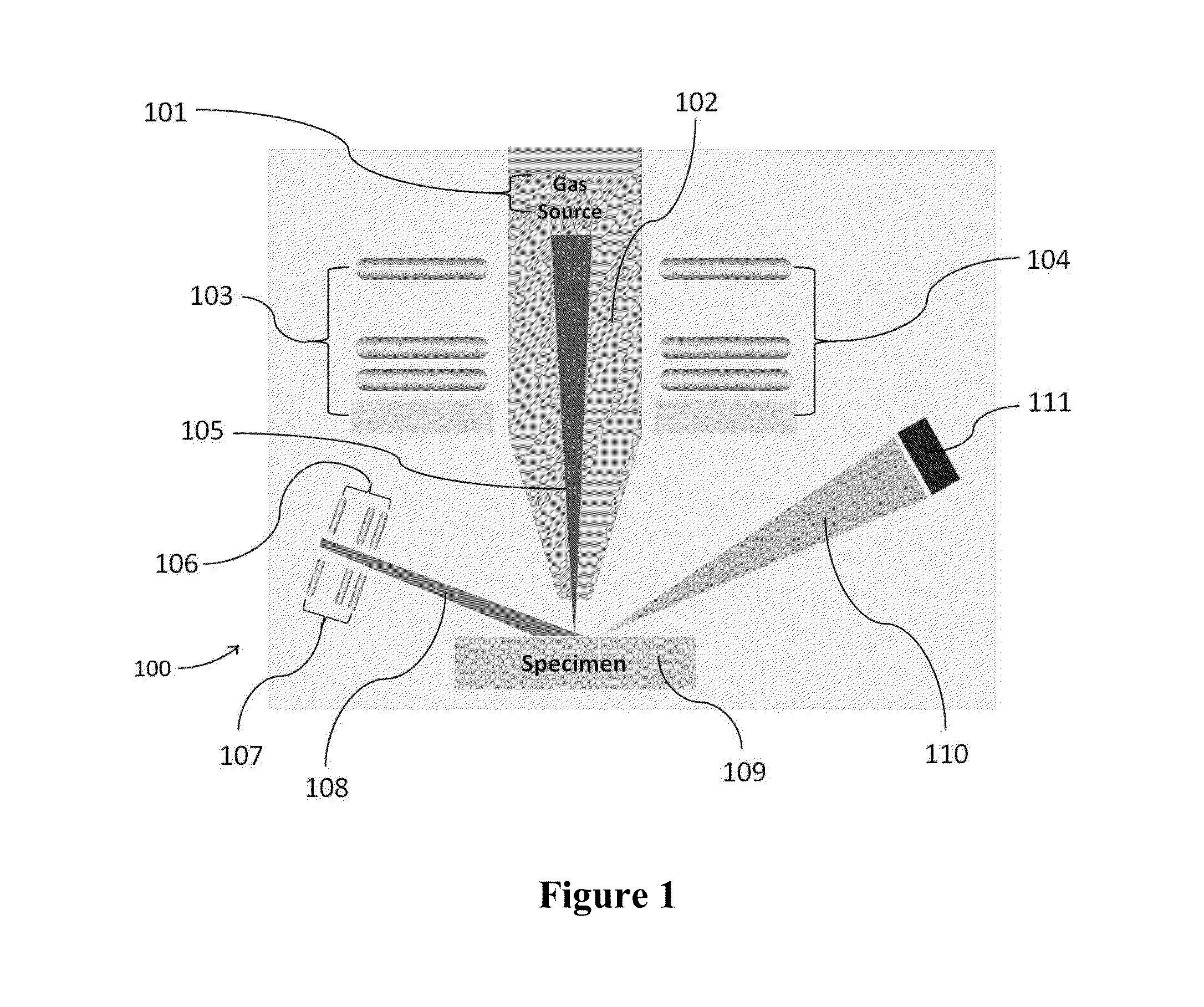

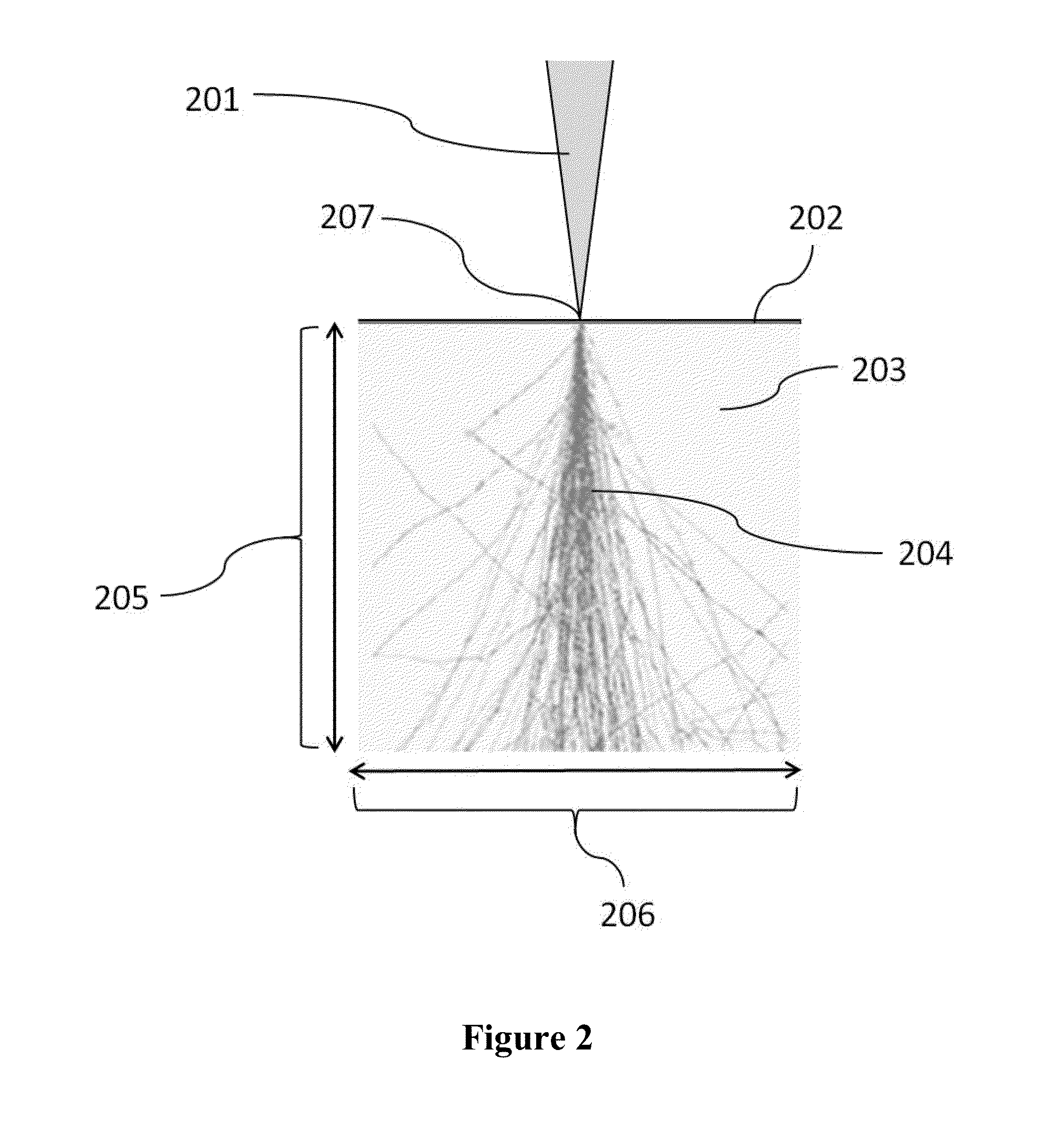

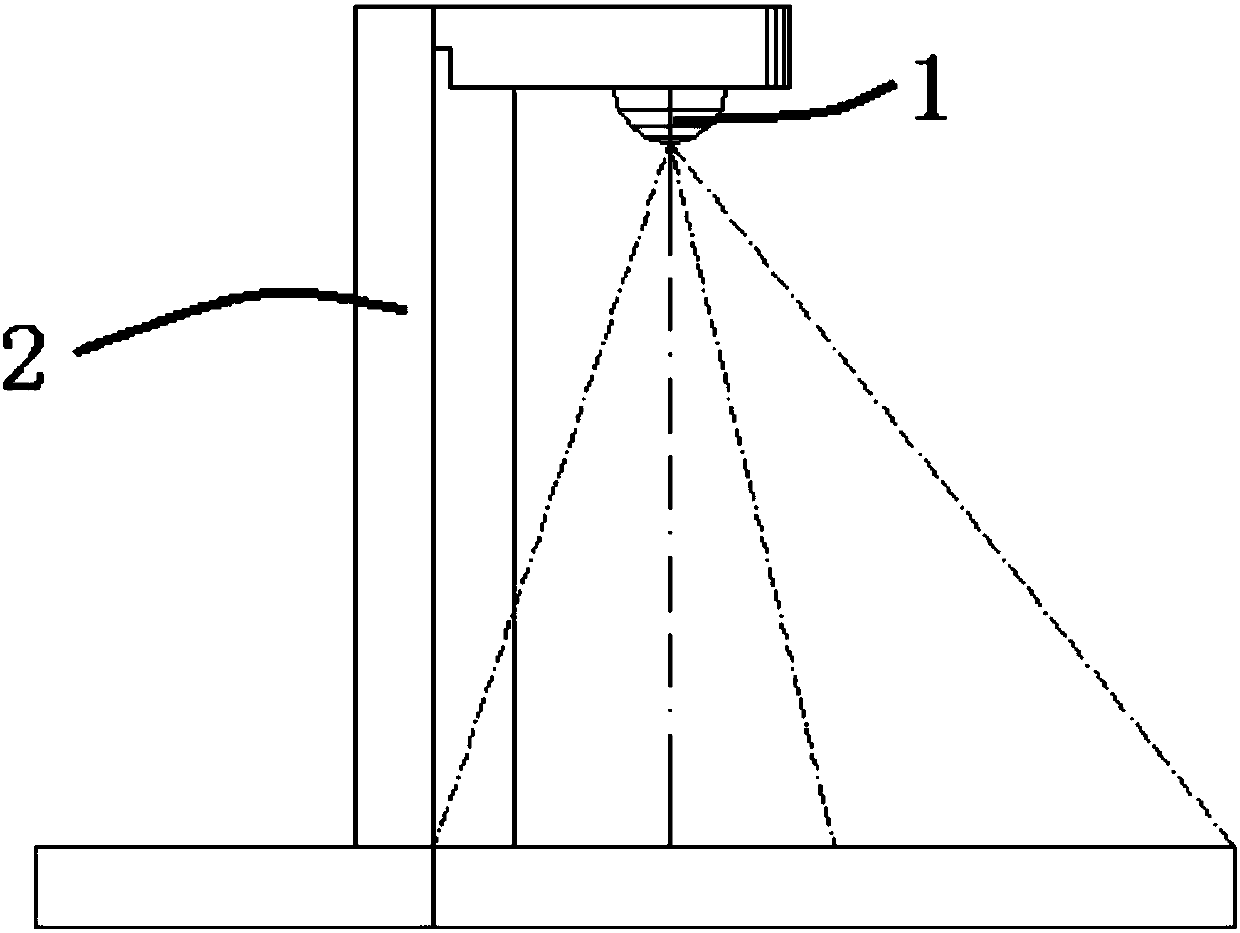

Simple calculation method of target laser scattering characteristics under local irradiation

ActiveCN106770045ACalculation of Scattering Cross SectionEasy and fast scattering cross sectionScattering properties measurementsTarget surfaceScattering cross-section

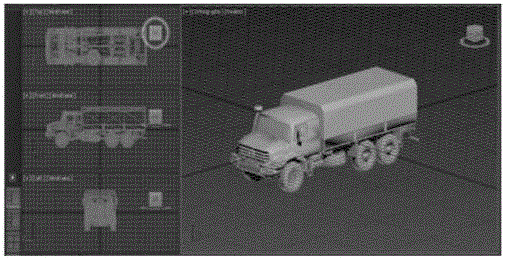

The invention discloses a simple calculation method of target laser scattering characteristics under local irradiation, and belongs to the technical field of target detection, recognition, and stealth. By modifying the parameters of view-frustum, the simple calculation of scattering cross-section of a target laser radar under local irradiation can be realized. The method comprises the following steps: at first, obtaining the bidirectional reflectance distribution function of a target surface material; establishing a geometric model of a complicated target; reading the target geometric model file, according to the size and position of an irritation laser spot, setting the parameters of view-frustum; calling an OpenGL function to carry out target rendering and blanking to realize real-time display of a target under local irradiation; and finally obtaining each parameter of a target laser radar scattering cross-section calculation formula to complete the target laser radar scattering cross-section imitation calculation under local irradiation. Compared with the conventional algorithms, the adopted algorithm is easy to operate and is flexible; the size and irritation position of the irritation laser spot can be easily modified; and the target laser radar scattering cross-section imitation calculation can be realized under laser overall / local irradiation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

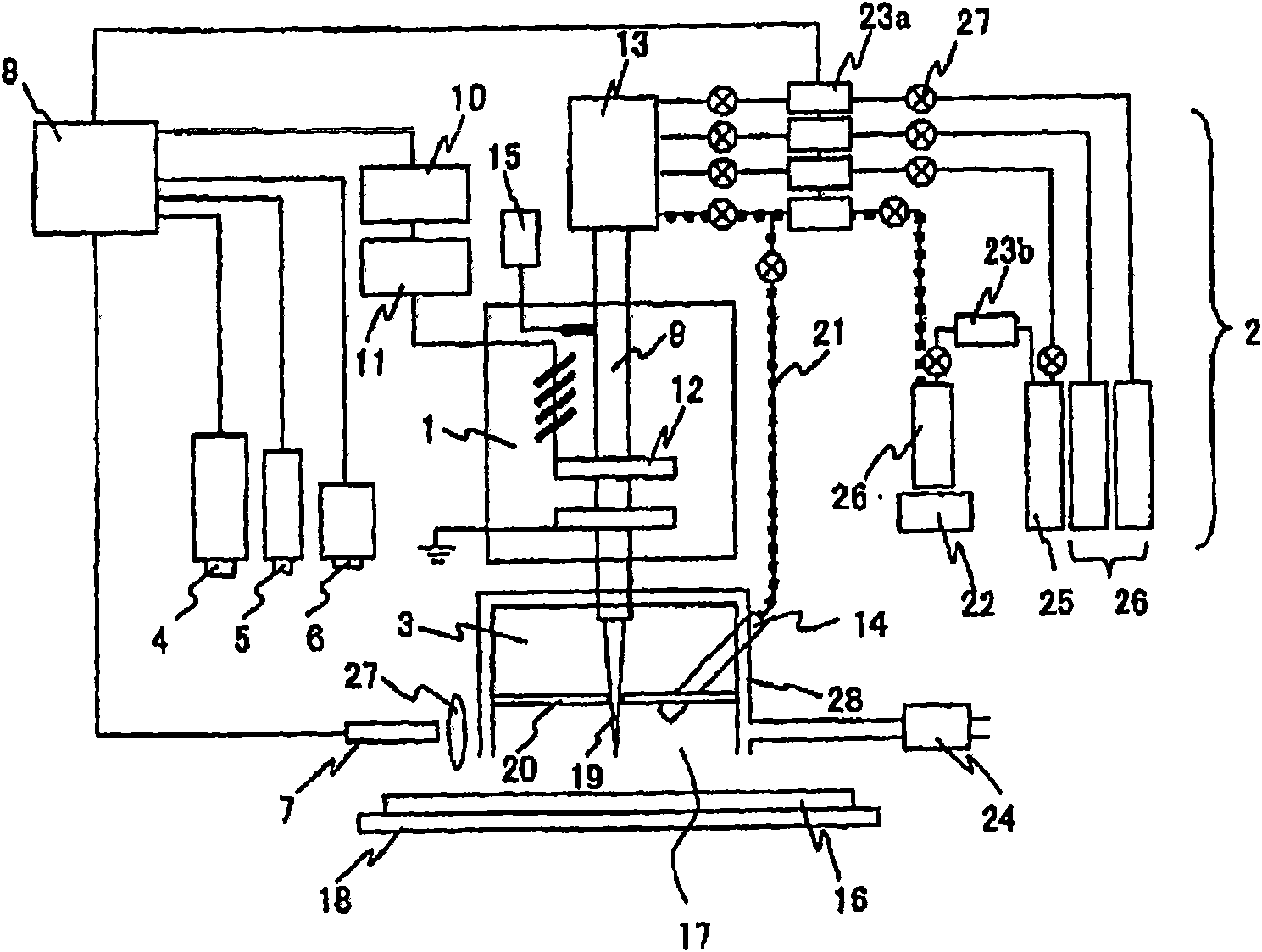

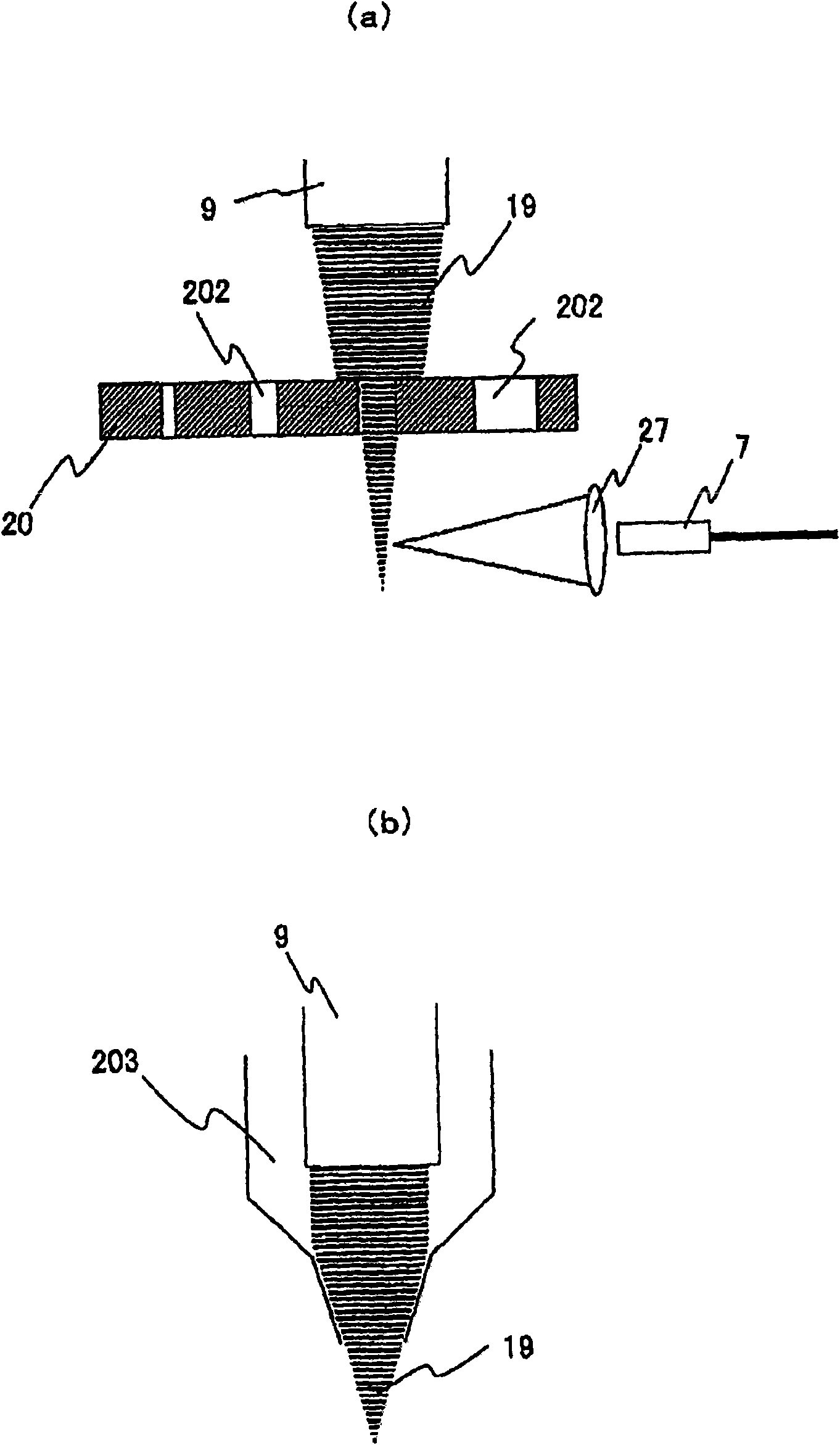

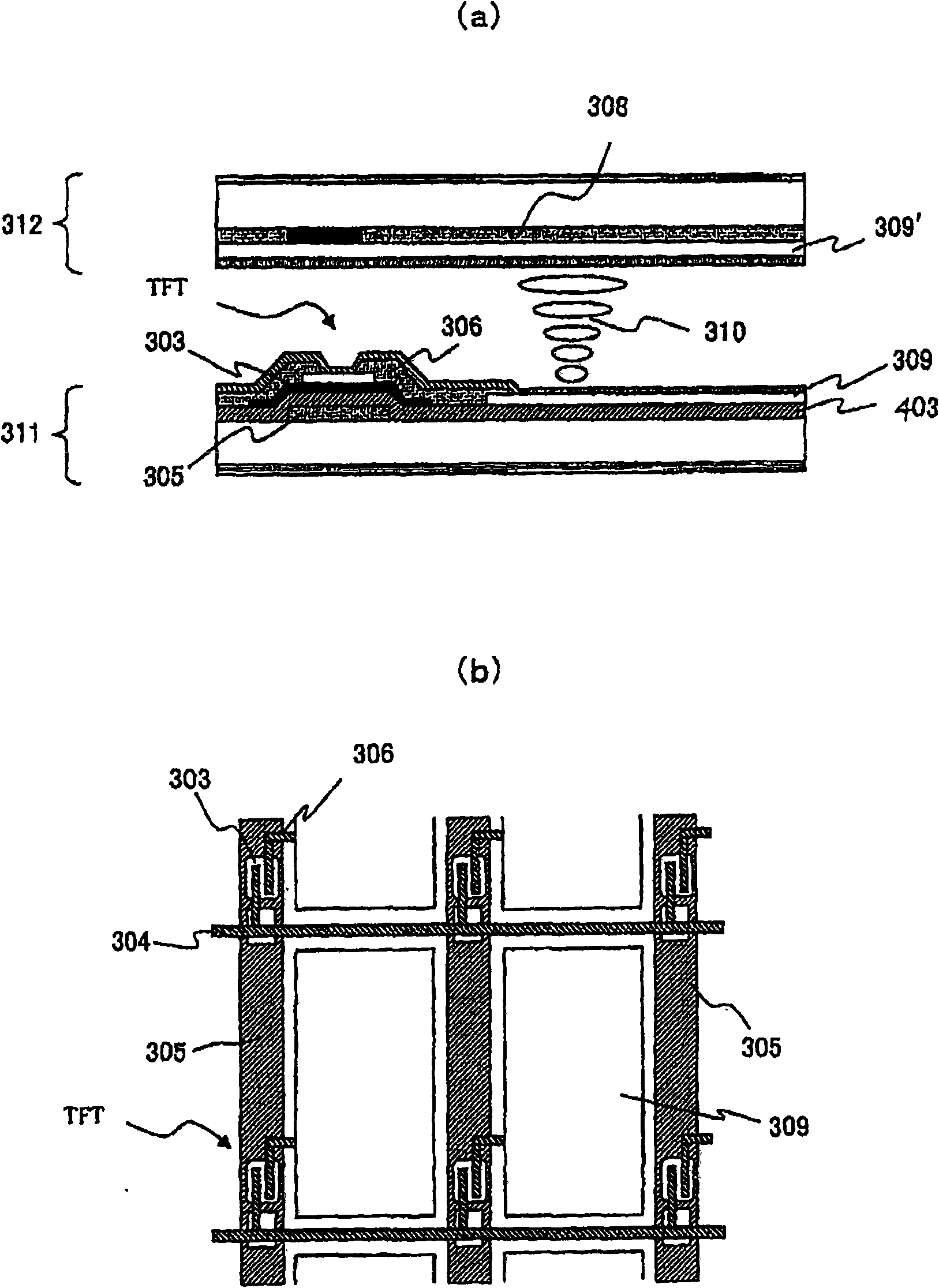

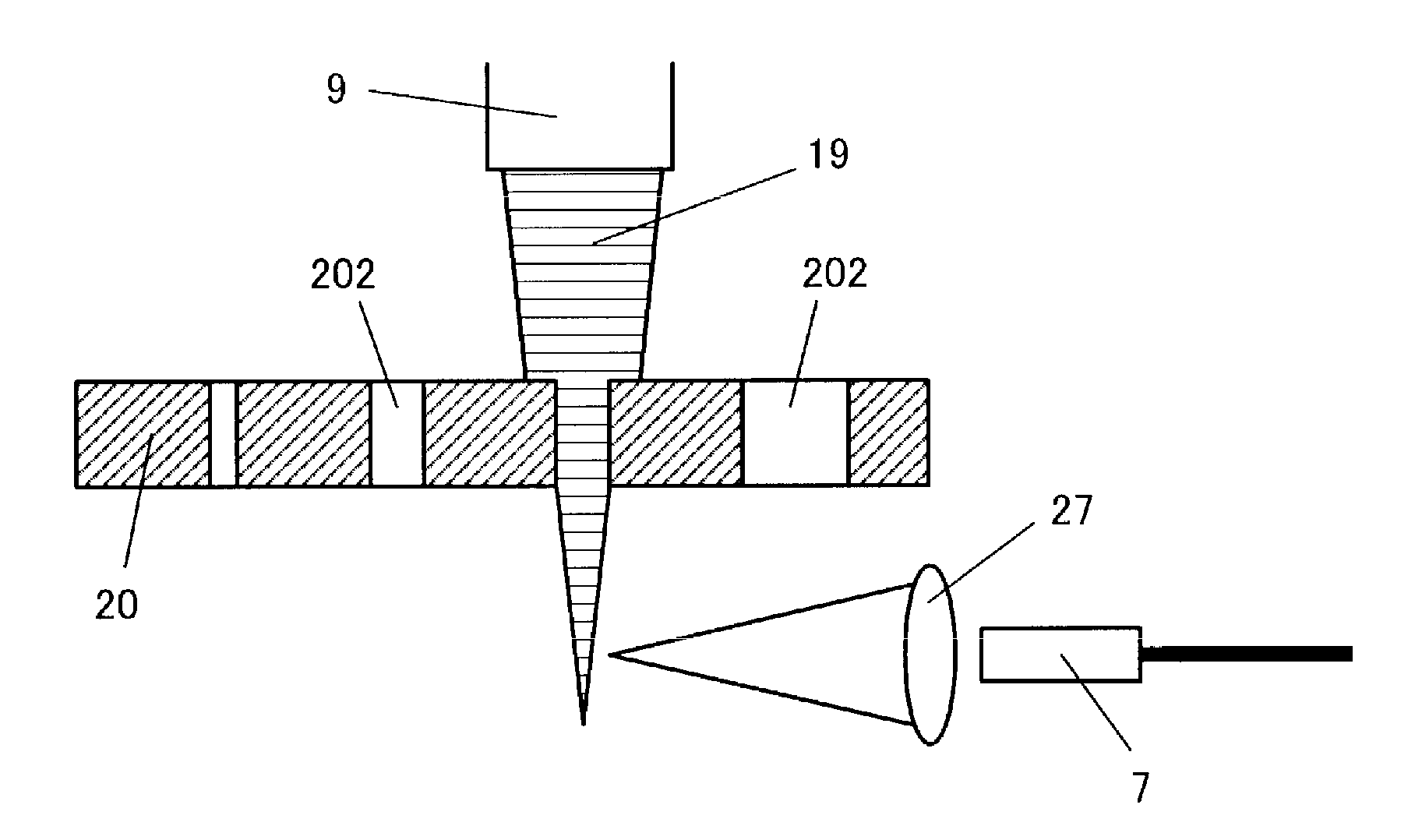

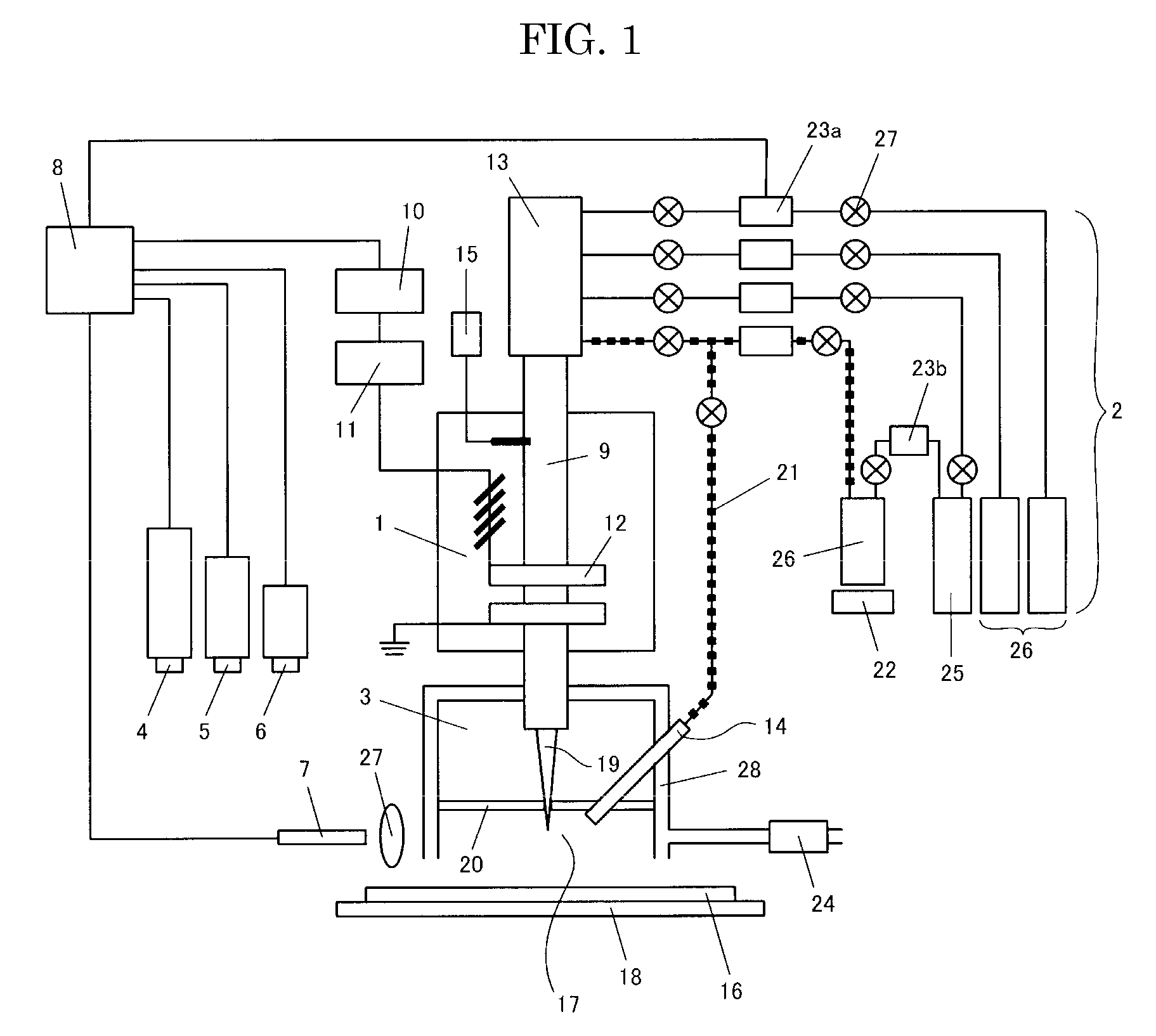

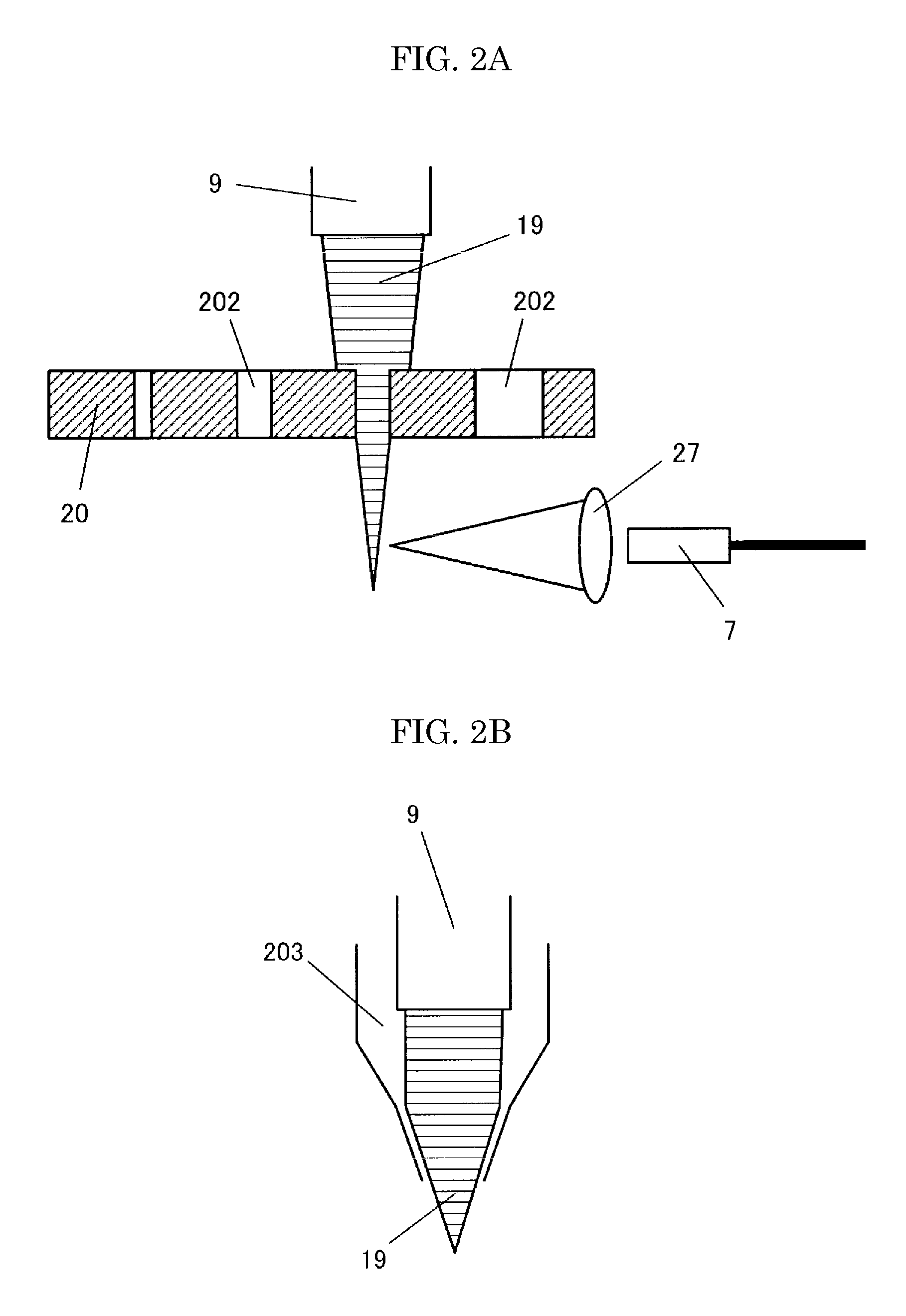

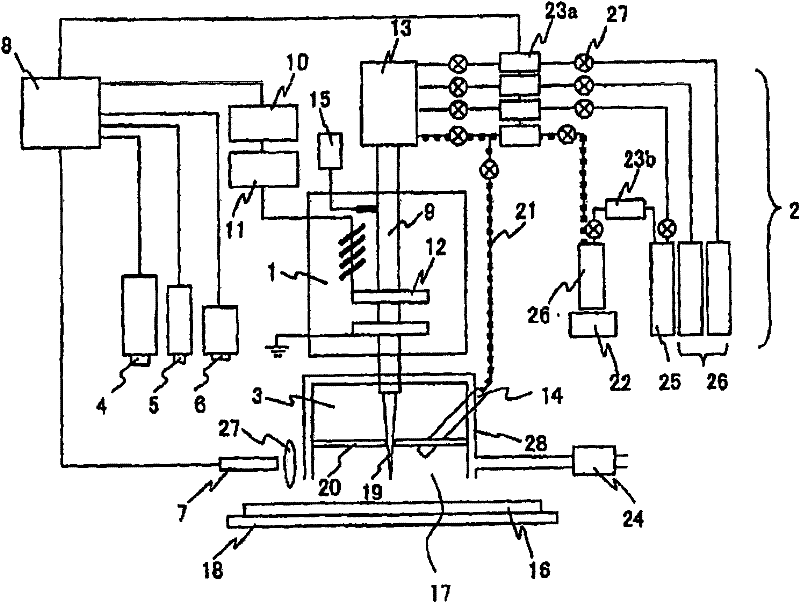

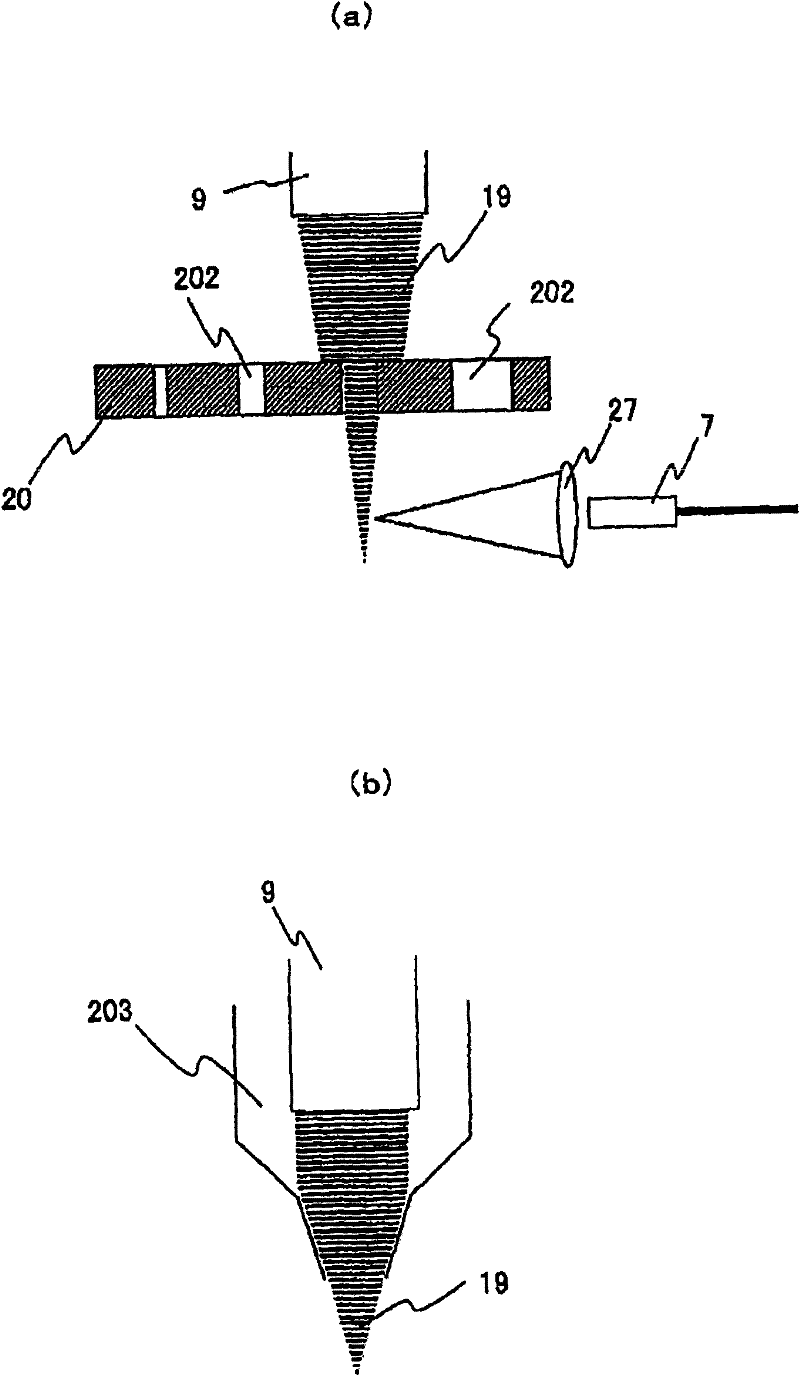

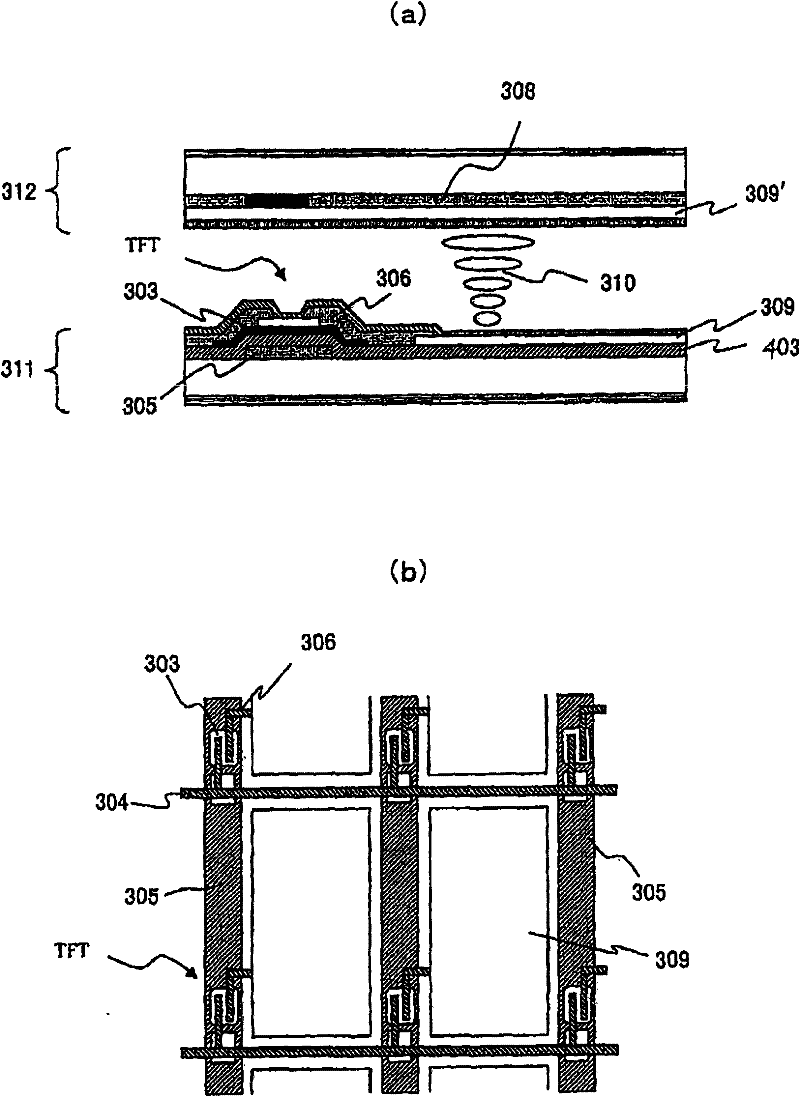

Method for repairing display device and apparatus for same

ActiveCN101667527AReduce quality fluctuationsImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An object of the present invention is to provide a method for repairing a display device according to which a wide variety of regions can be repaired in various ways using various materials, as well as an apparatus for the same. The present invention provides a repairing apparatus for repairing a pattern defect on a surface of a substrate in a display device where an electronic circuit pattern having the above described pattern defect is formed, characterized by having a plasma irradiation means for repairing the above described pattern defect through local irradiation of a region including the above described pattern defect with plasma.

Owner:JAPAN DISPLAY INC

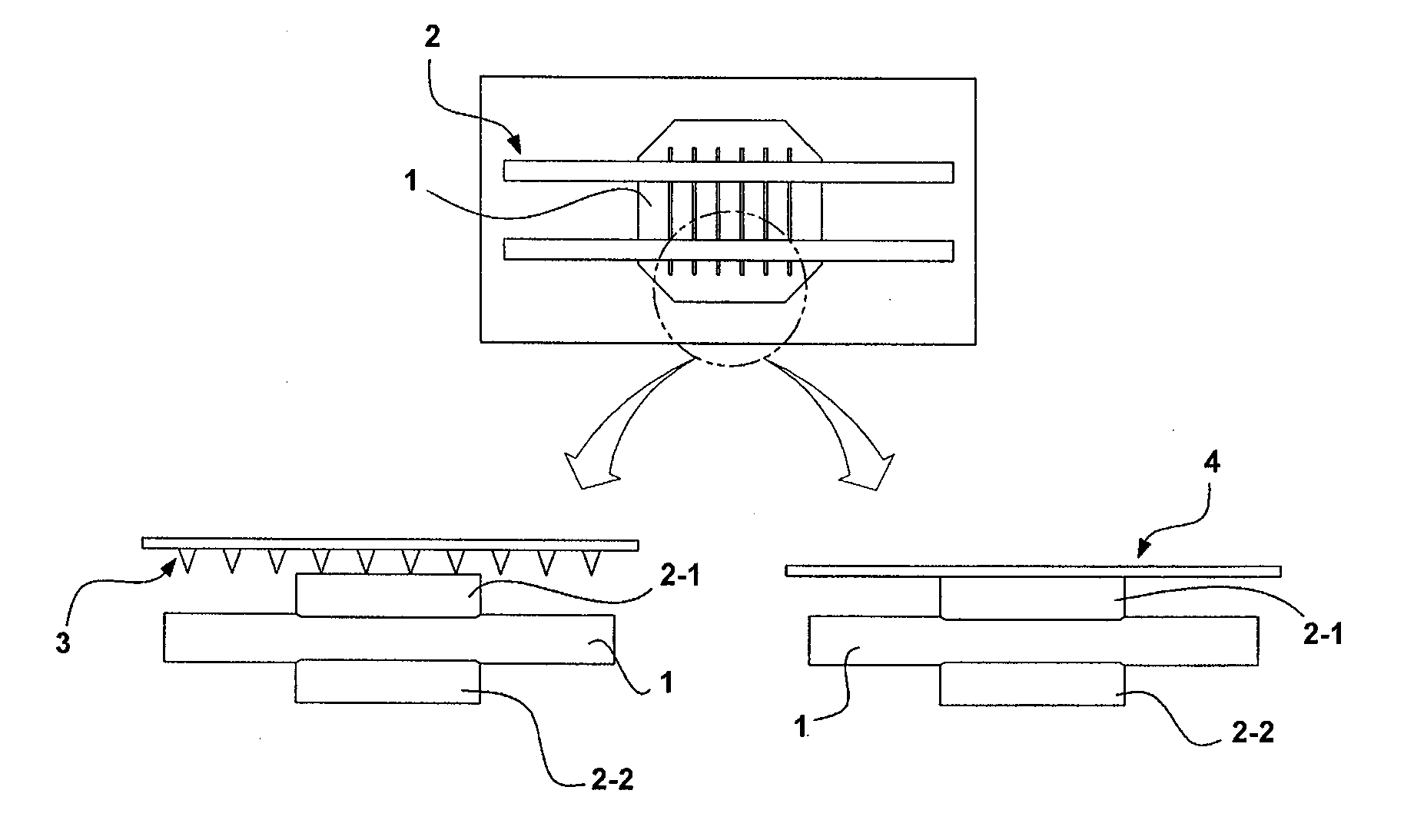

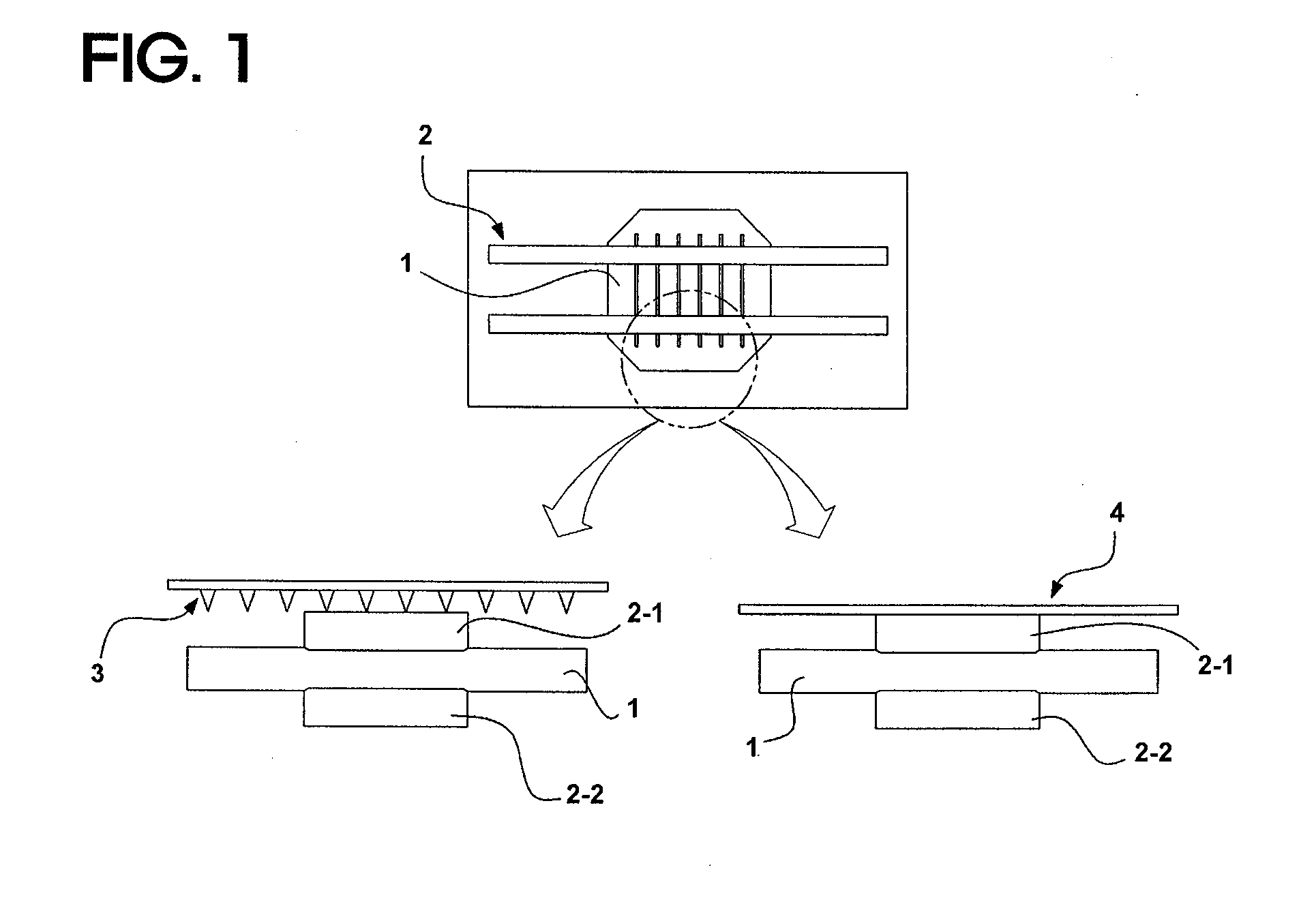

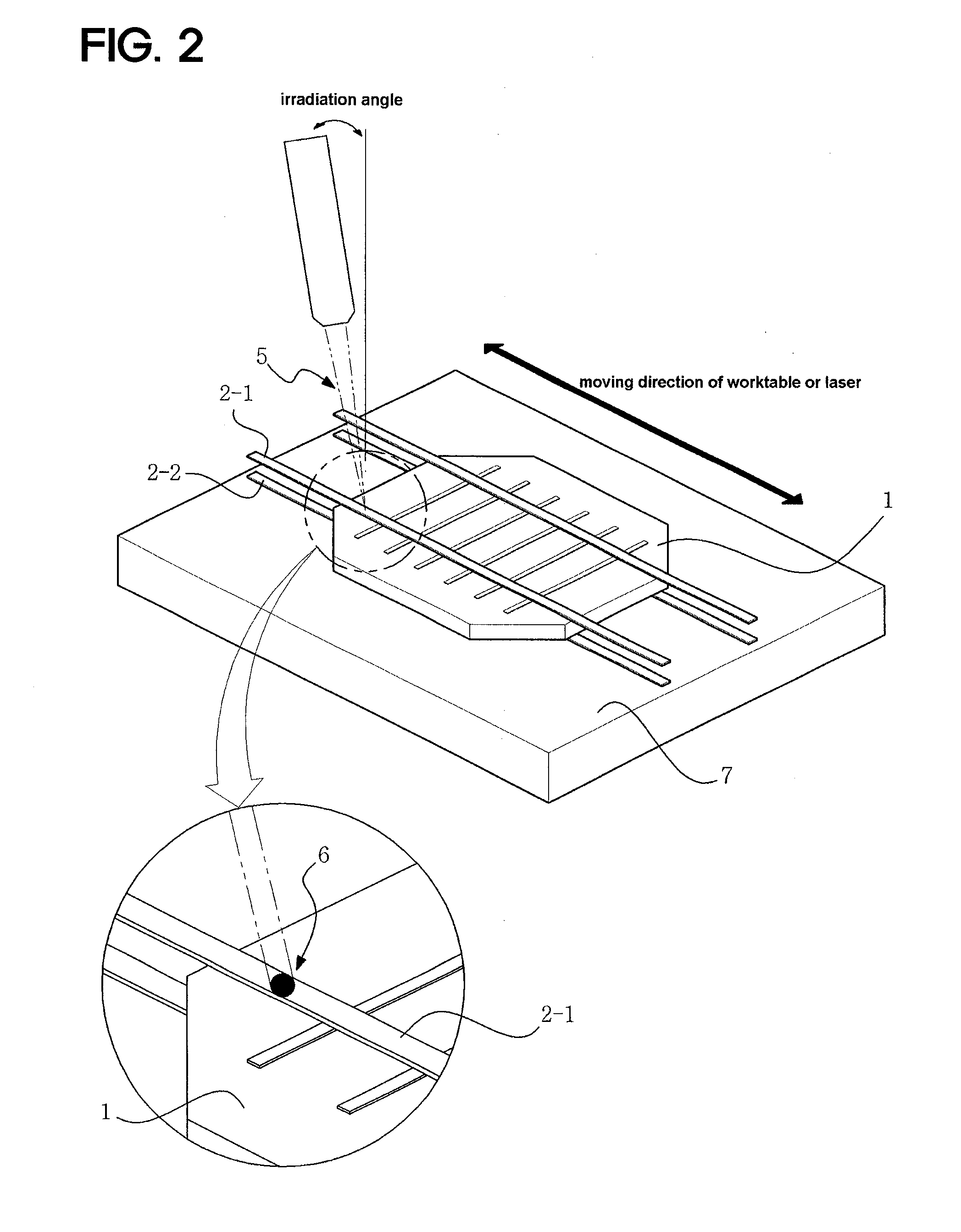

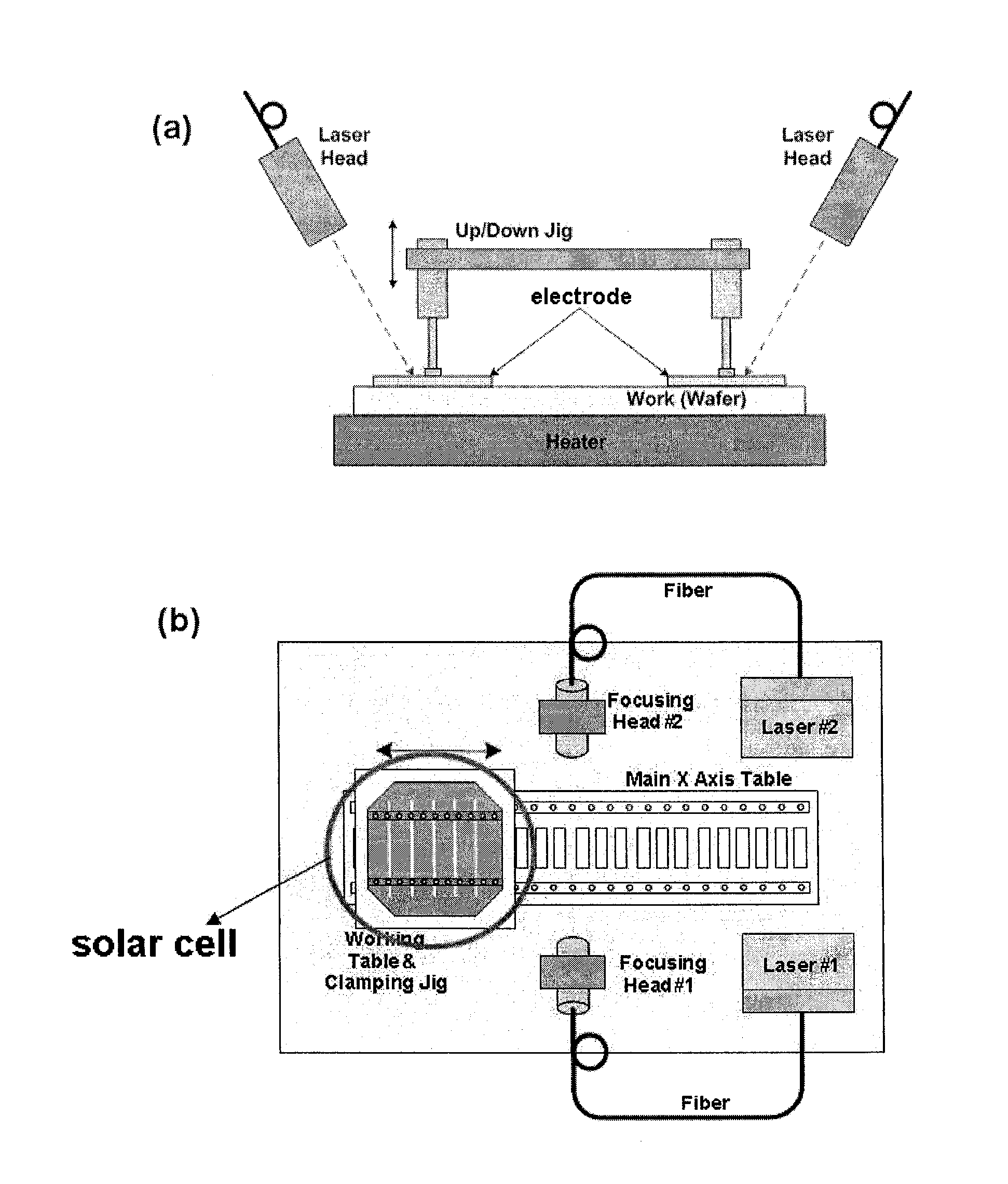

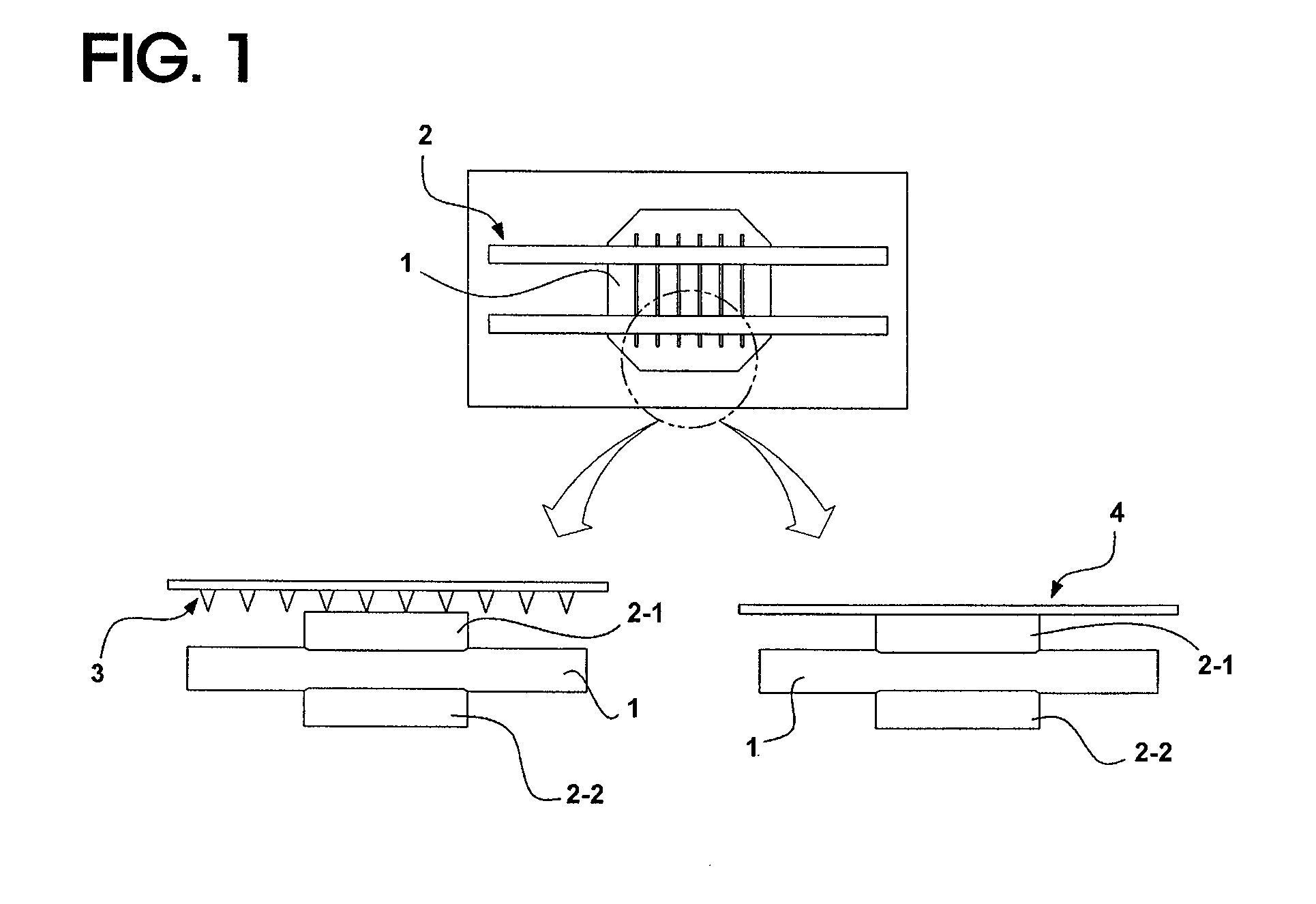

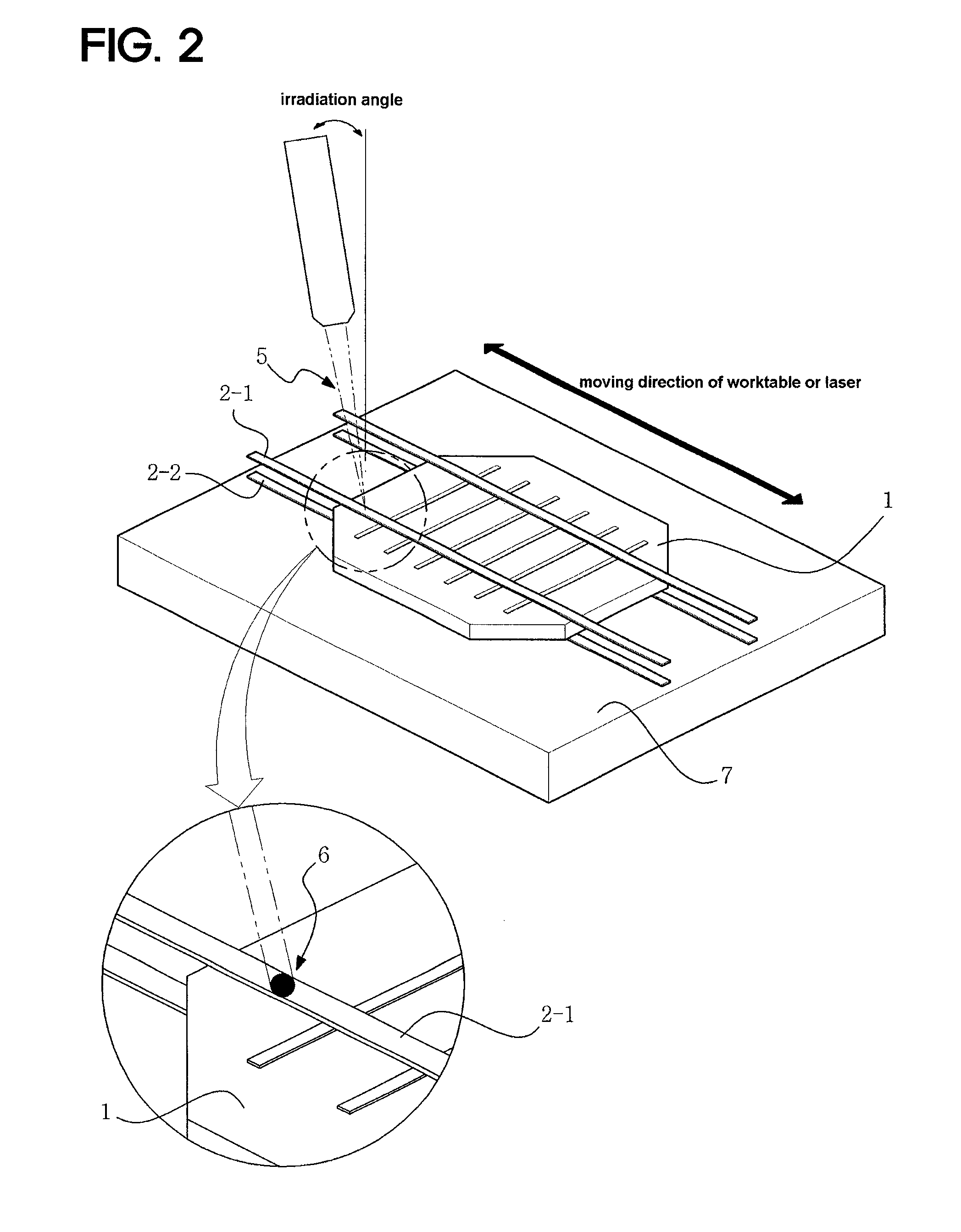

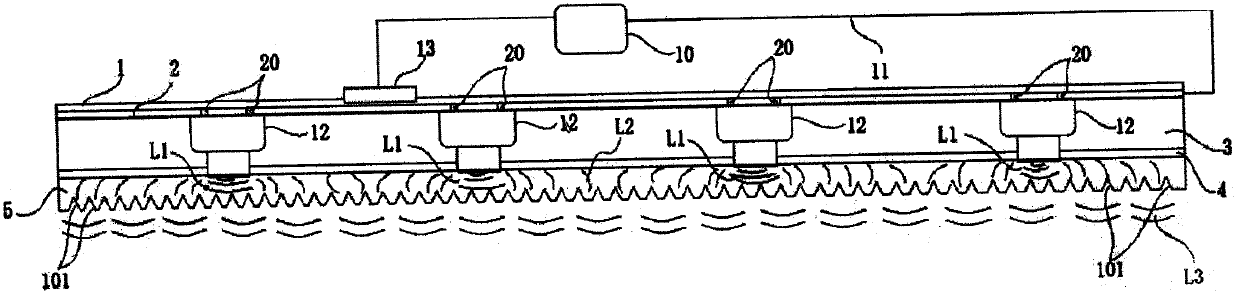

Methods for manufacturing solar cell module and apparatus for manufacturing the same

InactiveUS20110031225A1Increase productivityUniform and high strengthPhotovoltaic energy generationLaser beam welding apparatusEngineeringThermal expansion

The present invention relates to a method and apparatus for manufacturing a solar cell module using a laser. In the present invention, a tabbing process for bonding a solar cell and metal electrodes is performed by a local irradiation with a laser, so that the heating area can be localized only to a required zone (bonding area) for the tabbing process, thereby minimizing a direct heating zone which occurs in the process. Therefore, it is possible to reduce the damage such as cracks and breakage due to thermal expansion / contraction of a solar cell which is conventionally configured to have a multi-layered structure made of different materials, to improve the bonding strength and the bonding uniformity, and to reduce the processing time, thereby improving the production efficiency.

Owner:LG HAUSYS LTD

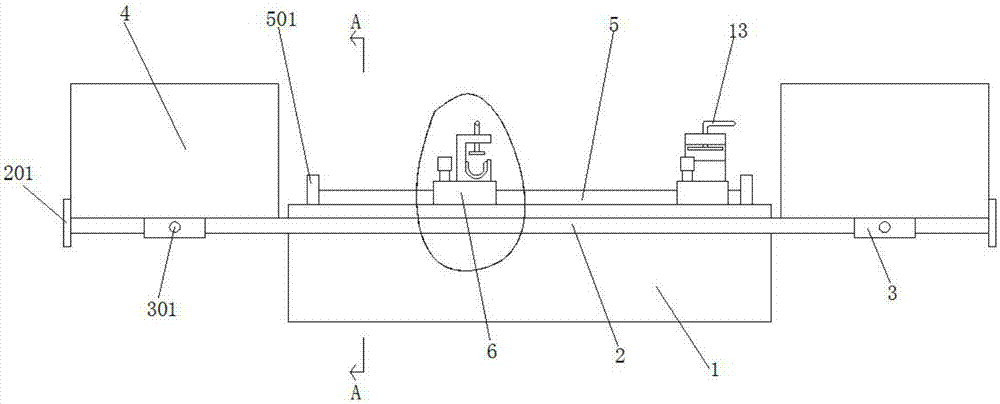

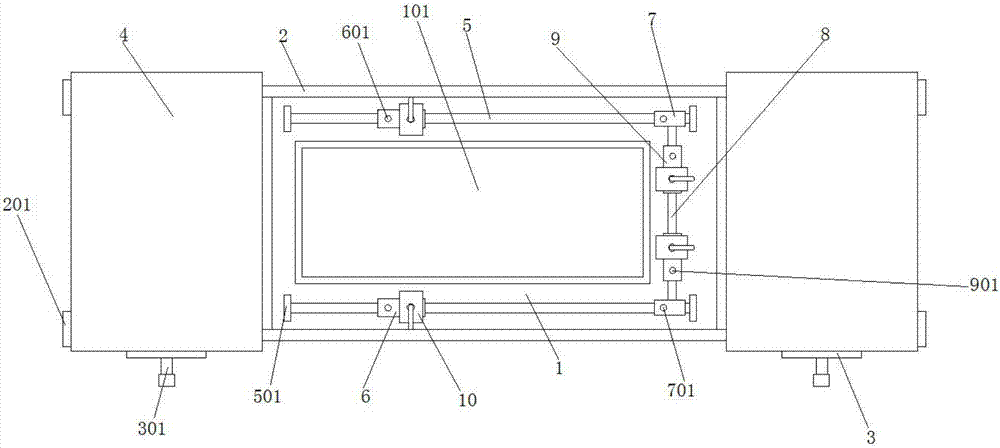

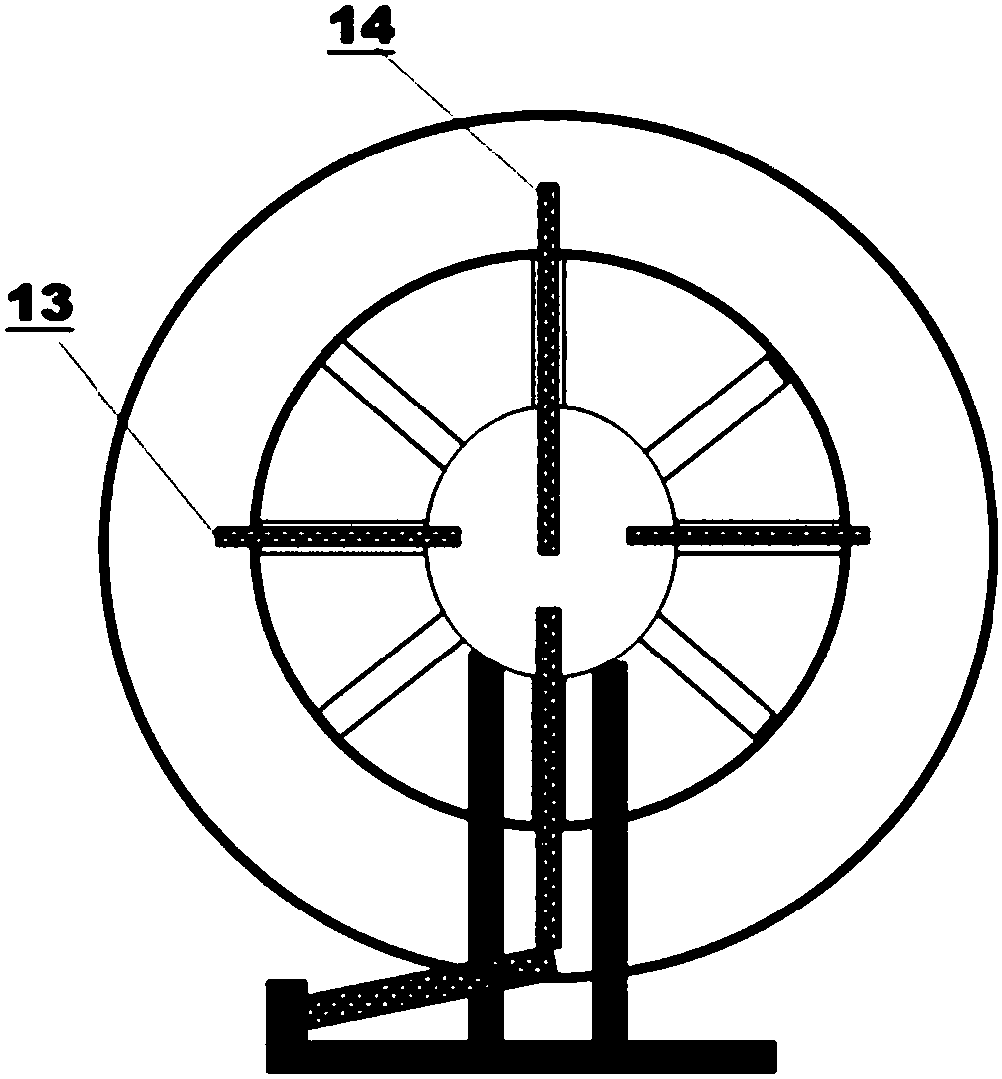

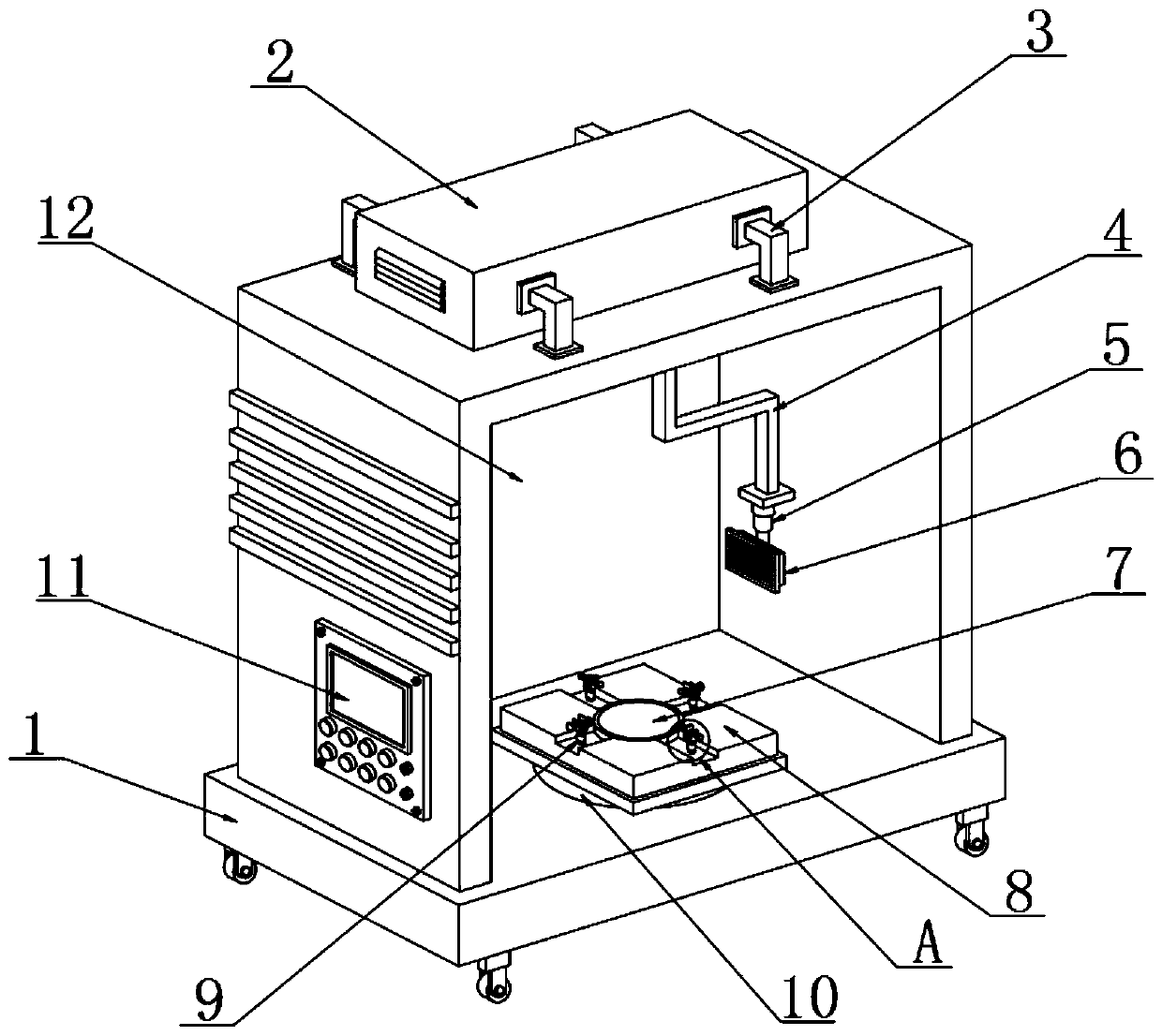

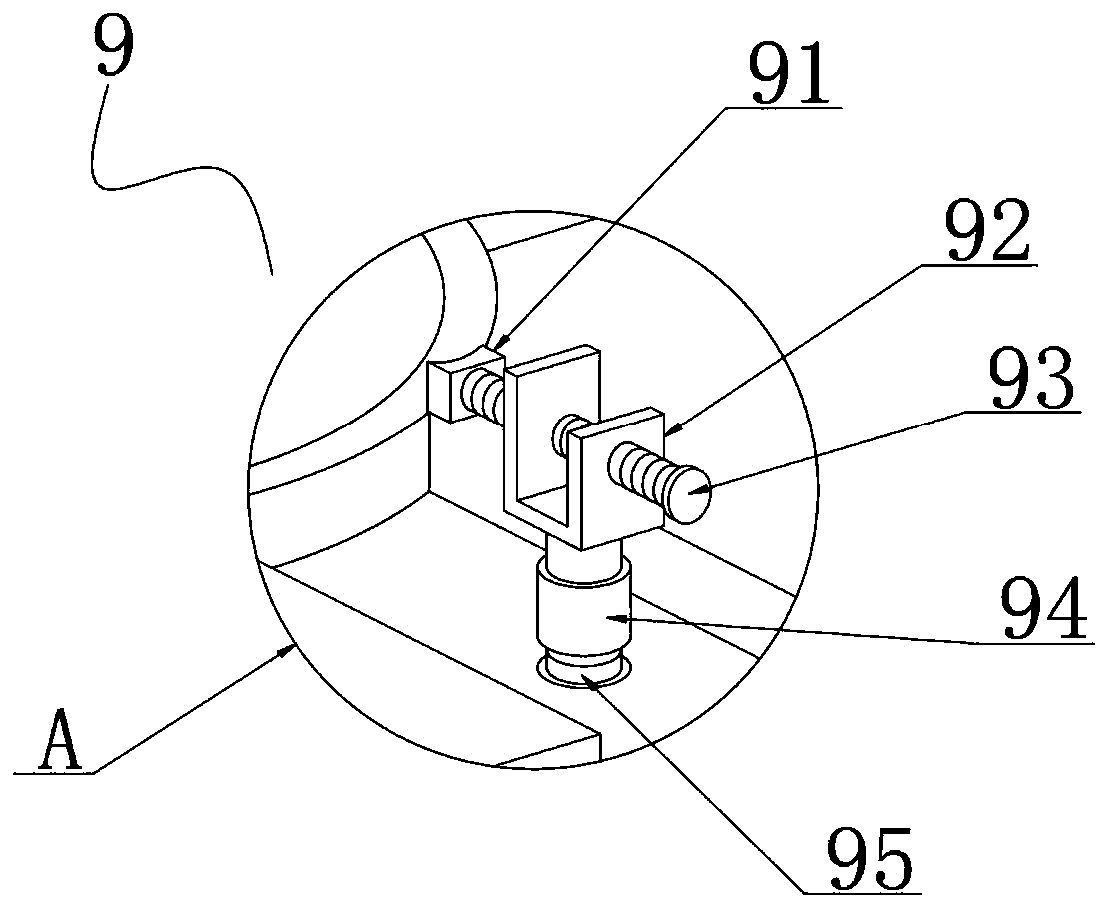

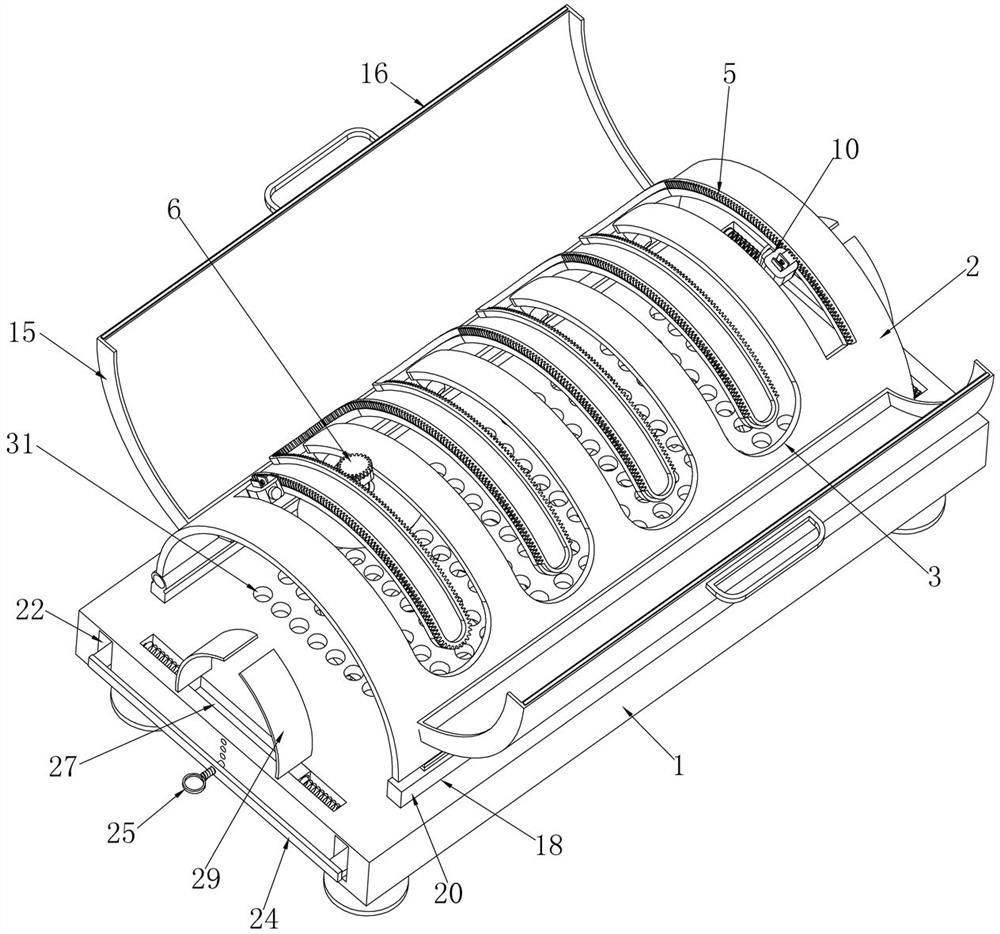

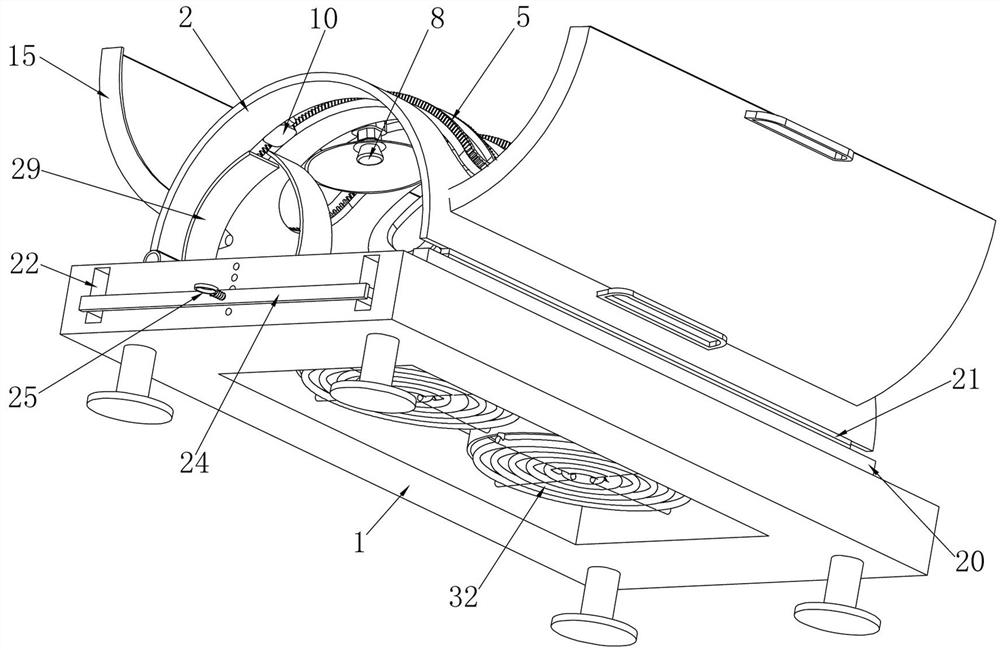

Fixing device for local irradiation of nude mouse

The invention discloses a local irradiation fixation device for nude mice, comprising a base, a first slide rail, a first slide block, a shielding plate, a second slide rail, a second slide block, a third slide block, a third slide rail, a fourth slide Slider, fixing plate, placement slot, soft pad, screw, pressing plate, this device for local irradiation of nude mice has ingenious structure and powerful functions. By using this device, it can not only effectively fix the limbs of experimental nude mice, so as to avoid The escape of nude mice improves the convenience of the experimental operation. In addition, according to the needs, the partial radiation protection of the nude mice can be realized through simple operations, thereby greatly improving the effectiveness of the experimental research.

Owner:张杰

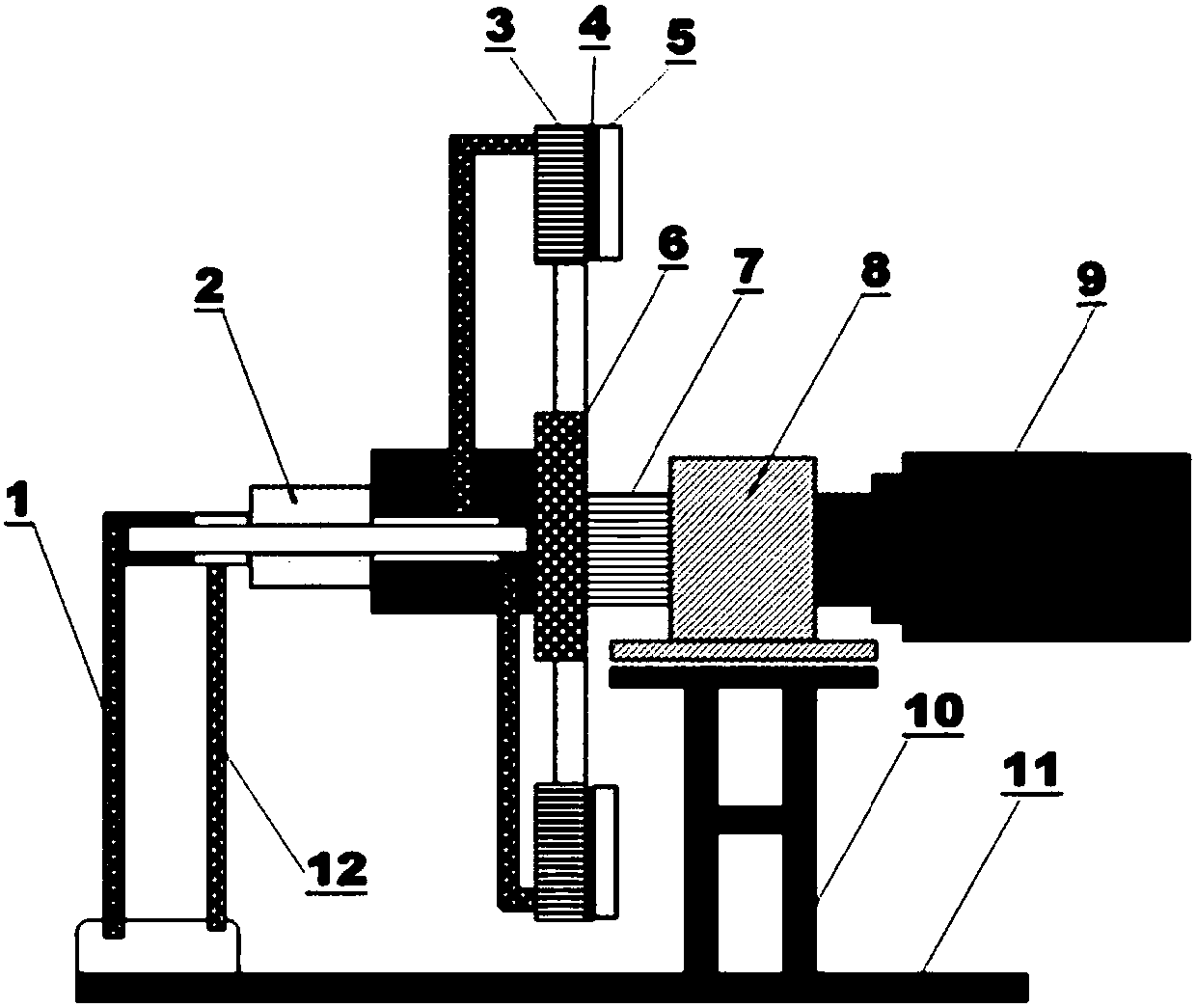

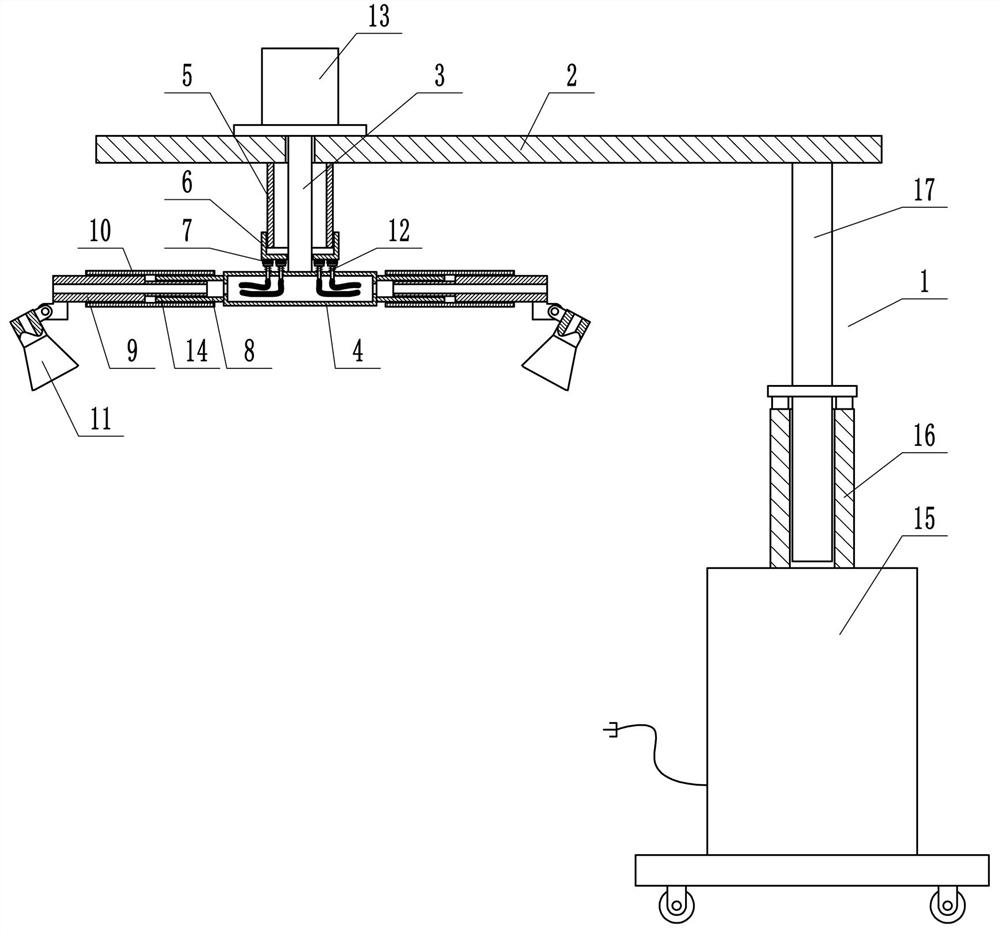

Baking lamp for surgical nursing

The invention provides a baking lamp for surgical nursing, and effectively solves the problems that an existing baking lamp is immobile during use, so that irradiation is non-uniform; scalds are possibly caused by excessive baking; a therapeutic effect is not realized possibly due to insufficient local irradiation. The baking lamp for surgical nursing is characterized by comprising a medical baking lamp main body; a supporting plate is fixed to the main body; a rotating shaft is arranged on the supporting plate; a shell is arranged at the lower end of the rotating shaft; a vertical barrel is arranged on the rotating shaft; a movable barrel is arranged at the lower end of the vertical barrel; an annular plate is arranged at the lower end of the movable barrel; two electrodes are arranged atthe lower end of the annular plate; first cylinders are arranged on the periphery of the shell; one sides of the first cylinders are provided with second cylinders; third cylinders are arranged on the first cylinders; one ends of the second cylinders are provided with revelation light covers; baking lamp bodies are arranged in the light covers; the upper side plate of the shell is provided with aplurality of groups of contacts; each group contains two contacts. The baking lamp for surgical nursing is ingenious in structure; the distance between the baking lamp and a wound can be adjusted; the wound is irradiated omni-directionally; uniform irradiation can be performed on the wound effectively; insufficient irradiation or scalds can be avoided; harm to tissues and the wound caused by excessive baking can be prevented.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

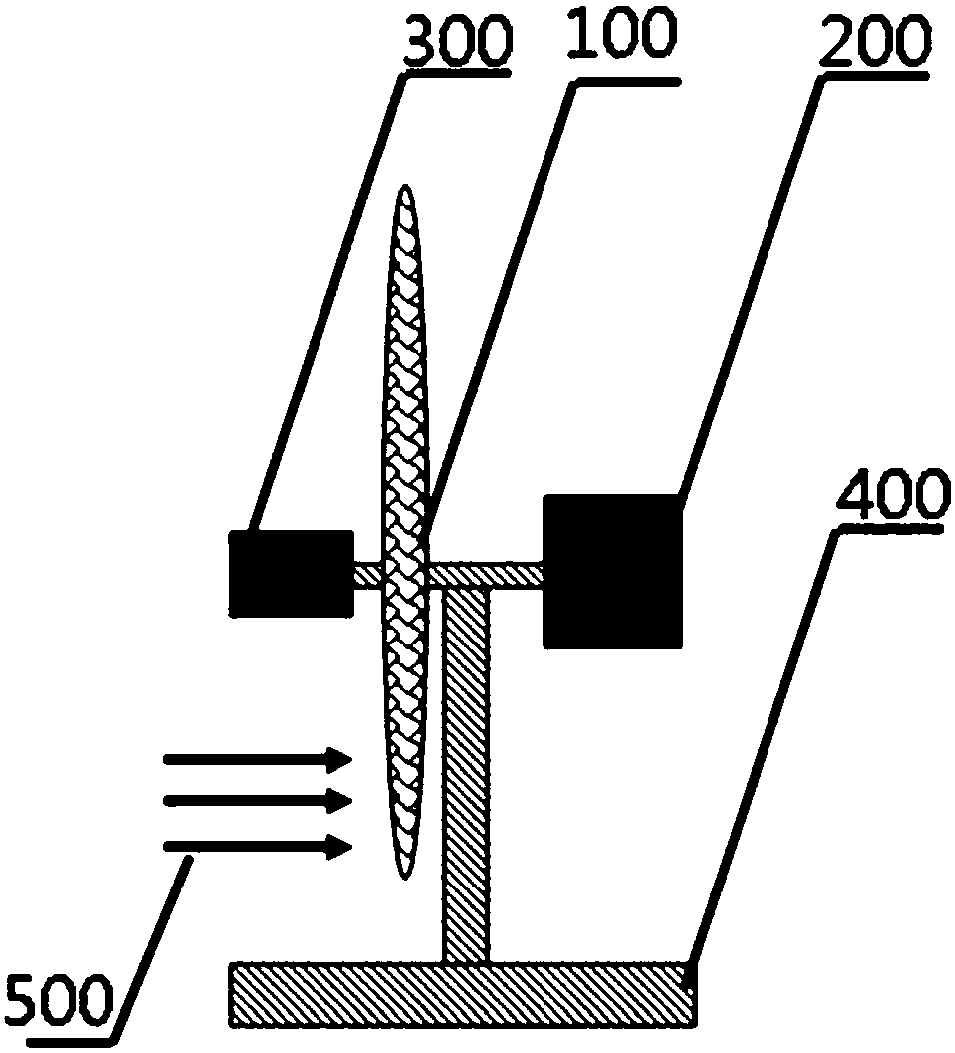

Rotating target for accelerator neutron source

InactiveCN108401354ATemperature controlAchieve coolingDirect voltage acceleratorsNuclear targetsEngineeringLiquid circulation

The invention provides a rotating target system for an accelerator neutron source. The rotating target system comprises rotating target, a cooling liquid circulation unit and a rotary driving unit, wherein the rotating target comprises a liquid cooling ring and a connecting disk arranged at the center of the liquid cooling ring, a target layer is arranged on the liquid cooling ring, the connecting disk is connected with the liquid cooling ring through a hub support, the rotary driving unit is fixedly connected to one side of the connecting disk for driving the rotating target to rotate, and the cooling liquid circulation unit is used for supplying cooling liquid to the liquid cooling ring. The rotating target system provided by the invention adopts an annular target layer, and disperses heat generated by local irradiation to the entire ring by rotation, thereby reducing the high heat generated by the local irradiation through large-area cooling of the ring, ensuring high cooling efficiency and good effect, the cooling of high-power heat can be achieved, and the temperature of the target is well controlled.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Sutureless ureterostenosis restoration operation material and system thereof

The invention provides a sutureless ureterostenosis restoration operation material, a preparation method of the material, a sutureless ureterostenosis restoration operation system including the material, and applications of rose bengal in the material and the system. Rose Bengal is supported on a rose bengal support, and a sutureless ureterostenosis restoration operation is completed through the local irradiation of a laser emission device. Results of clinic tests show that ureteral restenoses erupting after a traditional suture operation are not found, and there are also no tissue thermal damage phenomena.

Owner:NO 3 PEOPLE HOSPITAL AFFILIATED TO SHANGHAI JIAOTOG UNIV SCHOOL OF MEDICINE

Method for manufacturing a solar cell module by laser bonding

InactiveUS8674261B2Reduce a fraction defectiveUniform and high strengthElectric heatingSoldering apparatusLaser bondingThermal expansion

Owner:LG HAUSYS LTD

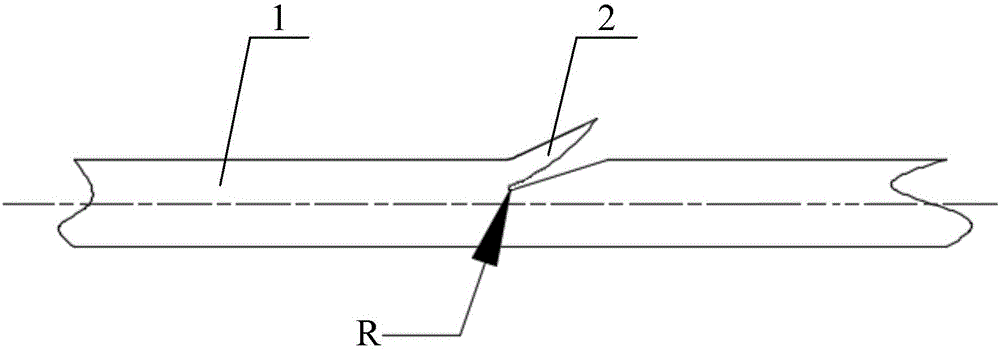

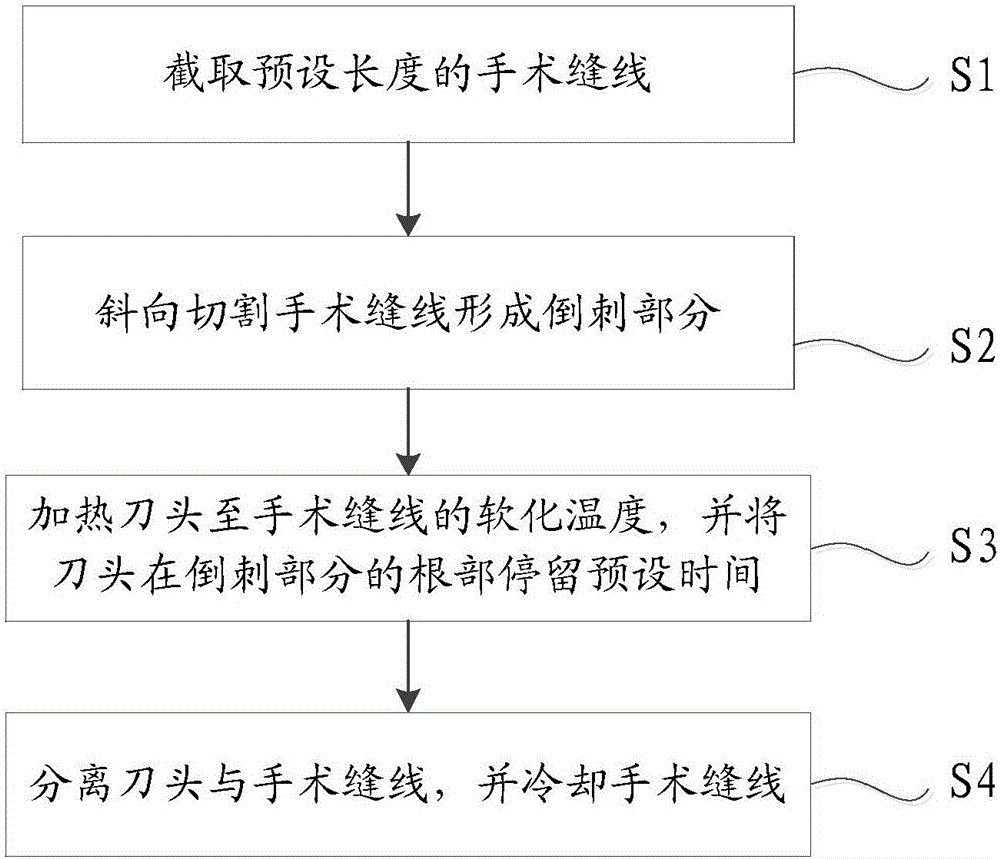

Operative suture and processing method thereof

InactiveCN106388891AAdd depthHigh strengthSuture equipmentsSurgical needlesUltimate tensile strengthTears

The invention discloses an operative suture and a processing method thereof. The processing method of the operative suture comprises the following steps of cutting the preset length of the operative suture; obliquely cutting the operative suture to form a barb part through a cutter head of a barb machine; heating the cutter head to a softening temperature of the operative suture and staying the cutter head in the root portion of the barb part for the preset time; separating the cutter head and the operative suture and cooling the operative suture. According to the processing method of the operative suture, stress tear gaps at an incision stop point are avoided as secondary melting solidification is performed at the root portion of the barb part namely the incision stop point; meanwhile, the crystalline state is changed through local irradiation, the incision root portion of the barb part can generate crosslinking, the shear strength of the incision root portion is improved, and the purpose of avoiding incision tear failure is achieved.

Owner:上海百玫医疗科技有限公司

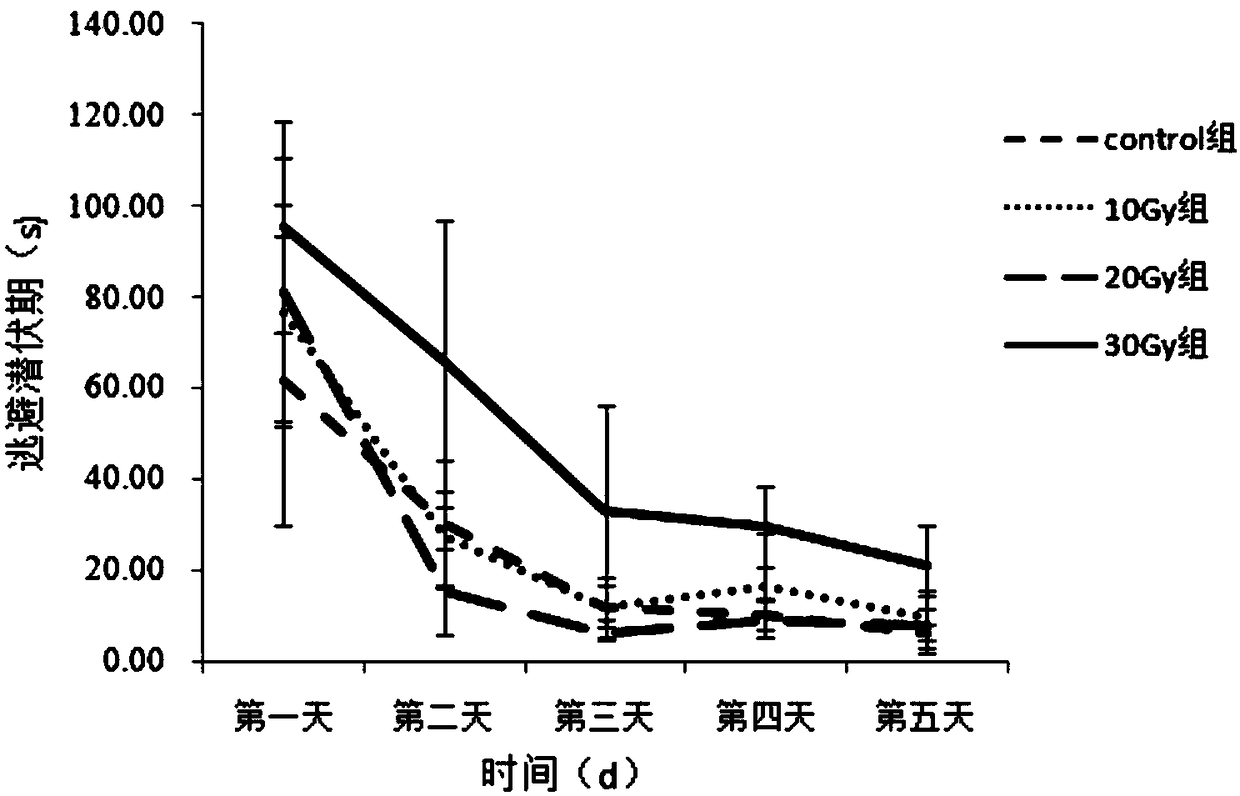

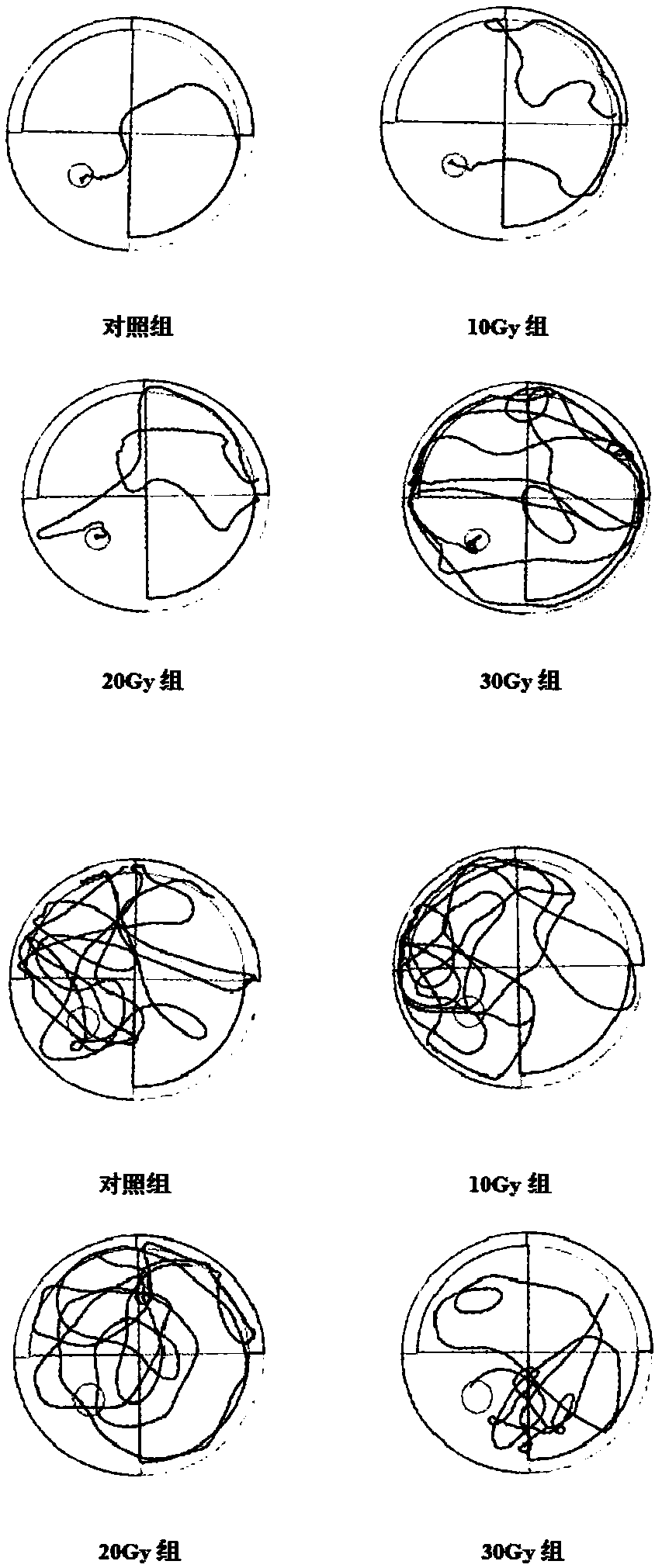

Method for establishing cognitive function injury rat animal model

PendingCN109381278AImprove cognitive impairmentHigh simulationVeterinary instrumentsHuman bodyPhysiology

The invention belongs to the technical field of radiation protection and relates to a method for establishing a cognitive function injury rat animal model. The method comprises the following steps of:after a rat is anesthetized, carrying out single head local irradiation by using rays so as to form the cognitive function injury animal model. By utilizing the method, the established rat model canbetter simulate the cognitive function injury of a human body caused by radiation.

Owner:CHINA INST FOR RADIATION PROTECTION

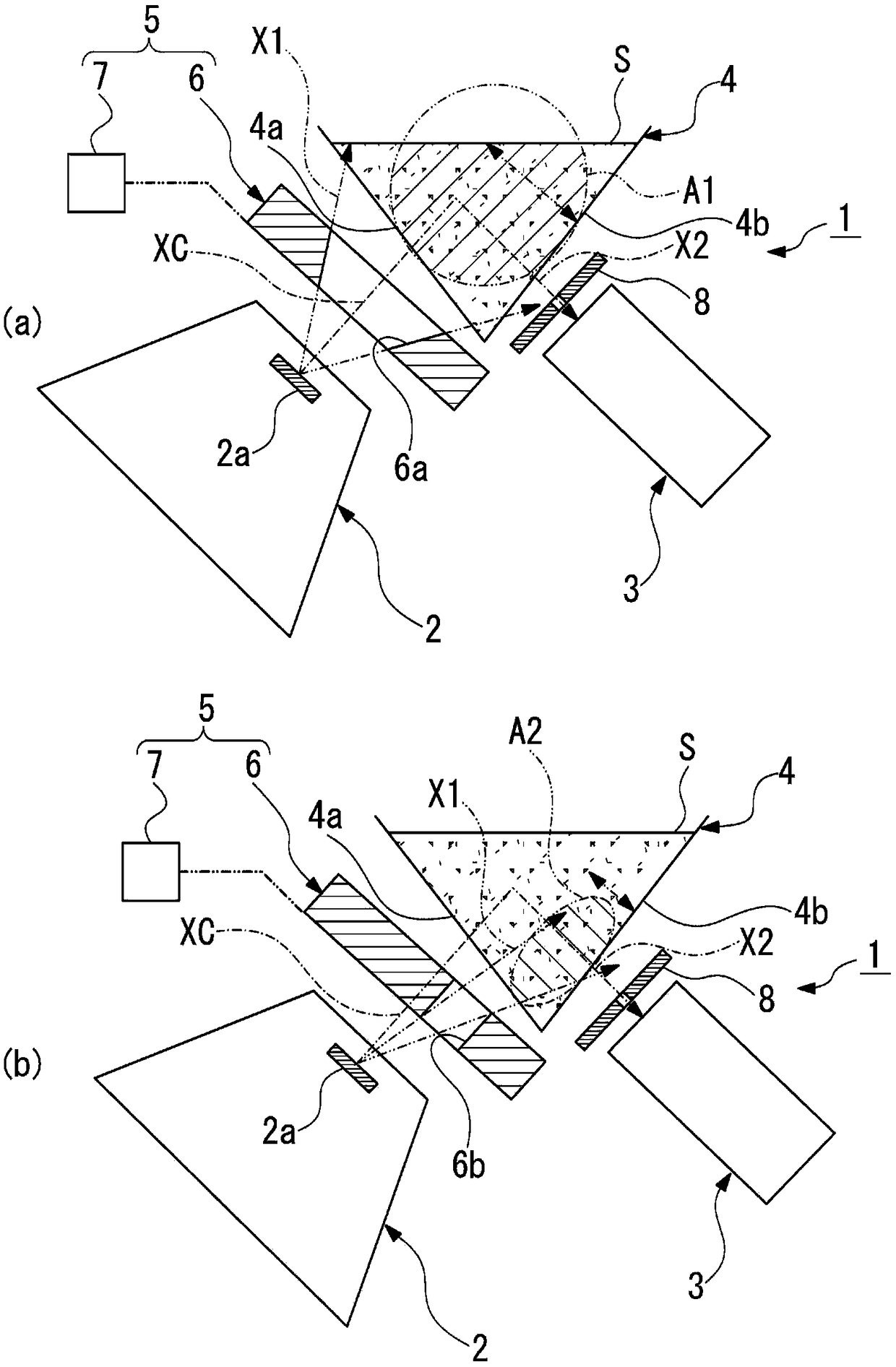

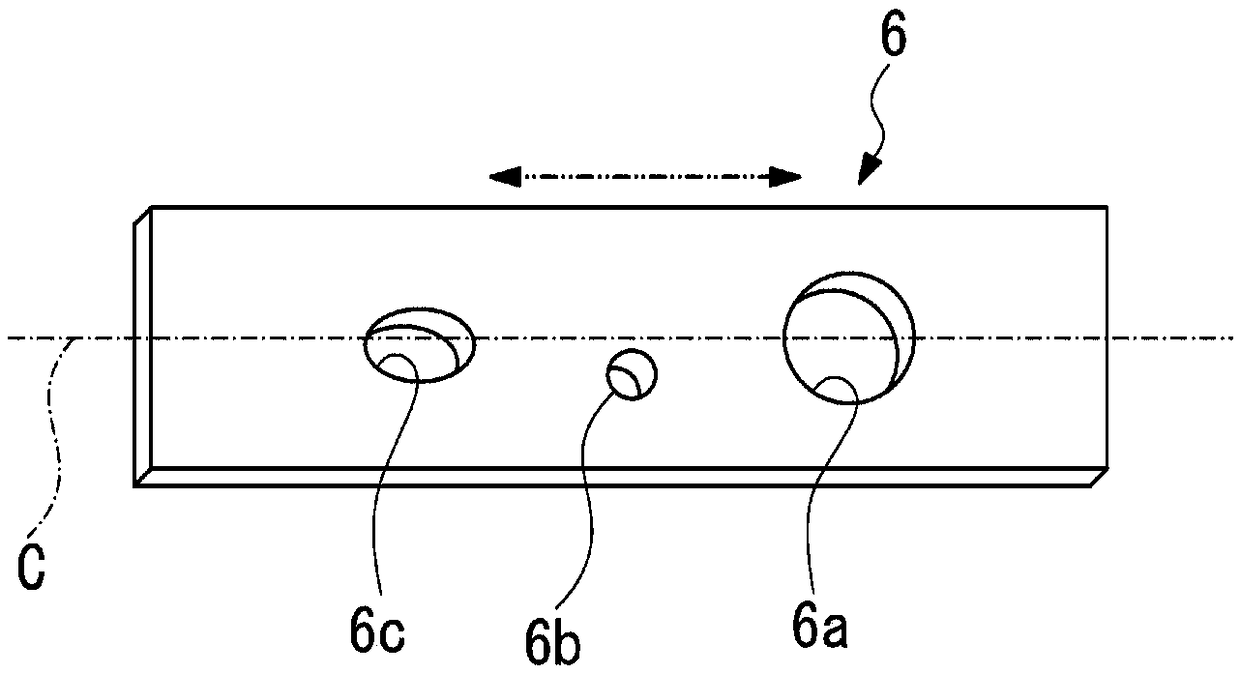

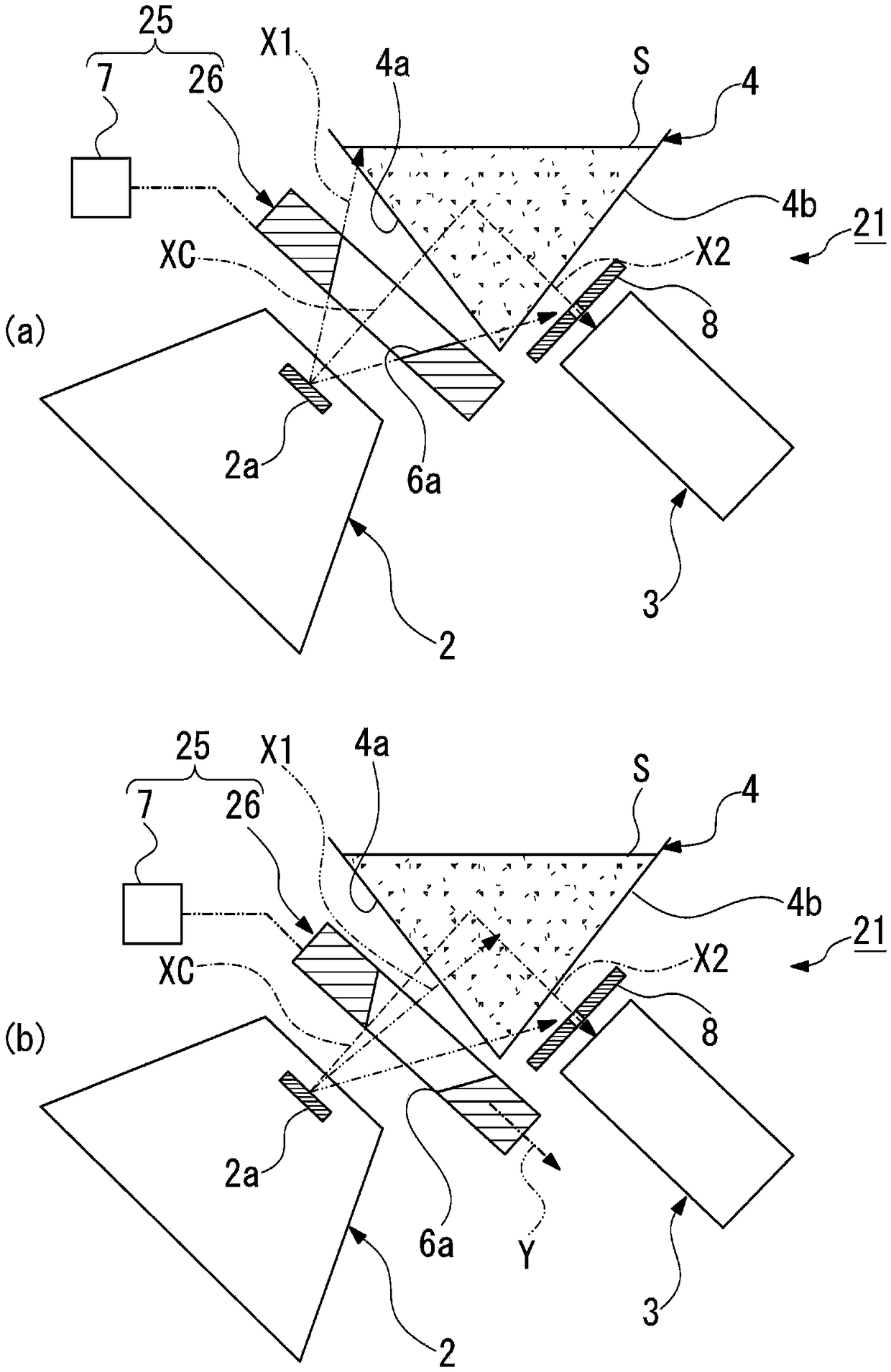

Fluorescent x-ray analyzer and fluorescent x-ray analysis method

ActiveCN109459458AEfficient detectionSuppress noiseMaterial analysis using wave/particle radiationFluorescencePhysical chemistry

The invention provides a fluorescent X-ray analyzer and a fluorescent X-ray analysis method capable of measuring elements having different analysis depths without changing the arrangement in the samesample container. The fluorescent X-ray analyzer includes a sample container (4) capable of accommodating the sample (S), an X-ray source (2) that irradiates the sample with the primary X-ray (X1), and a detector (3) detecting fluorescent X-ray (X2) generated from the sample irradiated with the primary X-ray; and an irradiation range changing mechanism (5) capable of changing the range in which the original X-ray is irradiated to the sample in the sample container, to partial irradiation and wide-range irradiation. In partial irradiation, at least the sample of the wall surface facing the sample container facing the sample container is irradiated with the primary X-ray; and in the wide-range irradiation, the sample in the sample container is irradiated with the original X-rays in a range larger than that of the local irradiation.

Owner:HITACHI HIGH TECH SCI CORP

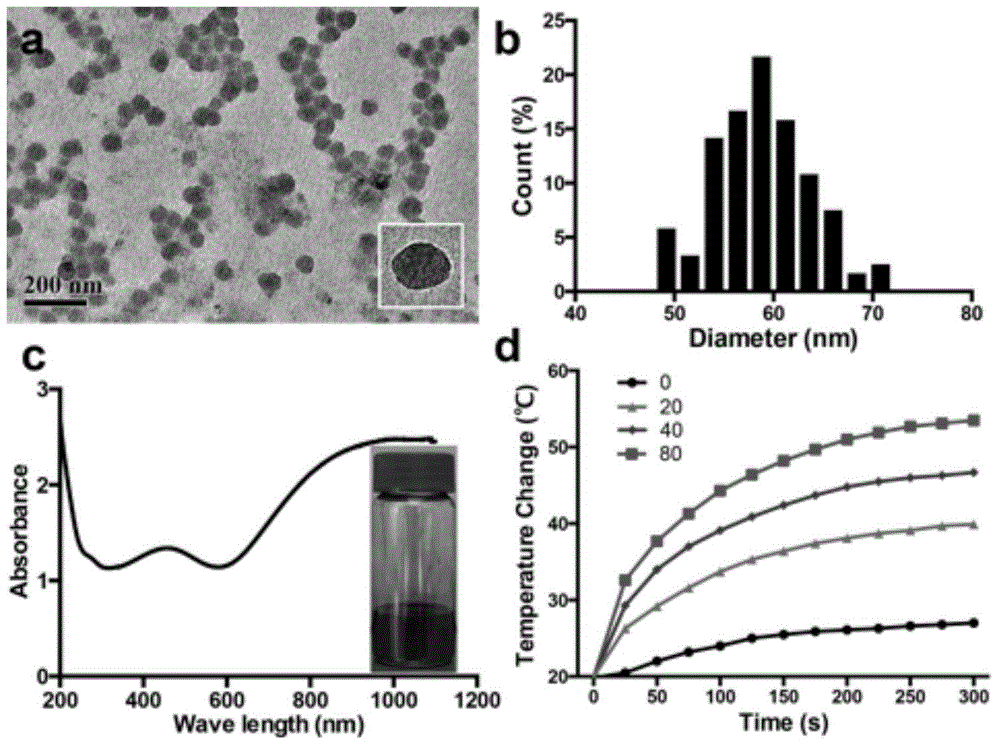

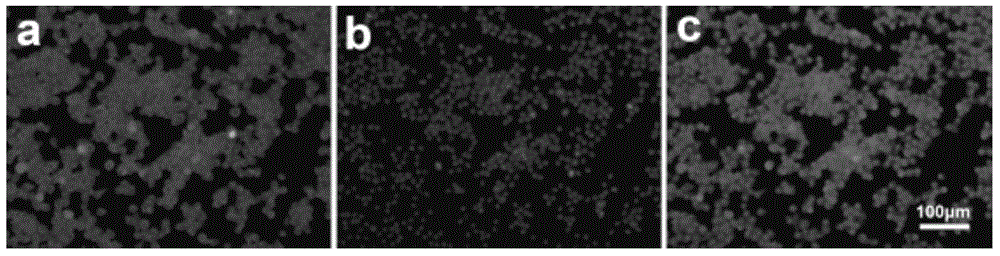

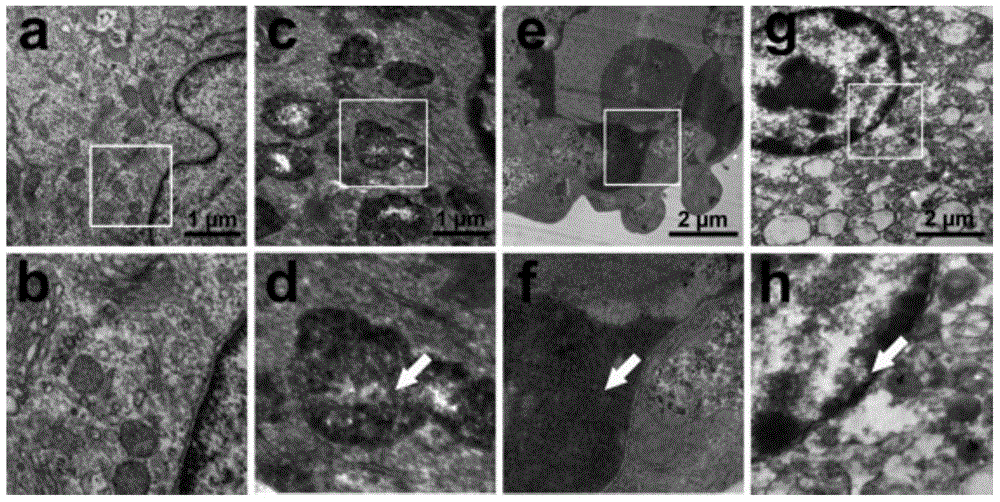

Polypyrrole nano particle having photo-thermal effect, preparation method and application thereof

InactiveCN105833269AGood light stabilityHigh photothermal conversion effectPowder deliveryEnergy modified materialsInfraredPercent Diameter Stenosis

The invention belongs to the crossing field of nano engineering and cell biology, and relates to a polypyrrole nano particle having a photo-thermal effect, a preparation method and an application thereof. The nano particle generates heat under irradiation of near infrared ray and can be used for preparing a medicine preparation for treating hemadostenosis caused by inflammatory reaction in blood vessel and vascular smooth muscle cell proliferation. In the invention, on the basis of killing effects on chronic inflammatory cells in vitro with photo-thermal therapy of the nano particle and near infrared laser, an application test of mouse vascular chronic inflammation and in an arteriostenosis model is carried out further, and a result proves that the nano particle can locally enter the focus of the chronic inflammation in artery, and can be used for inhibiting the local chronic inflammation with near infrared ray local irradiation, thereby inhibiting restenosis after intracavitary therapy and being used for evaluating the restenosis after intracavitary therapy through MRI.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

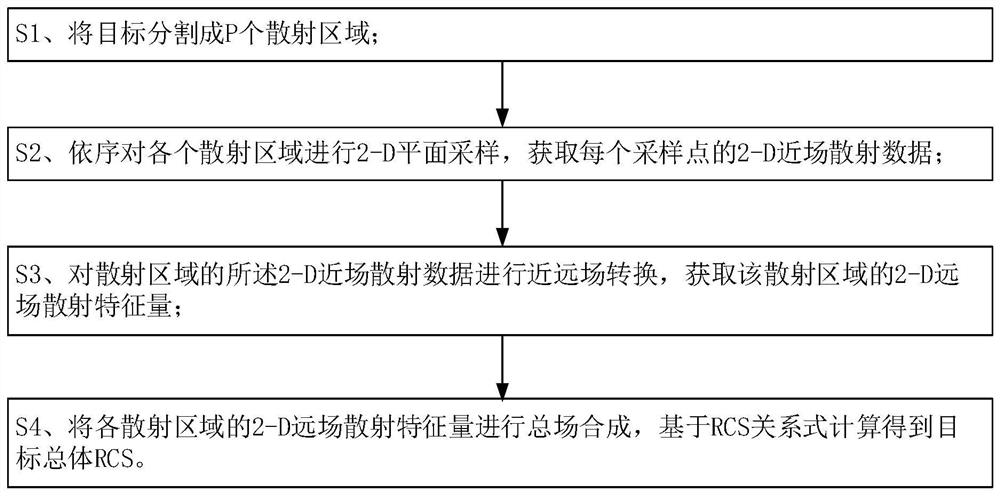

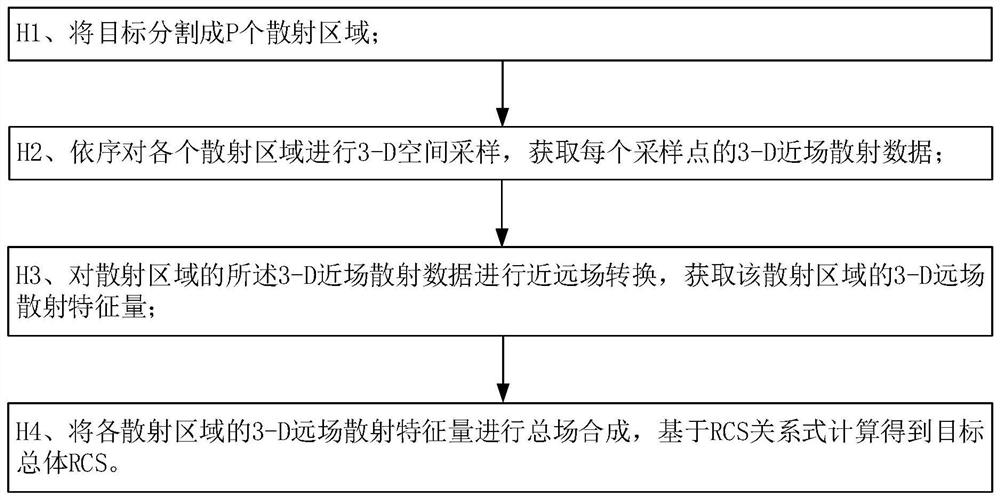

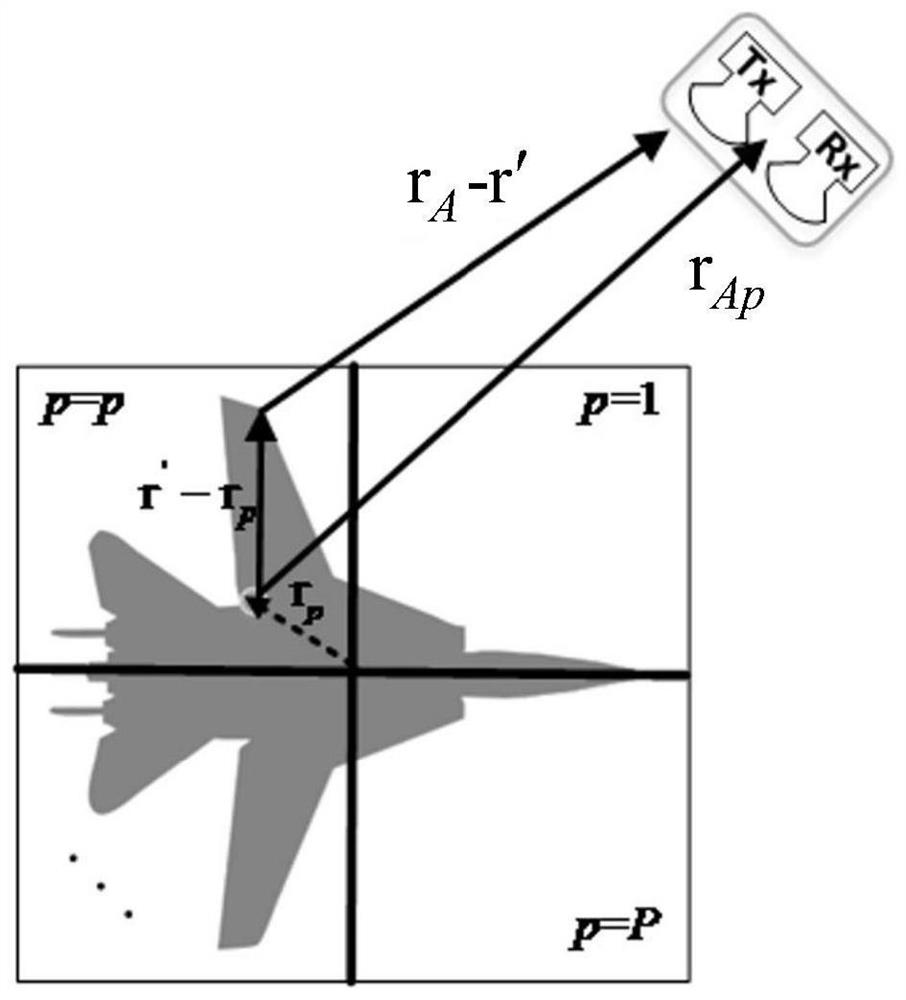

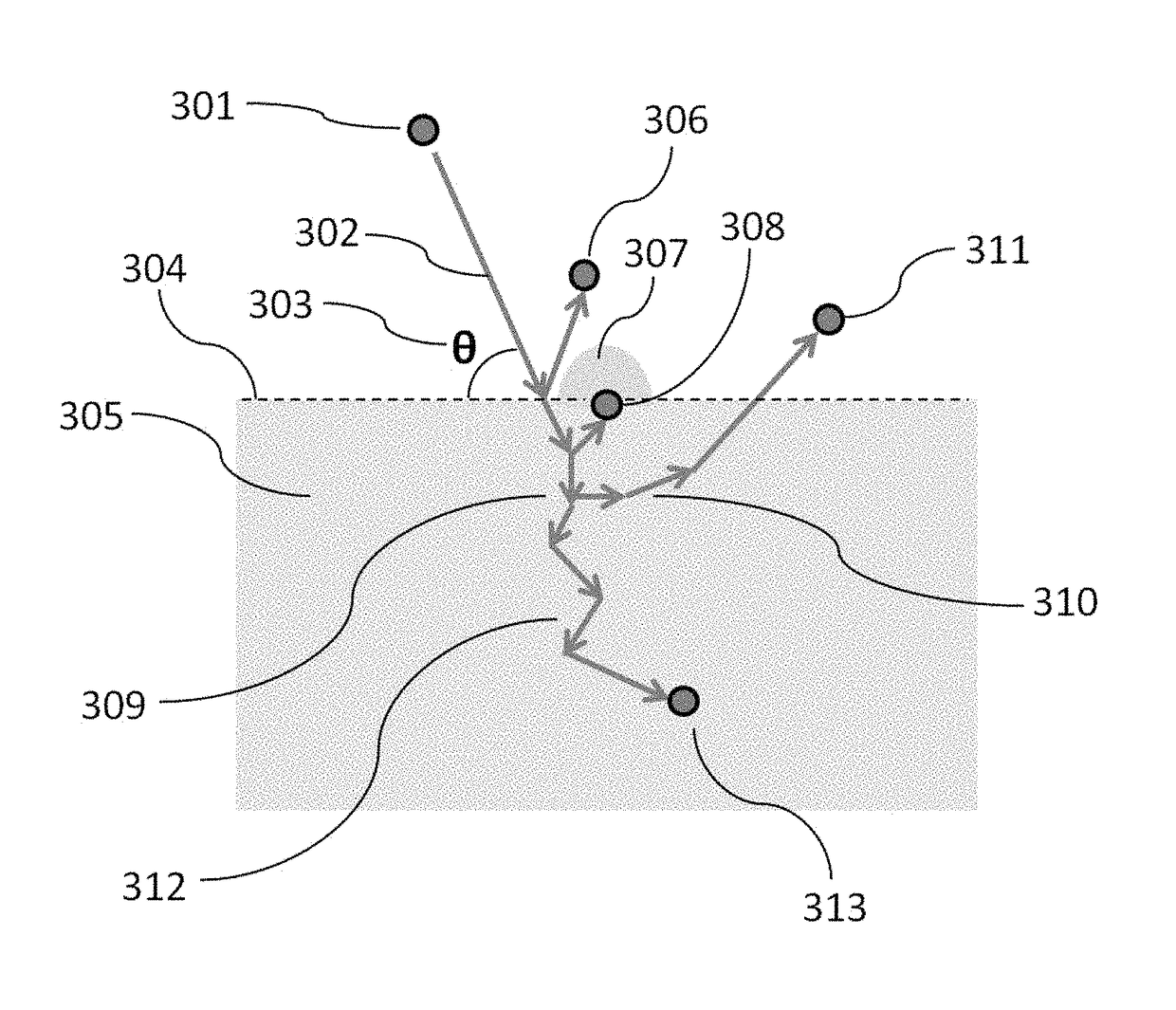

Near-field local irradiation target scattering near-far field conversion method

PendingCN113702939AFlexible sampling methodWave based measurement systemsComputational physicsLocal irradiation

The invention provides a near-field local irradiation target scattering near-far field conversion method. The method comprises the following steps: S1, segmenting a target into P scattering areas; s2, performing 2-D plane sampling on each scattering area in sequence to obtain 2-D near-field scattering data of each sampling point; s3, performing near-far field conversion on the 2-D near-field scattering data of the scattering area based on an expression of receiving voltage of a 2-D near-field test antenna, and obtaining a 2-D far-field scattering characteristic quantity of the scattering area; and S4, performing total field synthesis on the 2-D far field scattering characteristic quantity of each scattering region, and performing calculation based on an RCS relational expression to obtain a target total RCS. The invention further provides a near-field local irradiation target scattering near-far field conversion method which is suitable for obtaining the total RCS of the target under 3-D space sampling.

Owner:SHANGHAI RADIO EQUIP RES INST

Local paint baking device for mechanical equipment production

InactiveCN111438035AEasy to fixPartial paint effect is goodCombination devicesPretreated surfacesMechanical equipmentIndustrial engineering

The invention discloses a local paint baking device for mechanical equipment production, and relates to the technical field of mechanical equipment production. The local paint baking device comprisesa base; a paint baking chamber is arranged at the upper end of the base; a rotating frame is arranged at the upper end of the inside of the paint baking chamber; an electric lifting rod is connected at the lower end of the rotating frame; a baking lamp is connected at the lower end of the electric lifting rod; and a fine adjustment mechanism is further arranged between the electric lifting rod andthe baking lamp. According to the local paint baking device, under the actions of the rotating frame and the electric lifting rod, the baking lamp is adjusted vertically and transversely, and in cooperation with the action of the fine adjustment mechanism, the longitudinal irradiation angle of the baking lamp can be adjusted, so that local irradiation of the baking lamp to irregular mechanical equipment is realized; through cooperation of a rotating disk and a limiting mechanism, the mechanical equipment can be limited and fixed conveniently, and the condition that the paint baking effect isaffected by shaking of the mechanical equipment during paint baking is avoided; and the local paint baking device is convenient to operate, high in adjustment precision and better in local paint baking effect on the mechanical equipment.

Owner:王莹燕

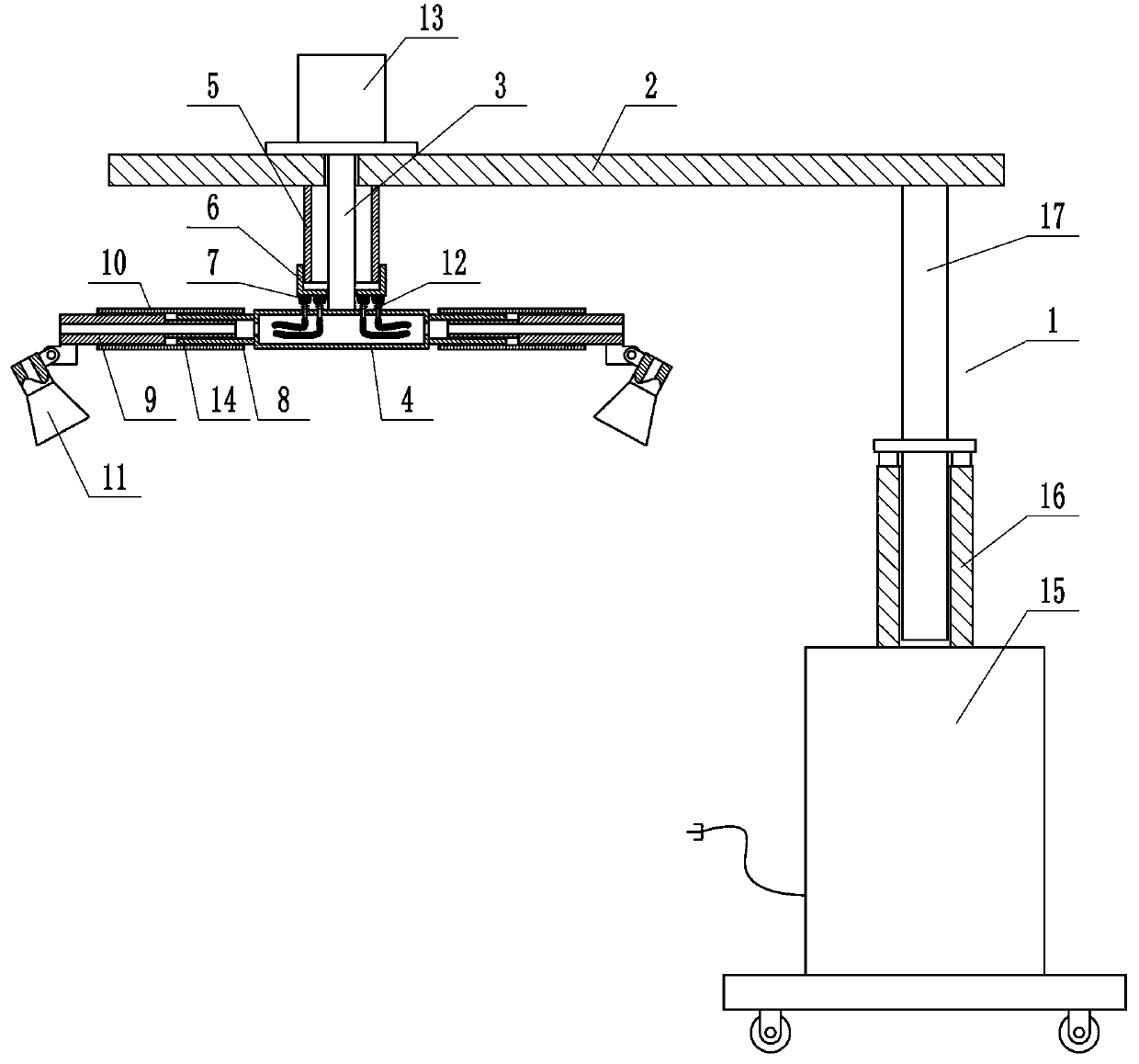

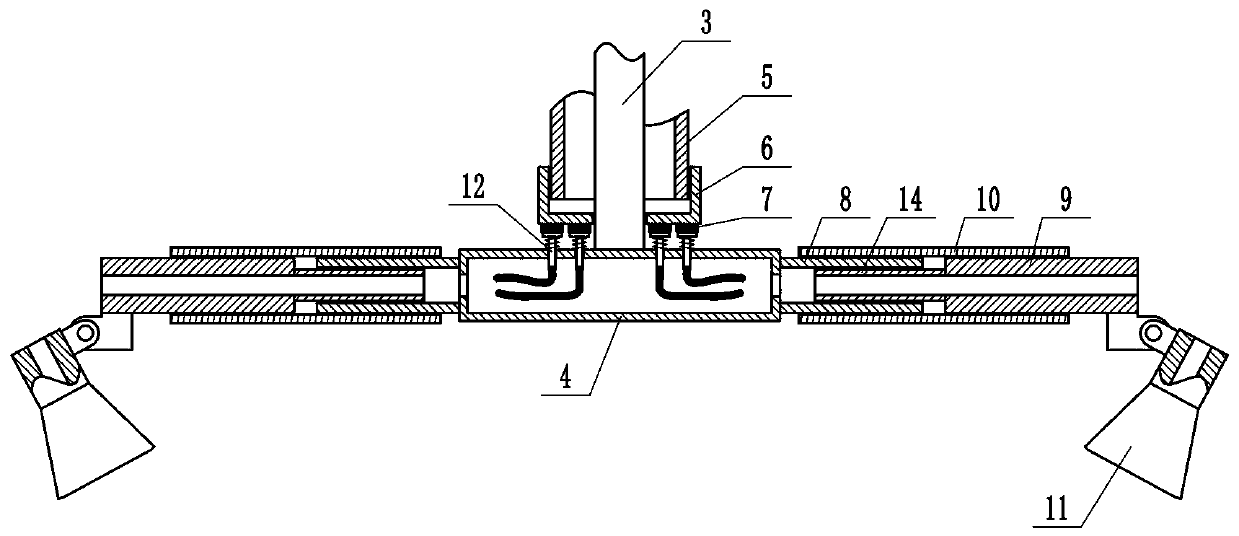

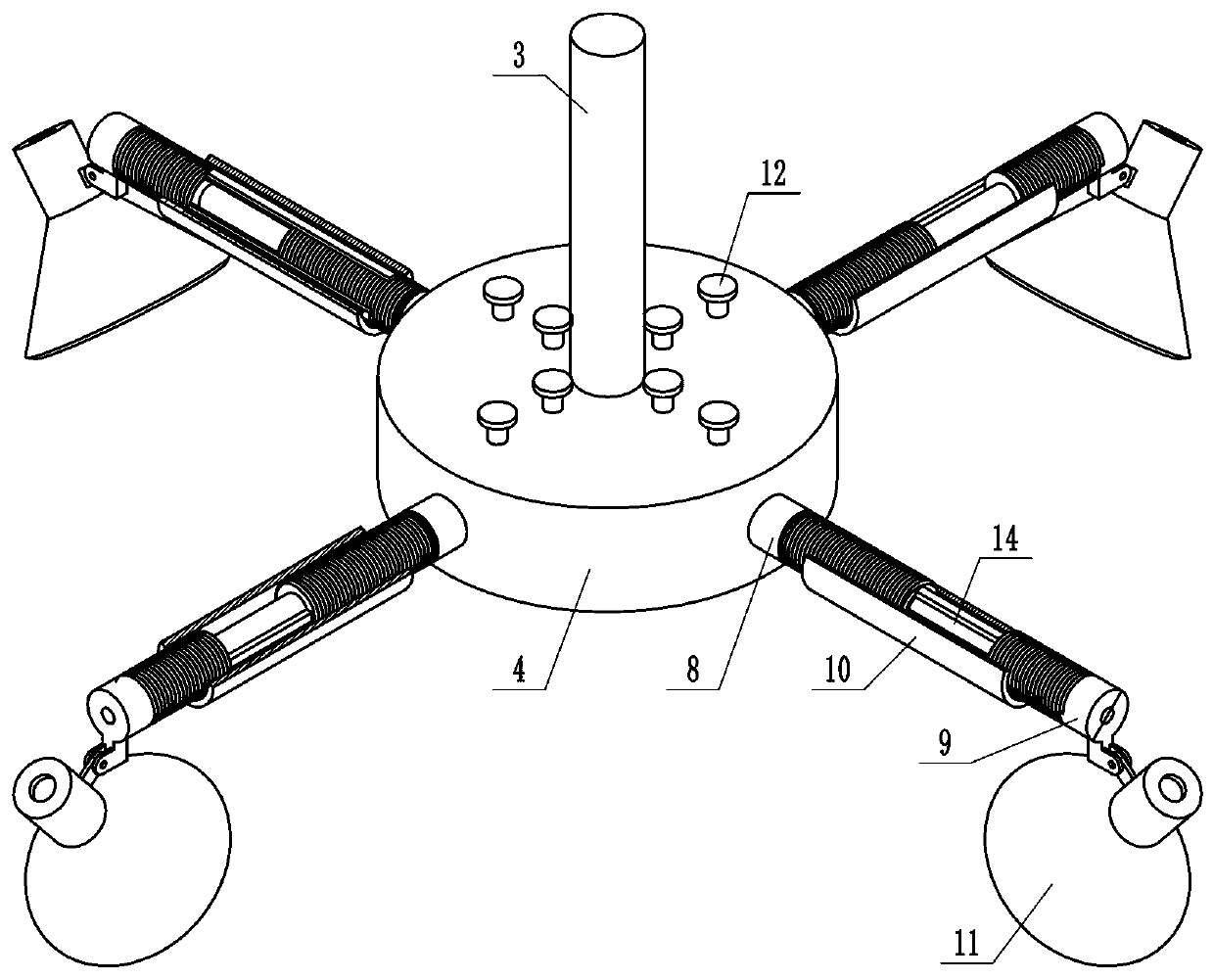

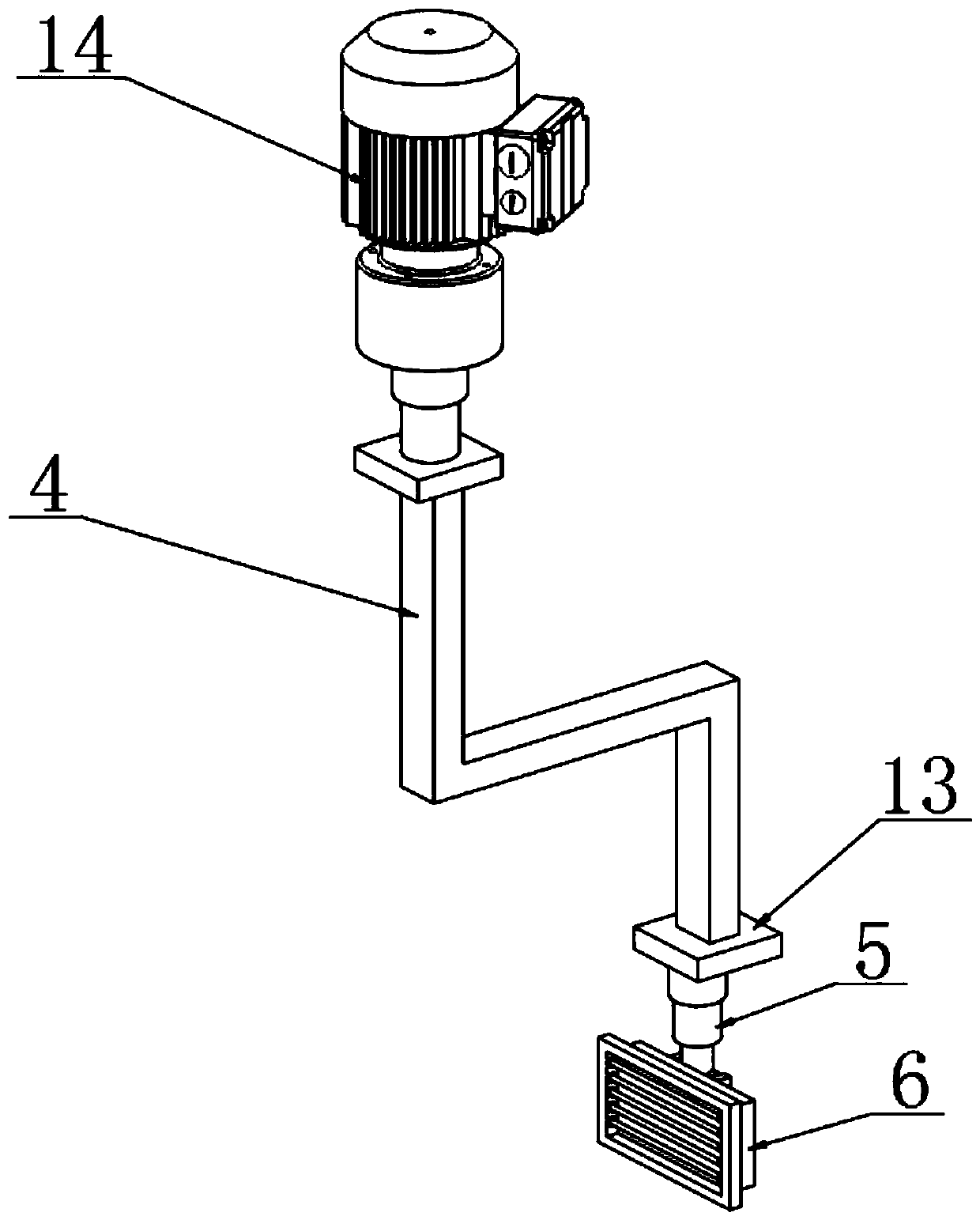

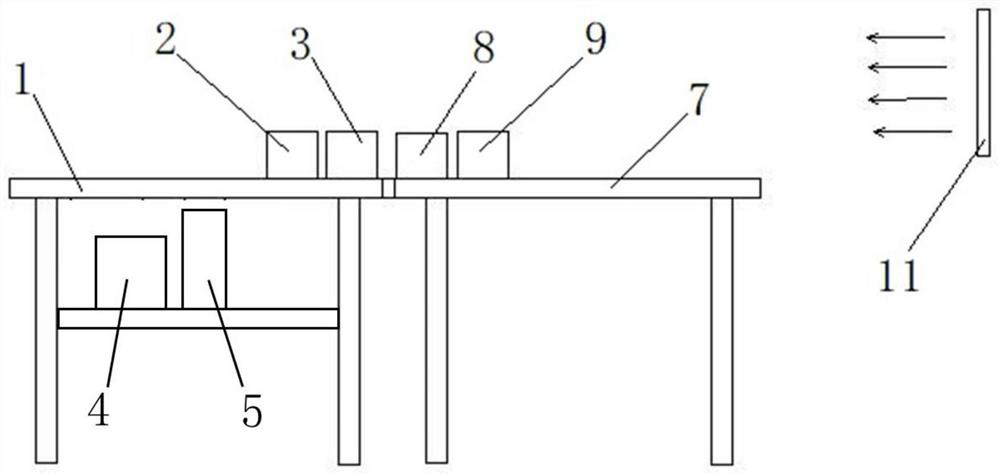

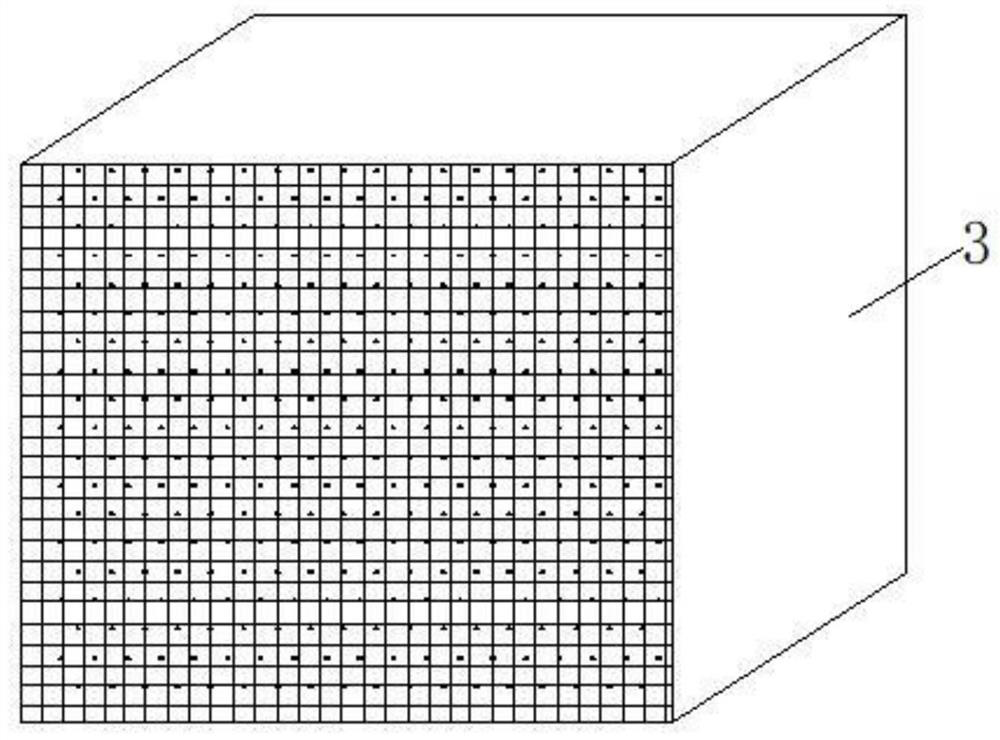

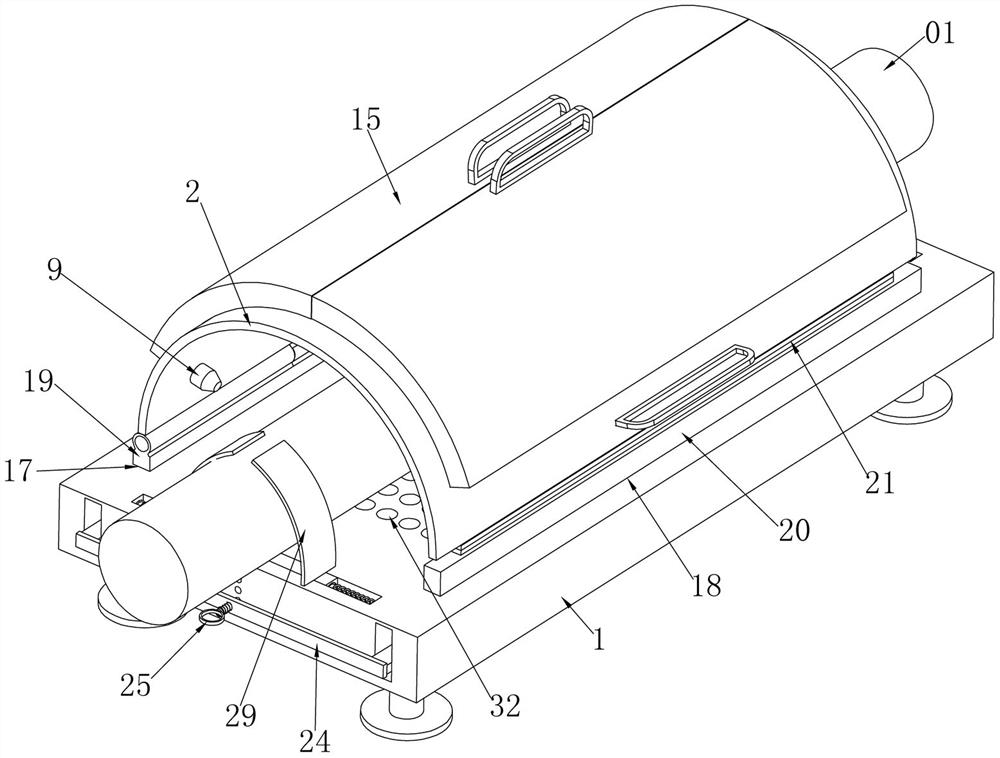

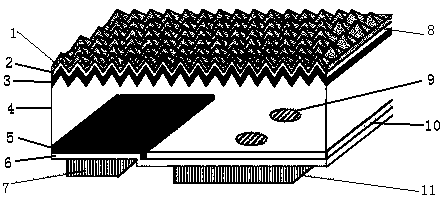

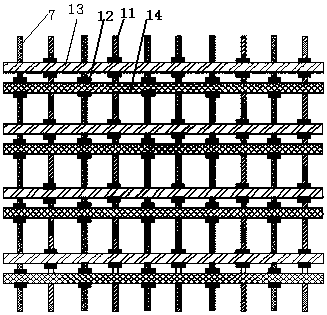

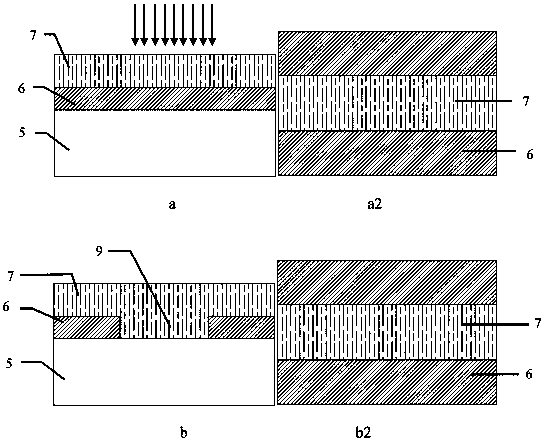

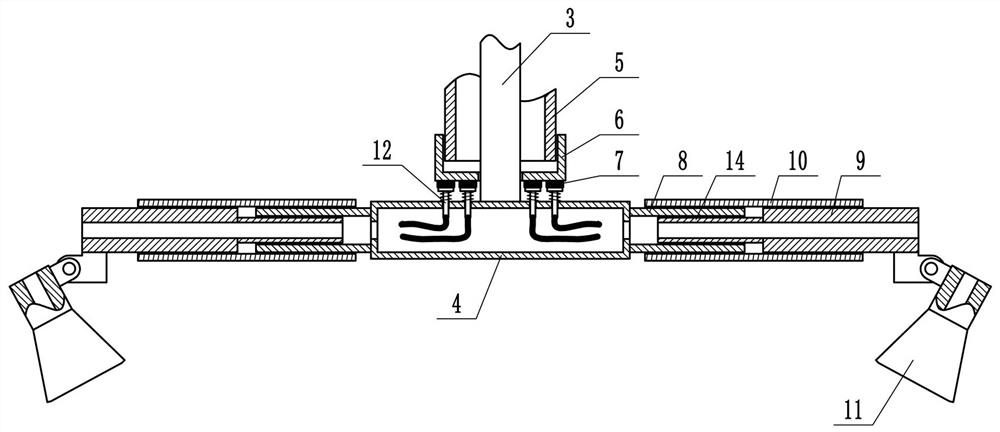

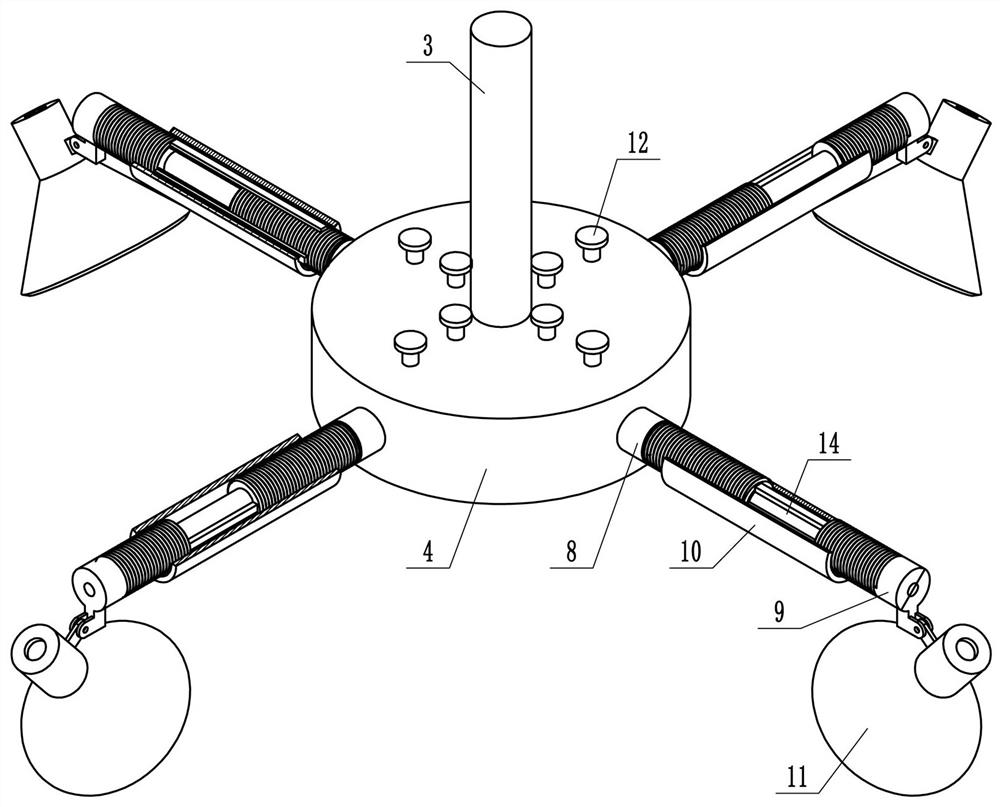

Target area adjustable type batch animal ionizing radiation local irradiation fixing and shielding device and method thereof

ActiveCN112402814AFix fixReduce the influence of other factorsAnimal fetteringX-ray/gamma-ray/particle-irradiation therapyShielding blockSurgery

The invention discloses a target area adjustable type batch animal ionizing radiation local irradiation fixing and shielding device. The device comprises an animal fixing part and a ray shielding part, wherein the animal fixing part comprises an animal anesthesia fixing table, and the ray shielding part comprises a ray shielding table; an anesthesia induction box and a batch animal fixing box arearranged on the table top of the animal anesthesia fixing table; a transverse adjusting and controlling shielding device, an up-down adjusting and controlling shielding device and a transverse-longitudinal scale division plate are arranged on the table top of the ray shielding table; the transverse adjusting and controlling shielding device blocks redundant rays in the horizontal direction, and afirst gap with the adjustable size and position in the direction perpendicular to the ground is exposed; the up-down adjusting and controlling shielding device blocks redundant rays in the direction parallel to the ground, and a second gap with the adjustable size and position in the direction parallel to the ground is exposed; a rectangular area, namely an irradiation field, is formed at the intersection of the two gaps; through stepped connection, leakage caused when the rays pass through the transverse arrangement position of a shielding block is blocked, and incomplete blocking is avoided;and the position and area of the irradiation area are flexible, adjustable and accurate in irradiation.

Owner:THE NAVAL MEDICAL UNIV OF PLA

Method of marking material and system therefore, and material marked according to same method

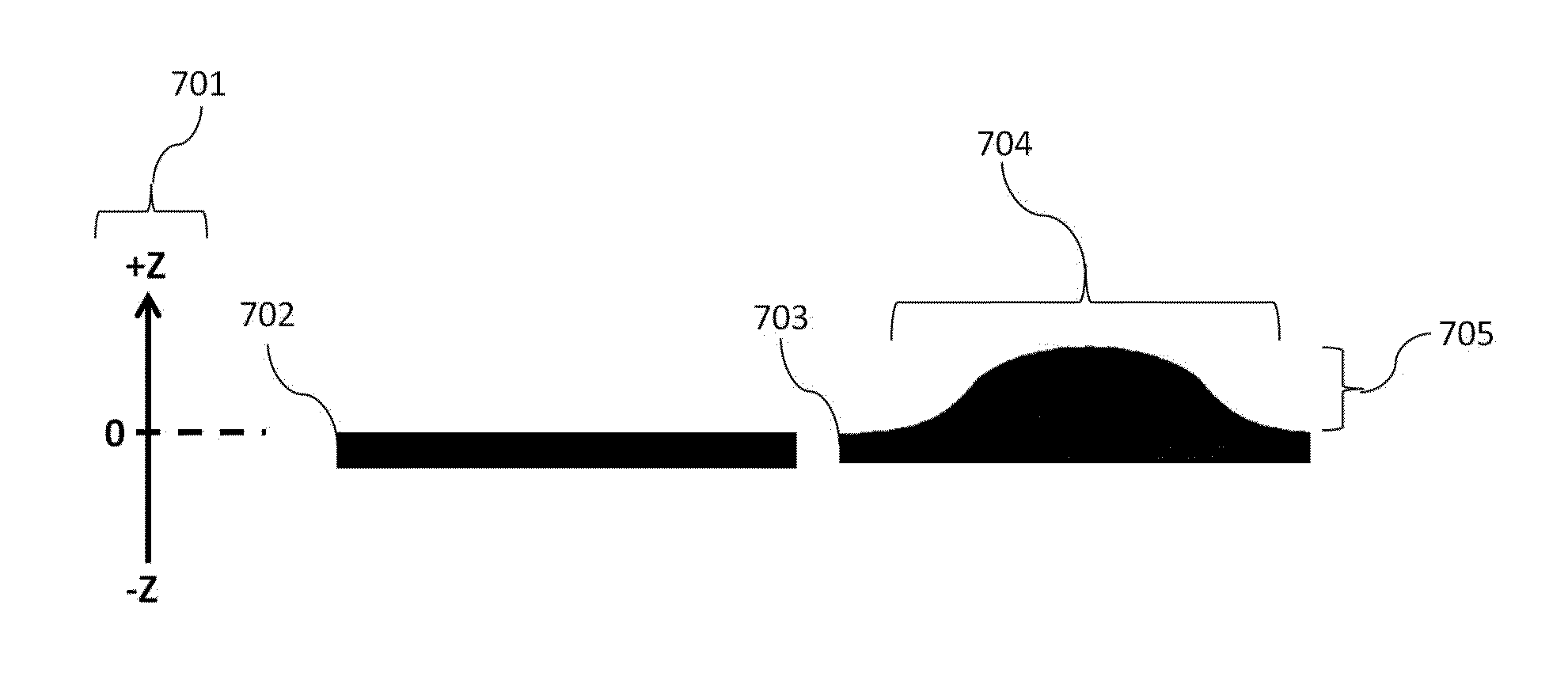

ActiveUS9901895B2No loss of qualityPreserve integrityPolycrystalline material growthAfter-treatment detailsIon beamMaterials science

A method of forming one or more protrusions on an outer surface of a polished face of a solid state material, said method including the step of applying focused inert gas ion beam local irradiation towards an outer surface of a polished facet of a solid state material in a way of protruding top surface material; wherein irradiated focused inert gas ions from said focused inert gas ion bean penetrate the outer surface of said polished facet of said solid state material; and wherein irradiated focused inert gas ions cause expansive strain within the solid state crystal lattice of the solid state material below said outer surface at a pressure so as to induce expansion of solid state crystal lattice, and form a protrusion on the outer surface of the polished face of said solid state material.

Owner:CHOW TAI FOOK JEWELLERY CO LTD

Bone injury adjuvant therapy device based on infrared therapy

The invention provides a bone injury adjuvant therapy device based on infrared therapy. The problems that an infrared therapeutic apparatus needs to adjust the angle for multiple times to prevent the skin of a patient from being scalded, and operation is complex are solved. The bone injury adjuvant therapy device comprises a base, wherein a semicircular plate is hinged to the top of the base; a snakelike groove penetrates through the side wall of the semicircular plate; a therapy sliding block is installed in the snakelike groove in a sliding mode; a snakelike rack is fixedly installed on the outer side face of the semicircular plate along one side of the snakelike groove; a therapy gear meshed with the snakelike rack is rotationally installed at the top of the therapy sliding block; a therapy motor is fixedly installed at the bottom of the therapy sliding block; a rotating shaft of the therapy motor penetrates through the therapy sliding block to be fixedly connected with the therapy gear; an infrared therapeutic apparatus is fixedly installed at the bottom of the therapy motor; and multiple temperature sensors are fixedly installed on the inner side face of the semicircular plate. By means of the infrared therapeutic apparatus circularly moving in the snakelike groove, the irradiation position and angle of the skin of the patient can be automatically adjusted while infrared therapy is conducted on the skin of the patient, and the patient can be prevented from being scalded during long-time local irradiation.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

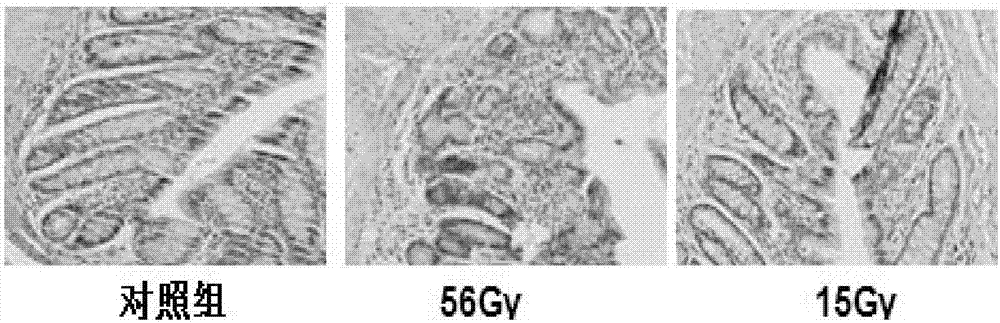

A method for the establishment of a systemic bone injury model based on local irradiation and the analysis of its pathological mechanism

ActiveCN107490701BAddress high mortalityAvoid complexityMicrobiological testing/measurementBiological material analysisKnee JointEfficacy

The invention discloses a method for establishing a systemic bone injury model and pathological mechanism analysis based on partial irradiation. Local irradiation of the knee joint is used to avoid high mortality and complicated pathological mechanisms of animals after whole-body irradiation; Irradiation damages intestines, kidneys, gonads and other organs closely related to bone metabolism; through single radiation damage to bone tissues and organs, the pathological mechanism of systemic radiation bone injury caused by local irradiation is effectively elucidated; it is helpful for the discovery of the pathological mechanism of radiation bone injury Early preventive intervention for clinical radiotherapy patients and as a model for new drug development and drug efficacy testing.

Owner:上海集技生物技术有限公司

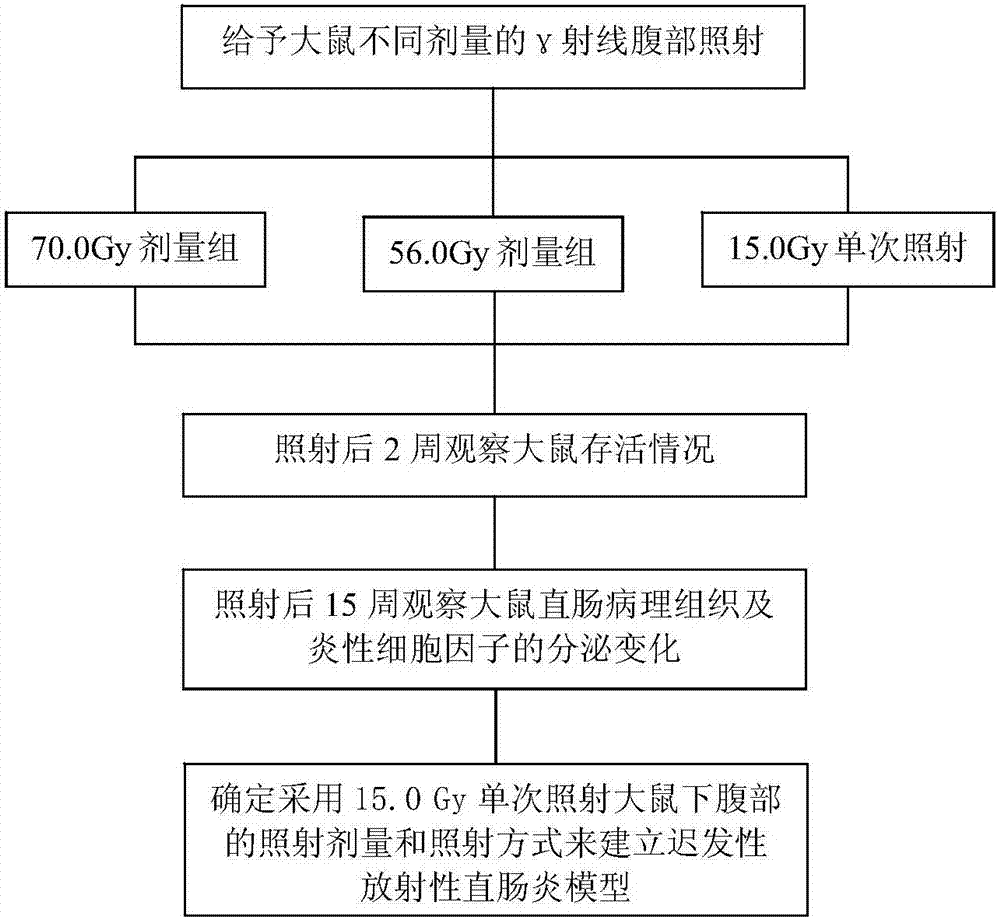

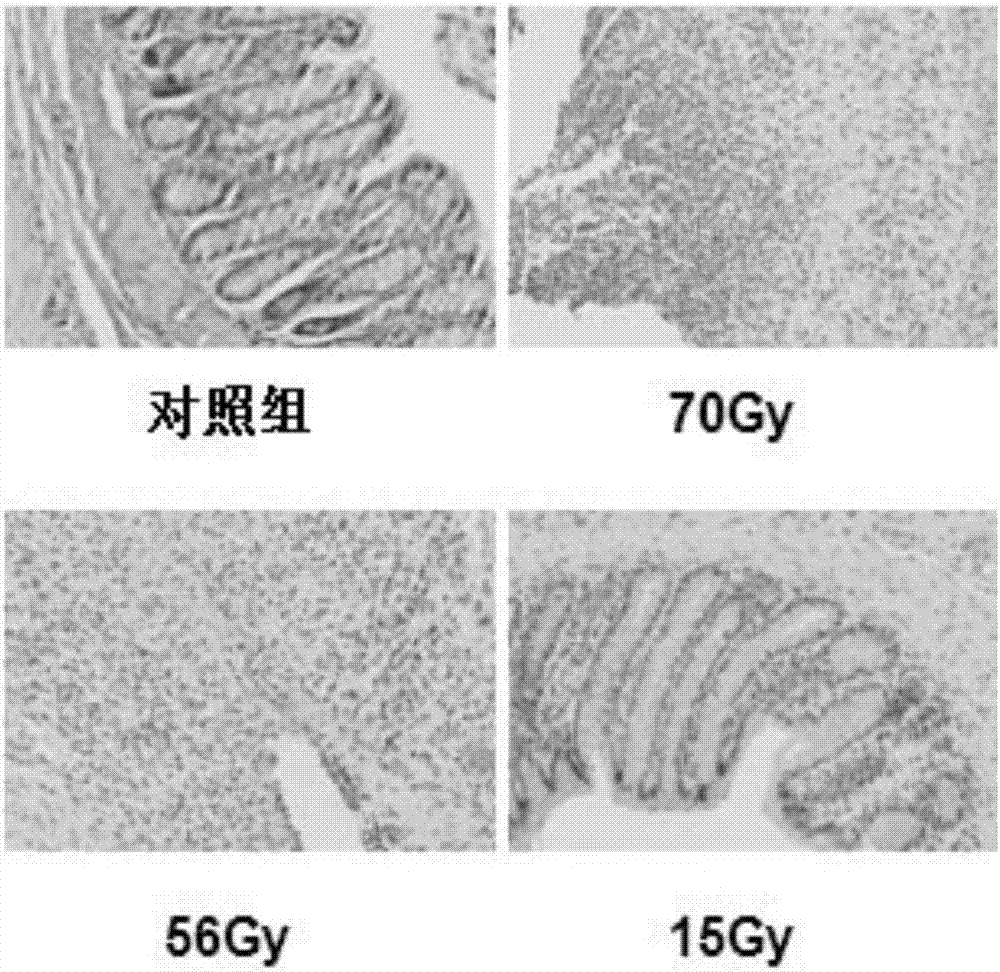

Method for establishing rat delayed radiation proctitis model

The invention belongs to the technical field of radiation medicine, and particularly relates to a method for establishing a rat delayed radiation proctitis model. According to the method, the optimalirradiation dose and the optimal irradiation mode for the successful establishment of the rat radiation proctitis model are screened out, and the rat model for the delayed radiation proctitis is established. The research result shows that 15 weeks after single local irradiation of 15.0Gy gamma rays, the rat rectum mucosa has inflammatory cell infiltration, fiber tissue hyperplasia also appears, and the secretion amount of inflammatory cytokines IL-2 and IL-6 of the rectum tissue is remarkably increased, which indicates the successful establishment of the radiation proctitis model. According tothe technical scheme provided by the invention, by establishing the rat delayed radiation proctitis model, an experimental basis is provided for the intensive study on the treatment means of the delayed radiation proctitis.

Owner:CHINA INST FOR RADIATION PROTECTION

Preparation method of interdigitated back contact solar cell

InactiveCN108039375ABroaden the sintering process windowImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationBack surface fieldConductive materials

The invention provides a preparation method of an interdigitated back contact solar cell. The damage removing and cleaning process is performed on a silicon substrate; a local emitter and a back surface field are formed on the back surface; the front surface is textured; a front surface field is prepared; front passivation antireflection and back passivation are performed; the back surface is patterned so as to form an electrode paste layer including conductive material; the first thermal treatment process is performed; the second thermal treatment process is performed, wherein the laser localirradiation treatment process is used in the second thermal treatment process, and the laser local irradiation treatment process is to perform local irradiation on the electrode paste layer; and theelectrode and the semiconductor are enabled to form local contact through laser local irradiation treatment so that the influence of composite metal on the cell performance can be effectively reduced.The sintering temperature can be reduced, the cell sintering process window can be expanded and the optimal passivation performance and the contact performance can be simultaneously realized so thatthe better cell conversion efficiency can be achieved; and perforating in advance and other complex process flow can be omitted.

Owner:TAIZHOU LERRISOLAR TECH CO LTD

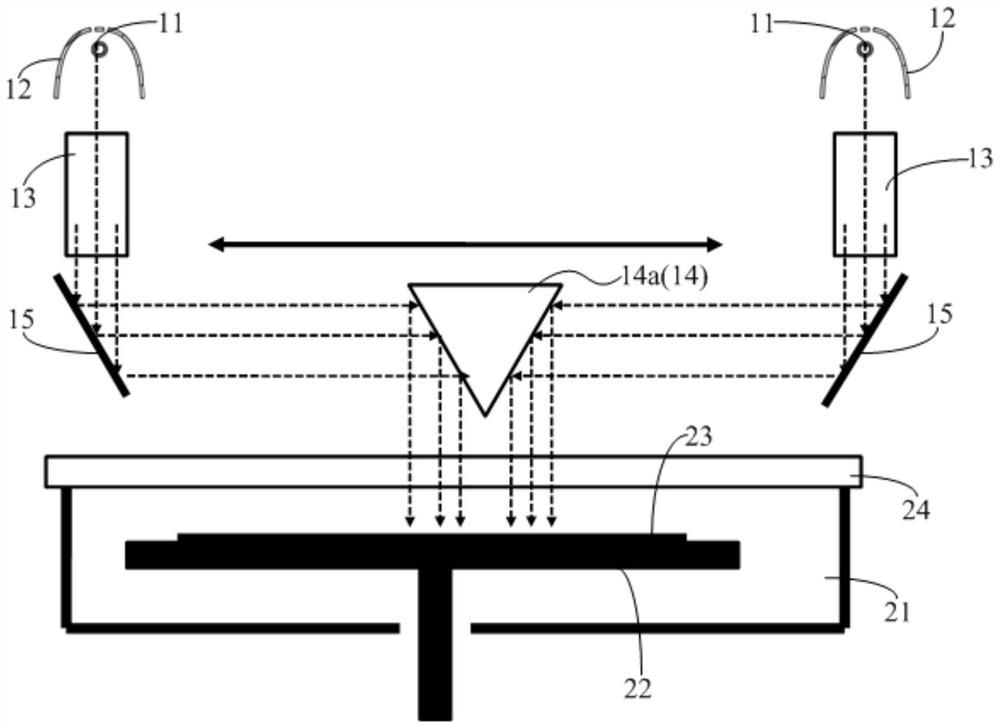

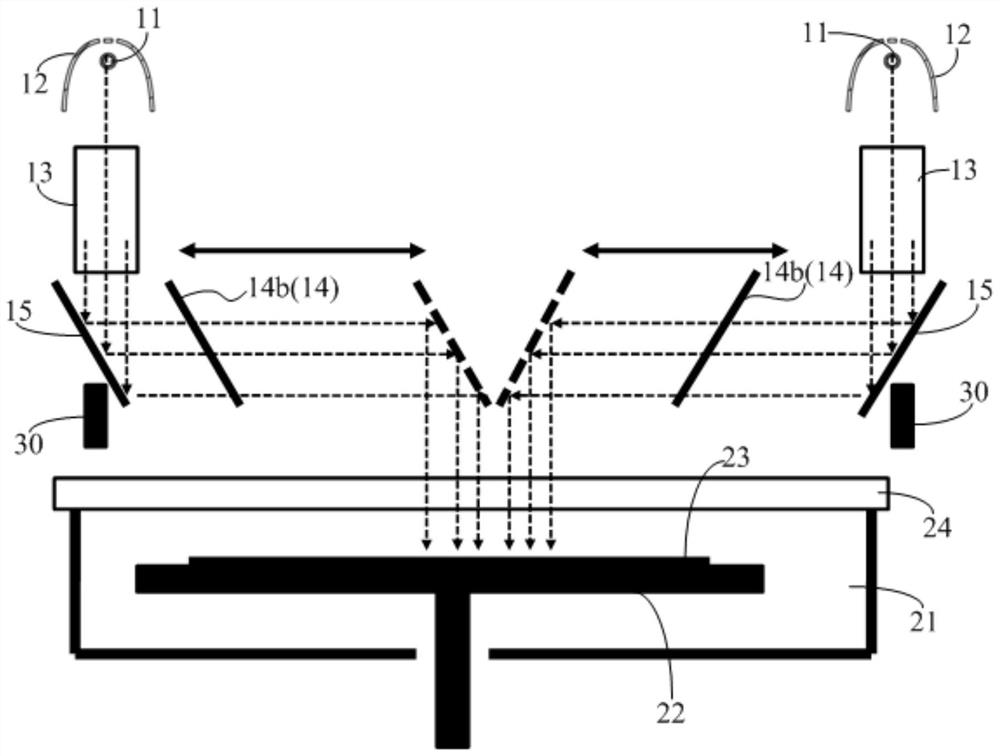

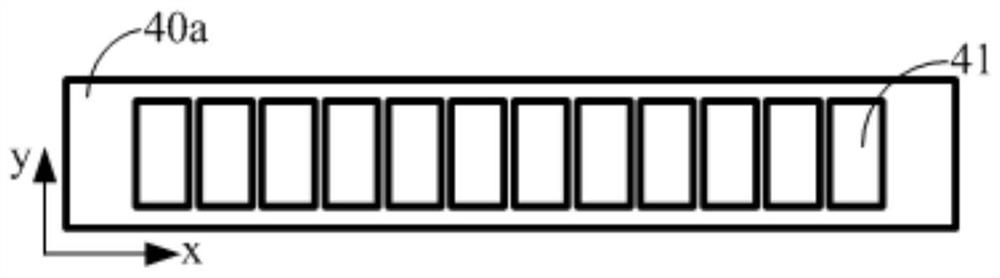

Optical lighting device and optical modification equipment

PendingCN114280701AIncrease local irradiation energy densityIncrease production capacityOptical elementsEngineeringLight modulation

The invention discloses an optical lighting device and optical modification equipment, the optical lighting device comprises two line light sources and a scanning reflection part, the scanning reflection part is provided with two reflection surfaces, each line light source is provided with a light modulation part, and the light modulation part is provided with a light source. The light modulation component is used for modulating light rays emitted by the line light source into parallel light and homogenizing the parallel light to form light bands with set lengths, and the two reflecting surfaces are respectively used for receiving the two light bands and reflecting the two light bands to a working surface of the same processing piece; the device further comprises a driving part, the driving part is used for driving the scanning reflection part to move in a reciprocating mode in the set direction, and the set direction is parallel to the working face. The structural arrangement of the optical lighting device can improve the local irradiation energy density, so that the total auxiliary energy borne by different areas of the target working face is relatively uniform, and meanwhile, the productivity can be improved.

Owner:PIOTECH CO LTD

Method for repairing display device and apparatus for same

ActiveUS9063356B2Inconsistency in the quality of the formed film can be reducedImprove surface qualityLiquid surface applicatorsChemical vapor deposition coatingDisplay deviceEngineering

An object of the present invention is to provide a method for repairing a display device according to which a wide variety of regions can be repaired in various ways using various materials, as well as an apparatus for the same. The present invention provides a repairing apparatus for repairing a pattern defect on a surface of a substrate in a display device where an electronic circuit pattern having the above described pattern defect is formed, characterized by having a plasma irradiation means for repairing the above described pattern defect through local irradiation of a region including the above described pattern defect with plasma.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

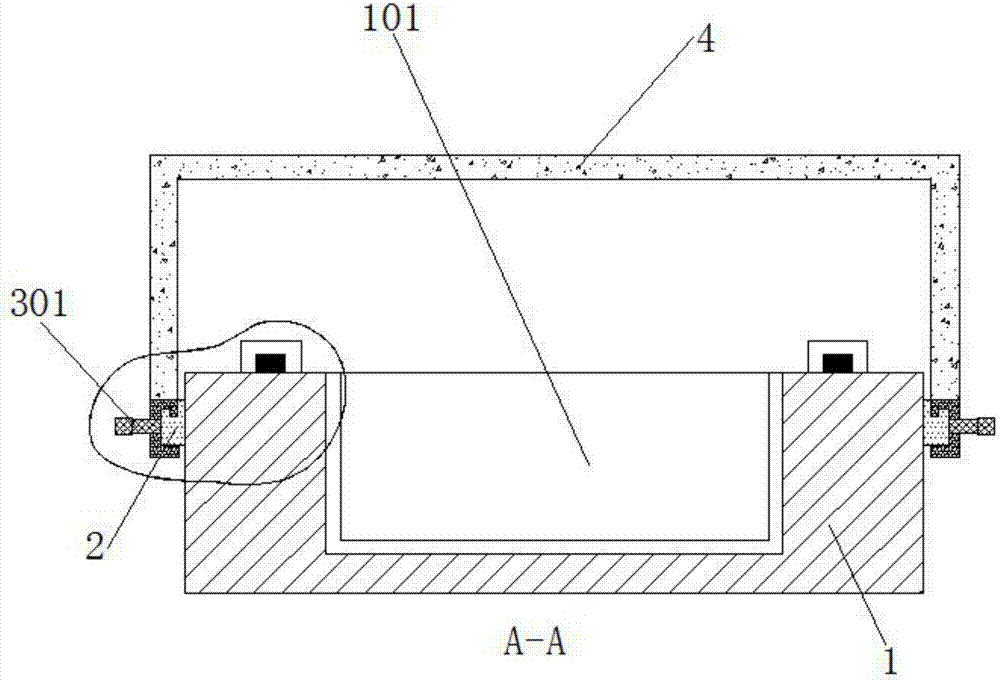

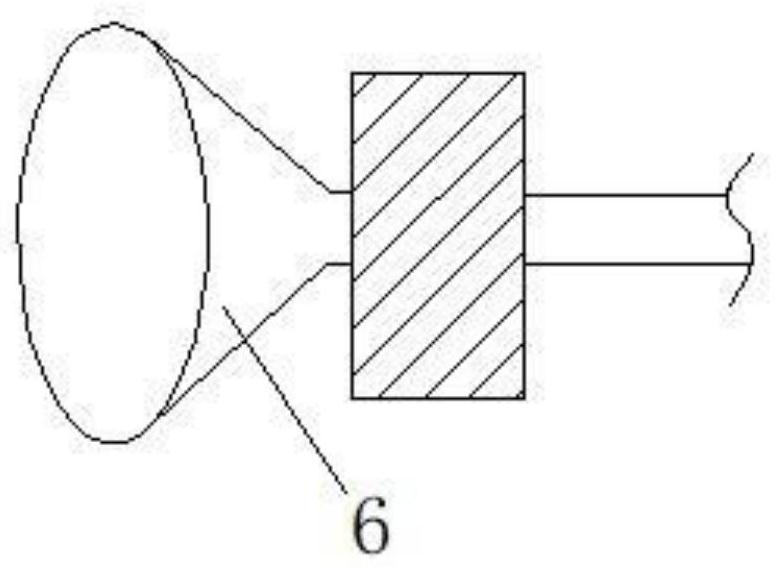

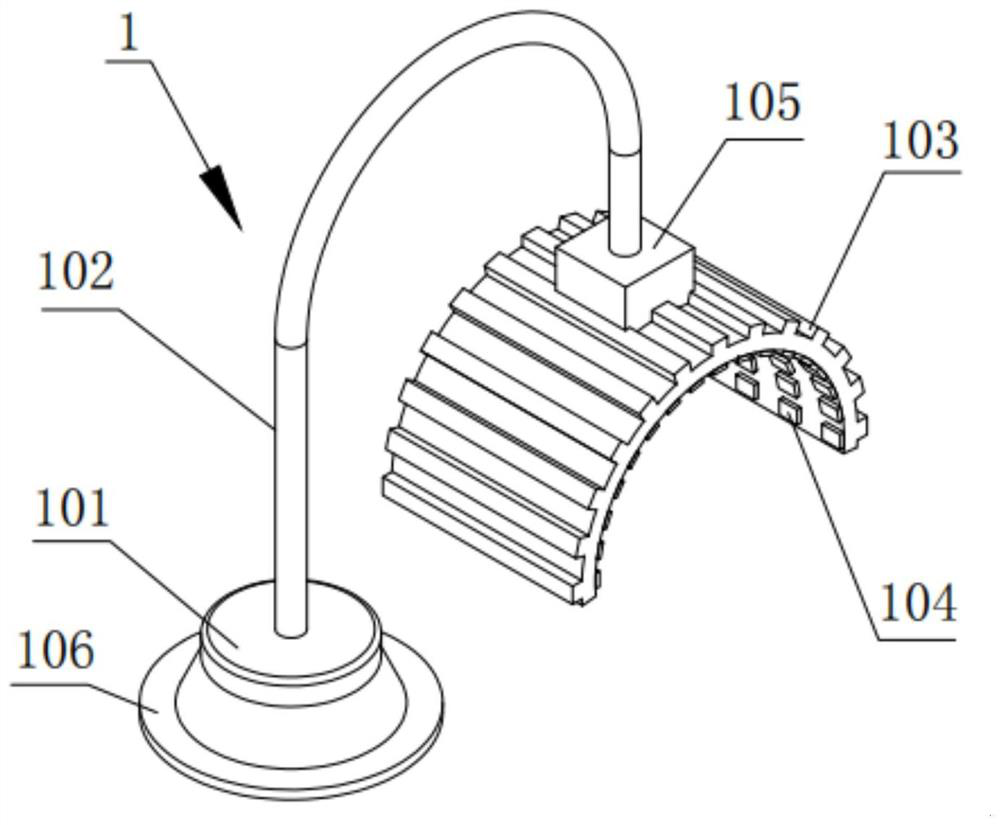

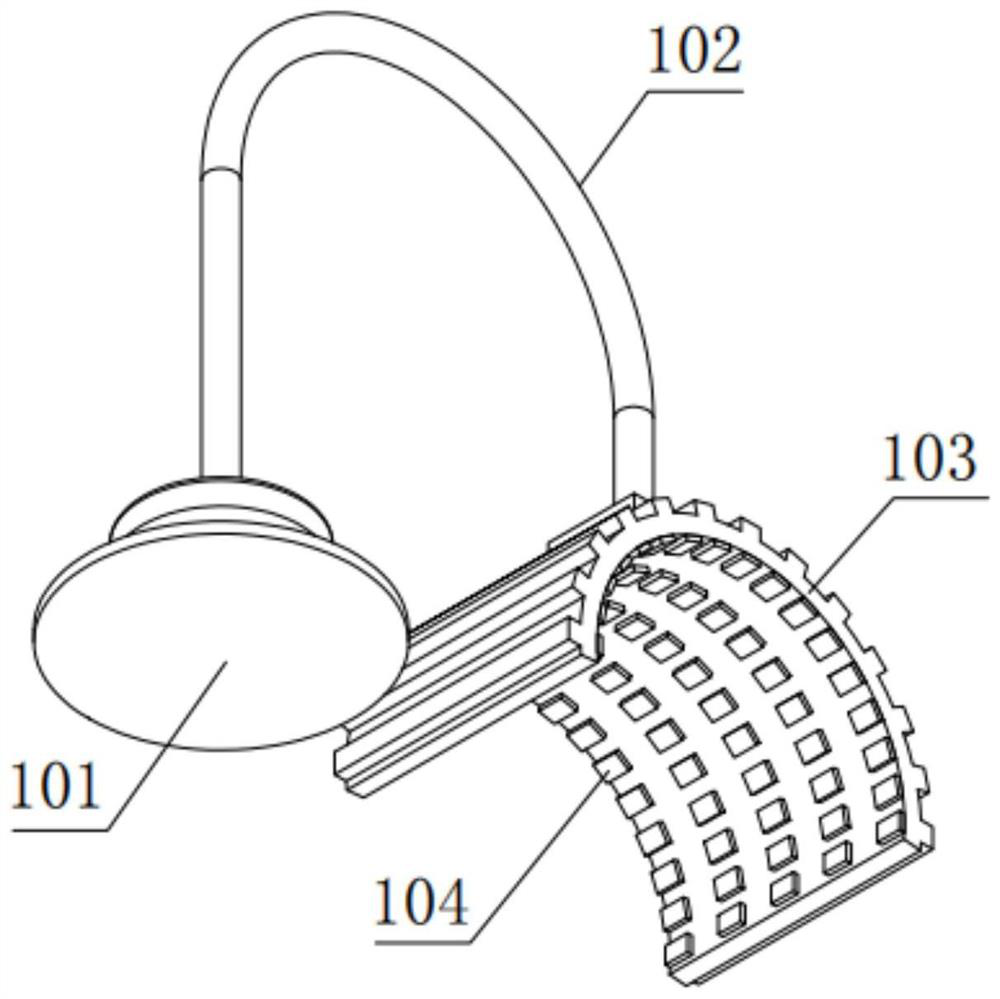

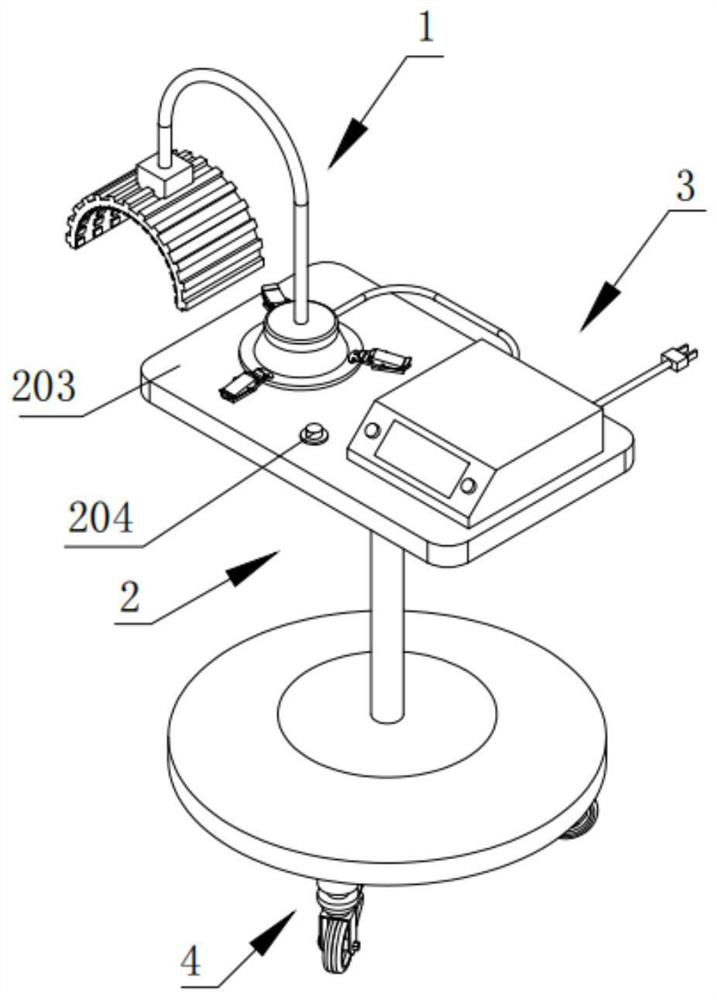

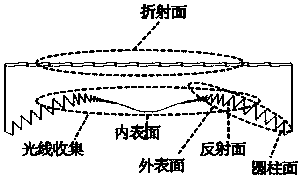

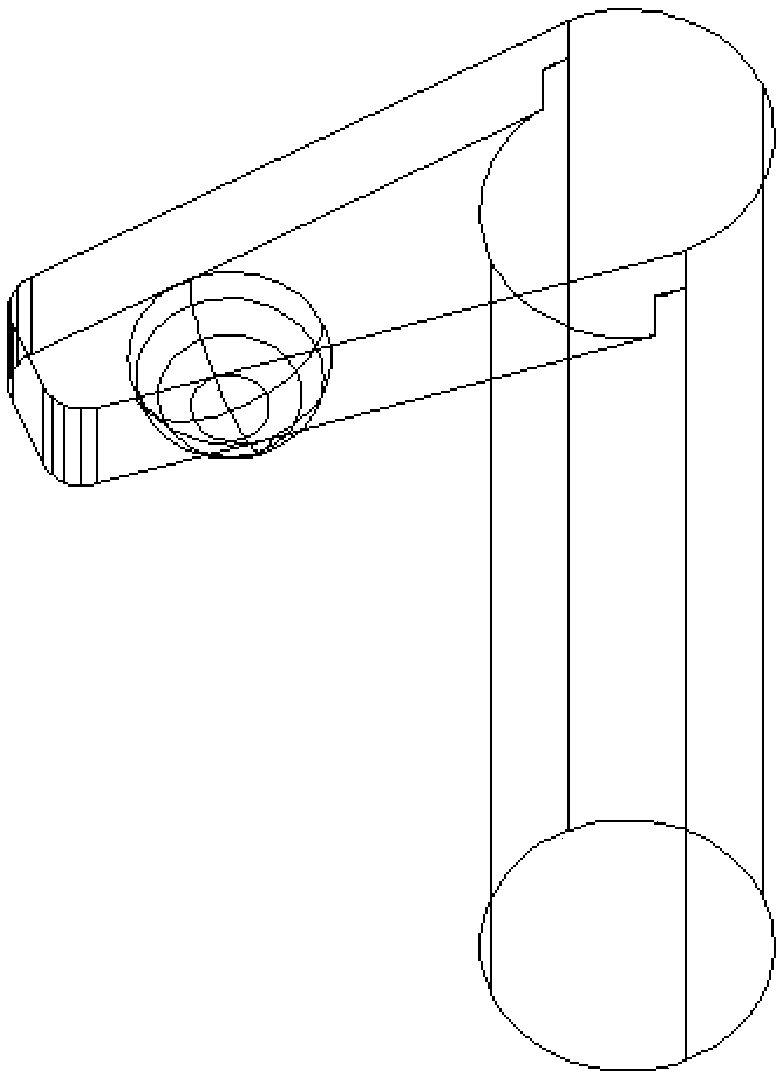

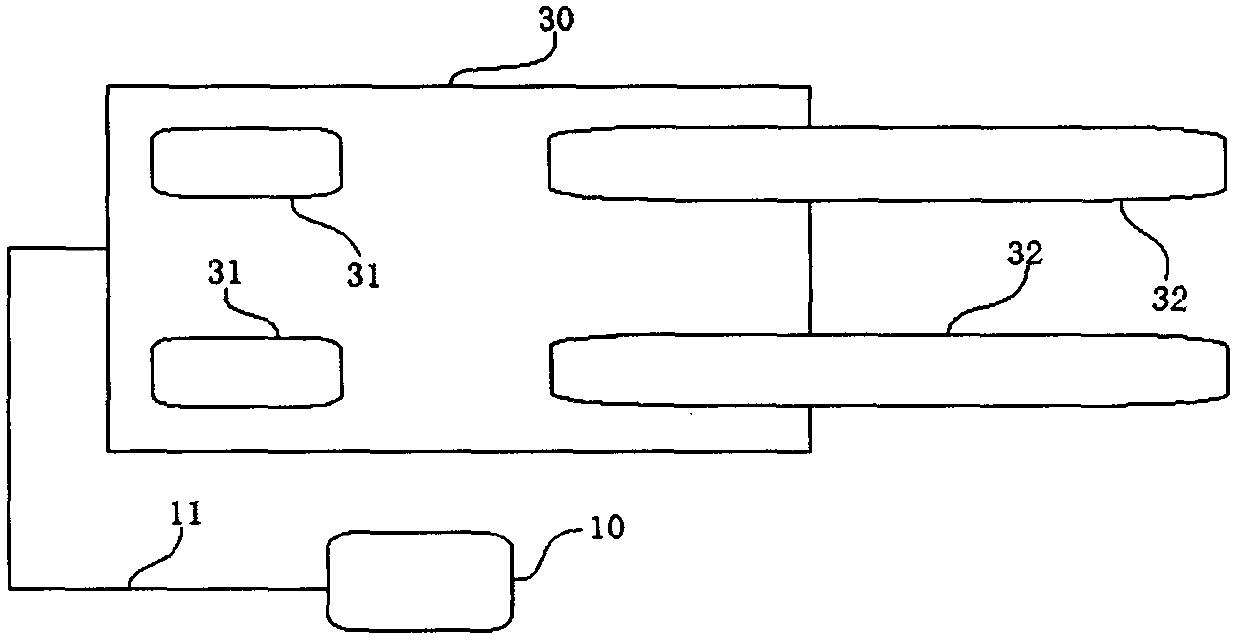

Annular LED light source and body local irradiation equipment

The invention discloses an annular LED light source and body local irradiation equipment. The annular LED light source comprises a main body structure which is used for providing local irradiation for the body of an animal in the animal experiment process, and comprises an arc-shaped cover and a plurality of equidistantly arranged LED lamp beads fixedly mounted on the inner arc surface of the arc-shaped cover. The invention further discloses equipment which comprises the annular LED light source, a bottom supporting assembly, a power supply device and a moving assembly. The annular LED light source provided by the invention is annular in structure, limited in illumination part, uniform in illumination, low in energy consumption and capable of meeting the scientificity and preciseness of experimental design, and meanwhile, the disclosed body local irradiation equipment is adjustable in height and convenient to move so as to adapt to experimental sites under different conditions, can generate irradiation light with various light wavelengths and various light intensities, and can well meet the experiment requirements.

Owner:FUDAN UNIV +2

Method for repairing display device and apparatus for same

ActiveCN101667527BReduce quality fluctuationsImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingDisplay devicePlasma irradiation

An object of the present invention is to provide a method for repairing a display device according to which a wide variety of regions can be repaired in various ways using various materials, as well as an apparatus for the same. The present invention provides a repairing apparatus for repairing a pattern defect on a surface of a substrate in a display device where an electronic circuit pattern having the above described pattern defect is formed, characterized by having a plasma irradiation means for repairing the above described pattern defect through local irradiation of a region including the above described pattern defect with plasma.

Owner:JAPAN DISPLAY INC +1

Method of marking material and system therefore, and material marked according to same method

ActiveUS20140356577A1No loss of qualityMaintain integrityPolycrystalline material growthAfter-treatment detailsIon beamMaterials science

A method of forming one or more protrusions on an outer surface of a polished face of a solid state material, said method including the step of applying focused inert gas ion beam local irradiation towards an outer surface of a polished facet of a solid state material in a way of protruding top surface material; wherein irradiated focused inert gas ions from said focused inert gas ion bean penetrate the outer surface of said polished facet of said solid state material; and wherein irradiated focused inert gas ions cause expansive strain within the solid state crystal lattice of the solid state material below said outer surface at a pressure so as to induce expansion of solid state crystal lattice, and form a protrusion on the outer surface of the polished face of said solid state material.

Owner:CHOW TAI FOOK JEWELLERY CO LTD

Oven Lamps for Surgical Nursing

The invention provides a baking lamp for surgical nursing, and effectively solves the problems that an existing baking lamp is immobile during use, so that irradiation is non-uniform; scalds are possibly caused by excessive baking; a therapeutic effect is not realized possibly due to insufficient local irradiation. The baking lamp for surgical nursing is characterized by comprising a medical baking lamp main body; a supporting plate is fixed to the main body; a rotating shaft is arranged on the supporting plate; a shell is arranged at the lower end of the rotating shaft; a vertical barrel is arranged on the rotating shaft; a movable barrel is arranged at the lower end of the vertical barrel; an annular plate is arranged at the lower end of the movable barrel; two electrodes are arranged atthe lower end of the annular plate; first cylinders are arranged on the periphery of the shell; one sides of the first cylinders are provided with second cylinders; third cylinders are arranged on the first cylinders; one ends of the second cylinders are provided with revelation light covers; baking lamp bodies are arranged in the light covers; the upper side plate of the shell is provided with aplurality of groups of contacts; each group contains two contacts. The baking lamp for surgical nursing is ingenious in structure; the distance between the baking lamp and a wound can be adjusted; the wound is irradiated omni-directionally; uniform irradiation can be performed on the wound effectively; insufficient irradiation or scalds can be avoided; harm to tissues and the wound caused by excessive baking can be prevented.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Laser etching method of MEMS silicon structure

InactiveCN109848569AReduce repetition rateReduce pollutionLaser beam welding apparatusHeat-affected zoneSmoke plume

The invention belongs to the technical field of microprocessing, and relates to a laser etching method of an MEMS silicon structure. The laser etching method comprises the following steps: a laser beam conducts local irradiation on the surface of a silicon material through an objective lens, and the silicon material absorbs part of energy and then is heated; the surface of an irradiation area is molten into a molten area, part of the molten silicon material is vaporized into a smoke plume and molten splashes, and the molten part is scattered on the processed surface of the silicon material toform solid splashes; and laser irradiation is completed, the silicon material is condensed, and heat affected areas and cracks appear on the irradiation area of the silicon material. Under the condition that the average power and pulse width of the laser beam are not changed, influences of recast layers and pollution of the surrounding splashes can be reduced by decreasing the repetition frequencyof a laser device and increasing single-time pulse energy; through defocusing amount compensation, the maximum local irradiation intensity and the minimum etching diameter are obtained, and etching splashing is relieved; and through an auxiliary vacuum environment, dissipation in the laser transmitting process is reduced, the relatively-high irradiation intensity is obtained, and the heat affected areas are reduced.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Street lamp based on combined reflecting surface

PendingCN107687603AIncrease flexibilityAvoid projectionPlanar light sourcesMechanical apparatusTarget surfacePlane mirror

The invention discloses a street lamp based on a combined reflecting surface. The street lamp comprises a lamp holder, a lamp pole and a control box; the lamp holder comprises a lamp base as well as acombined curved surface reflector, an LED lamp panel and a lens which are sequentially mounted on the lamp base from inside to outside; the combined curved surface reflector comprises a plurality ofplanar reflecting mirrors in different directions; light of the LED lamp panel is completely radiated by all the planar reflecting mirrors to a target plane, and all light spots radiated to the targetplane are completely superposed with the position of the target plane; a plurality of LED lamps arranged in a square array are arranged on the LED lamp panel; and the lens are in the rectangular shape which is asymmetric in transverse and longitudinal directions. The street lamp has the very high flexibility and is applicable to various road conditions. Partial lighting dead corners can be avoided, so that dead zones are reduced; the light can be prevented from being projected to some areas which are not required to be lit, lighting of the unnecessary areas is reduced as much as possible, theutilization rate of energy is increased, and environmental protection and energy saving are realized.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

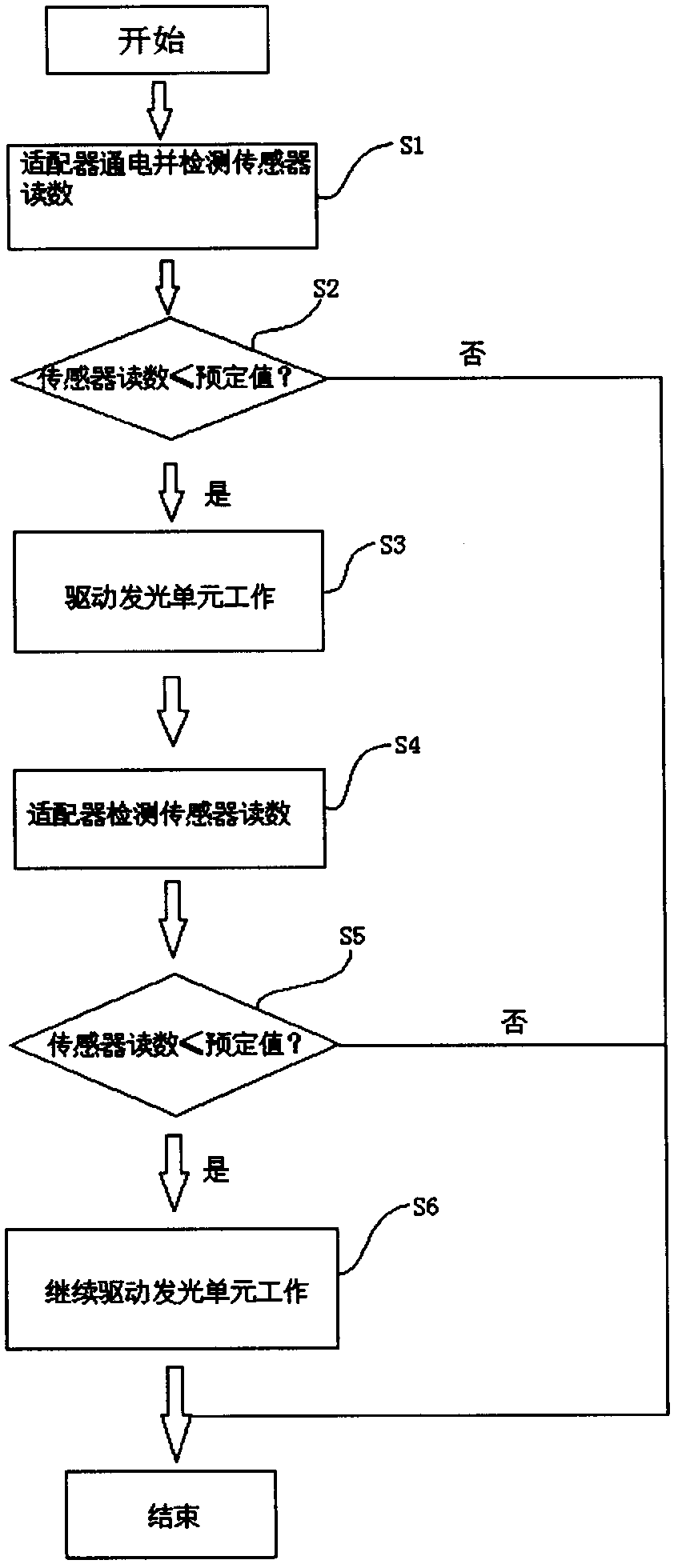

Wearable blue-light treatment system an method

InactiveCN109663213AWon't hurtImprove light irradiation efficiencyLight therapyWhole bodyEngineering

The invention relates to a wearable blue-light treatment system and method. The system comprises an adapter used for driving a light-emitting unit, a light-emitting unit which emits a specific wavelength light wave, a temperature sensor used for measuring the temperature of equipment, a flexible insulating layer used for electrical insulation, a flexible printed circuit board used for making the adapter electrically connected with the light emitting unit, a flexible substrate used for fixing and installing the light emitting unit, the flexible insulating layer and a flexible reflecting layer,the flexible reflecting layer used for the reflecting the light wave, a flexible light guide plate used for the propagating the light wave, and self-adhesive tape used for wearing and adjustment of the equipment. The system is characterized in that a blue light treatment box is miniaturized and wraps and is worn on human organs such as arms and shanks for blue light irradiation treatment; Due to blood circulation of the human body, by means of reasonable control over the time of local irradiation, the same effect as whole body irradiation can be achieved; due to the fact that strong light exposure does not exist for local wearable irradiation, eyes of newborns cannot be injured, and full medical escort is not needed.

Owner:李芝宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com