Preparation method of interdigitated back contact solar cell

A solar cell, back contact technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex process flow, difficult stability control, etc. Good contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

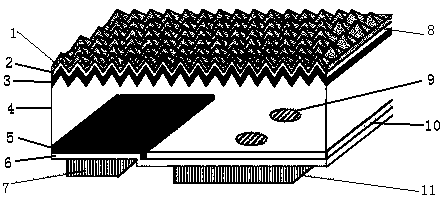

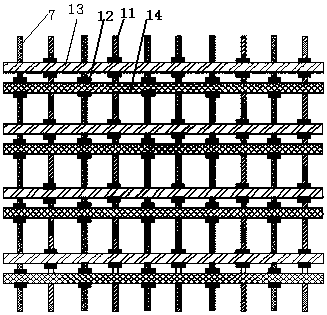

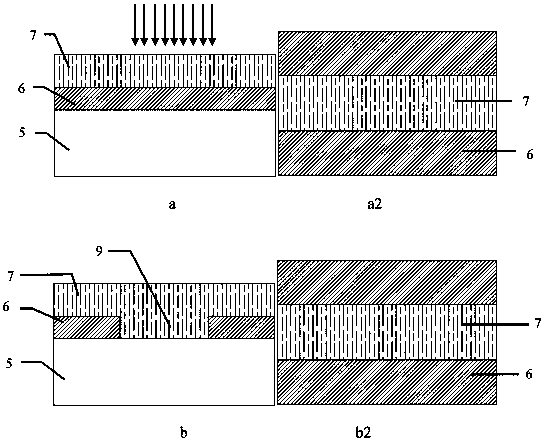

[0030] A method for fabricating interdigitated back-contact solar cells, in which a silicon substrate 4 is dedamaged and cleaned to form a suede structure 8; a local emitter 10 and a back surface field 5 are respectively formed on the back; the front surface is textured ; front surface field 3 preparation; front passivation anti-reflection and back passivation; patterning and forming an electrode paste layer containing conductive components on the back; The electrode paste layer containing conductive components is then subjected to a first heat treatment process and a local laser irradiation process to form local contact, and the order of the first heat treatment process and the second heat treatment process can be exchanged. Effectively reduces the impact of metal recombination on battery performance. In addition, due to the use of laser localized heating, the sintering temperature can be reduced, which can broaden the battery sintering process window, because the passivation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com