Preparation method of solar battery electrode

A solar cell and electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high contact resistance and series resistance of battery electrodes, low passivation performance at electrodes, and affect battery conversion efficiency. resistance, good cell conversion efficiency, and the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

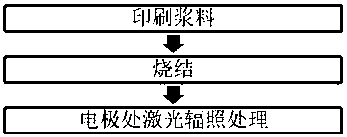

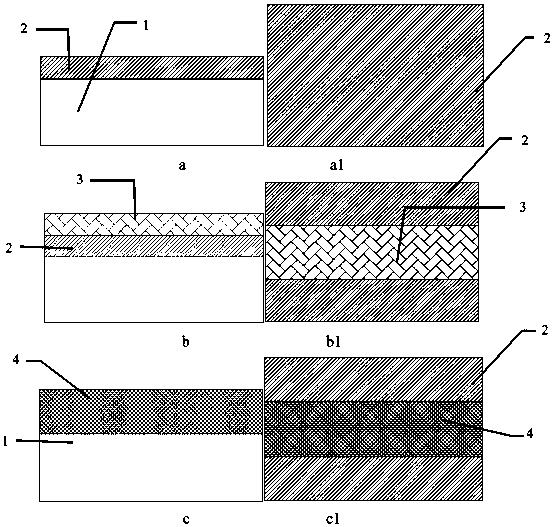

[0022] A method for preparing a solar cell electrode, patterning and forming an electrode paste layer 3 containing conductive components on a semiconductor 1 substrate that has completed surface texturing, emitter preparation, and passivation; the first heat treatment process; the second heat treatment process; wherein the first heat treatment process and the second heat treatment process can exchange order. The above electrode preparation method has small contact resistance, good passivation performance, and has a wide process window.

[0023] An embodiment of the electrode preparation method of this solar cell below, as figure 1 ,details as follows:

[0024] In the first step, the patterned distribution of the conductive layer is completed by directly coating the conductive paste on the surface of the semi-finished semiconductor solar cell for which the electrode needs to be prepared. In the embodiment, the coating of the conductive paste is selected on both the light-rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com