Patents

Literature

86results about How to "Components are easily available" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antifogging agent composition and antifogging colored window film formed by same

ActiveCN102618102AEasy to prepareReduce manufacturing costOther chemical processesSynthetic resin layered productsPolyesterDiamine

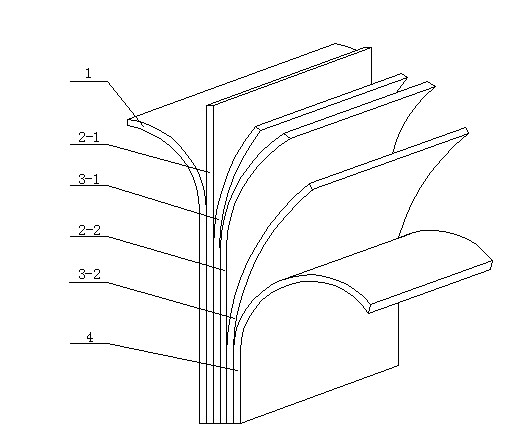

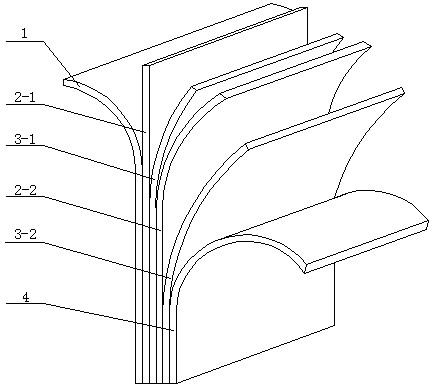

The invention relates to an antifogging agent composition and an antifogging colored window film formed by the same. The antifogging agent composition comprises 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylene-diamine, 1-5wt% of leveling agent, 5-26wt% of isopropanol and 5-24wt% of ethanol. The antifogging colored window film comprises an antifogging agent coating layer (1), a first transparent polyester film or transparent polyethylene film substrate (2-1), a dyed acrylic acid adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic acid adhesive layer (3-2) and a releasing film (4) which are integrally composited, wherein the antifogging agent coating layer (1) is formed by the antifogging agent composition. The antifogging colored window film is antifogging, attractive, transparent and safe.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

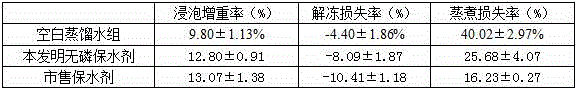

Water-retaining agent for frozen shrimp meat, and preparation method and application thereof

InactiveCN105076350AGuaranteed qualityComponents are easily availableMeat/fish preservation using chemicalsFlavorShrimp

The present invention discloses a water-retaining agent for frozen shrimp meat. The water-retaining agent comprises the following components by weight: 2-4% of alginate oligosaccharide, 1-3% of sucrose ester, 0.3-0.5% of sodium carbonate, 0.5-1% of sorbitol, 0.5-1% of sodium caseinate, 0.3-0.5% of xanthan gum and the balance of water. The water-retaining agent for frozen shrimp meat uses readily available and low-cost ingredients, which are environment-friendly and safe and mutually cooperate. The water-retaining agent has excellent water retention properties, and can better maintain the fresh flavor and flexibility of shrimp, so as to reduce loss of shrimp juice and guarantee the quality of frozen shrimp meat. The present invention also discloses a preparation method of the frozen shrimp meat; the method has simple steps, less investment in equipment, and strong operability, and is applicable to industrial production.

Owner:ZHEJIANG OCEAN UNIV

Antifogging agent composition and transparent antifogging window membrane formed therefrom

ActiveCN102627880AGood anti-fog durabilityEasy to prepareOther chemical processesFilm/foil adhesivesPolyesterPolymer science

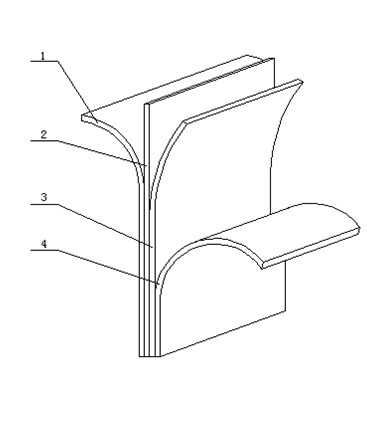

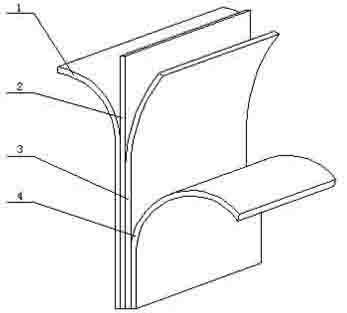

The invention relates to an antifogging agent composition and a transparent antifogging window membrane formed from the composition. The antifogging agent composition consists of 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylenediamine, 1-5wt% of a levelling agent, 5-26wt% of isopropanol, and 5-24wt% of ethanol. The antifogging window membrane is composed of an antifogging agent coating (1), a transparent polyester membrane or transparent polyethylene membrane base material (2), an acrylic adhesive layer (3) and a release membrane (4), and all layers are integrated. The antifogging agent coating (1) is formed by the antifogging agent composition, while the acrylic adhesive layer (3) is formed by a mixture of an acrylic adhesive, a curing agent, toluene and butanone. The transparent antifogging window membrane has effective antifogging function and high light transmittance, as well as a protection effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

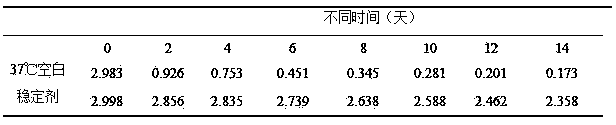

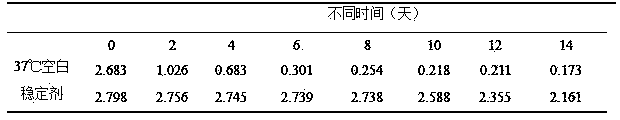

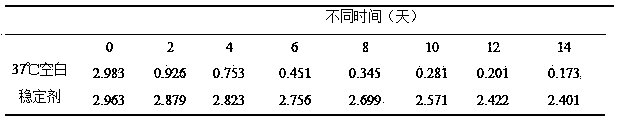

Long-acting ELISA plate stabilizing agent

ActiveCN103472222AGuaranteed continuous stabilityLow costMaterial analysisProtein activityBULK ACTIVE INGREDIENT

The invention relates to a long-acting ELISA (Enzyme-linked Immunosorbent Assay) plate stabilizing agent for keeping protein activity in an ELISA plate. The agent comprises 0.1-5g protein, 1-15g sugar, 0.1-10g organic matter, 0.01-0.1%(V / V) of preservative, and 10-200mmol buffer solution salt per 100ml water, and a pH (Potential of Hydrogen) value is 7.2-7.4. The stabilizing agent adopts a technical route integrating a closing process and a stabilization process, and can effectively close excessive sites in the ELISA plate, and some active ingredients in the stabilizing agent can ensure continuous stabilization of the ELISA plate. The agent is simple in formula, can stabilize the ELISA plate, and does not produce any influence on a result simultaneously. The ingredients of the agent are easy to obtain, and the formula is simple, so that the cost of the stabilizing agent is lowered.

Owner:河北渤腾医药技术有限公司

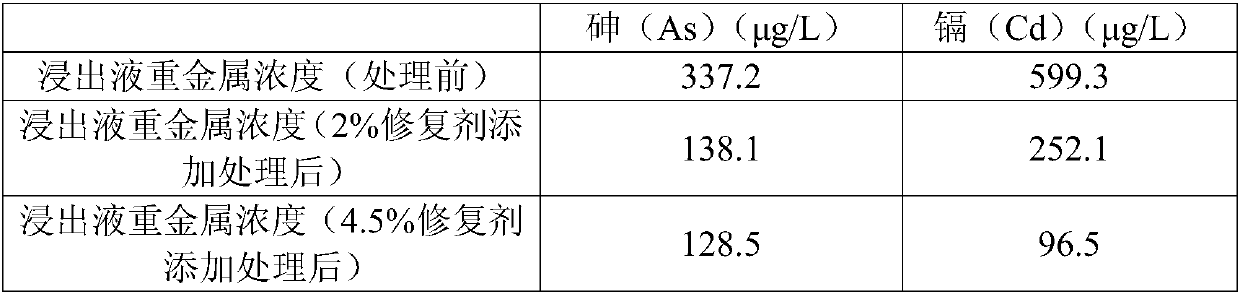

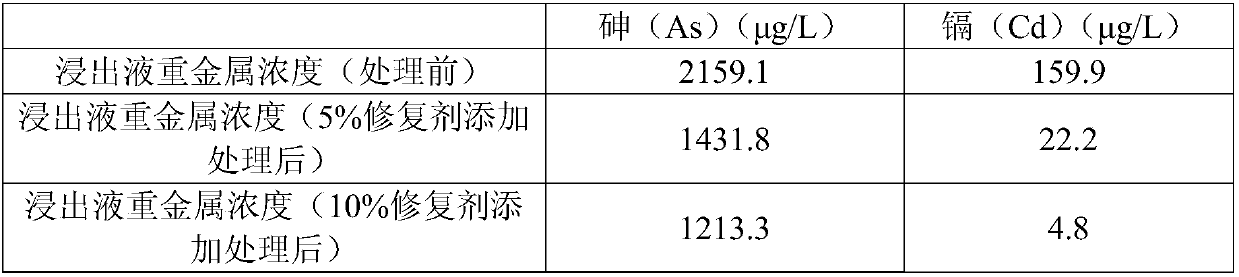

Cadmium-arsenic composite polluted soil remediation agent

PendingCN109575926AReduced ability to migrateReduce ecological and environmental risksOrganic fertilisersSoil conditioning compositionsEcological environmentIon exchange

The invention discloses a cadmium-arsenic composite polluted soil remediation agent, which comprises the following raw materials in parts by weight: 0-10 parts of hematite; 20-30 parts of ferrous sulfate; 10 parts of manganese dioxide; 15-20 parts of fly ash; 10-15 parts of quicklime; 10-15 parts of sepiolite; 10-15 parts of calcium dihydrogen phosphate; and 0-10 parts of wollastonite. The remediation agent enables cadmium and arsenic heavy metals to form stable chemical forms through oxidation reduction, adsorption, ion exchange, precipitation or coprecipitation and the like to reduce the migration and diffusion capability of the cadmium and arsenic heavy metals in the environment, so that the ecological environment risk of the cadmium and arsenic heavy metals is reduced; and the remediation agent has the advantages of high remediation efficiency for cadmium-arsenic composite polluted soil, short remediation period, low remediation cost, easily available raw material components and simple application method, so that the agent is one of the few remediation agents in the industry that simultaneously act on yin and yang heavy metal ions.

Owner:HUAZHONG AGRI UNIV

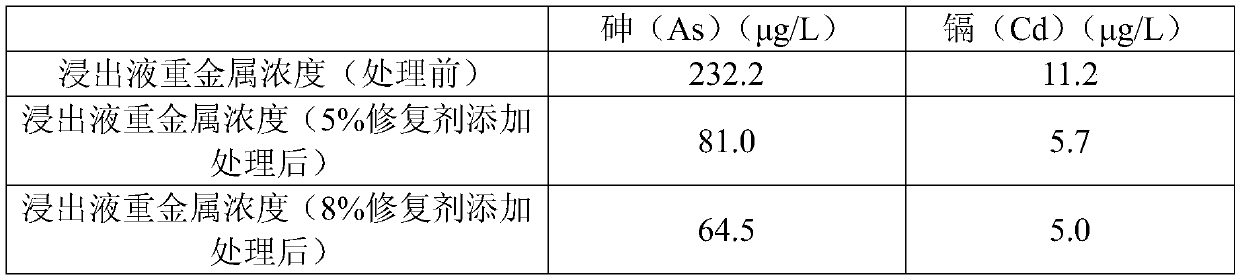

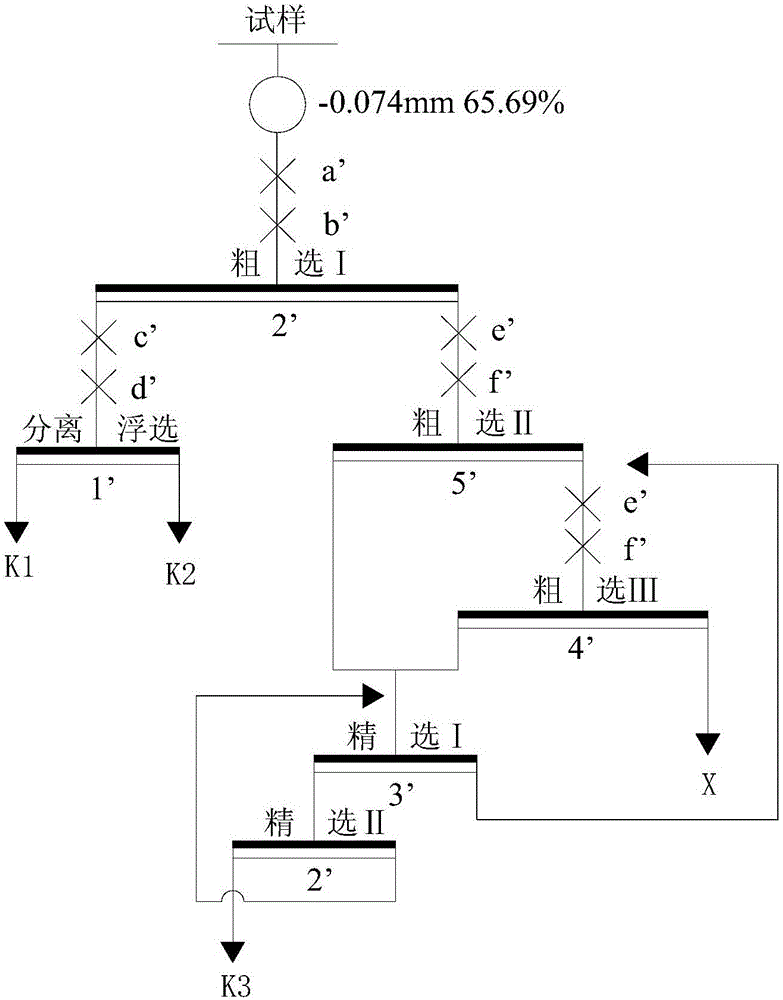

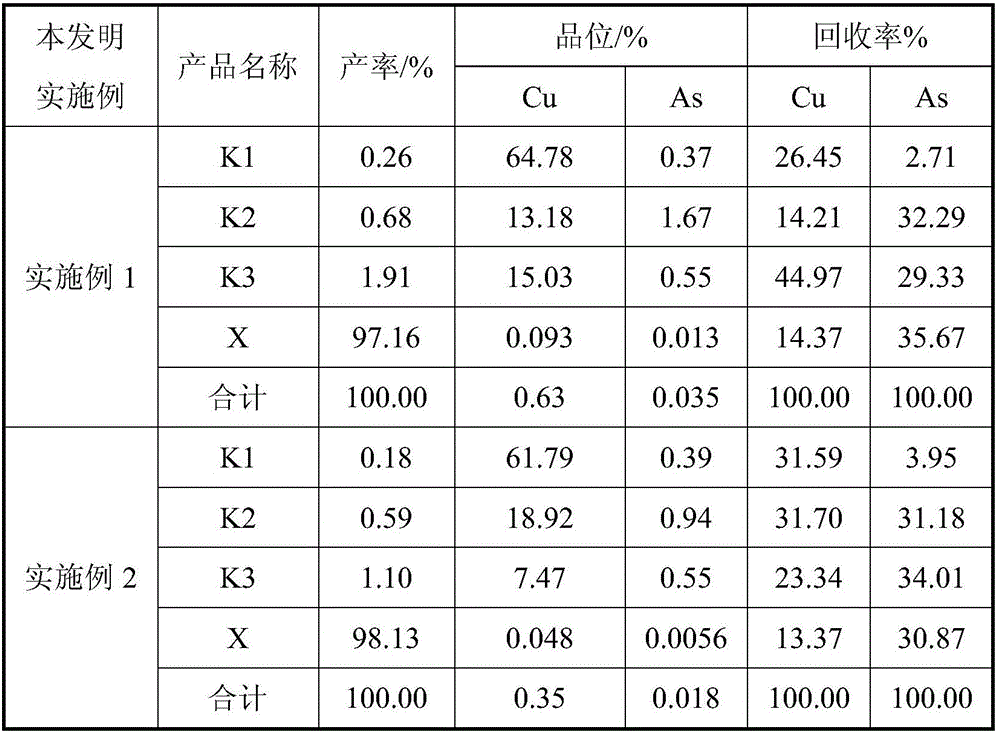

Composite beneficiation inhibitor used for copper-arsenic separating flotation

The invention discloses a composite beneficiation inhibitor used for copper-arsenic separating flotation. A hydrophilic oxide film can be formed on the surface of a mineral containing arsenic and copper to selectively separate a mineral which does not contain the arsenic and the copper from the mineral containing the arsenic and the copper. The composite beneficiation inhibitor is composed of, by weight, 75-95 parts of calcium hypochlorite, 8-25 parts of sodium humate and 8-17 parts of sodium hexametaphosphate. The composite beneficiation inhibitor is prepared sequentially through the steps of mixing, grinding and remixing.

Owner:厦门紫金矿冶技术有限公司

Water-retaining agent for squid surimi, and preparation method and application thereof

InactiveCN105076917AComponents are easily availableLow costFood ingredient as humectantFood ultrasonic treatmentSucroseSodium Caseinate

The invention discloses a water-retaining agent for squid surimi. The water-retaining agent comprises the following components by weight: 3-5% of soy protein powder, 0.01-0.03% of transglutaminase, 3-5% of alga oligosaccharides, 0.5-1% of sodium caseinate, 1-3% of sodium gluconate, 1-1.5% of sorbitol, 1-3% sucrose esters, 0.1-0.3% of calcium chloride, and the balance of water. The water-retaining agent for squid surimi of the present invention uses readily available components at low cost, and is environment-friendly and secure; the components collaborate to effectively prevent freezing denaturation of squid surimi protein, reduce loss of thawed squid surimi juice, and improve adhesive properties and frozen quality of squid surimi; therefore, the water-retaining agent is worthy of popularization and application in refrigeration processing of squid surimi. The present invention also discloses a preparation method of the water-retaining agent for squid surimi; and the method has simple steps, less investment in equipment, and strong operability, and is applicable to industrial production.

Owner:ZHEJIANG OCEAN UNIV

Waterproof material for construction and preparation method of waterproof material

InactiveCN107117910AImprove penetration resistanceResist high frequency repeated impactEmulsionStearic acid

The invention discloses a waterproof material for construction. The waterproof material comprises the following raw materials in parts by weight: 2-6 parts of a waterproof agent, 30-40 parts of cement, 60-90 parts of mineral powder, 70-80 parts of quartz sand, 20-30 parts of an acrylic emulsion, 3-5 parts of aluminum hydroxide, 5-7 parts of triethanolamine, 2-4 parts of stearic acid, 5-7 parts of a thickener and 4-6 parts of a permeability crystalline agent. The waterproof material has a dense structure, has higher compressive strength and impermeability pressure resistance, is excellent in waterproofness, can be resistant to temperature shock, is adapted to climate temperature changes, and is not prone to cracks, less likely to cause leakage and less likely to age; meanwhile, raw material components of the waterproof material are safe and reliable and pollution-free to the environment, the raw materials are available, the cost is lower, and the process is simple, so that the waterproof material has higher practical value and good application prospect.

Owner:合肥一片美环保科技有限公司

Elastic high-strength antistatic shoe sole material and preparation method thereof

The invention discloses an elastic high-strength antistatic shoe sole material, which comprises the following raw materials in parts by weight: 6-10 parts of organotin stabilizer, 7-9 parts of anti-slip agent, 2-4 parts of conductive filler, and 25-35 parts of hydroxylated polypropylene 50-60 parts of elastic filler, 4-8 parts of calcium carbonate, 5-7 parts of binder, 10-18 parts of reinforced inorganic fiber, 1-2 parts of antistatic agent, 3-5 parts of coupling agent, processing aid Dose 10-12 parts. The sole material of the present invention has good elasticity and mechanical strength, good anti-slip effect, excellent antistatic performance, excellent heat resistance, weather resistance and impact resistance; meanwhile, the raw material components of the present invention are safe and reliable, and have no pollution to the environment, and the raw material It is easy to obtain, low in cost, simple in process, low-carbon, environmentally friendly and pollution-free, and has high practical value and good application prospect.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Weather-proof anti-flaming high-performance glass surface protection film and preparation method thereof

The invention discloses a weather-proof anti-flaming high-performance glass surface protection film which comprises the following raw materials in parts by weight: 26-32 parts of polytetrafluoroethylene, 10-14 parts of polyvinyl alcohol, 2-6 parts of lubricating auxiliaries, 18-24 parts of polyurethane resin, 8-10 parts of a processing agent, 9-13 parts of silicone resin, 10-12 parts of an anti-flaming additive, 6-8 parts of vinyl silicone oil, 1-2 parts of a catalyst, 4-8 parts of a metallic oxide additive, 3-7 parts of a coupling agent and 16-22 parts of water. The protection film disclosed by the invention is higher in adhesive force and has excellent light transmittance performance and impact strength, better anti-scraping property, better fireproof anti-flaming property and excellent weather-proof property; meanwhile, the raw material components are safe and reliable, are harmless to environment and are easily acquired according to the preparation method disclosed by the invention; the cost is lower, the technology is simple, the operation is easy, and the industrial production is easily realized; and the protection film has higher practical values and good application prospects.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Anti-slip heat insulation and sound isolation environment-friendly ground coating and preparation method thereof

InactiveCN108384390AImprove thermal insulation performanceImprove corrosion resistanceEpoxy resin coatingsPolyester coatingsCorrosion resistantEnvironmental resistance

The invention discloses anti-slip heat insulation and sound isolation environment-friendly ground coating and a preparation method thereof. The coating is prepared from the following raw materials inparts by weight: 90 to 100 parts of modified composite resin, 7 to 11 parts of sound insulation additives, 8 to 14 parts of heat insulation fillers, 6 to 10 parts of anti-slip additives, 20 to 30 parts of property enhancing resin, 2 to 4 parts of desinsectization and sterilization extraction liquid, 10 to 20 parts of mixed dibasic acid ester, 15 to 20 parts of propylene glycol methyl ether acetate, 3 to 5 parts of titanium dioxide, 0.5 to 1.5 parts of anti-settling agents, 1 to 2 parts of film forming agents, 0.4 to 0.8 part of anti-foaming agents, 0.8 to 1.4 parts of leveling agents and 2 to4 parts of dispersing agents. The coating is used as ground coating; the surface is fine; the leveling performance and the touch sense are excellent; the heat insulation and sound isolation performance is good; the anti-slip, friction resistant and anti-corrosion performance is good; meanwhile, the raw material ingredients are safe and reliable; no toxin and no harm exist; the raw materials can beeasily obtained; the cost is lower; the process is simple and clear; the operation is easy; the industrial production can be realized; higher practical value and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Weather-proof, antibacterial, flame-retardant and anti-rusting paint for metals and preparation method of paint

InactiveCN107502143ANot easy to crack and dropImprove rust resistanceFireproof paintsAntifouling/underwater paintsDiethylene glycol monobutyl etherPolyvinyl alcohol

The invention discloses weather-proof, antibacterial, flame-retardant and anti-rusting paint for metals. The paint contains the following raw materials in parts by weight: 28-34 parts of compound resin, 5-7 parts of polyvinyl alcohol, 2-4 parts of liquefied paraffin, 0.5-1.3 parts of a compound defoaming agent, 1-3 parts of zinc borate, 1-2 parts of zinc sulfate, 3-5 parts of antimonous oxide, 3-5 parts of diethylene glycol monobutyl ether, 5-7 parts of a flame retardant, 3-5 parts of sodium dodecyl benzene sulfonate, 6-8 parts of modified filing soil, 2-4 parts of a rare earth compound, 14-16 parts of mixed grease, 2-3 parts of a corrosion inhibitor, 2-4 parts of polycarbonate, 3-4 parts of a curing agent and 1-3 parts of an antibacterial agent. The paint provided by the invention is suitable for occasions in a salt-spray environment and a hygrothermal environment or requiring long-term rusting prevention, has excellent contact anti-rusting property, very good gas-phase anti-rusting effect and relatively good anti-friction performance, antibacterial activity and flame retardance, has a relatively strong adhesion force to metal products and can be widely applied to metal processing industry.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

Environmentally-friendly sterilizing and deodorizing air freshener, and preparation method thereof

InactiveCN107007863AEasy to buyRelieve discomfortBiocideDead animal preservationChemistryBroad spectrum

The invention discloses an environmentally-friendly sterilizing and deodorizing air freshener. The air freshener comprises, by weight, 1-3 parts of mixed essential oil, 15-25 parts of plant extract, 10-20 parts of ethanol, 7-9 parts of sodium alkyl benzene sulfonate, 0.2-0.6 parts of an antiseptic, 0.2-0.4 parts of an antioxidant, 25-35 parts of carrageenan, 10-20 parts of agar, 6-12 parts of sodium alginate and 5-8 parts of a cellulose thickener. The air freshener can effectively remove some odorous substances in air and keep the indoor fragrance for a long time, also can effectively inhibit the activity of Escherichia coli and Staphylococcus aureus in the air, has broad spectrum antibacterial activity, and can completely improve the air quality and keep the indoor air fresh and clean; the freshener has the characteristics of good resistance to a high temperature, good oxidation resistance, long-time moisturizing, low volatility and long service life; and above raw materials have safe and reliable components, are beneficial for human bodies, are harmless, are easy to obtain and have low cost, the method is concise, and the air freshener and the method have high practical values and good application prospects.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Novel phosphate-free water retaining agent for shrimp meat and usage method thereof

InactiveCN106689336ATo achieve the effect of water retentionComponents are easily availableMeat/fish preservation using chemicalsPhosphateRefrigerated temperature

The invention discloses novel phosphate-free water retaining agent for shrimp meat and a usage method thereof. The novel phosphate-free water retaining agent for the shrimp meat comprises the following compositions: 0.3-1.5% w / v of chitosan, 0.5-2.5% w / v of collagen peptide, 0.1-0.9% w / v of sodium chloride, and the balance deionized water. The usage method of the novel phosphate-free water retaining agent for the shrimp meat comprises the following steps: obtaining shrimp meat from live shrimps; adding the novel phosphate-free water retaining agent, wherein the volume of the novel phosphate-free water retaining agent is 5 times of the volume of the shrimp meat, carrying out soaking at 4 DEG C for 10-120 minutes, and carrying out stirring every 15 minutes; fishing the soaked shrimp meat out, thoroughly draining the shrimp meat, and putting the drained shrimp meat into a freshness preservation package; exhausting air, and carrying out storing in a refrigerator at 80 DEG C below zero for 5-10 days; and then, transferring the shrimp meat into a refrigerator at 20 DEG C below zero so as to carry out refrigeration. Being determined by using related water holding indexes, the water retention property of the novel phosphate-free water retaining agent for the shrimp meat is comparable to marketed phosphate water retaining agent; moreover, the raw-material components of the novel phosphate-free water retaining agent are easy to obtain, low in cost, edible, and environmentally friendly. In addition, the whole preparation process and the preparation method are simple in steps, the equipment investment is small, and the cost is low; thus, the novel phosphate-free water retaining agent for the shrimp meat and the usage method thereof are suitable for industrialized production.

Owner:FUZHOU UNIV

Thermal-insulation protective coating for aluminum alloy doors and windows and preparation method thereof

InactiveCN107083185AImprove waterproof performanceGood adhesionAnti-corrosive paintsMicrosphereThermal insulation

The invention discloses a thermal-insulation protective coating for aluminum alloy doors and windows. The thermal-insulation protective coating is prepared from, by weight, 50-60 parts of fluoro-siloxane resin, 10-16 parts of bisphenol A diglycidyl ether, 12-16 parts of hollow microspheres, 30-40 parts of solvent, 6-8 parts of nano additive, 9-13 parts of processing aid, 1-3 parts of silane coupling agent, 4-6 parts of thickening agent and 20-30 parts of heat insulation packing. The thermal-insulation protective coating is low in thermal conductivity, good in thermal insulation effect and strong in corrosion resistance. The chemical properties of the thermal-insulation protective coating are stable, the surface hardness is better, and the thermal-insulation protective coating is resistant to friction and convenient to construct and is formed at a time. In addition, the raw material components of the thermal-insulation protective coating are safe and reliable, are harmless to the human body and are easy to obtain, the cost is lower, the process is simple and clear and easy to operate and achieves industrialized production, and the coating has a higher practical value and good application prospect.

Owner:合肥市旺友门窗有限公司

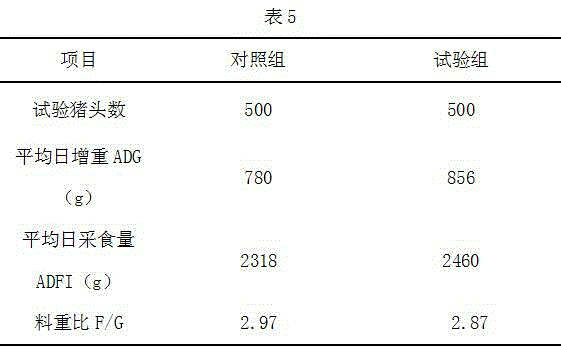

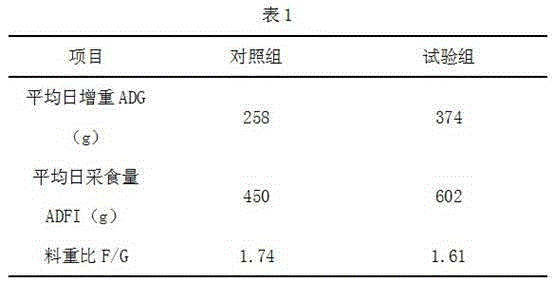

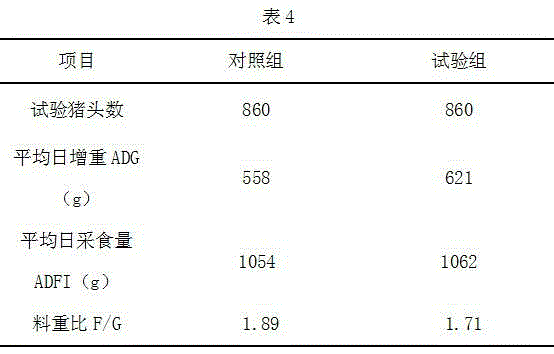

Feed additive for improving pig stress resistance and application of feed additive

InactiveCN104431615AIncrease production capacityImprove immunityAnimal feeding stuffSodium bicarbonateFood additive

The invention discloses a feed additive for improving pig stress resistance. The feed additive is prepared from the following components in parts by weight: 2-4 parts of L-threonine, 1-2 parts of L-arginine, 0.1-0.3 part of L-tryptophan, 2-3 parts of zinc glycinate, 2-3 parts of ferrous glycine, 1-2 parts of chromium picolinate, 18-22 parts of sodium bicarbonate, 5-8 parts of potassium chloride, 15-25 parts of glucose, 8-12 parts of taurine, 1-3 parts of selenium yeast, 3-6 parts of vitamin C and 2-5 parts of vitamin E. According to the feed additive, adverse effects on health and production performance of pigs caused by various stresses of the pigs in the growth process can be relieved through nutrition means; and by using the additive, the production capacity and the immunity of the pigs can be significantly improved.

Owner:SICHUAN AGRI UNIV

Production technology of rock wool

InactiveCN108675645AComponents are easily availableLow priceGlass making apparatusElectric furnaceFiberMagma

The invention discloses a production technology of rock wool. The technology comprises the following steps: (1) preparing raw materials: mixing dolomite, basalt, blast-furnace slag and waste residuesas raw materials; (2) melting the raw materials: adding the raw materials into an electric furnace and melting into molten rock; (3) centrifuging to form fibers: spinning the molten rock into the fibers through a centrifugal machine and collecting the fibers; (4) molding a cotton felt: paving the collected fibers on a pendulum bob cotton paving machine and molding the fibers into the cotton felt through a molding conveyor; (5) molding a cotton plate: pleating the cotton felt and pressurizing and molding; drying and curing to obtain the cotton plate; (6) cutting: cutting the cotton plate into aregulated size. According to the production technology of the rock wool, the electric furnace is used as raw material melting equipment and the production of harmful gas is effectively prevented; a waste gas treatment link is avoided and a production process is simple and easy to realize.

Owner:溧阳市腾达机械设备有限公司

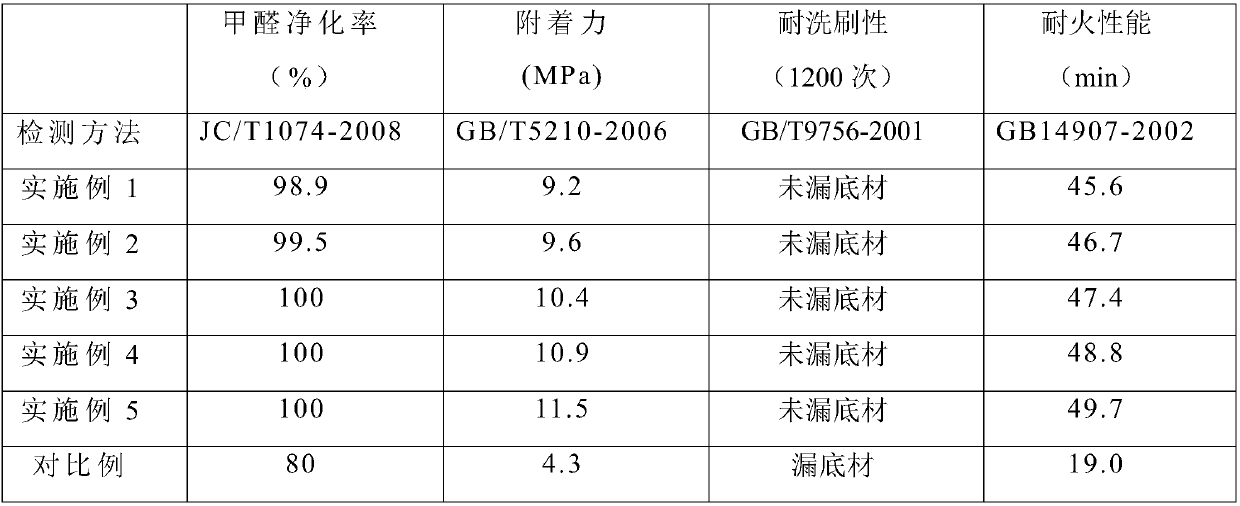

Environment-friendly inner wall paint and preparation method thereof

InactiveCN108034323AComponents are easily availableLow priceFireproof paintsAntifouling/underwater paintsFoaming agentDecomposition

The invention discloses environment-friendly inner wall paint, which is prepared from the following ingredients in parts by weight: 35 to 45 parts of fluorine-containing triazine type film forming polymers, 10 to 15 parts of phosphoric acid modified nanometer titanium dioxide, 20 to 30 parts of pigment filling materials, 2 to 5 parts of anti-foaming agents, 3 to 7 parts of coalescing agents and 20to 30 parts of water. The preparation method of the environment-friendly inner wall paint comprises the following steps that the fluorine-containing triazine type film forming polymers, the phosphoric acid modified nanometer titanium dioxide, the pigment filling materials, the anti-foaming agents, the dispersing agents and the coalescing agents are proportionally put into a high-speed mixing machine to be mixed for 20 to 30min, and are then charged into a ball milling tank; after the ball milling treatment is performed for 5 to 8h, mixed powder is obtained; then, water is added into the mixedpowder; at the rotating speed being 1200 to 1500 turns per minute, dispersion is performed for 10 to 15 minutes; next, curing is performed for 2 to 5 days; sampling for inspection is performed; afterthe products are qualified, sieving and packaging are performed. The environment-friendly inner wall paint disclosed by the invention has the advantages that the price is cheap; the formaldehyde absorption and decomposition effects are obvious; the efficiency is high; the secondary pollution cannot be caused; the visible light response speed is high; the fireproof performance and the bonding capability are high; the weathering performance is good.

Owner:南通涂冠环保科技有限公司

Environment-friendly flame-retardant rubber floor and manufacturing method thereof

InactiveCN107090106AImprove wear resistanceUniform colorCovering/liningsFlat articlesStearic acidAccelerant

The invention discloses environment-friendly flame-retardant rubber floor. The environment-friendly flame-retardant rubber floor is prepared from the following raw materials in parts by weight: 20-30 parts of butadiene styrene rubber, 50-60 parts of acrylonitrile-butadiene rubber, 6-8 parts of titanium dioxide, 4-6 parts of a vulcanizing agent, 1-3 parts of zinc oxide, 0.5-2 parts of stearic acid, 4-6 parts of white carbon black, 0.8-1.4 parts of an accelerant, 1-2 parts of a weather resistant, 3-5 parts of antimonous oxide, 5-7 parts of a flame retardant, 1-3 parts of an antistatic agent and 20-30 parts of reinforcing filler. The rubber floor disclosed by the invention has the advantages of stronger wear resistance, static electricity resistance, low smoke, low toxicity, low corrosion, good flame resistance, high tensile strength, good skid resistance, good resilience and the like. A manufacturing method for the rubber floor adopts safe and reliable raw material components, is harmless on environment, adopts easily available raw materials, is relatively low in cost, is simple in process, is easy to operate and realize industrial production, and has relatively high practical value and a good application prospect.

Owner:合肥市老海新材料有限公司

Medicament for treating diabetes

InactiveCN102406711AWon't bearQuick resultsMetabolism disorderMammal material medical ingredientsDiabetes mellitusMedicine

The invention discloses a medicament for treating diabetes. One dose of the medicament comprises the following five components: 90-120g of semen momordicae, 48-52g of pharbitis seed, 48-52g of semen pharbitidis, 7-8 granules of white pepper and 3-4 of white-skin eggs. The medicament can be used as follows: peeling semen momordicae to reserve inner kernels, then grinding the kernels together with pharbitis seed, semen pharbitidis and white pepper into powder, breaking the eggs to remove shells and then uniformly mixing with the powder, uniformly smearing the mixture on a piece of white cloth, and finally covering the arches, upper surfaces and ankles of feet of patients with the white cloth to realize contact between the medicament with all parts of feet. According to the invention, the medicament can take effect to a patient with mild symptom at the day or next day after being taken a dose (piece) by the patient; and for a patient with serious symptom, the medicament has remarkable effect after being taken not more than three doses generally and symptoms of diabetes can disappear. The raw materials are easily available and are low in price, thus the medicament is affordable for common people.

Owner:刘德忠

Wear-resistant anti-cracking environment-friendly plasterboard and preparation method thereof

The invention discloses a wear-resistant anti-cracking environment-friendly plasterboard which is prepared from the following raw materials in parts by weight: polyvinyl alcohol 8-14 parts, pulverized fuel ash 7-9 parts, old plasterboard powder 35-45 parts, gypsum powder 25-35 parts, anti-cracking fiber 10-14 parts, an initiator 1-3 parts, an antifoamer 1-1.4 parts, a dispersant 2-4 parts, crystalline flake graphite 10-14 parts, starch 5-10 parts, and deionized water 50-70 parts. The plasterboard of the invention has the advantages of high and compression strength, static bending strength, large screw holding capability and breaking resistant elasticity modulus, low heat conductivity coefficient, and has the characteristics of good antibacterial property, mechanical property, anti-electromagnetic radiation property and anti-friction property. Meanwhile, the raw materials of the wear-resistant anti-cracking environment-friendly plasterboard are safe and reliable, environment-friendly and easily-accessible, the cost is low, the process is simple and is easy to operate and realize industrial production, and the process has high practical value and good application prospects.

Owner:合肥市淑芹美装饰工程有限公司

Pretreatment liquid capable of forming washable natural color conversion film on metal surface and preparation method thereof

PendingCN111534815AReduce pollutionNo change in performanceMetallic material coating processesPhysical chemistrySurface roughness

The invention discloses a pretreatment liquid capable of forming a washable natural color conversion film on the metal surface and a preparation method thereof. The pretreatment liquid is composed ofthe following components of 0%-10% of a chelating agent, 1%-12% of a modified chelating agent, 0.1%-0.2% of auxiliary salt, 0.5%-1% of an auxiliary agent, 0.05%-2% of a complexing agent, 0%-10% of a neutralizing agent and the balance water, wherein the modified chelating agent comprises at least three elements of C, N, O, H, P, S, B, Na, Ca, Mg, Fe, Zn, Cl, F and Si. The metal surface treatment liquid contains few types of substances and is simple and easy to operate, and a waste liquid is environmentally friendly and free of pollution; a treated workpiece can be washed with water to obtain the colorless and uniform natural color conversion film, the colorless and uniform natural color conversion film prevents the appearance of the metal workpiece from being damaged, and the application range of the pretreatment liquid is expanded to a great extent; and the conversion film obtained through the pretreatment liquid increases the surface roughness of a base material greatly, a film layeris firmly combined with the base material, and the adhesive force and the corrosion resistance of a coating and the surface of the base material are effectively improved.

Owner:SHANDONG UNIV

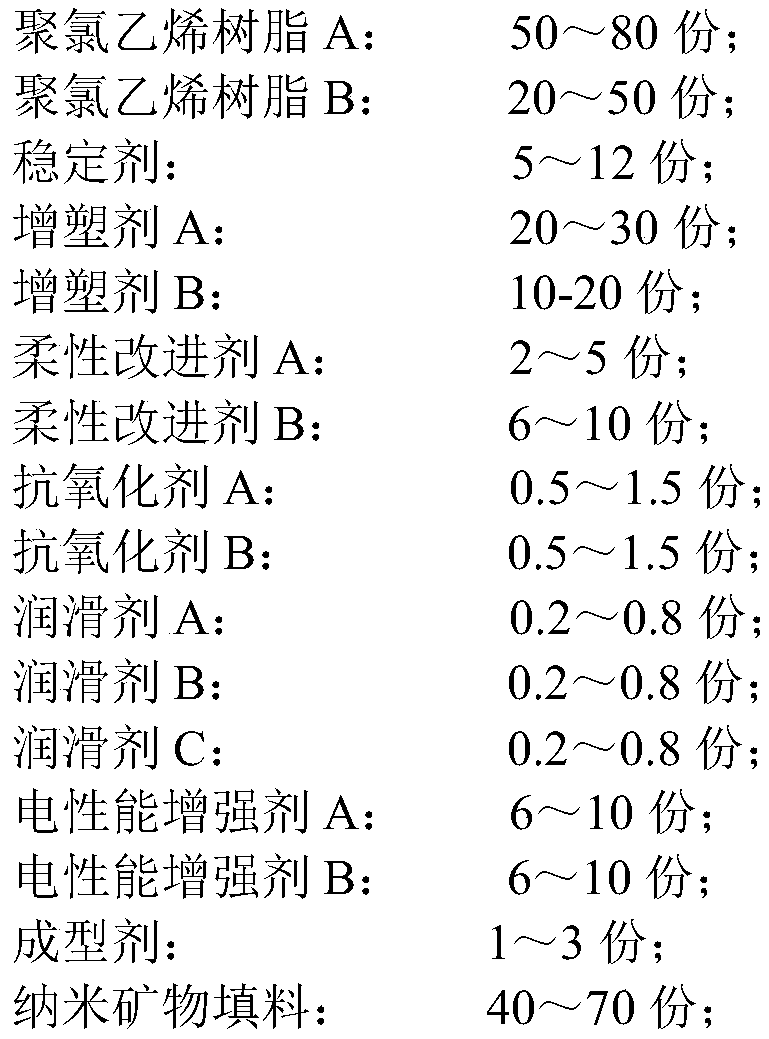

Environment-friendly 90-DEG C high-flexibility PVC insulating material for charging pile cable and preparation method thereof

PendingCN111234412AFast processingLow pricePlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

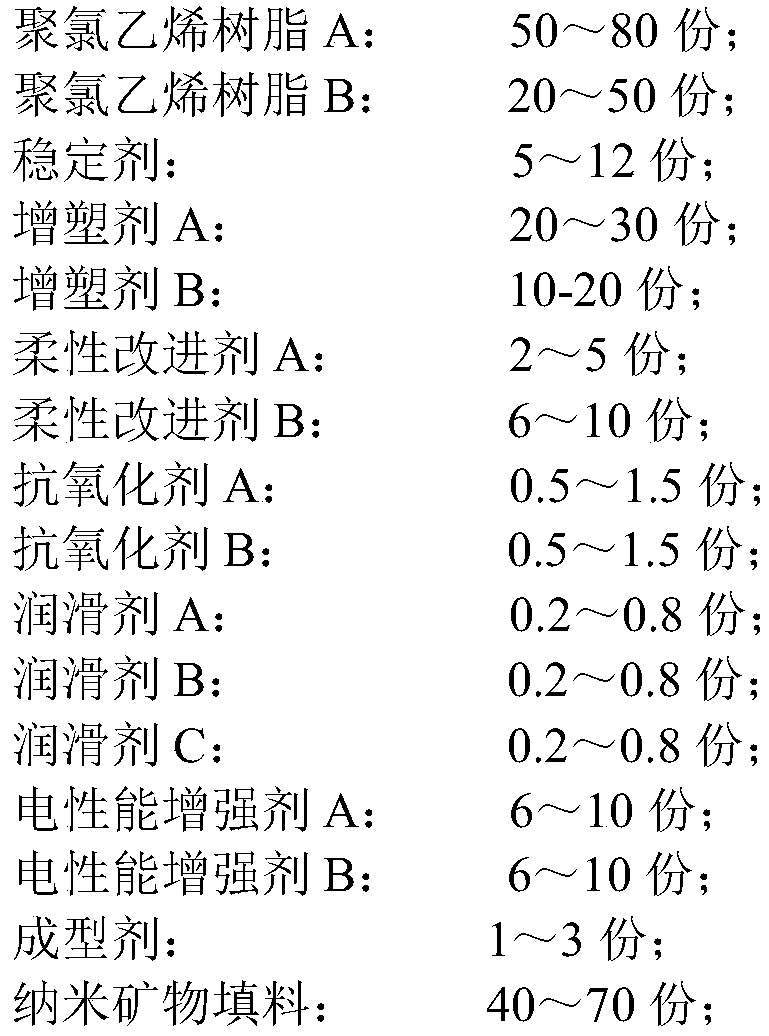

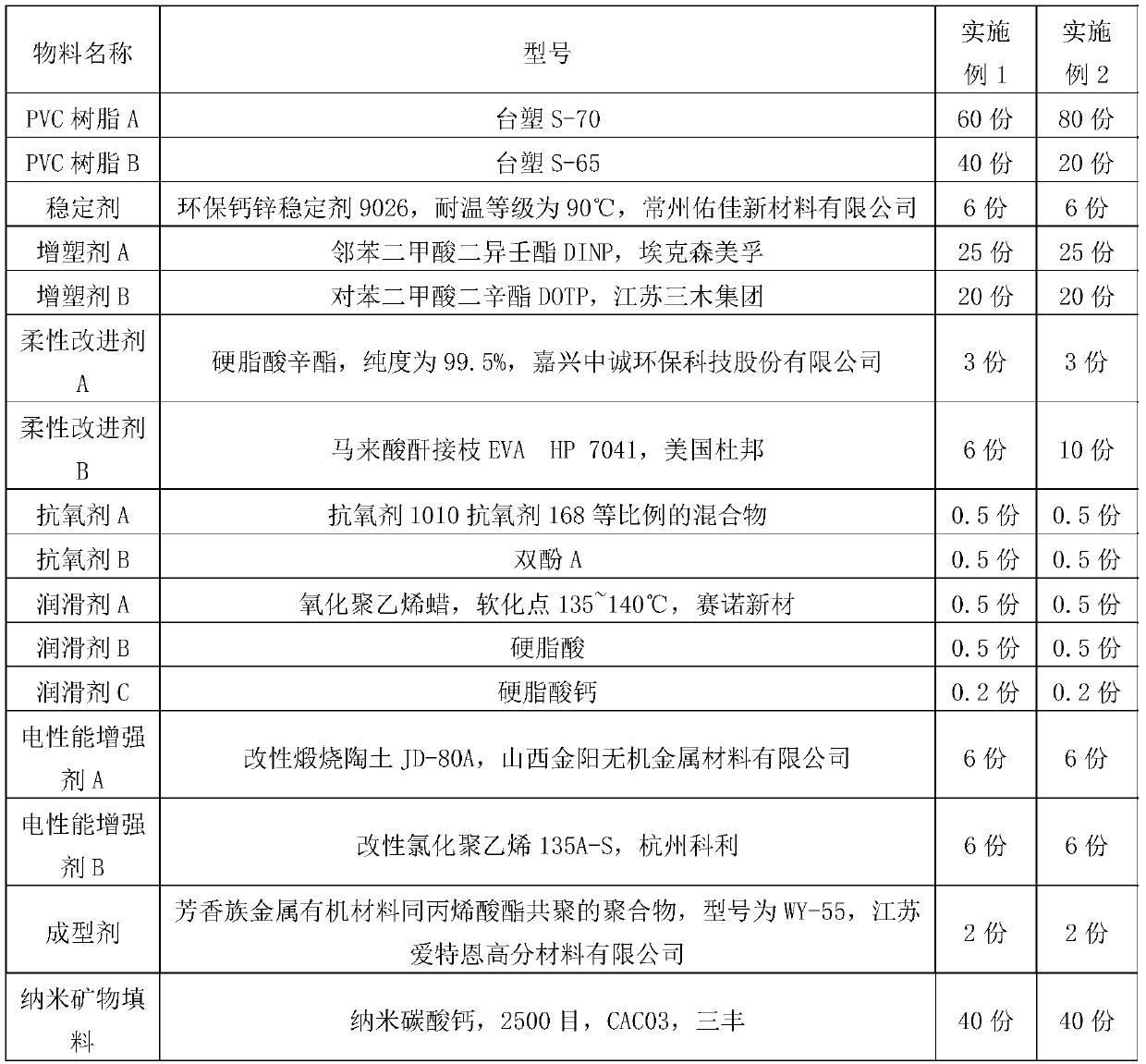

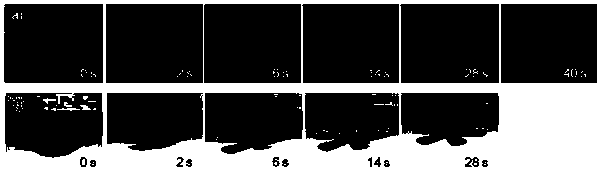

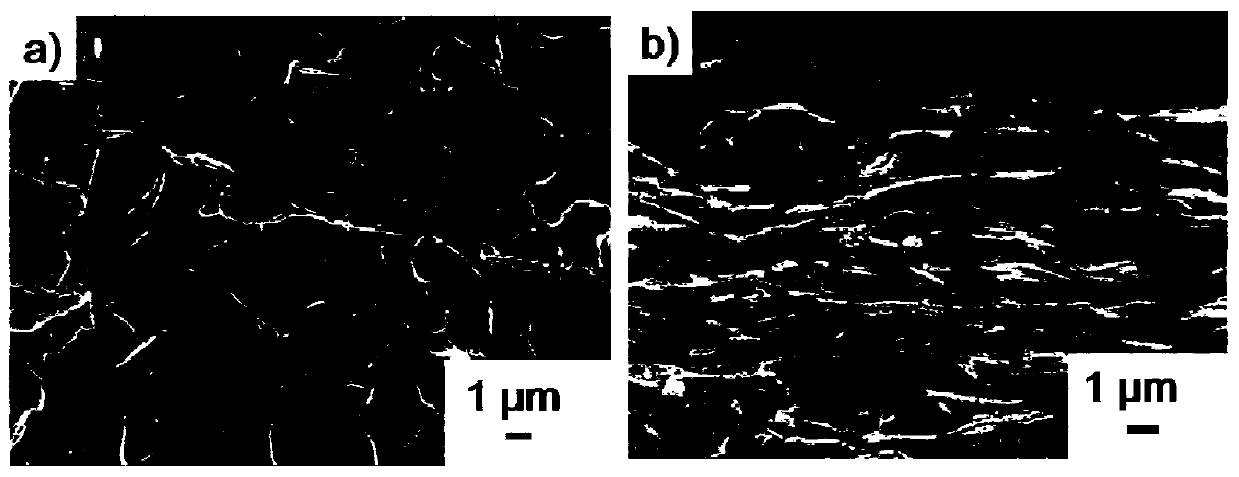

The invention discloses an environment-friendly 90-DEG C high-flexibility PVC insulating material for a charging pile cable and a preparation method thereof. The 90-DEG C high-flexibility PVC insulating material comprises the following raw materials in parts by weight: 50-80 parts of polyvinyl chloride resin A; 20 to 50 parts of polyvinyl chloride resin B; 5-12 parts of a stabilizer; 20 to 30 parts of a plasticizer A; 10 to 20 parts of a plasticizer B; 2-5 parts of a flexibility improver A; 6-10 parts of a flexibility improver B; 0.5 to 1.5 parts of an antioxidant A; 0.5 to 1.5 parts of an antioxidant B; 0.2 to 0.8 part of a lubricant A; 0.2 to 0.8 part of a lubricant B; 0.2 to 0.8 part of a lubricant C; 6-10 parts of an electrical property enhancer A; 6-10 parts of an electrical propertyenhancer B; 1-3 parts of a forming agent; and 40 to 70 parts of a nano mineral filler. The 90 DEG C high-flexibility PVC insulating material has the advantages that the flexibility is obviously improved; the advantages of high-speed extrusion, smooth and fine extrusion surface and the like are realized; the used raw materials are cheap and easily available, the material cost is reduced; and the preparation method is simple and easy to operate.

Owner:JIANGSUSNGSHANG CABLE GROUP

Efficient impervious leakage-blocking waterproof material and preparation method thereof

InactiveCN107216063AImprove penetration resistanceEffective resistance to high frequency repeated impactFiberEmulsion

The invention discloses an efficient impervious leakage-blocking waterproof material. The material is prepared from the following raw materials in parts by weight: 40-50 parts of an elastic acrylic emulsion, 0.5-1.5 parts of a chemical root resistant, 15-25 parts of calcined kaolin powder, 6-12 parts of calcined vermiculite powder, 1-3 parts of a hydroxide solution, 1-4 parts of an nano additive, 2-5 parts of a thickening agent, 8-14 parts of reinforced fibers and 18-24 parts of water. The waterproof material disclosed by the invention has excellent cold resistance, heat resistance, aging resistance and water tolerance, is not deformed to flow at a high temperature, is not fractured at a low temperature and can resist high-frequency repeated impact of rainstorm, and slight deformation can be automatically restored; and meanwhile, the raw material components are safe, reliable and have no environmental pollution, the raw materials are easily available and relatively low in cost, a process is simple and clear, and the waterproof material has relatively high practical values and good application prospects.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Unfired magnesia carbon brick as well as preparation method and application thereof

InactiveCN113943145AExtended service lifeThe number of vacuum smelting furnaces has increasedMelt-holding vesselsBrickRefractory

The invention belongs to the technical field of refractory materials, and relates to an unfired magnesia carbon brick as well as a preparation method and application thereof. The unfired magnesia carbon brick comprises the following components of: 2% to 6% of C, 87% to 92 % of MgO, 1% to 5% of SiO2, 1% to 3 % of CaO and 1% to 3 % of Al2O3. In actual production, the unfired magnesia carbon brick provided by the invention is used in a VOD steel ladle, so that the consumption of a refractory material of the steel ladle can be reduced, the service life of the steel ladle is prolonged, the number of vacuum smelting furnaces of the steel ladle is increased to 15 from 3, the service life of the steel ladle is increased to 80 furnaces from 28 furnaces, meanwhile, the production cost is reduced, and the purity of molten steel is favorably controlled. The unfired magnesia carbon brick comprises carbon, magnesium oxide, silicon dioxide, calcium oxide and aluminum oxide in specific quantities, the components are simple and easy to obtain; and when the unfired magnesia carbon brick is used in the VOD steel ladle, the erosion resistance, oxidation resistance and thermal shock resistance of the steel ladle can be remarkably improved.

Owner:邯郸市翰润达耐火材料有限公司

Fire-proof pressure-resistant anti-aging material for fire hose and preparation method thereof

InactiveCN108485148APromote carbonizationImprove flame retardant performanceMelamine resinButadiene-styrene rubber

The invention discloses a fire-proof pressure-resistant anti-aging material for a fire hose and a preparation method thereof. The fire-proof pressure-resistant anti-aging material for the fire hose isprepared from the following raw materials according to the parts by weight: 30-40 parts of polyacrylate rubber, 20-30 parts of butadiene styrene rubber, 10-15 parts of melamine resin, 2-4 parts of calcium-zinc stabilizer, 1-2 parts of activator, 1-2 parts of vulcanizer, 5-7 parts of high-aluminum aluminum silicate fiber cotton, 3-5 parts of organic silicone oil, 10-14 parts of modified enhanced fibers, 7-9 parts of tackifier, 10-12 parts of flame-retardant additive, and 0.5-1.5 parts of sterilization insect repellent agent. The fire-proof pressure-resistant anti-aging material for the fire hose is high-temperature-resistant, high-pressure-resistant, high in adhesive strength, difficult in stripping, ageing-resistant, long in service life, and better in fire-proof flame-retardant property,and has a certain sterilization insect repellent effect. In addition, raw material components of the fire-proof pressure-resistant anti-aging material are safe and reliable, and environment-friendly.The raw materials are easily obtained, the cost is lower, the process is simple, the operation is easy and the industrial production is easily realized, the fire-proof pressure-resistant anti-aging material has higher practical value and a good application prospect.

Owner:合肥市晨雷思建筑材料科技有限公司

Heat-conducting graphene-polymer composite thin film and preparation method and application thereof

InactiveCN110734560AGood flexibilityHigh lateral thermal conductivityPolymer sciencePolyethylene glycol

The invention discloses a heat-conducting graphene-polymer composite thin film which is prepared from the following components by the weight percentage: 10%-30% of graphene, 35%-45% of nano-celluloseand 35%-45% of polyethylene glycol. The invention also discloses a preparation method of the heat-conducting graphene-polymer composite thin film, wherein the preparation method comprises the steps: uniformly mixing and stirring a prepared graphene dispersion liquid, a nano-cellulose dispersion liquid and a polyethylene glycol dispersion liquid according to a certain weight ratio, and then carrying out ultrasonic treatment for 0.5-1 h to obtain a graphene-nano-cellulose-polyethylene glycol mixed solution with the concentration of 1-5 mg / mL; putting the graphene-polyethylene glycol-nano-cellulose mixed solution into a vacuum drying oven, standing for 1-2 h in a vacuum environment at room temperature, removing gas existing in the mixed solution, pouring the liquid into a mold, putting the mold into a drying oven, and drying for 12-24 h at the temperature of 40-50 DEG C, so as to obtain the heat-conducting graphene-polymer composite thin film. The preparation method disclosed by the invention is simple in process and easy to industrialize; the prepared composite thin film has flexibility, high transverse thermal conductivity and thermally driven shape memory performance, and can be applied to manufacturing of intelligent products.

Owner:SHANGHAI UNIV

Mould-proof antibacterial environment-friendly ceramic tile

InactiveCN110407560AEnvironmental protection is goodAntibacterialClaywaresBamboo charcoalCeramic tiles

The invention discloses a mould-proof antibacterial environment-friendly ceramic tile. The ceramic tile is prepared from kaolin, ceramic clay, wollastonite, quartz, potassium feldspar, fluorite, lithium chinastone, zirconium silicate, aluminum oxide, zinc oxide, sodium silicate, activated carbon, nano titanium dioxide, nano bamboo charcoal, glass beads, glass fibers and nano composite antibacterial particles. The ceramic tile has the functions of bacterium resistance, bacteriostat, and sterilization, and meets the requirements of modern wall materials.

Owner:姜春丽

Archaistic environment-friendly high-viscosity weather-resistant paint and preparation method thereof

InactiveCN108384388AImprove stabilityNot easy to fadeAntifouling/underwater paintsPaints with biocidesEmulsionGraphene

The invention discloses archaistic environment-friendly high-viscosity weather-resistant paint and a preparation method thereof. The archaistic environment-friendly high-viscosity weather-resistant paint is prepared from the following raw materials in parts by weight: 70 to 90 parts of waterborne mixed emulsion, 8 to 10 parts of dimethyl hydroxyl silicone oil, 7 to 9 parts of polyacrylamide, 6 to10 parts of modified added filler, 3 to 5 parts of coupling agent, 7 to 11 parts of archaistic pigment, 3 to 7 parts of modified graphene, 2 to 4 parts of nano additive and 5 to 9 parts of performance-increasing assistant. The archaistic environment-friendly high-viscosity weather-resistant paint is high in viscosity, is difficult to fade, is excellent in waterproof and weather-resistant performance and obvious in archaistic and oldness-presentation effect, can be used for increasing the ancient and unsophisticated feelings of a product, is exquisite, and is excellent in tactility, good in stability and excellent in surface compact, stain-resistant and self-cleaning performance; meanwhile, raw-material components of the archaistic environment-friendly high-viscosity weather-resistant paintare safe, reliable, nontoxic and harmless; the raw materials are easily obtained; the cost is lower; the process is concise, and the archaistic environment-friendly high-viscosity weather-resistant paint is easy to operate and realize industrialized production, and has higher practical value and a favorable application prospect.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Culture medium for promoting rapid germination of bacillus stearothermophilus spores

InactiveCN106497851AImprove germination rateShorten the timeBacteriaMicrobiological testing/measurementSolventLaboratory culture

The invention relates to a culture medium for promoting rapid germination of bacillus stearothermophilus spores, and belongs to the technical field of microorganism culture media. The culture medium comprises 3-5g / L of glucose, 6-8g / L of peptone, 1-3g / L of dipotassium phosphate, 1.5-2.5g / L of soluble starch, 0.3-0.5g / L of alanine, 0.5-0.8g / L of leucine and 0.1-0.3g / L of creatinine, wherein water serves as a solvent. The culture medium has the advantages that through addition of special inducing factors, the germination rate of the bacillus stearothermophilus spores is increased effectively, and time for the bacillus stearothermophilus spores recovering to propagules is shortened; the components of the culture medium are low in price and easy to get.

Owner:SHINVA MEDICAL INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com