Environment-friendly 90-DEG C high-flexibility PVC insulating material for charging pile cable and preparation method thereof

A charging pile and environmentally friendly technology, which is applied to insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of uneven quality of PVC insulating materials, slow processing speed, and difficult to achieve. Excellent processing performance, significant improvement in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

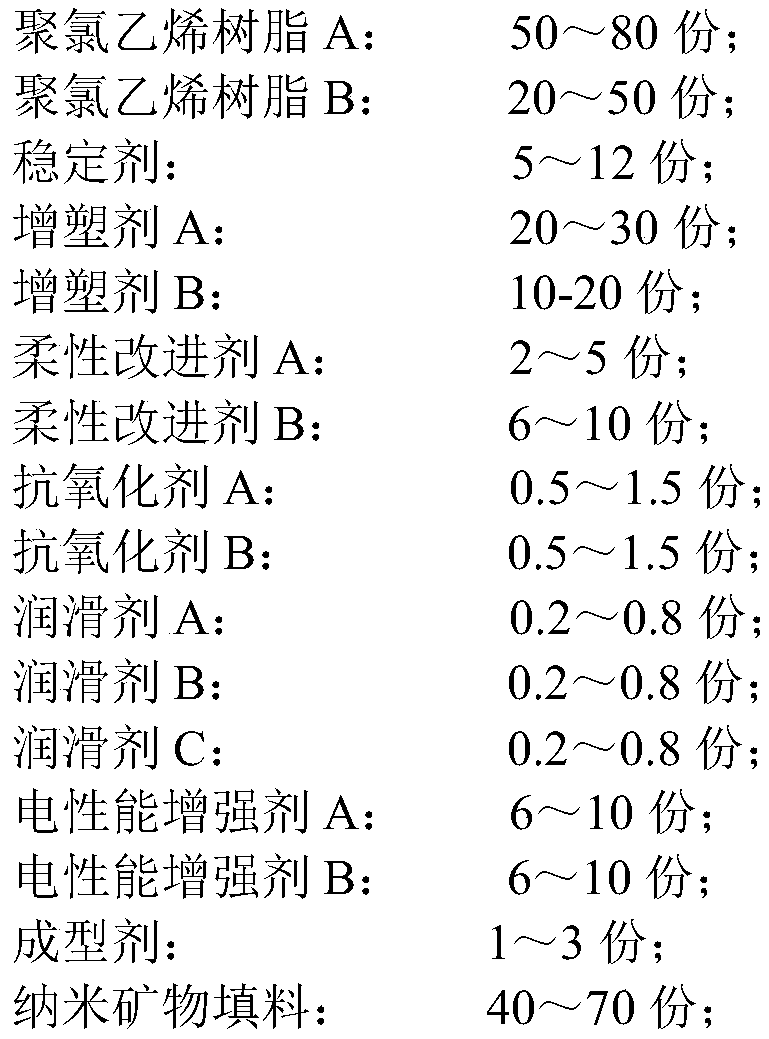

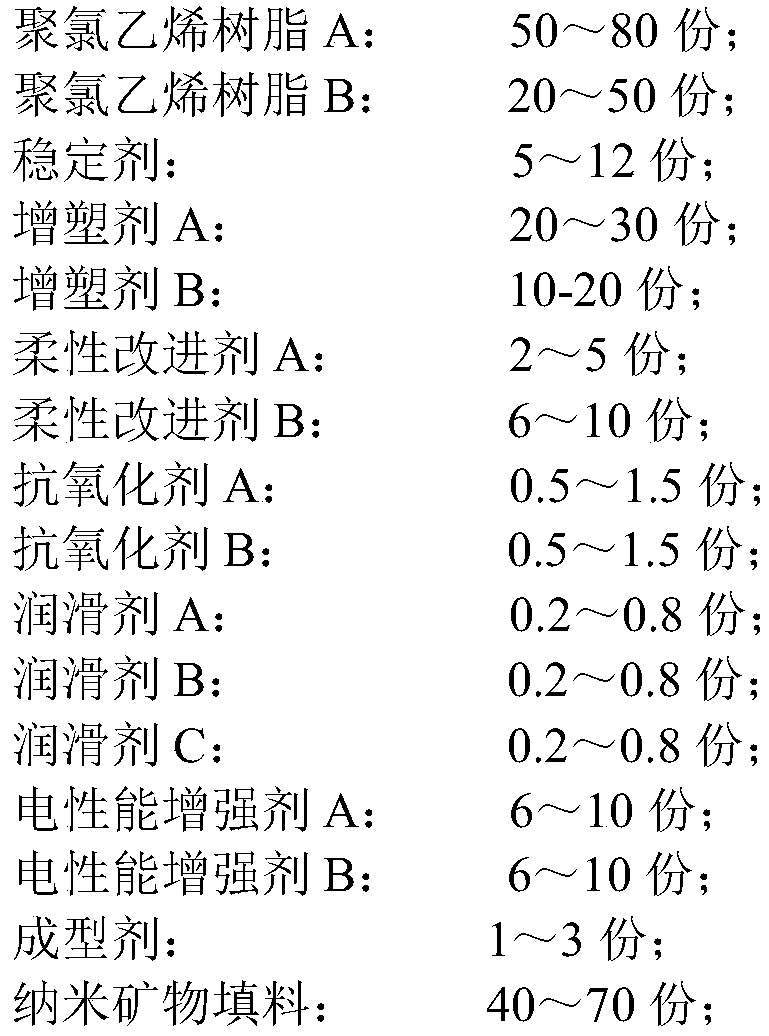

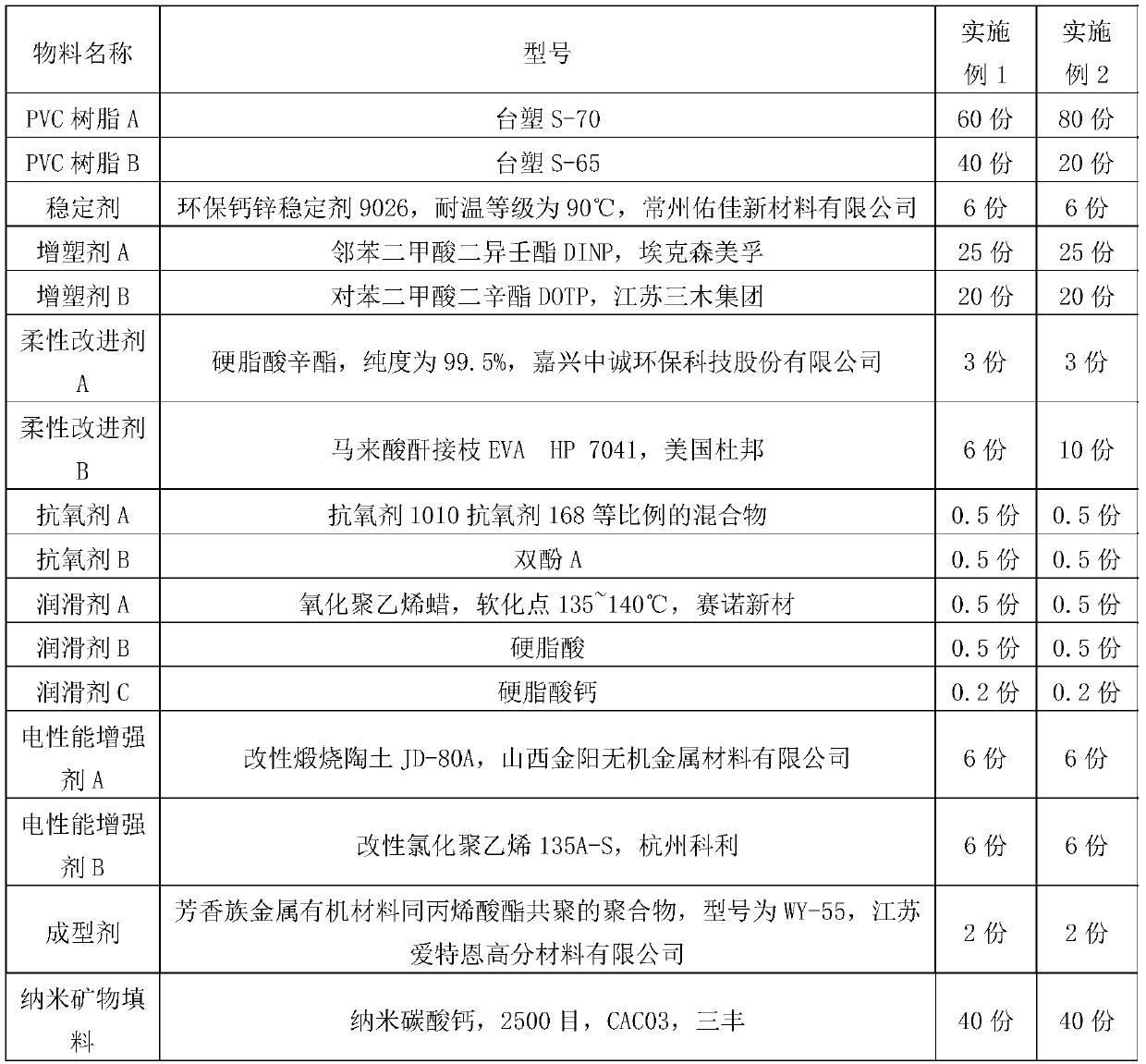

[0028] Table 1 The raw material composition formula of the environment-friendly 90°C highly flexible PVC insulating material for charging pile cables in each embodiment

[0029]

[0030] The environment-friendly 90°C high-flexibility PVC insulating material for charging pile cables in the above examples is prepared according to the following methods:

[0031] (a) PVC resin A, PVC resin B, stabilizer, plasticizer A, plasticizer B, flexibility improver A, flexibility improver B, lubricant A, lubricant B, lubricant C of formula quantity , antioxidant A, antioxidant B, electrical performance enhancer A, electrical performance enhancer B, processing aids, nano-mineral fillers and other raw materials are added to the high-speed mixer accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com