Environment-friendly inner wall paint and preparation method thereof

An interior wall coating and environmental protection technology, applied in the direction of fireproof coating, antifouling/underwater coating, coating, etc., can solve the problems of poor bonding ability, difficult construction, poor fire protection level, etc., and achieve good absorption and decomposition of formaldehyde Ability, simple and easy preparation method, fireproof performance and strong bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

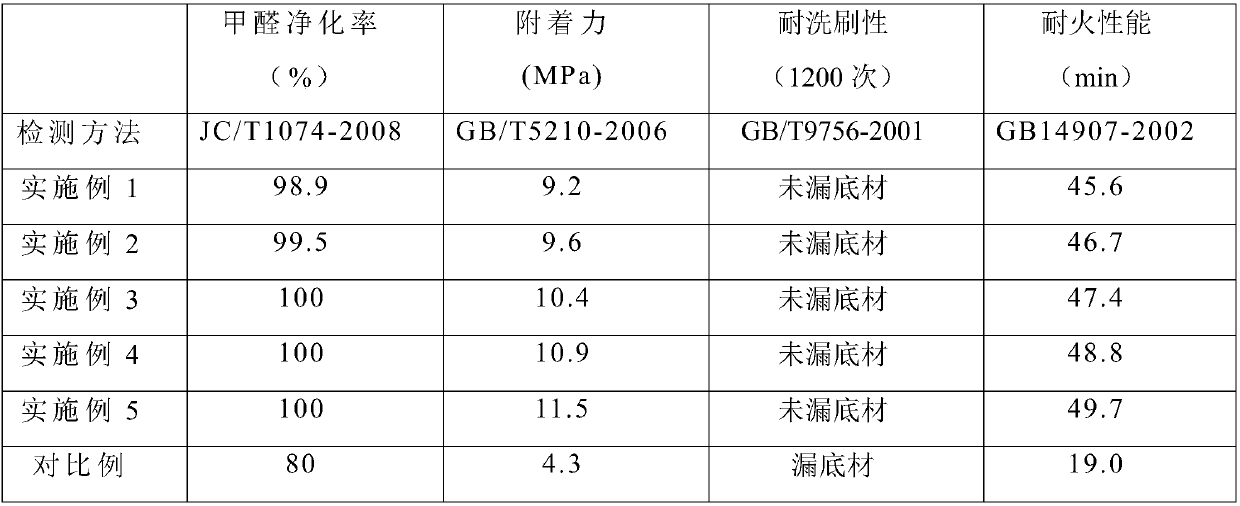

Examples

Embodiment 1

[0038]An environment-friendly interior wall paint, comprising the following components by weight: 35 parts of fluorine-containing triazine film-forming polymer, 10 parts of phosphonic acid-modified nano-titanium dioxide, 20 parts of rutile titanium dioxide, 2 parts of tributyl phosphate, 3 parts of propylene glycol, 20 parts of water.

[0039] The preparation method of described fluorine-containing triazine film-forming polymer comprises the steps:

[0040] 1) Add 10g of glycidyl methacrylate, 4,6-bis(2,2,2-trifluoroethoxy)-1,3,5-triazin-2-amine (CAS: 301211-00-7 ) 20g into 100g of isopropanol, and 0.1g of the polymerization inhibitor chlorobenzoquinone was added therein, stirred and reacted at 80°C for 6 hours, then the solvent was removed by rotary evaporation, then washed 4 times with ether, and the ether was removed by rotary evaporation again ;

[0041] 2) Add 10g of glycidyl methacrylate and 20g of 2,4-dioxohexahydro-1,3,5-triazine (CAS: 27032-78-6) into 100g of tetrah...

Embodiment 2

[0049] An environment-friendly interior wall paint, comprising the following components in parts by weight: 38 parts of fluorine-containing triazine film-forming polymer, 12 parts of phosphonic acid-modified nano-titanium dioxide, 23 parts of lithopone, and 3 parts of defoamer Deqian 3100 , 4 parts of methyl ether, 23 parts of water.

[0050] The preparation method of described fluorine-containing triazine film-forming polymer comprises the steps:

[0051] 1) Add 10g of glycidyl methacrylate, 4,6-bis(2,2,2-trifluoroethoxy)-1,3,5-triazin-2-amine (CAS: 301211-00-7 ) 25g into 120g of dichloromethane, and 0.15g of chloranil, a polymerization inhibitor, was added thereto, stirred and reacted at 83°C for 6.5 hours, then the solvent was removed by rotary evaporation, and washed 5 times with ether, and the ether was removed by rotary evaporation again ;

[0052] 2) Add 10g of glycidyl methacrylate and 25g of 2,4-dioxohexahydro-1,3,5-triazine (CAS: 27032-78-6) into 125g of tetrahydro...

Embodiment 3

[0060] An environment-friendly interior wall paint, comprising the following components by weight: 40 parts of fluorine-containing triazine film-forming polymer, 14 parts of phosphonic acid modified nano-titanium dioxide, 27 parts of heavy calcium carbonate, 4 parts of defoamer BYK0888, propylene glycol 5 parts of butyl ether, 26 parts of water.

[0061] The preparation method of described fluorine-containing triazine film-forming polymer comprises the steps:

[0062] 1) Add 10g of glycidyl methacrylate, 4,6-bis(2,2,2-trifluoroethoxy)-1,3,5-triazin-2-amine (CAS: 301211-00-7 ) 26 g into 135 g of acetone, and 0.22 g of the polymerization inhibitor chlorobenzoquinone was added therein, stirred and reacted at 86° C. for 7 hours, then the solvent was removed by rotary evaporation, and then washed 6 times with ether, and the ether was removed by rotary evaporation again;

[0063] 2) Add 10g of glycidyl methacrylate and 25g of 2,4-dioxohexahydro-1,3,5-triazine (CAS: 27032-78-6) into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com