Patents

Literature

34results about How to "Good anti-fog durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light cured antifogging coating

ActiveCN102911582ASufficiently hydrophilic structureGood anti-fog durabilityCoatingsGlycidyl methacrylateUltraviolet lights

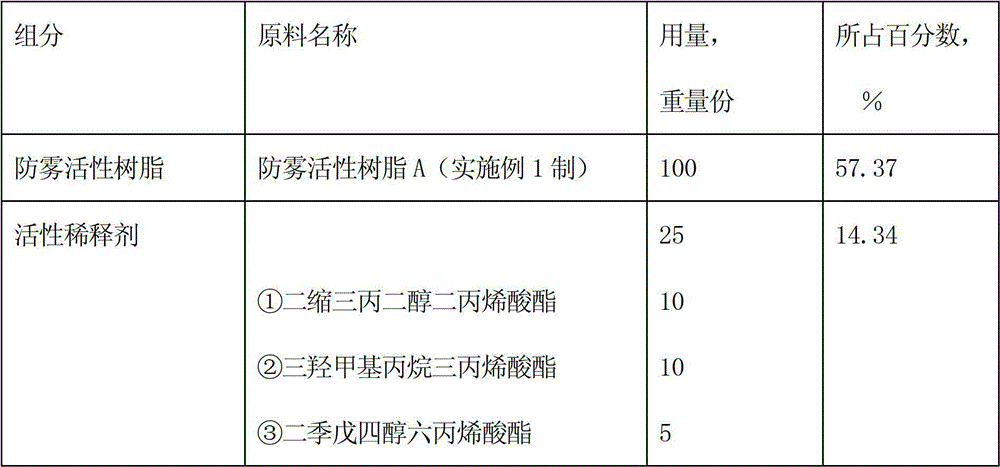

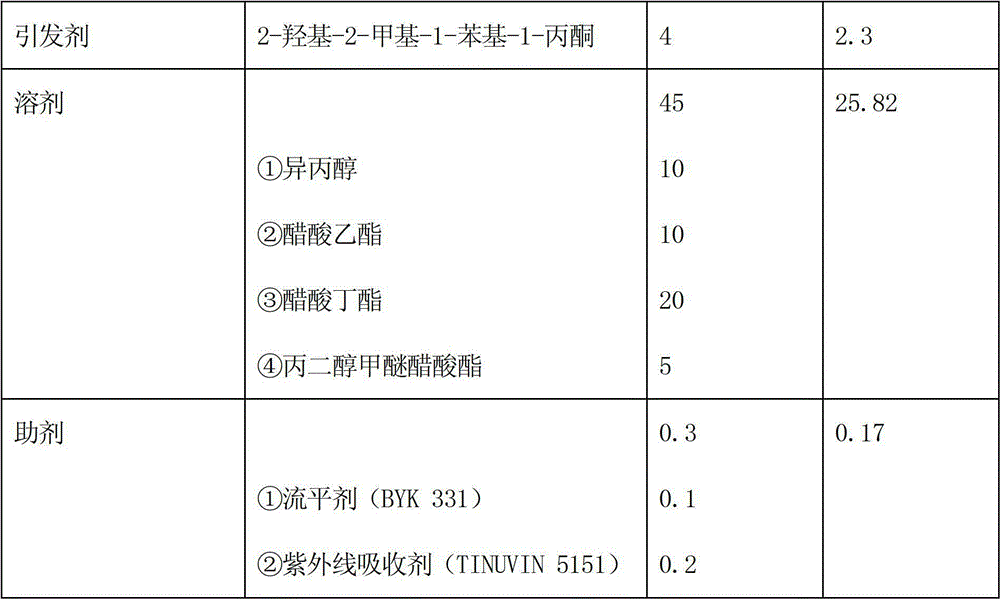

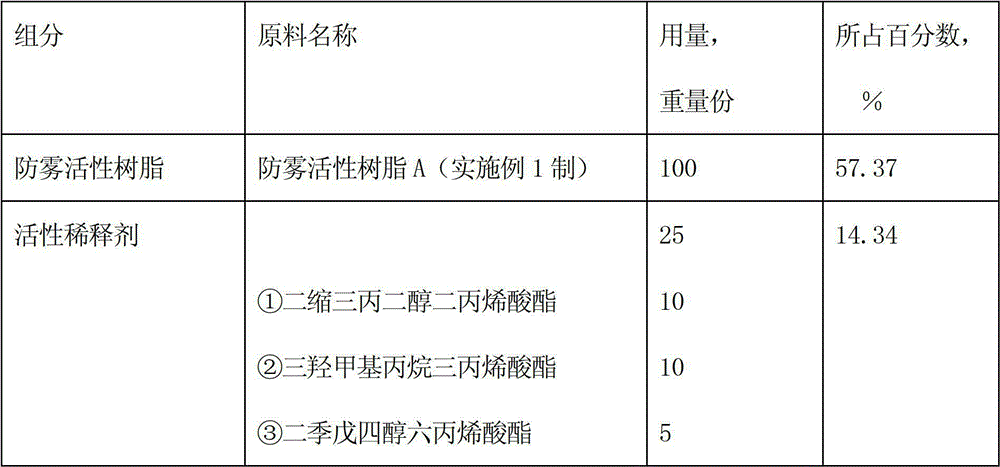

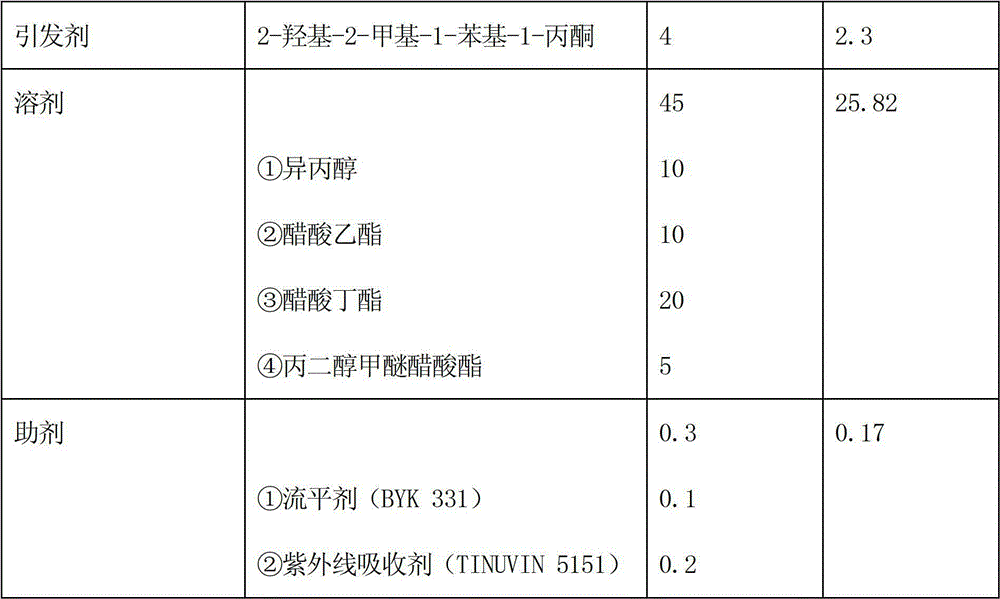

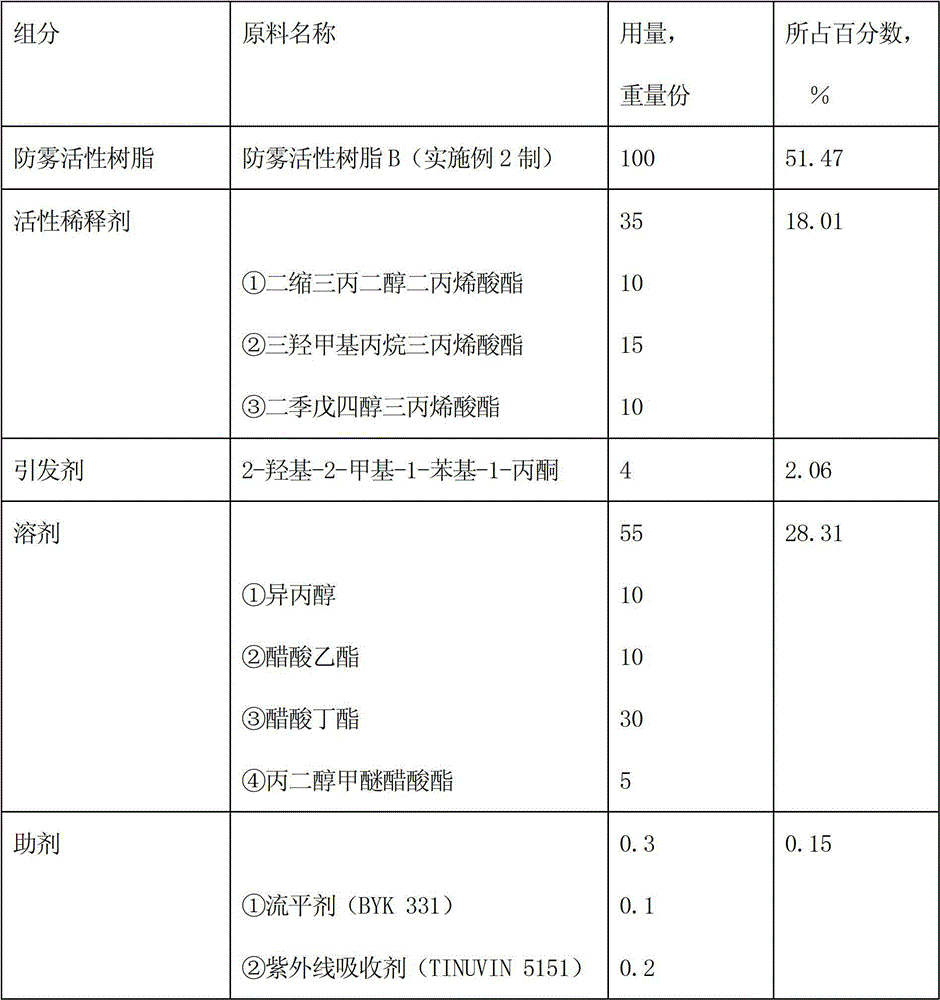

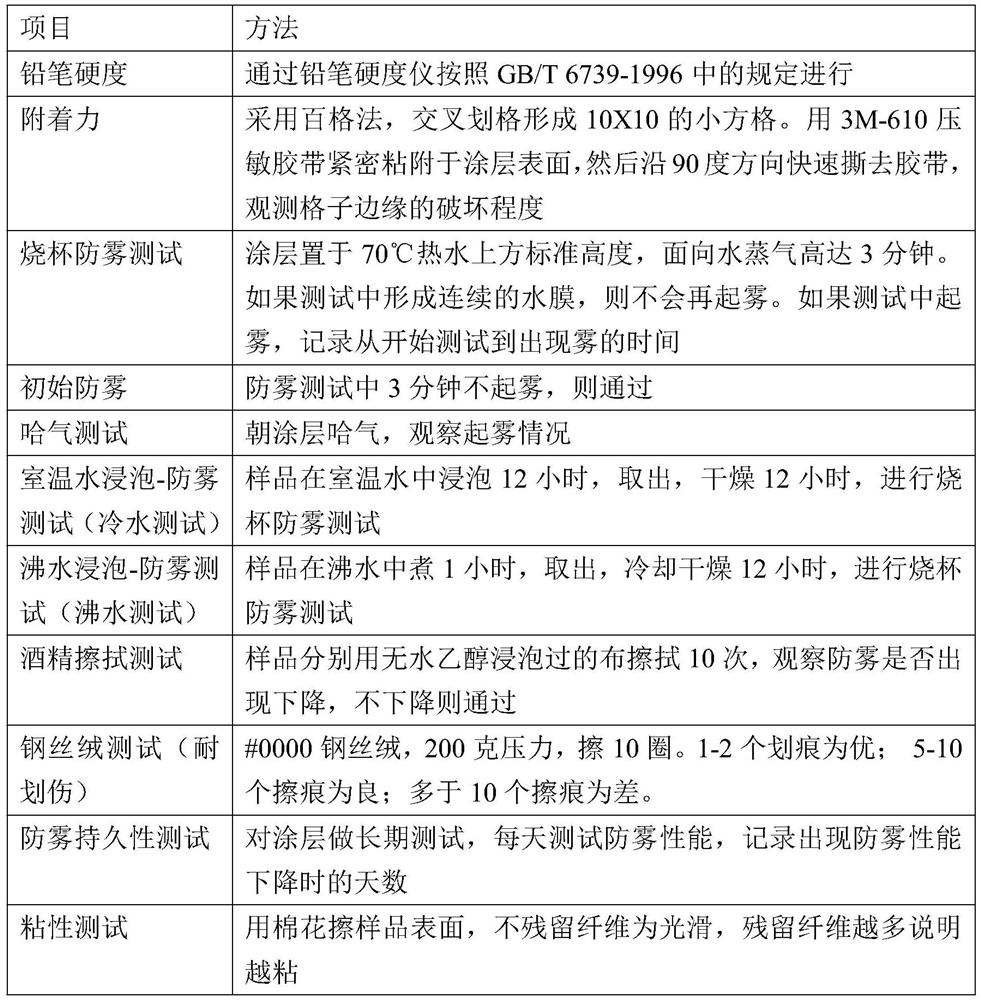

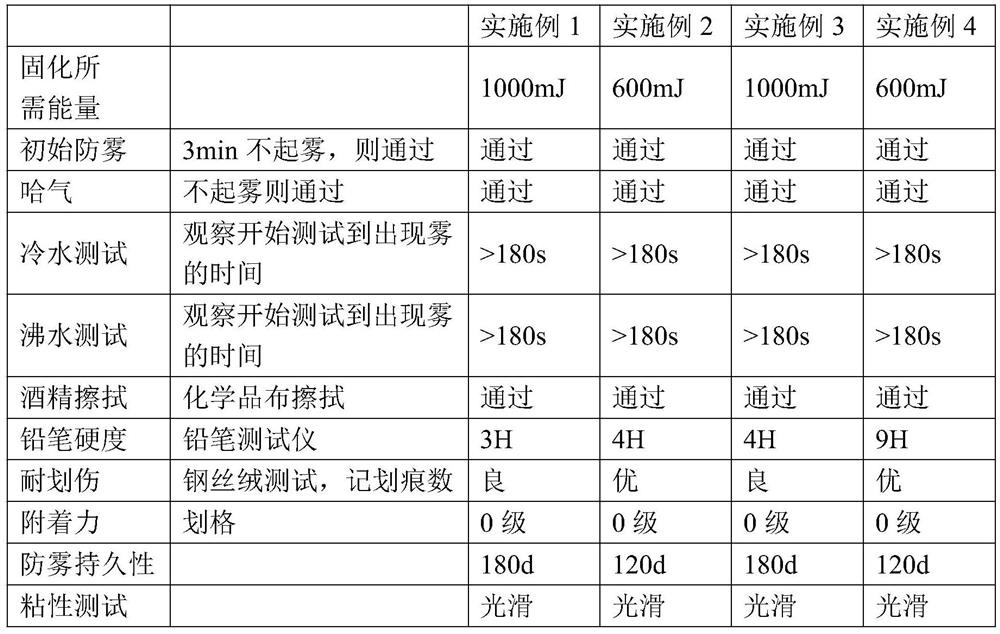

The invention relates to an ultraviolet light cured antifogging coating. The ltraviolet light cured antifogging coating adopts antifogging activated resin which contains activated double bond and can be cured by ultraviolet light as the main film-forming resin, and is prepared by mixing, based on total weight of the antifogging coating, 32-60% of the antifogging activated resin, 10-25% of activated diluent, 1.5-2.5% of photoinitiator, 25-40% of solvent, and 0.1-1% of adjuvant. The antifogging activated resin is prepared by subjecting reactive nonionic surfactant allyloxy nonyl phenoxy propanol polyoxyethylene ether, (methyl) acrylic acid and (methyl) butyl acrylate to free radical polymerization, and grafting and modifying by the polymer via glycidyl methacrylate, wherein the amount ratio of the glycidyl methacrylate to the (methyl) acrylic acid is 1-1.4. The film formed by the coating cured by the ultraviolet light is high in water resistance performance, durable in antifogging effect and high in hardness, and wiping resistance is improved remarkably.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

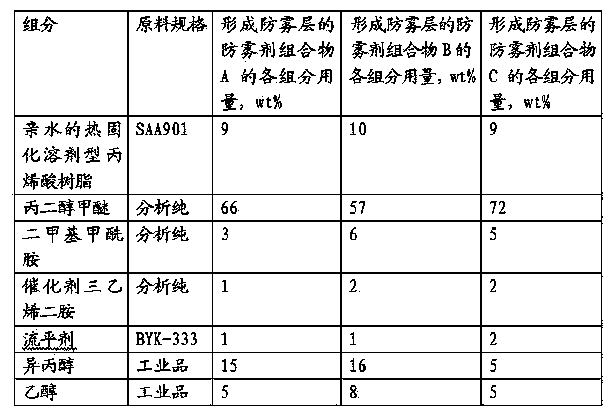

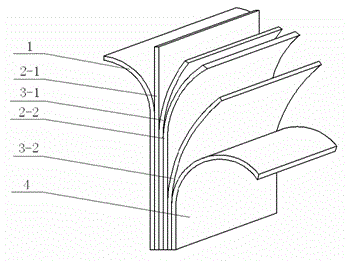

Antifogging agent composition and antifogging colored window film formed by same

ActiveCN102618102AEasy to prepareReduce manufacturing costOther chemical processesSynthetic resin layered productsPolyesterDiamine

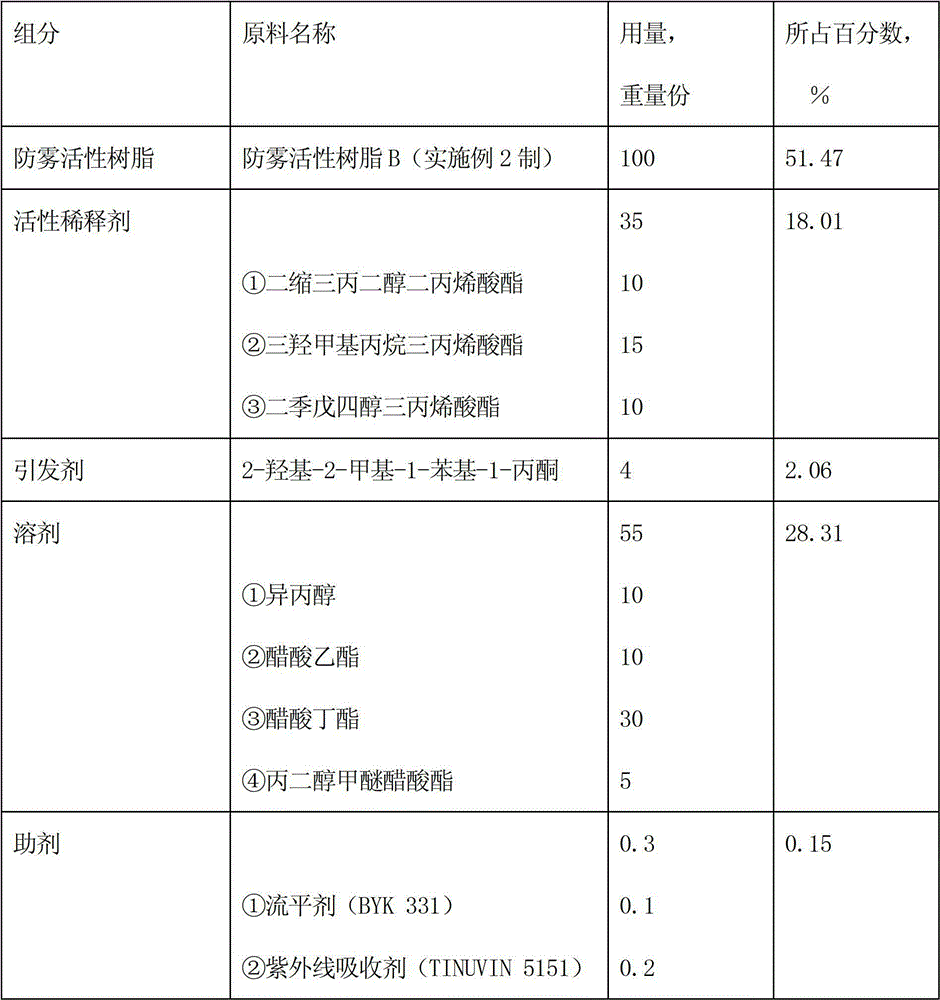

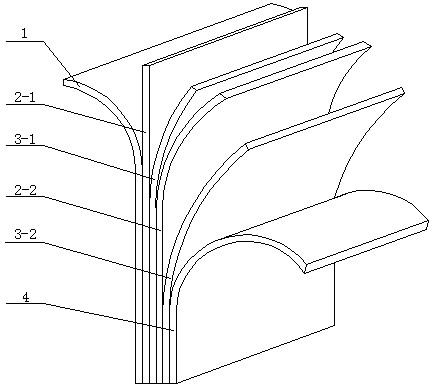

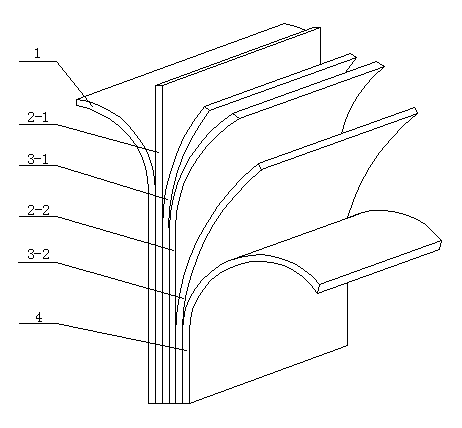

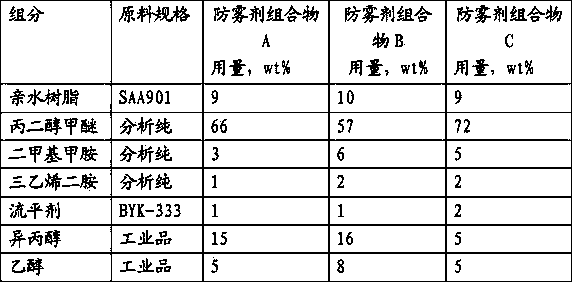

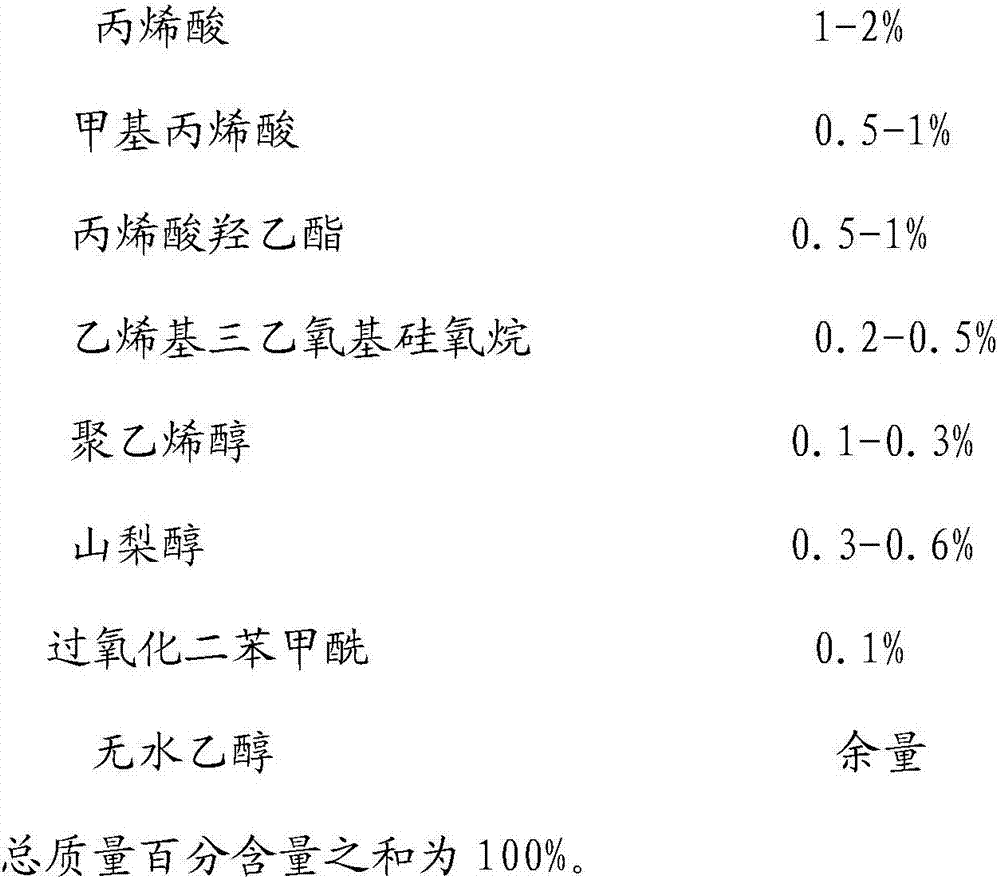

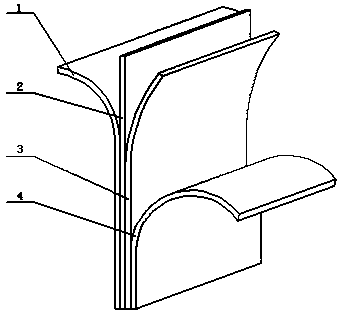

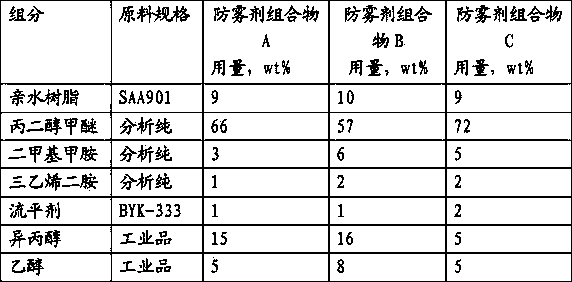

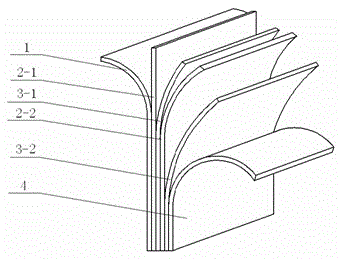

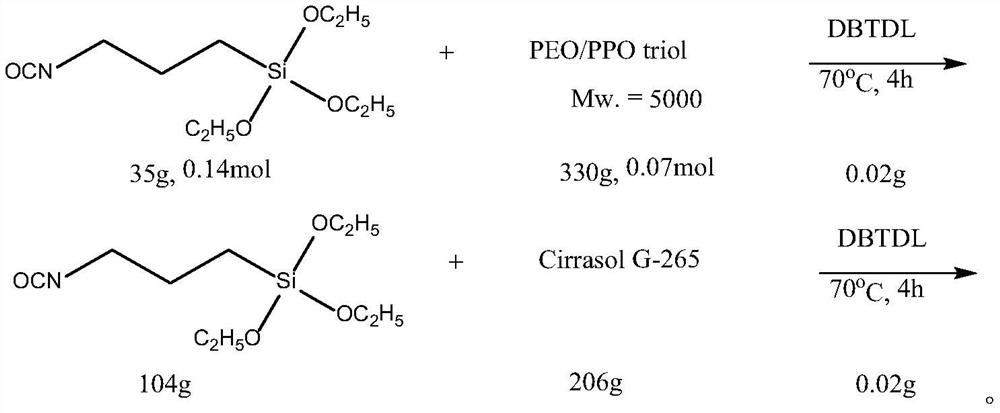

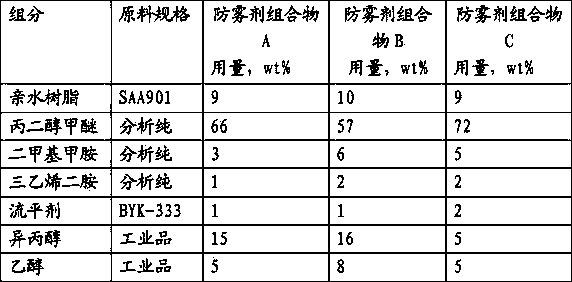

The invention relates to an antifogging agent composition and an antifogging colored window film formed by the same. The antifogging agent composition comprises 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylene-diamine, 1-5wt% of leveling agent, 5-26wt% of isopropanol and 5-24wt% of ethanol. The antifogging colored window film comprises an antifogging agent coating layer (1), a first transparent polyester film or transparent polyethylene film substrate (2-1), a dyed acrylic acid adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic acid adhesive layer (3-2) and a releasing film (4) which are integrally composited, wherein the antifogging agent coating layer (1) is formed by the antifogging agent composition. The antifogging colored window film is antifogging, attractive, transparent and safe.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

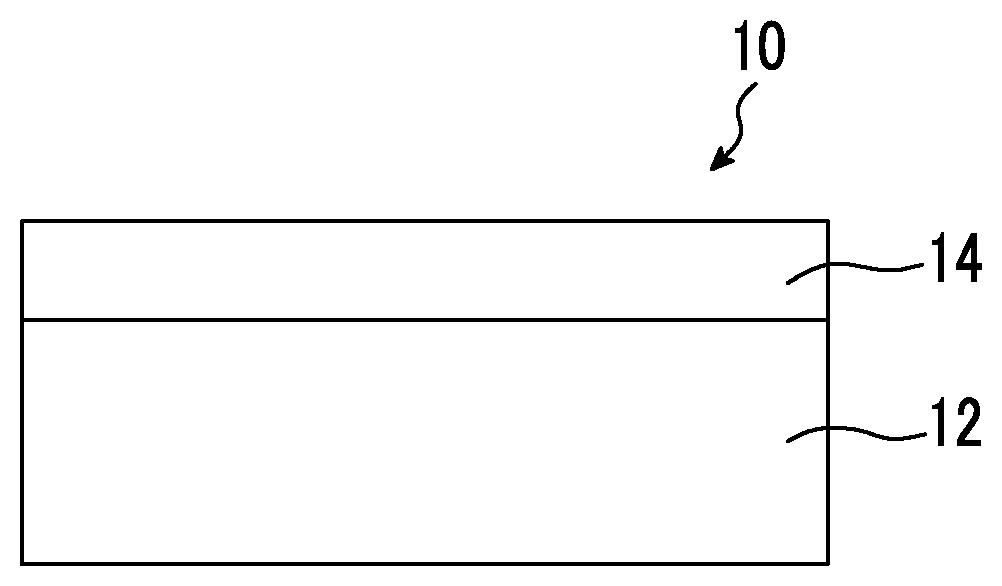

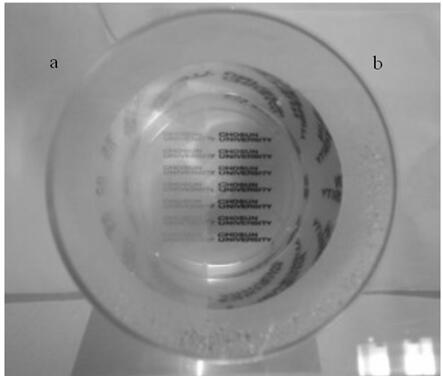

Antifogging agent composition and transparent antifogging window membrane formed therefrom

ActiveCN102627880AGood anti-fog durabilityEasy to prepareOther chemical processesFilm/foil adhesivesPolyesterPolymer science

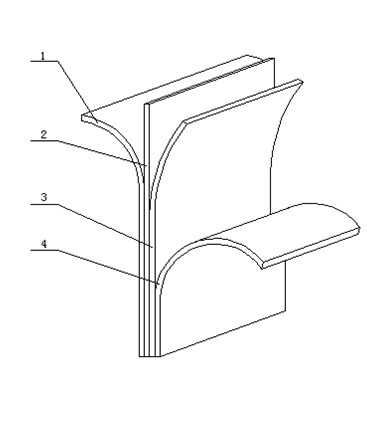

The invention relates to an antifogging agent composition and a transparent antifogging window membrane formed from the composition. The antifogging agent composition consists of 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylenediamine, 1-5wt% of a levelling agent, 5-26wt% of isopropanol, and 5-24wt% of ethanol. The antifogging window membrane is composed of an antifogging agent coating (1), a transparent polyester membrane or transparent polyethylene membrane base material (2), an acrylic adhesive layer (3) and a release membrane (4), and all layers are integrated. The antifogging agent coating (1) is formed by the antifogging agent composition, while the acrylic adhesive layer (3) is formed by a mixture of an acrylic adhesive, a curing agent, toluene and butanone. The transparent antifogging window membrane has effective antifogging function and high light transmittance, as well as a protection effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Long-acting anti-fog agent for automotive glass and preparation method of anti-fog agent

ActiveCN105713575ALong durationGood anti-fog performanceOther chemical processesPolyethylene glycolGlycerol

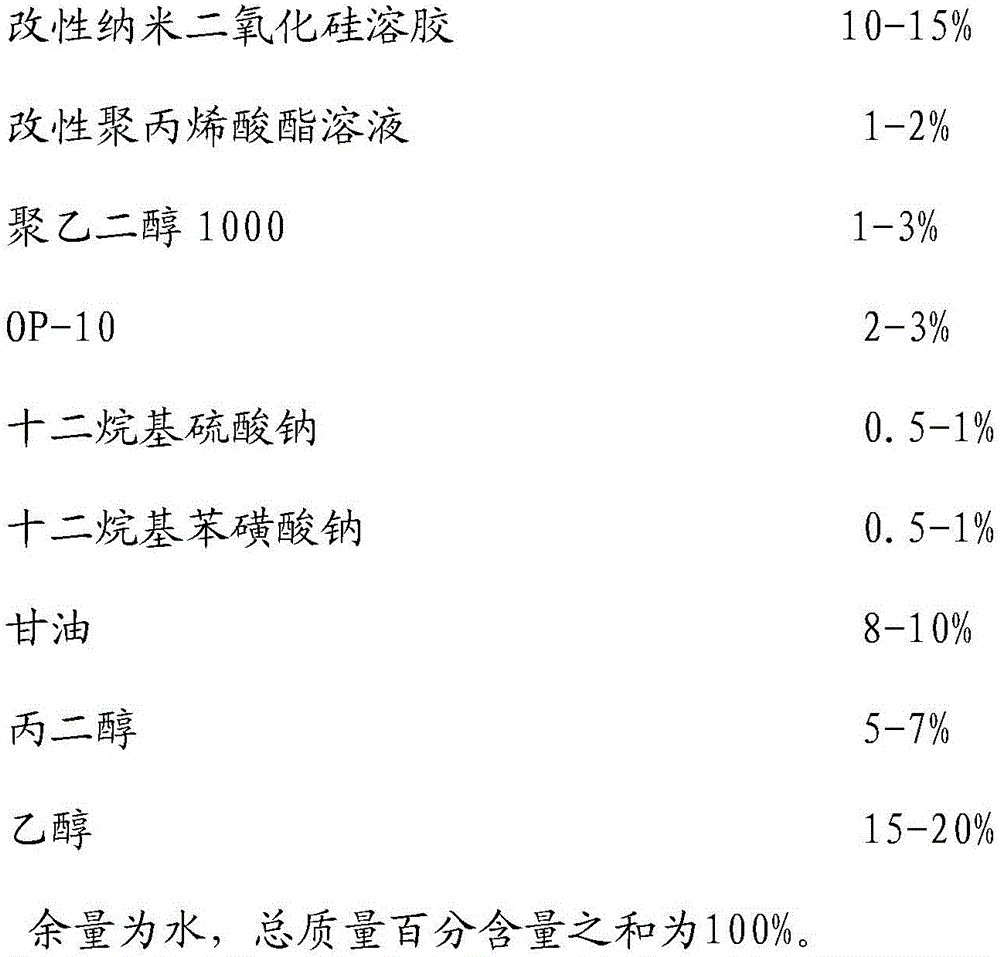

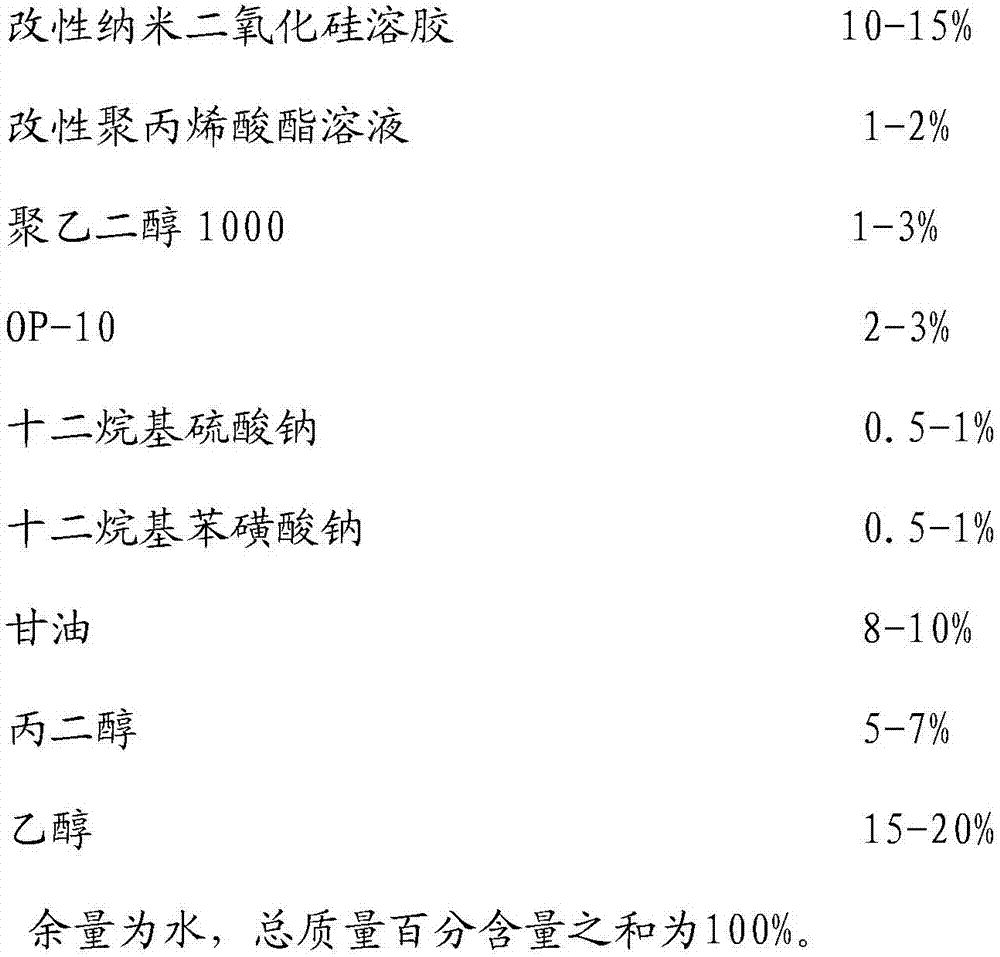

The invention belongs to the technical field of preparation of anti-fog agents for automotive glass and particularly discloses a long-acting anti-fog agent for automotive glass and a preparation method of the anti-fog agent. The anti-fog agent comprises raw materials in percentage by mass as follows: 10%-15% of modified nano-silica sol, 1%-2% of a modified polyacrylate solution, 1%-3% of polyethylene glycol 1000, 2%-3% of OP-10, 0.5%-1% of sodium dodecyl sulfate, 0.5%-1% of sodium dodecylbenzenesulfonate, 8%-10% of glycerin, 5%-7% of propylene glycol, 15%-20% of ethyl alcohol and the balance of water, and the sum of total mass percentage composition is 100%. The anti-fog effect of the anti-fog agent is greatly enhanced through adoption of modified super-hydrophilic nano-silica; with adoption of the modified polyacrylate solution with better adhesion performance, super-hydrophilic nanoparticles and surfactant components can adhere to the glass without falling, so that the durability of the anti-fog agent is enhanced, and the anti-fog effect can be kept for 3 months.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

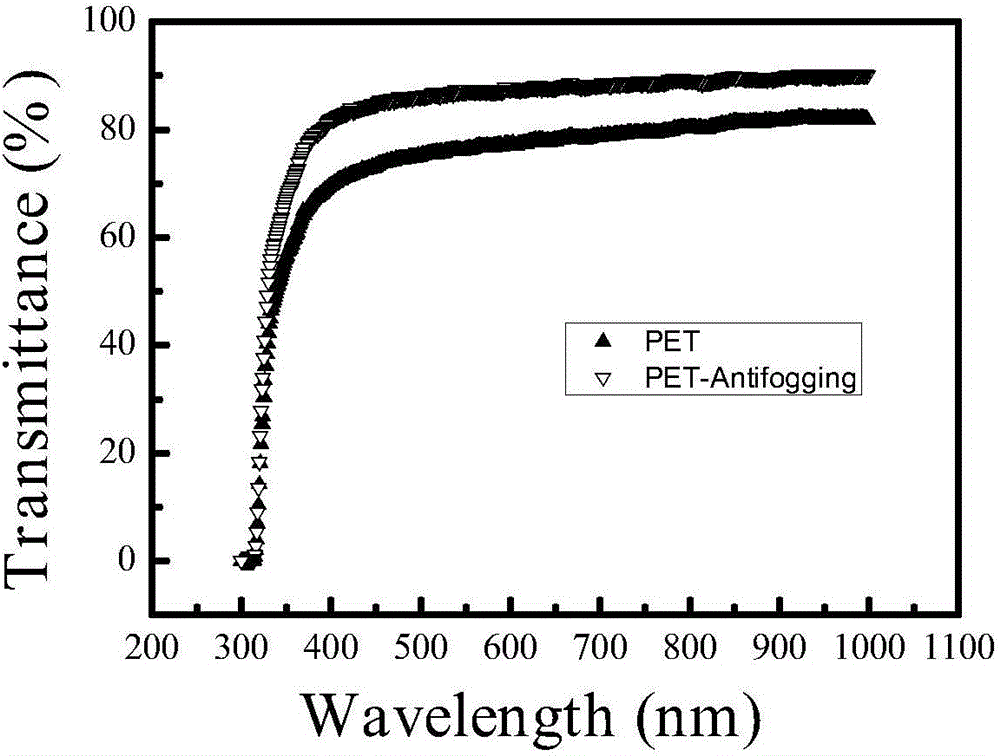

Super-thermal hydrogen treatment method of durable anti-fog plastic sheet

ActiveCN104861192AImprove chemical reactivityImprove water resistancePolyether coatingsHyaluronic acid coatingsPolymer scienceHydrophilic polymers

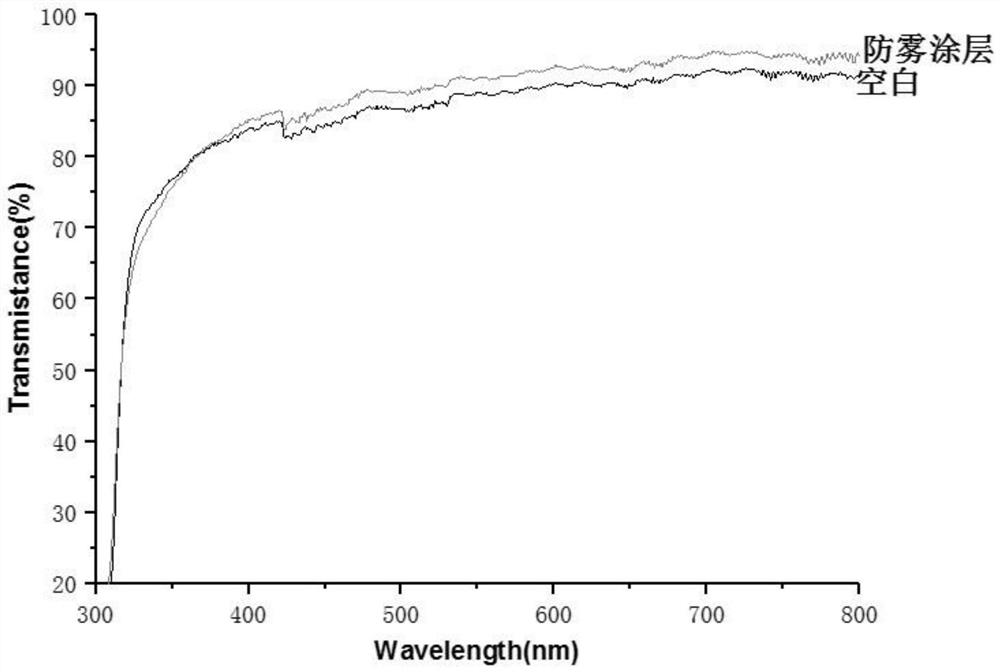

The invention discloses a super-thermal hydrogen treatment method of durable anti-fog plastic sheet, which comprises the following steps: (1) pretreating a plastic substrate with a low-temperature plasma surface finishing machine; (2) spreading a solution containing polymer / nano-silica onto the surface of the pretreated plastic substrate; and (3) stoving the plastic substrate, and then performing super-thermal hydrogen treatment of the plastic substrate to obtain the durable anti-fog plastic sheet. The preparation technology of the durable anti-fog plastic sheet is green and environment-friendly, and can be used for directly grafting and modifying a common hydrophobic polymer substrate with a hydrophilic polymer, a final product has high transparency and a certain permeability improvement effect, and meanwhile the anti-fog performance of the surface of a sample is durable so as to overcome the defect of poor anti-fog durability of the conventional anti-fog product.

Owner:怀宁县成科新材料研究院有限公司

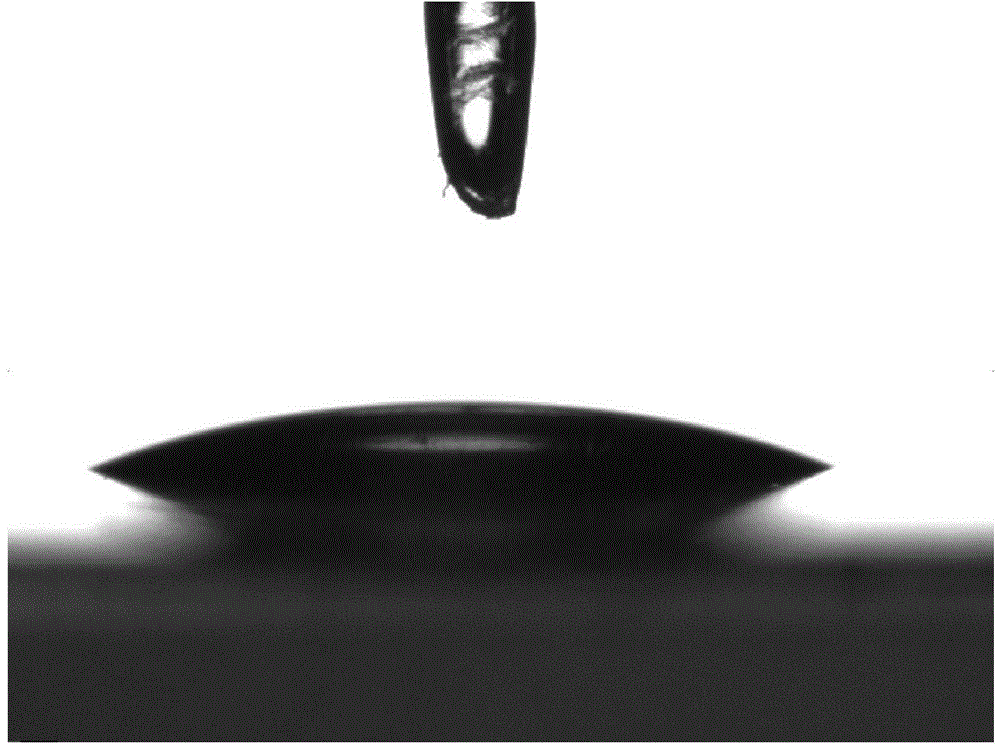

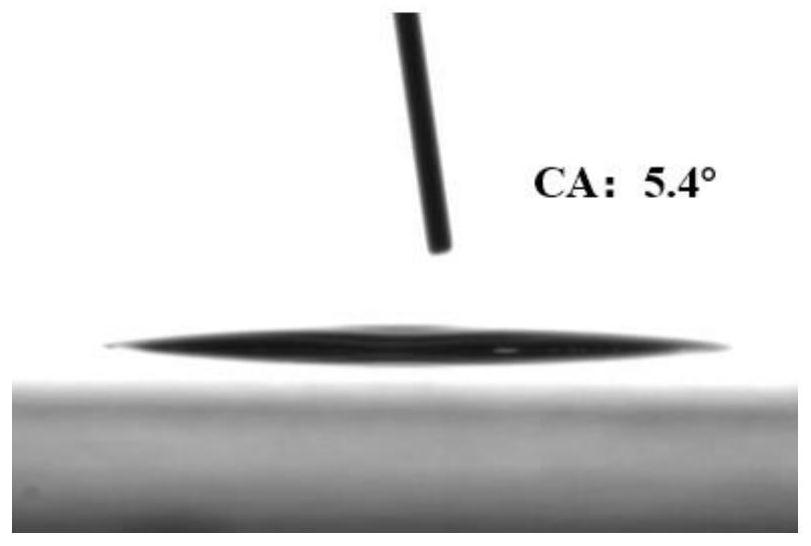

Preparation method of self-cleaning antifogging astronomical telescope lens

InactiveCN110591555ALower contact angleAnti-reflection effectAntifouling/underwater paintsPaints with biocidesNano siliconAstronomical telescopes

The invention relates to a preparation method of a self-cleaning antifogging astronomical telescope lens. According to a preparation method of a self-cleaning antifogging coating, nano silicon dioxideis doped with nano titanium dioxide for the first time, the nano silicon dioxide, the nano titanium dioxide and nano silver are taken as main components to enable the coating to be self-cleaning andantifogging, the coating not only has a good self-cleaning effect, but also has a lasting antifogging effect, and a coating film has excellent antibacterial function. By the prepared self-cleaning antifogging coating film, a thin and transparent protecting film can be formed on the surface of the glass, the adhesive force of the film is high, a lens surface can be rapidly cleaned, rapid volatilization is implemented, and marks do not remain on the lens surface. Meanwhile, the prepared lens also has the characteristics of excellent self-cleaning, antifogging, stabilization and high transmittance properties and the like.

Owner:福建中美友拓科技发展有限公司

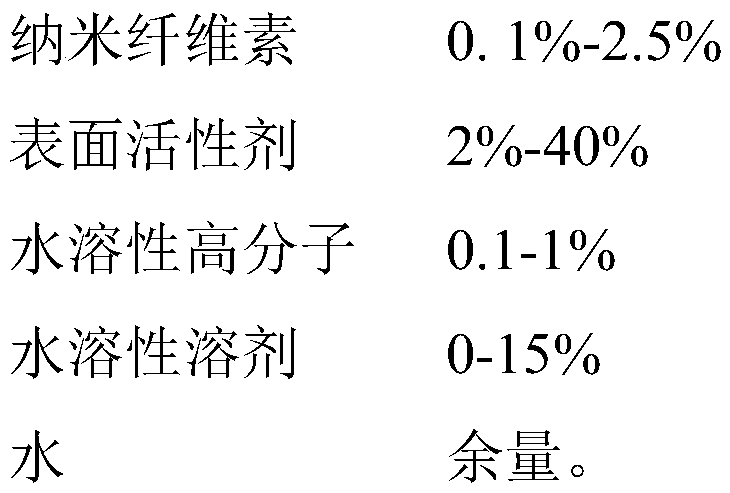

Anti-mist liquid, anti-mist cloth and preparation method of anti-mist cloth

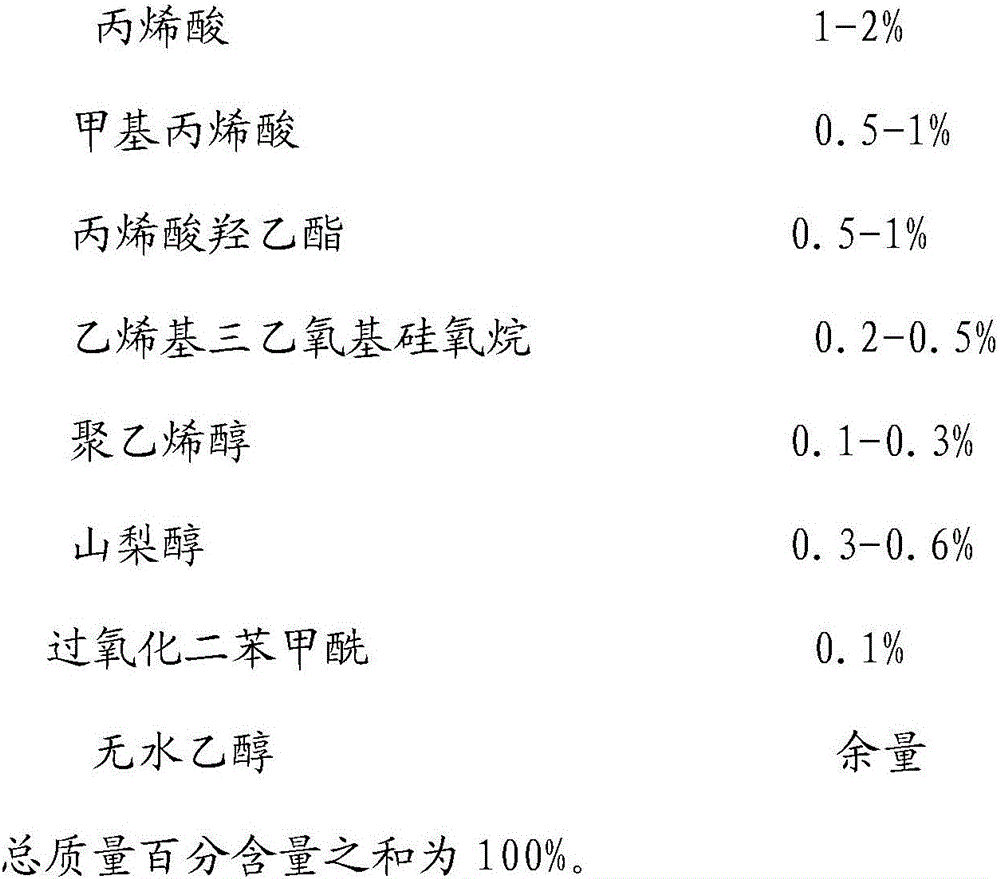

PendingCN110184816AImprove hydrophilicityGood anti-fog performanceOther chemical processesFibre treatmentWater solubleSolvent

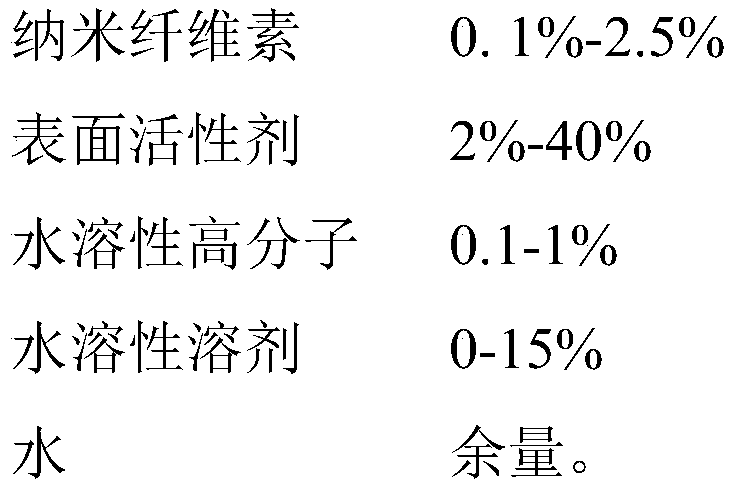

The invention provides an anti-mist liquid good in anti-mist effect, an anti-mist cloth prepared from the same and a preparation method of the anti-mist cloth. The anti-mist cloth is convenient to useand long in effect duration. The anti-mist liquid comprises nano-cellulose, water-soluble macromolecules, a surfactant, a water-soluble solvent and the like, wherein the surfactant plays a role in wetting and spreading, the nano-cellulose can improve the moisture retention and water scouring resistance functions of a coating, the water-soluble macromolecules and the nano-cellulose achieve a synergistic function to improve the anti-mist effect, and the water-soluble solvent makes the anti-mist liquid dry faster.

Owner:浙江跃维新材料科技有限公司

Urethan coating composition, cured coating film and resin member

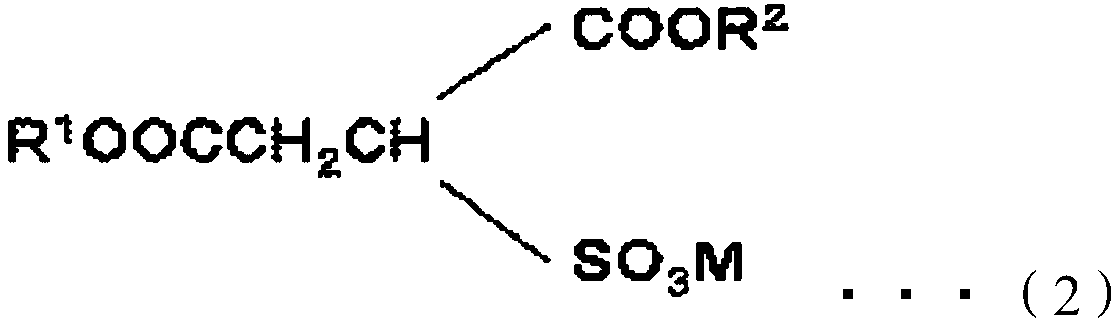

ActiveCN109306238AExcellent scratch resistanceExcellent anti-fog persistencePolyurea/polyurethane coatingsPolyolPolyurethane coating

The present invention provides a liquid polyurethane coating composition capable of forming a cured coating film having excellent scratch resistance and excellent antifogging durability, and a resin member having the cured coating film. The polyurethane coating composition contains a specific amount of a polyisocyanate (a), a polyether polyol (b), and a surfactant (c), and the polyether polyol (b)has a number average molecular weight of more than 300 and less than 600, a polyether polyol (b-2) having a number average molecular weight of more than 600 and less than 900, and a polyether polyol(b-3) having a number average molecular weight of more than 900 and less than 1800. The surfactant (c) is an ionic surfactant having a hydroxyl group in the molecule, and an anionic surfactant and / oran amphoteric surfactant having no group reactive with an isocyanate group.

Owner:NOF CORP

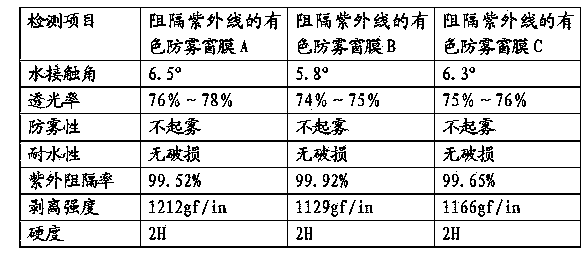

Colored anti-fog window film capable of insulating ultraviolet light

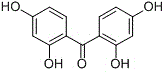

ActiveCN104175666AExtend the life cycleReduce photodegradationNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterAcrylic resin

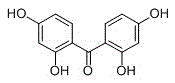

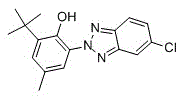

The invention relates to a colored anti-fog window film capable of insulating ultraviolet light. The colored anti-fog window film consists of an anti-fog layer (1), a first polyester film or polyethylene film substrate (2-1), an ultraviolet insulating colored pressure-sensitive adhesive layer (3), a second polyester film or polyethylene film substrate (2-2), an ultraviolet insulating pressure-sensitive adhesive layer (4) and a release film (5) which are integrally compounded layer to layer, wherein the anti-fog layer (1) consists of hydrophilic thermocuring solvent type acrylic resin, propylene glycol monomethyl ether, dimethylformamide, a catalyst triethylene diamine, a flatting agent, isopropanol and ethanol; the ultraviolet insulating pressure-sensitive adhesive layer (4) consists of a mixture material which comprises a benzophenone ultraviolet absorbent, a benzotriazole ultraviolet absorbent, an acrylic acid adhesive, a curing agent and a solvent; the ultraviolet insulating colored pressure-sensitive adhesive layer (3) consists of the mixture of the ultraviolet insulating pressure-sensitive adhesive layer (4) and dyes. The colored anti-fog window film provided by the invention is long-lasting in insulating ultraviolet light, anti-fog and attractive in appearance.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

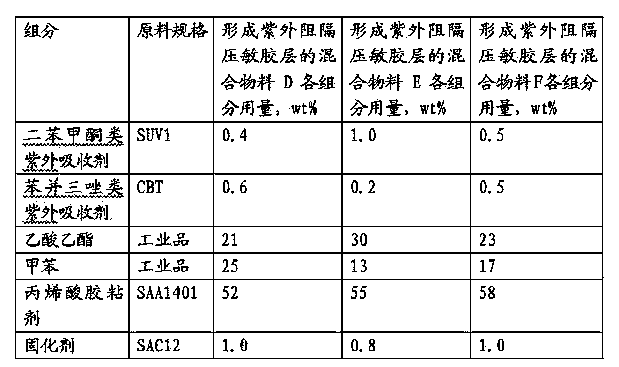

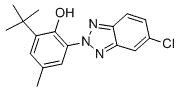

Ultraviolet-blocking transparent antifogging window film

ActiveCN104149432AExtend the life cycleReduce photodegradationSynthetic resin layered productsPolyesterAcrylic resin

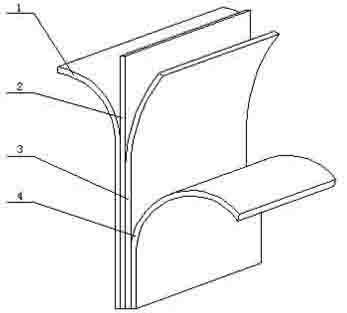

The invention relates to an ultraviolet-blocking transparent antifogging window film. The ultraviolet-blocking transparent antifogging window film consists of an antifogging layer (1), a first transparent polyester film or polyethylene film base material (2-1), a first ultraviolet-blocking pressure-sensitive adhesive layer (3-1), a second transparent polyester film or polyethylene film base material (2-2), a second ultraviolet-blocking pressure-sensitive adhesive layer (3-2) and a release film (4) which are compounded into a whole, wherein the antifogging layer (1) is made from an antifogging agent composition consisting of hydrophilic thermocuring solvent-type acrylic resin SAA901, propylene glycol methyl ether, dimethyl formamide, a catalyst triethylenediamine, a leveling agent, isopropyl alcohol and ethanol; both the first ultraviolet-blocking pressure-sensitive adhesive layer (3-1) and the second ultraviolet-blocking pressure-sensitive adhesive layer (3-2) are made from a mixed material consisting of a benzophenone ultraviolet absorbent, a benzotriazole ultraviolet absorbent, acrylic adhesive, a curing agent and a solvent. The ultraviolet-blocking transparent antifogging window film can block ultraviolet lastingly and prevent fog lastingly.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

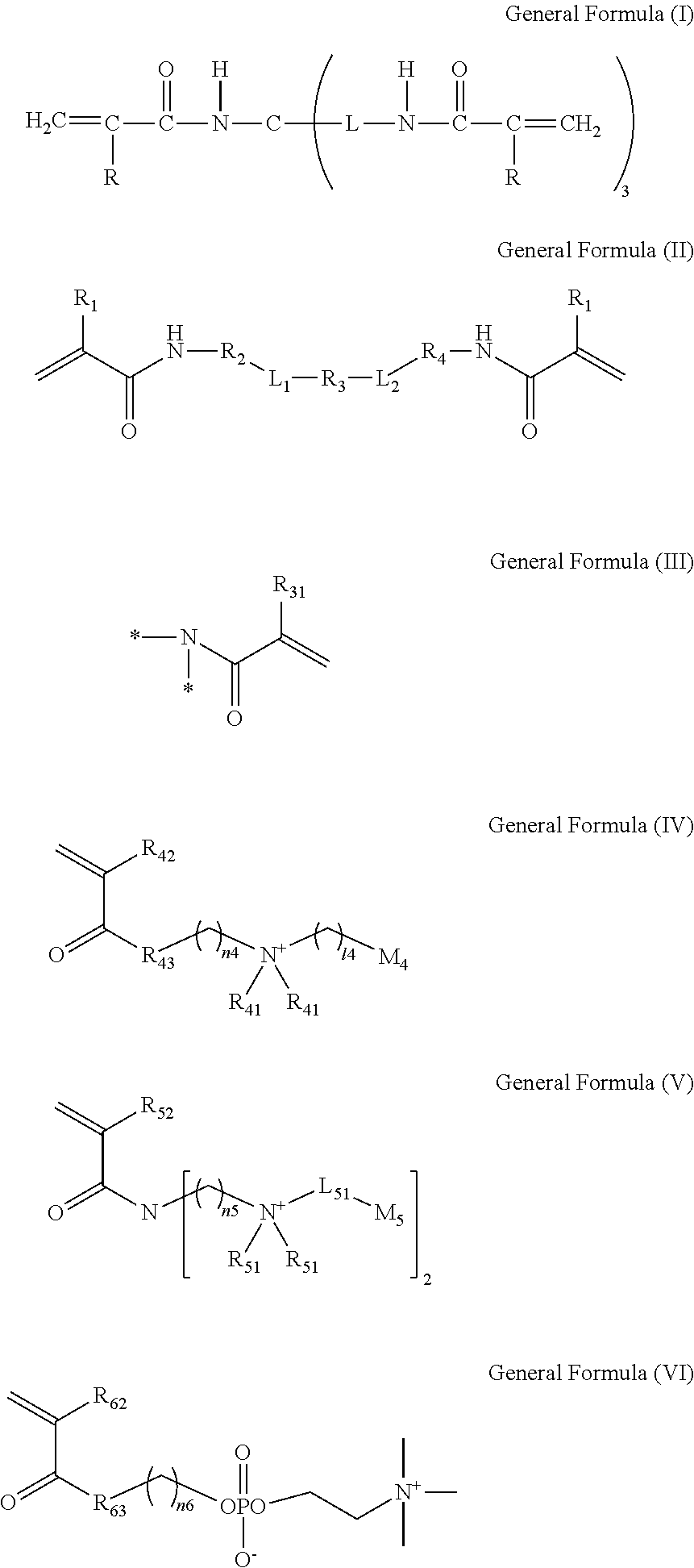

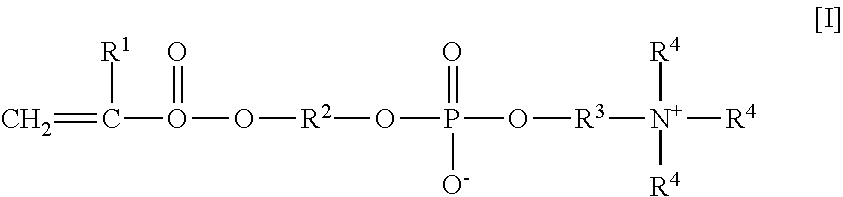

Curable composition, coating, and laminate

ActiveUS10494540B2Good anti-fog durabilityHigh hardnessSynthetic resin layered productsLaminationMeth-Betaine

An object of the present invention is to provide a curable composition, a coating, and a laminate which enable production of a coating that can exhibit excellent antifogging properties and is excellent in antifogging durability while maintaining a high hardness. The present invention relates to a curable composition including: at least one polyfunctional (meth)acrylamide compound selected from the group consisting of a compound represented by General Formula (I) and a compound represented by General Formula (II); and at least one betaine monomer selected from the group consisting of compounds represented by General Formula (IV) to (VI); and a coating and a laminate obtained by using the curable composition.

Owner:FUJIFILM CORP

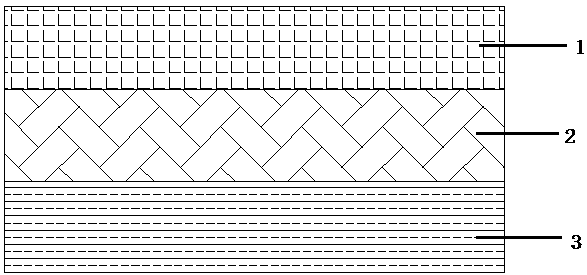

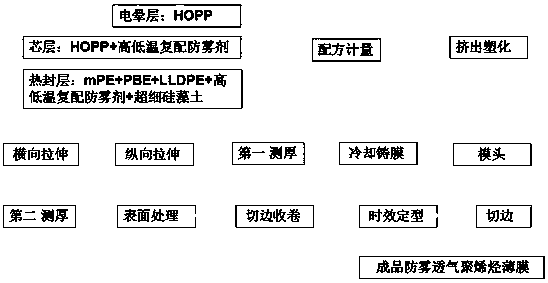

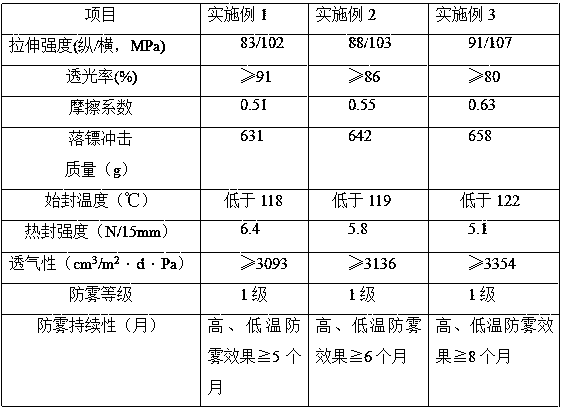

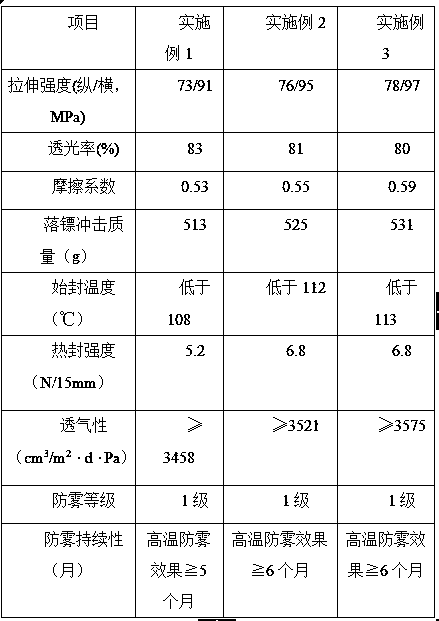

High-low-temperature anti-fog gas-permeable polyolefin heat-sealing film for fruit and vegetable packaging, and preparation method thereof

InactiveCN111300940AReduce precipitationProlong the action timeFlexible coversWrappersPolymer sciencePolyolefin

The invention discloses a high-and-low-temperature anti-fog gas-permeable polyolefin heat-sealing film for fruit and vegetable packaging. The high-and-low-temperature anti-fog gas-permeable polyolefinheat-sealing film comprises a corona layer, a core layer and a heat-sealing layer from top to bottom, wherein a layer ratio structure of three-layer co-extrusion is as follows: the layer ratio structure corona layer / core layer / heat-sealing layer of three-layer co-extrusion is HOPP / (HOPP and high-and-low temperature antifogging agent) / (mPE and LLDPE and PBS and high-and-low temperature antifoggingagent and superfine diatomite). According to the invention, a certain proportion of a high-and-low-temperature compound antifogging agent is added into a heat-sealing layer and a core layer, so thatthe film has high temperature and low temperature antifogging performance at the same time; superfine diatomite is added into the heat-sealing layer, so that the precipitation of the antifogging agentis delayed and the antifogging time of the film is prolonged by using the adsorption function of the superfine diatomite, and the granularity of diatomite can increase the gas permeability and the opening property of the film and increase the strength of the film so as to solve the problem of film strength reducing caused by addition of the antifogging agent and prepare the polyolefin heat-seal film being transparent, high in heat-seal strength and good in antifogging effect.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV +1

Polysiloxane and application thereof

The invention discloses polysiloxane and application thereof. The polysiloxane is formed by reacting a semi-closed isocyanate prepolymer with an organic polymer silanol. The polysiloxane has an anti-fog function, and when the polysiloxane is applied to an anti-fog coating, UV curing can be achieved, and the hardness of the coating can be improved.

Owner:武汉中科先进材料科技有限公司

Anti-fogging agent and preparation method thereof

The invention discloses an anti-fogging agent and a preparation method thereof, and relates to the technical field of anti-fogging agents. The anti-fogging agent disclosed by the invention comprises the following components in parts by weight: 30 to 80 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 15 to 55 parts of sodium ethoxylated alkyl sulfate, 10 to 50 parts of fatty alcohol ether sodium sulfate, 10 to 50 parts of alkylphenol polyoxyethylene, 3 to 20 parts of amine oxide, 5 to 25 parts of rosin, 1 to 9 parts of sodium chloride and 10 to 35 parts of softened water. A mild formula is adopted, and does not contain acid and alkaline corrosion materials, the prepared product is free of corrosion for laminated films and glass of automobiles, an anti-fog test shows that fog can be prevented for 7 to 10 days after rubbing once, the fog removal and anti-fog effects are obvious, the anti-fogging agent is free of glare at night, the view is clear, and the anti-fogging agent does not contain any pigment or volatile gas.

Owner:王露露

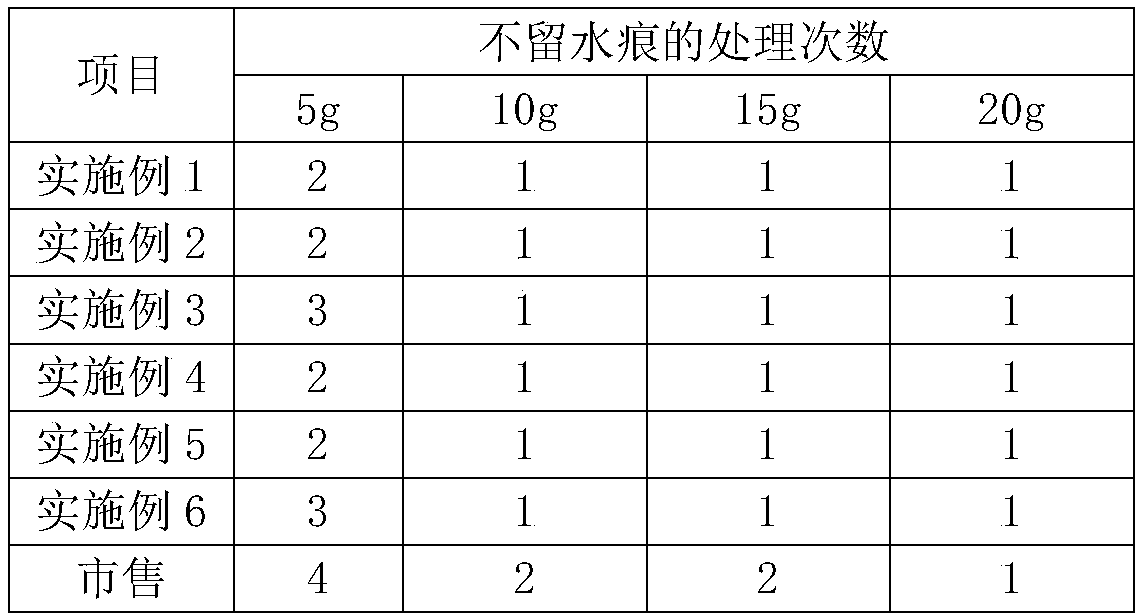

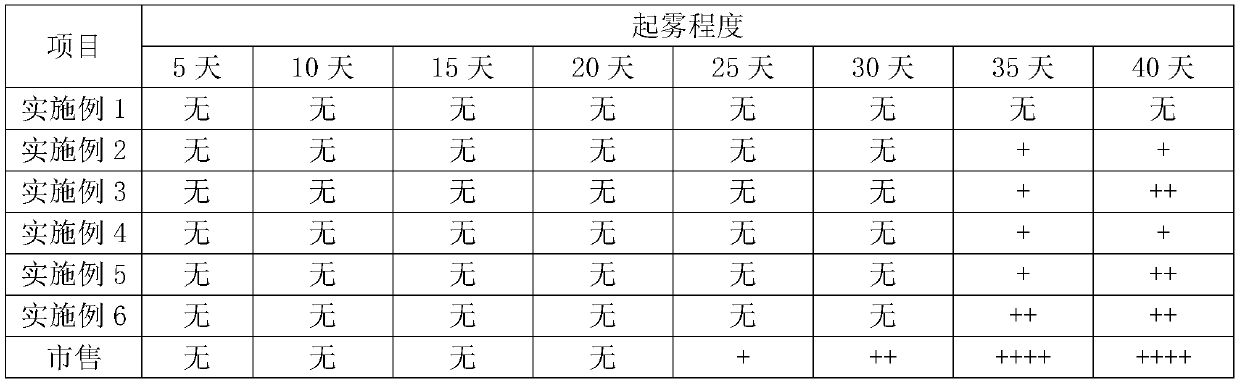

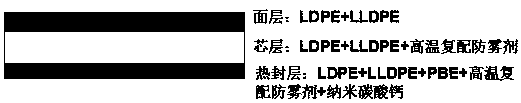

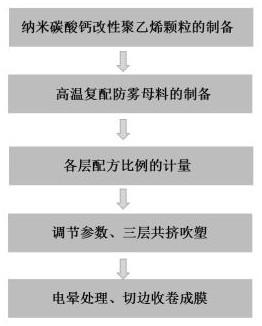

High-temperature anti-fog breathable polyethylene heat-seal film and preparation method thereof

InactiveCN111070834AReduce precipitationImprove hydrophilicityFlexible coversWrappersPolymer scienceNano carbon

The invention belongs to the field of preparation of anti-fog heat-sealing films, and particularly relates to a high-temperature anti-fog breathable polyethylene heat-sealing film and a preparation method thereof. The heat-sealing film comprises a surface layer, a core layer and a heat sealing layer from top to bottom, a three-layer co-extrusion layer ratio structure is as follows: LDPE + LLDPE / (LDPE + LLDPE + an initial high-temperature antifogging agent + a long-acting high-temperature antifogging agent) / (LDPE + LLDPE + PBE + an initial high-temperature antifogging agent + a long-acting high-temperature antifogging agent + nano calcium carbonate); wherein the surface layer accounts for 10-30 wt%, the core layer accounts for 40-75 wt%, and the heat sealing layer accounts for 15-30 wt%. The anti-fog heat-sealing film prepared by the invention has the characteristics of better anti-fog durability, better air permeability, high heat-sealing strength and good comprehensive performance, isparticularly suitable for packaging of fruit and vegetable products, is particularly beneficial to market development, and promotes the progress of packaging materials.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV +1

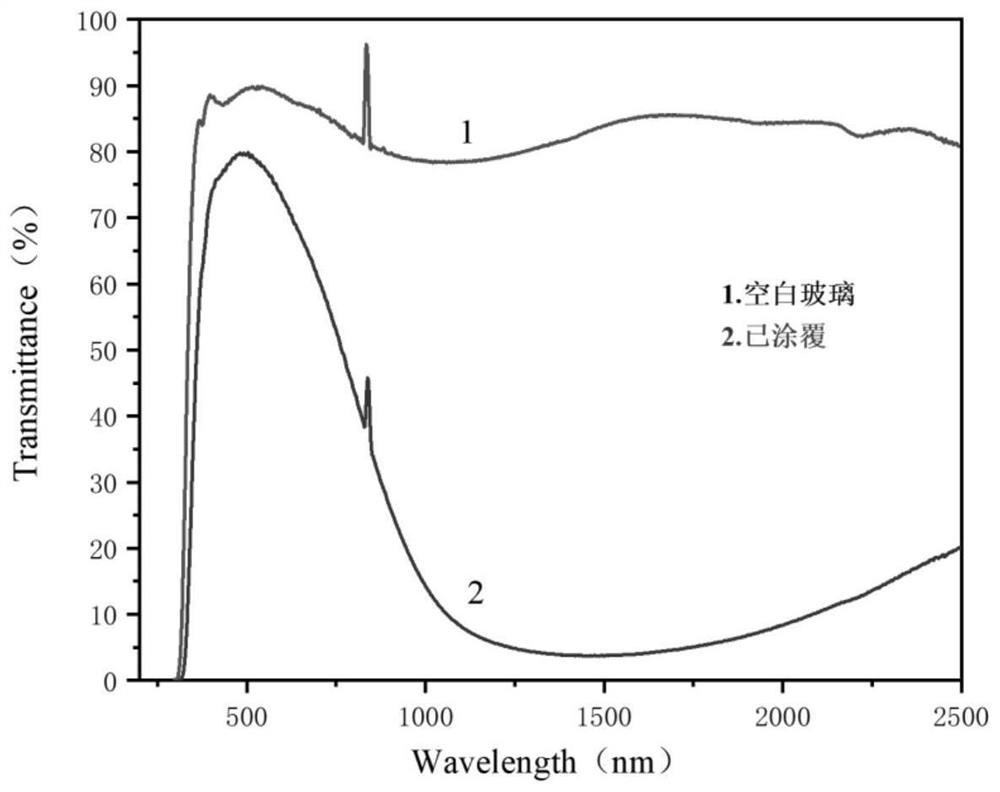

Preparation method of a heat-insulating, anti-fog, self-cleaning superhydrophilic transparent coating

ActiveCN114181626BImprove surface roughnessImprove water resistanceCoatingsHydrophilic coatingPolymer science

The invention discloses a method for preparing a heat-insulating, anti-fogging, self-cleaning super-hydrophilic transparent coating. Step 1, preparing nano-heat-insulating powder slurry dispersion; Step 2, preparing a hydrophilic polymer with a certain degree of crosslinking solution; Step 3, preparing a super-hydrophilic transparent coating with heat insulation, anti-fog, and self-cleaning functions; dispersing the nano-insulation powder slurry obtained in Step 1 and step 2 to obtain a hydrophilic polymerization with a certain degree of crosslinking Stir the material and additives evenly, then spray the obtained solution on the surface of the glass substrate, put the coated glass in an oven to dry, and after drying, you can get a super-friendly glass with heat insulation, anti-fog and self-cleaning functions. Water clear coat. The invention solves the problems of poor anti-fog durability, poor water resistance, poor weather resistance and impermanence to wiping existing in the existing super-hydrophilic coating.

Owner:江西善纳新材料科技有限公司

Ultraviolet light cured antifogging coating

ActiveCN102911582BSufficiently hydrophilic structureGood anti-fog durabilityCoatingsGlycidyl methacrylateUltraviolet lights

The invention relates to an ultraviolet light cured antifogging coating. The ltraviolet light cured antifogging coating adopts antifogging activated resin which contains activated double bond and can be cured by ultraviolet light as the main film-forming resin, and is prepared by mixing, based on total weight of the antifogging coating, 32-60% of the antifogging activated resin, 10-25% of activated diluent, 1.5-2.5% of photoinitiator, 25-40% of solvent, and 0.1-1% of adjuvant. The antifogging activated resin is prepared by subjecting reactive nonionic surfactant allyloxy nonyl phenoxy propanol polyoxyethylene ether, (methyl) acrylic acid and (methyl) butyl acrylate to free radical polymerization, and grafting and modifying by the polymer via glycidyl methacrylate, wherein the amount ratio of the glycidyl methacrylate to the (methyl) acrylic acid is 1-1.4. The film formed by the coating cured by the ultraviolet light is high in water resistance performance, durable in antifogging effect and high in hardness, and wiping resistance is improved remarkably.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Anti-fog treatment method for plastic substrate and anti-fog plastic prepared therefrom

ActiveCN104861192BImprove water resistanceAvoid anti-fog performance impactPolyether coatingsHyaluronic acid coatingsPolymer scienceHydrophilic polymers

The invention discloses a super-thermal hydrogen treatment method of durable anti-fog plastic sheet, which comprises the following steps: (1) pretreating a plastic substrate with a low-temperature plasma surface finishing machine; (2) spreading a solution containing polymer / nano-silica onto the surface of the pretreated plastic substrate; and (3) stoving the plastic substrate, and then performing super-thermal hydrogen treatment of the plastic substrate to obtain the durable anti-fog plastic sheet. The preparation technology of the durable anti-fog plastic sheet is green and environment-friendly, and can be used for directly grafting and modifying a common hydrophobic polymer substrate with a hydrophilic polymer, a final product has high transparency and a certain permeability improvement effect, and meanwhile the anti-fog performance of the surface of a sample is durable so as to overcome the defect of poor anti-fog durability of the conventional anti-fog product.

Owner:怀宁县成科新材料研究院有限公司

Antifoggant composition and antifog and heat-insulation colored window film formed by composition

InactiveCN102618101BGood anti-fog durabilityEasy to prepareOther chemical processesSynthetic resin layered productsPolyesterMonomethyl ether

Owner:西安航天三沃化学有限公司

A kind of long-acting antifogging agent for automobile glass and preparation method thereof

ActiveCN105713575BLong durationGood anti-fog performanceOther chemical processesPolyethylene glycolSilicon dioxide

The invention belongs to the technical field of preparation of anti-fog agents for automotive glass and particularly discloses a long-acting anti-fog agent for automotive glass and a preparation method of the anti-fog agent. The anti-fog agent comprises raw materials in percentage by mass as follows: 10%-15% of modified nano-silica sol, 1%-2% of a modified polyacrylate solution, 1%-3% of polyethylene glycol 1000, 2%-3% of OP-10, 0.5%-1% of sodium dodecyl sulfate, 0.5%-1% of sodium dodecylbenzenesulfonate, 8%-10% of glycerin, 5%-7% of propylene glycol, 15%-20% of ethyl alcohol and the balance of water, and the sum of total mass percentage composition is 100%. The anti-fog effect of the anti-fog agent is greatly enhanced through adoption of modified super-hydrophilic nano-silica; with adoption of the modified polyacrylate solution with better adhesion performance, super-hydrophilic nanoparticles and surfactant components can adhere to the glass without falling, so that the durability of the anti-fog agent is enhanced, and the anti-fog effect can be kept for 3 months.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Antifogging agent composition and transparent antifogging window membrane formed therefrom

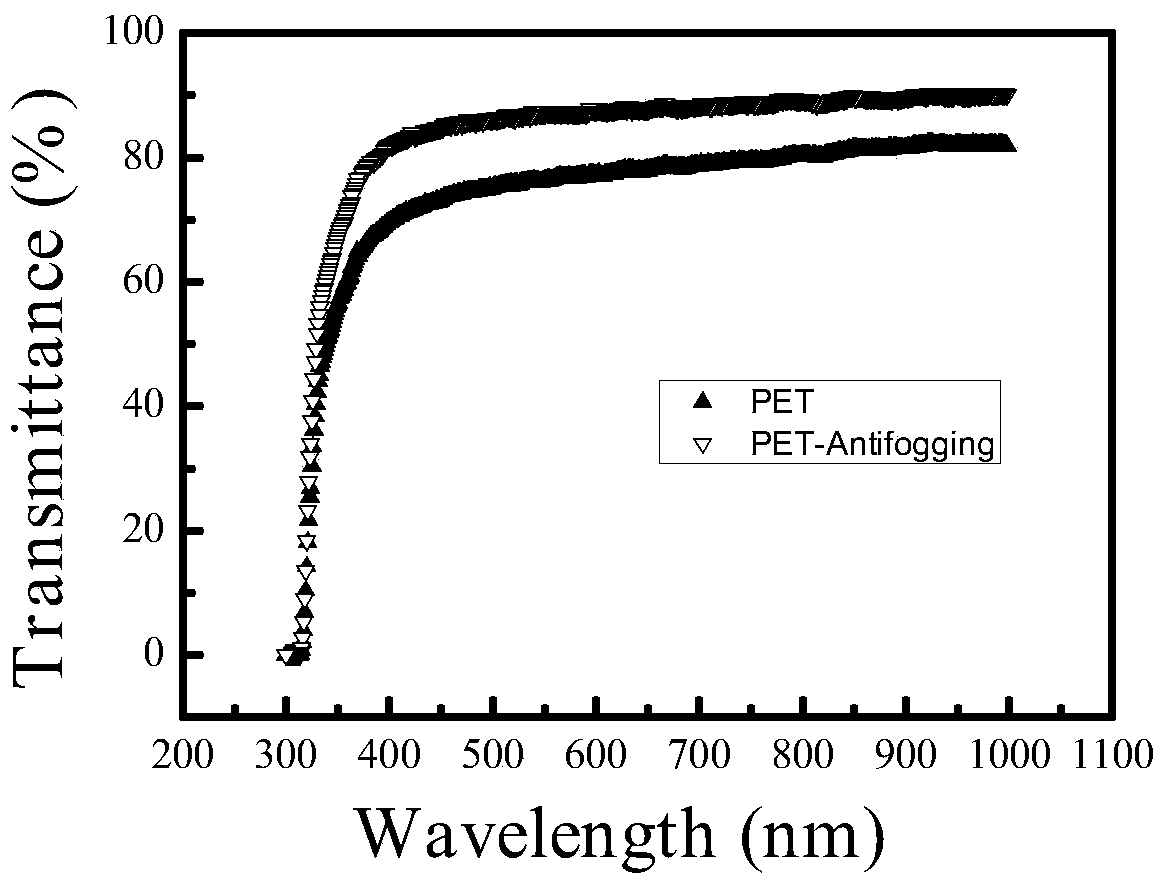

ActiveCN102627880BGood anti-fog durabilityEasy to prepareOther chemical processesFilm/foil adhesivesPolyesterOptical transmittance

The invention relates to an antifogging agent composition and a transparent antifogging window membrane formed from the composition. The antifogging agent composition consists of 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylenediamine, 1-5wt% of a levelling agent, 5-26wt% of isopropanol, and 5-24wt% of ethanol. The antifogging window membrane is composed of an antifogging agent coating (1), a transparent polyester membrane or transparent polyethylene membrane base material (2), an acrylic adhesive layer (3) and a release membrane (4), and all layers are integrated. The antifogging agent coating (1) is formed by the antifogging agent composition, while the acrylic adhesive layer (3) is formed by a mixture of an acrylic adhesive, a curing agent, toluene and butanone. The transparent antifogging window membrane has effective antifogging function and high light transmittance, as well as a protection effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

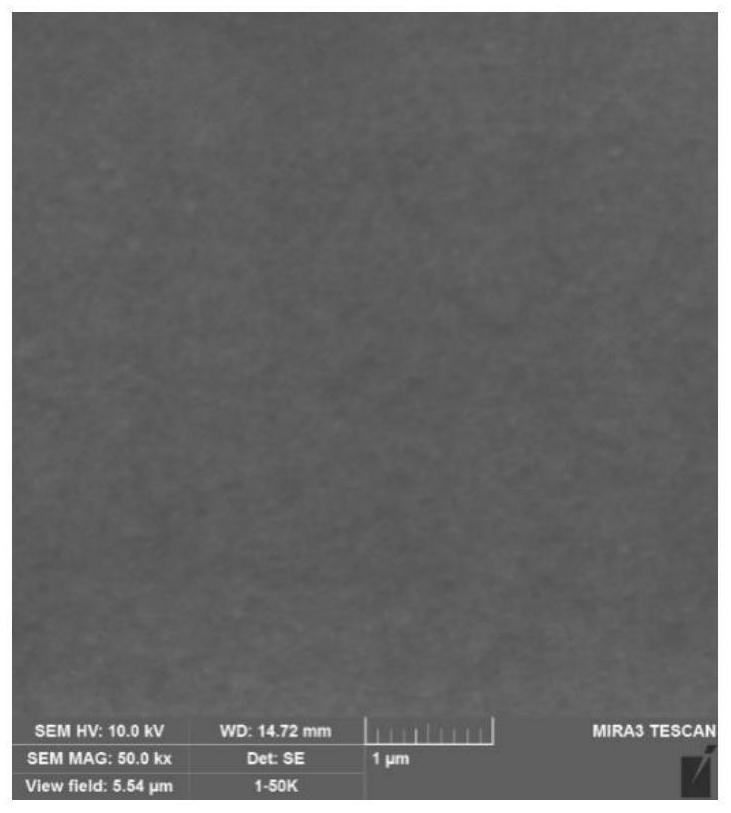

A kind of preparation method of water-based normal temperature self-crosslinking superhydrophilic anti-fog coating

ActiveCN109868025BNo pollution in the processImprove performanceCoatingsNano siliconWeather resistance

Owner:江西省龙海化工有限公司

Polyurethane coating composition, cured coating film and resin member

ActiveCN109306238BImprove scratch resistanceExcellent anti-fog persistencePolyurea/polyurethane coatingsPolymer sciencePolyol

The present invention provides a one-component polyurethane coating composition capable of forming a cured coating film having good scratch resistance and excellent anti-fog persistence, and a resin member having the cured coating film. The polyurethane coating composition contains a specific amount of polyisocyanate (a), polyether polyol (b) and surfactant (c), and the polyether polyol (b) has a number average molecular weight of more than 300 and less than 600 Polyether polyol (b‑1), polyether polyol (b‑2) with number average molecular weight of 600 to 900, polyether polyol (b‑3) with number average molecular weight of 900 to 1800, all The above-mentioned surfactant (c) is an ionic surfactant having a hydroxyl group in a molecule, an anionic surfactant and / or an amphoteric surfactant not having a group reactive with an isocyanate group.

Owner:NOF CORP

Transparent anti-fog window film that blocks UV rays

ActiveCN104149432BExtend the life cycleReduce photodegradationSynthetic resin layered productsPolyesterAcrylic resin

The invention relates to an ultraviolet-blocking transparent antifogging window film. The ultraviolet-blocking transparent antifogging window film consists of an antifogging layer (1), a first transparent polyester film or polyethylene film base material (2-1), a first ultraviolet-blocking pressure-sensitive adhesive layer (3-1), a second transparent polyester film or polyethylene film base material (2-2), a second ultraviolet-blocking pressure-sensitive adhesive layer (3-2) and a release film (4) which are compounded into a whole, wherein the antifogging layer (1) is made from an antifogging agent composition consisting of hydrophilic thermocuring solvent-type acrylic resin SAA901, propylene glycol methyl ether, dimethyl formamide, a catalyst triethylenediamine, a leveling agent, isopropyl alcohol and ethanol; both the first ultraviolet-blocking pressure-sensitive adhesive layer (3-1) and the second ultraviolet-blocking pressure-sensitive adhesive layer (3-2) are made from a mixed material consisting of a benzophenone ultraviolet absorbent, a benzotriazole ultraviolet absorbent, acrylic adhesive, a curing agent and a solvent. The ultraviolet-blocking transparent antifogging window film can block ultraviolet lastingly and prevent fog lastingly.

Owner:江苏航天山由科技有限公司

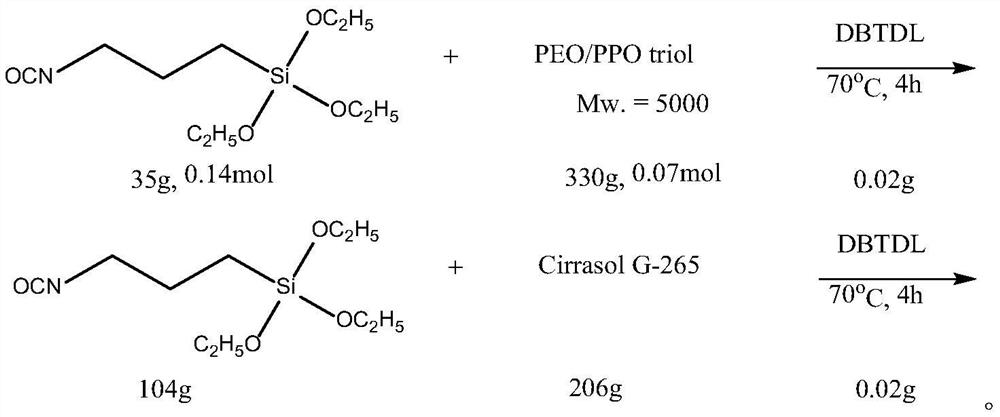

A kind of polysiloxane and its application

The invention discloses a polysiloxane and an application thereof. The polysiloxane is formed by reacting a semi-closed isocyanate prepolymer and an organic polymer silanol. The polysiloxane itself has an anti-fog function, and applying the polysiloxane to the anti-fog coating can realize UV curing and increase the hardness of the coating.

Owner:武汉中科先进材料科技有限公司

Anti-fogging agent composition and anti-fogging insulation window film formed thereby

InactiveCN102604460BGood anti-fog durabilityEasy to prepareFilm/foil adhesivesSynthetic resin layered productsPolyesterMonomethyl ether

The invention relates to an anti-fogging agent composition and an anti-fogging insulation window film formed thereby, wherein the anti-fogging agent composition comprises 9 to 14 wt% of hydrophilic resin, 55 to 76 wt% of propylene glycol monomethyl ether, 3 to 10 wt% of dimethyl methylamine, 1 to 5 wt% of triethylene diamine, 1 to 5 wt% of leveling agent, 5 to 26wt% of isopropanol and 5 to 24wt% of ethanol; the anti-fogging insulation window film comprises a first transparent polyester film or transparent polyethylene film substrate (2-1), a heat insulation acrylic adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic adhesive layer (3-2) and a release film (4), which are composited as a whole, wherein the anti-fogging coating (1) is formed by the anti-fogging agent composition; and the heat insulation acrylic adhesive layer (3-1) contains a specific insulation material. According to the invention, the anti-fogging insulation window film is anti-fogging, insulating and safe.

Owner:西安航天三沃化学有限公司

A kind of preparation method of urethane acrylate anti-fog coating containing hydroxyl ammonium salt cured by UV

ActiveCN112625590BImprove hydrophilicityGood anti-fog effectPolyurea/polyurethane coatingsArchitectural glassPolymer science

The invention discloses a method for preparing a UV-cured urethane acrylate anti-fog coating containing hydroxyl ammonium salt, which belongs to the technical field of acrylate preparation. The present invention synthesizes a monomer with ammonium salt, and then introduces it into the urethane acrylate oligomer. The product contains hydrophilic hydroxyl group and quaternary ammonium salt, which provides good hydrophilicity. It brings excellent anti-fog effect, good anti-fog durability, simple implementation method and short curing time, and realizes efficient process output. It can be widely used in fields requiring high anti-fog effects, such as architectural glass, automotive glass, and optical devices.

Owner:JIANGNAN UNIV

High-wear-resistance hydrophilic resin, high-wear-resistance solvent-free anti-fog coating and preparation method and application thereof

ActiveCN113603850AHigh hardnessHigh functionalityPolyurea/polyurethane coatingsPolymer scienceHydrophilic polymers

The invention discloses high-wear-resistance hydrophilic resin, a high-wear-resistance solvent-free anti-fog coating and a preparation method and application thereof. The anti-fog coating comprises the following components: the high-wear-resistance hydrophilic resin, hydrophobic resin, a reactive diluent, a photoinitiator and an auxiliary agent, the hydrophilic resin is a UV-curable hydrophilic polymer designed by the invention. The hydrophilic resin with high wear resistance is designed and applied to an antifogging formula to obtain the high-wear-resistance solvent-free antifogging coating, and the coating is safe and non-toxic, can form a film on various types of base materials, can be rapidly cured under ultraviolet irradiation, has high bonding strength with the base materials, yhe formed coating has good transparency, wear resistance and chemical resistance, and has excellent antifogging performance.

Owner:武汉中科先进材料科技有限公司

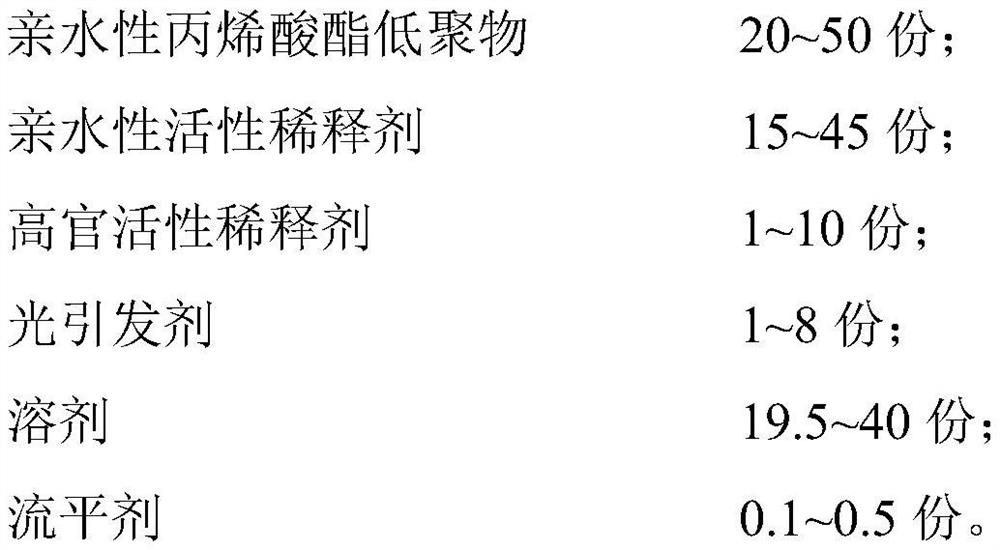

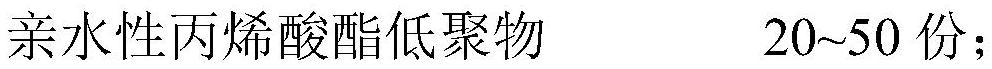

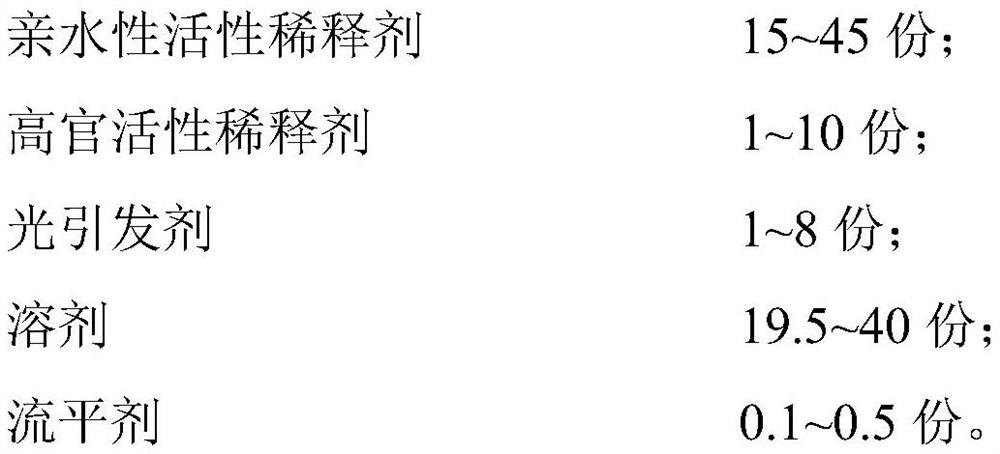

UV antifogging coating for protective mask and preparation method of UV antifogging coating

PendingCN114456700ALow costImprove water resistancePolyurea/polyurethane coatingsOligomerAcrylate ester

The invention relates to a UV anti-fog coating for a protective mask and a preparation method of the UV anti-fog coating. The anti-fog coating comprises the following components in parts by weight: 20-50 parts of hydrophilic acrylate oligomer; 15 to 45 parts of a hydrophilic reactive diluent; 1-10 parts of a high-functionality reactive diluent; 1-8 parts of a photoinitiator; 19.5 to 40 parts of a solvent; and 0.1-0.5 part of a leveling agent. The preparation method comprises the following steps: mixing the hydrophilic acrylate oligomer, the hydrophilic active diluent, the high-functional-group active diluent, the solvent and the photoinitiator, and then adding the flatting agent to obtain the UV anti-fog coating for the protective mask. Compared with the prior art, the prepared UV-cured super-hydrophilic anti-fog coating can be rapidly cured, the coating stability is good, the content of hydrotropic substances of the raw materials is high, the hydrophilic performance is excellent, the water resistance and the wear resistance are excellent due to the high-functional-group reactive diluent, the industrially-produced UV diluent with polyhydroxy groups is adopted to replace hydrophilic acrylate oligomer, and the cost is low.

Owner:DONGLAI COATING TECH SHANGHAI

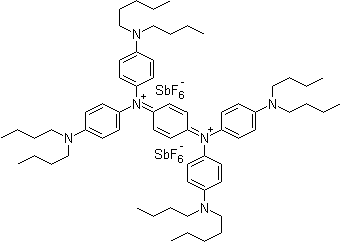

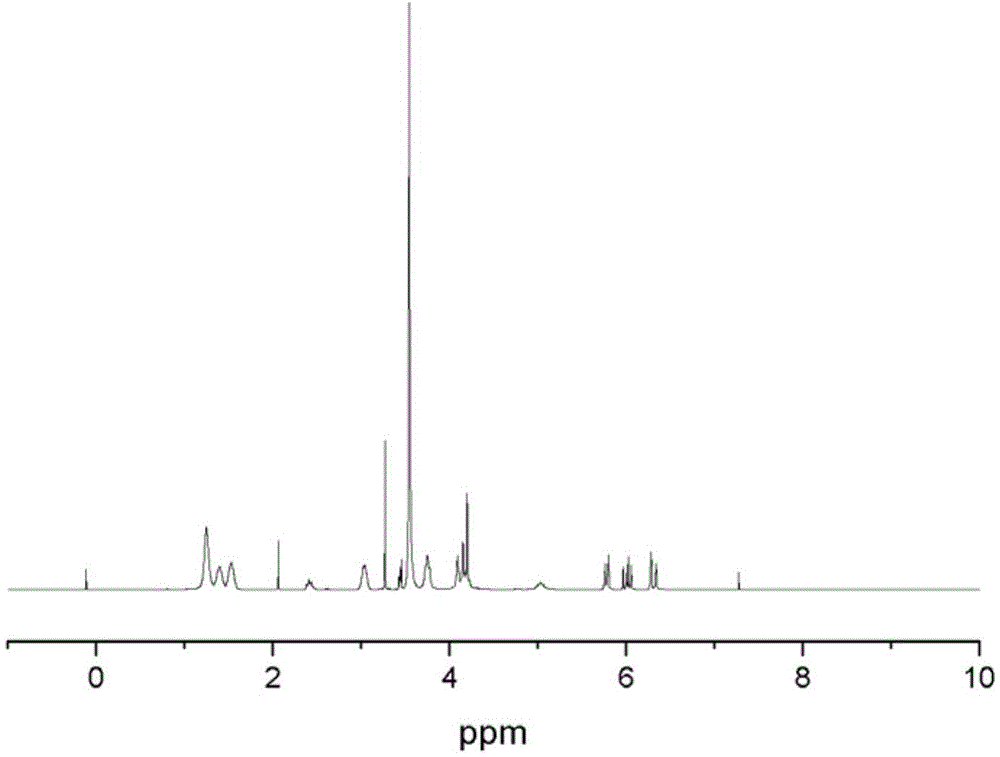

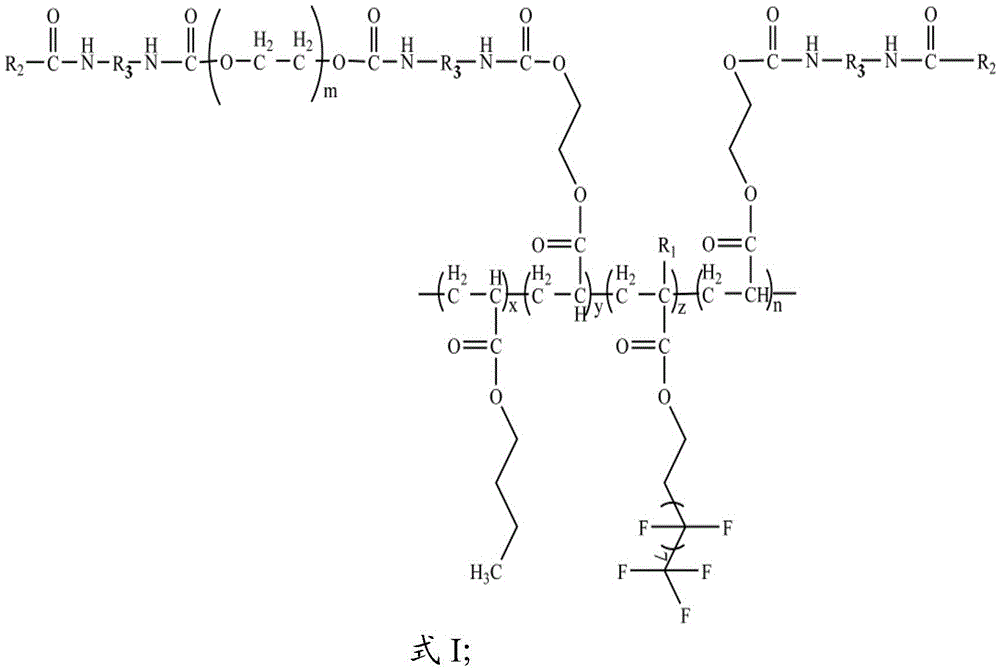

A kind of urethane acrylate oligomer, its preparation method and ultraviolet curing anti-fog coating

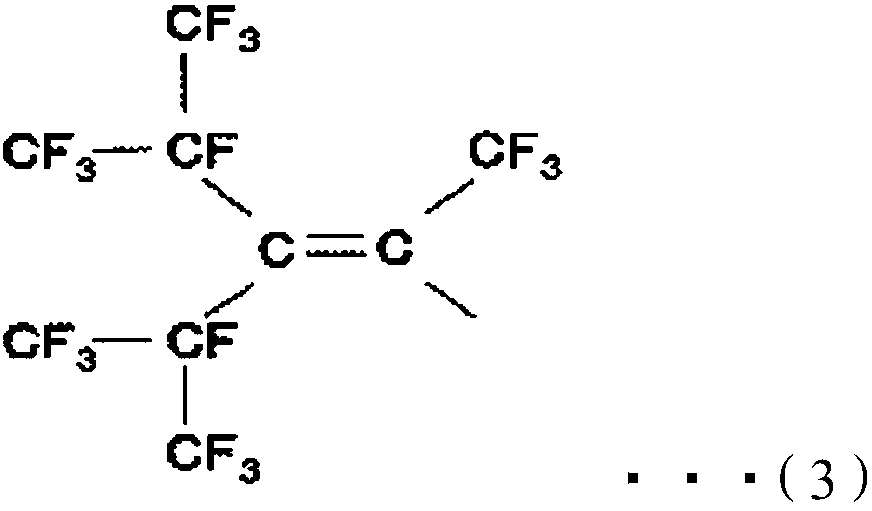

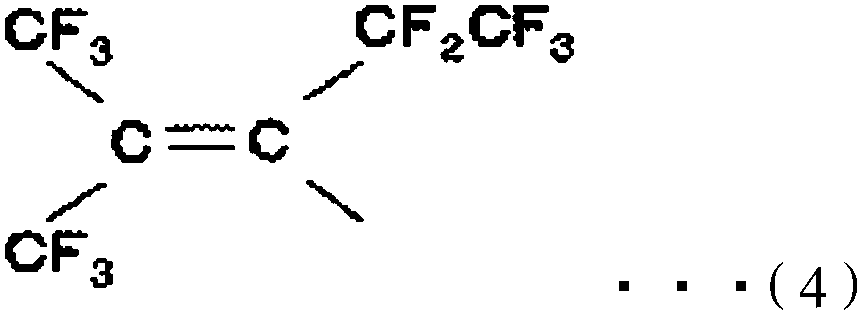

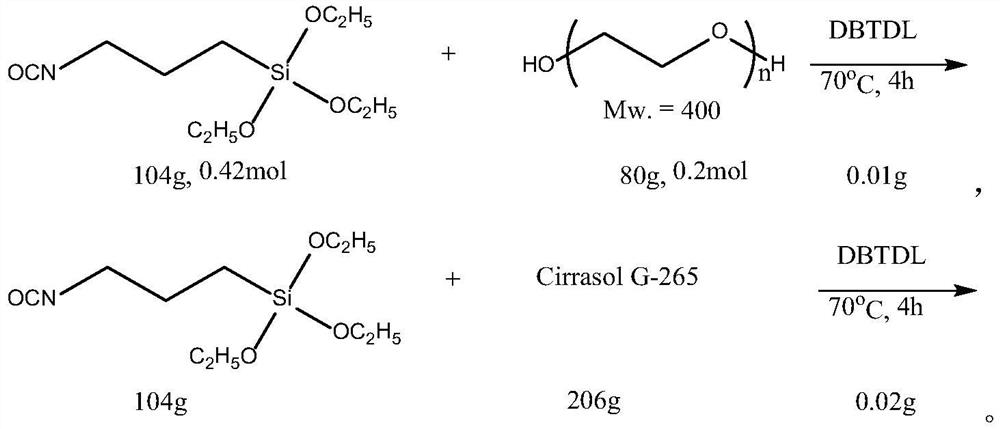

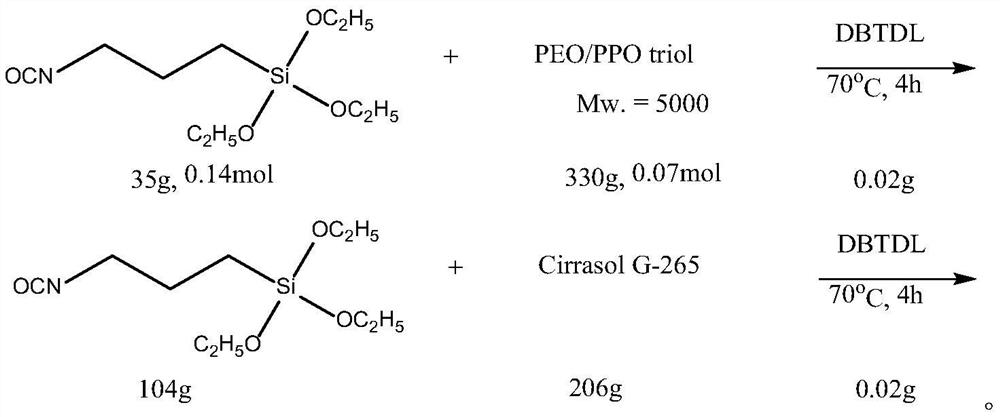

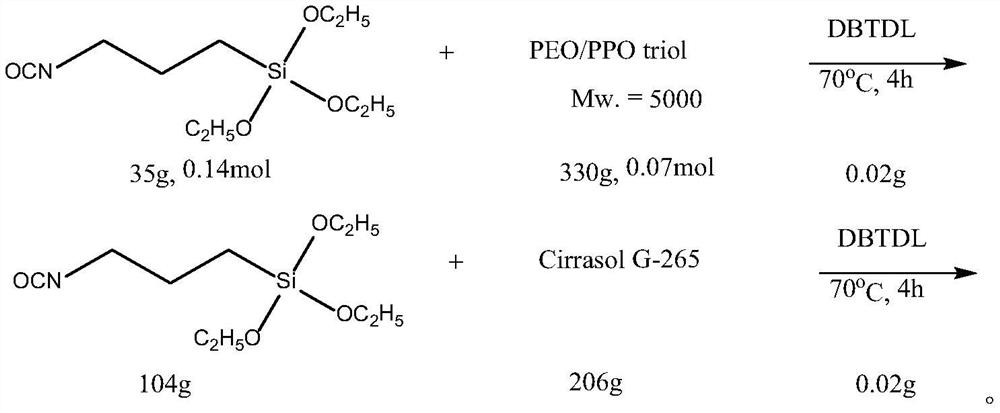

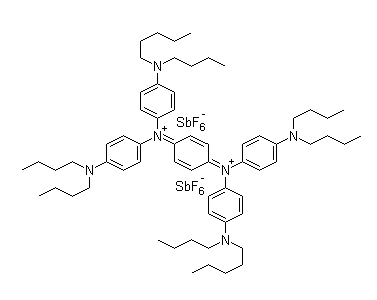

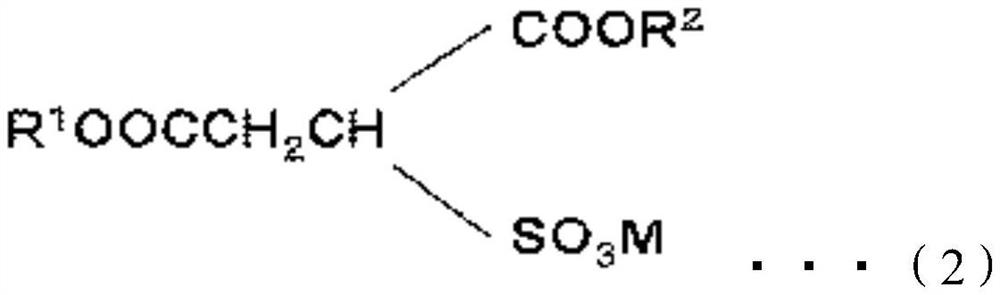

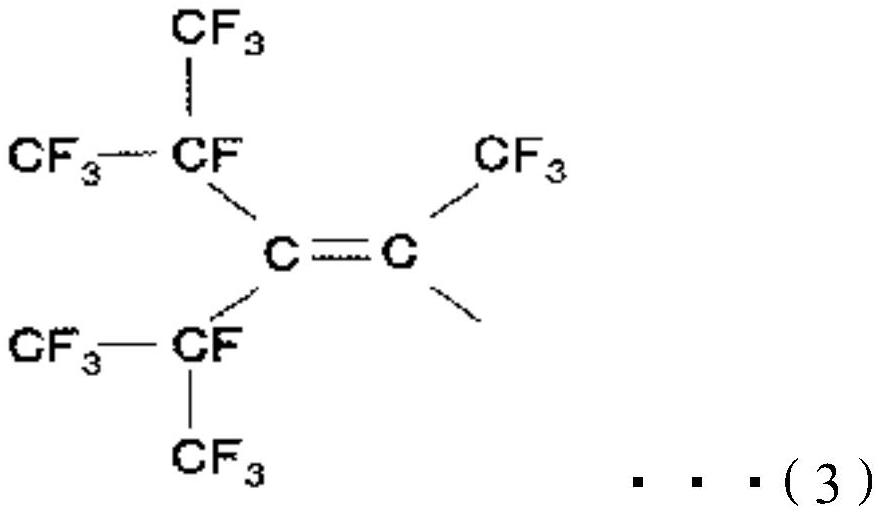

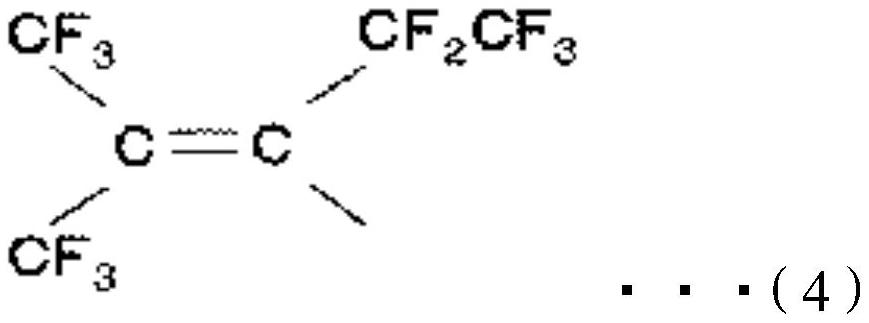

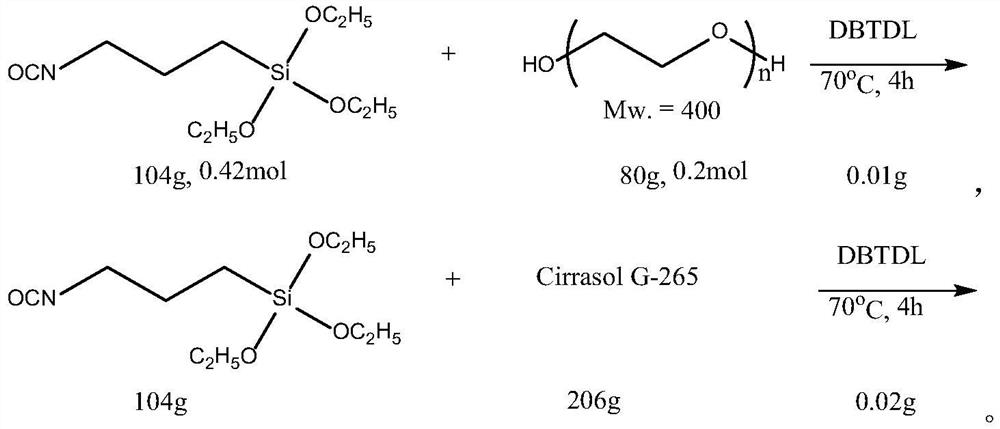

ActiveCN103980455BHydrophilicLower surface energyPolyurea/polyurethane coatingsUltravioletUrethane acrylate

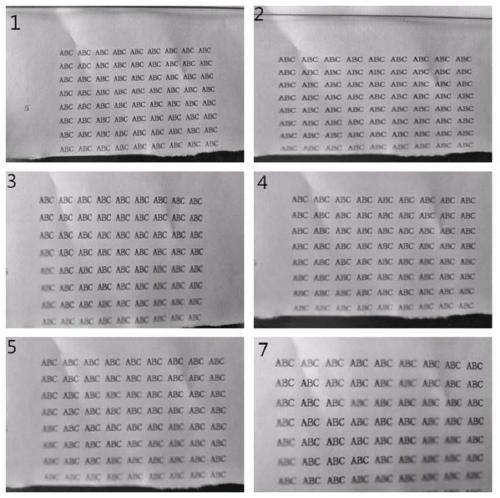

The invention provides a urethane acrylate oligomer, which has a structure shown in a formula I. The urethane acrylate oligomer with the structure shown in the formula I is taken as matrix resin, and the ultraviolet-curing antifogging coating is provided, and comprises the urethane acrylate oligomer, a flatting agent, a defoamer, a photoinitiator and a silane coupling agent. The urethane acrylate oligomer provided by the invention comprises an ethoxy group and a fluoride group; the urethane acrylate oligomer has hydrophily by the ethoxy group; the urethane acrylate oligomer has low surface energy by the fluoride group, so that the ultraviolet-curing antifogging coating has lasting anti-fog performance. The experiment result shows that the primary anti-fog performance of the film cured by the ultraviolet-curing antifogging coating provided by the invention can be up to 10 levels, and the anti-fog persistence can be up to 8-10 levels.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com