High-wear-resistance hydrophilic resin, high-wear-resistance solvent-free anti-fog coating and preparation method and application thereof

A technology of hydrophilic resin and anti-fog coating, applied in the field of coatings, can solve the problems of difficult to obtain wear-resistant anti-fog performance coating, unfavorable green sustainable development, difficult unblocking reaction, etc., and achieve continuous hydrophilic anti-fog performance , Excellent anti-fog effect, good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

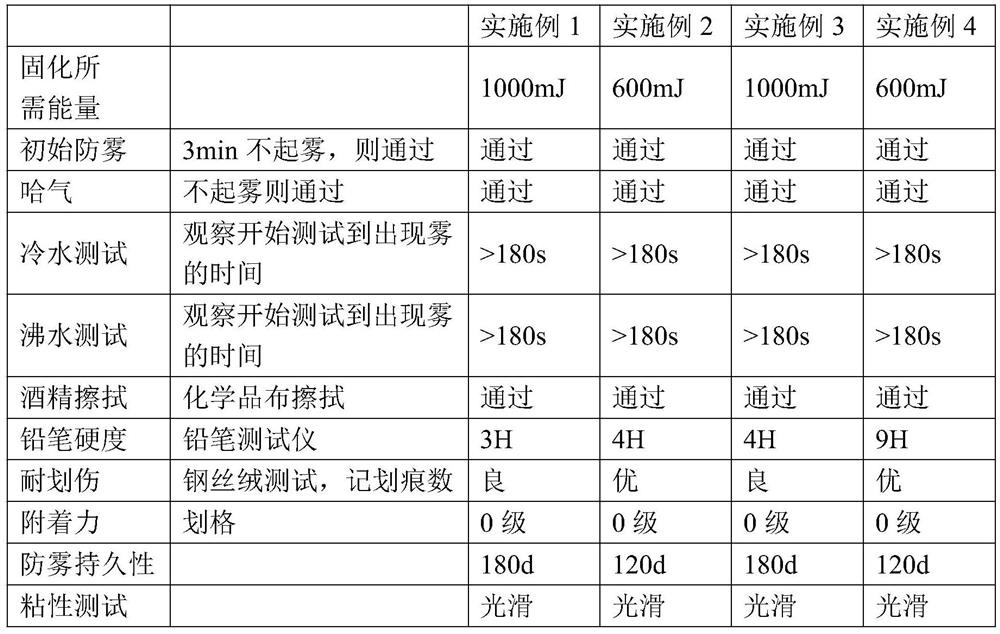

Embodiment 1

[0032] 1. Preparation of high wear-resistant hydrophilic resin:

[0033] (a) Add 8.46g (0.02mol) isocyanurate triacrylate and 4.2g (0.04mol) diethanolamine to a 100mL three-necked flask, start stirring and raise the temperature to 65°C for 2 hours to obtain a hydrophilic modified prepolymer 1;

[0034](b) Take another 100mL three-neck flask, add 17.78g (0.08mol) isophorone diisocyanate and 0.021g (0.05wt%) dibutyltin dilaurate and start stirring; another 0.11g (0.262wt%) is weighed in turn p-Hydroxyanisole, 0.22g (0.525wt%) 2,6-di-tert-butyl-4-methylphenol and 24.0g (0.04mol) polyethylene glycol monomethyl ether 600 and 11.92g (0.04mol) pentaerythritol Triacrylate (PETA), fully mixed until completely dissolved, transferred to a constant pressure dropping funnel, and slowly added dropwise to the above-mentioned three-necked flask at room temperature (the reaction is violently exothermic, control the dropping speed to avoid local overheating), drop it After continuing to react...

Embodiment 2

[0040] 1. Preparation of high wear-resistant hydrophilic resin:

[0041] (a) Add 40.11g (0.03mol) glycidyl etheroxypropyl caged polysilsesquioxane and 25.23g (0.24mol) diethanolamine to a 250mL three-necked flask, start stirring and raise the temperature to 65°C for 2 hours to obtain the Water-modified prepolymer 1;

[0042] (b) Take another 500mL three-necked flask, add 125.92g (0.48mol) dicyclohexylmethane diisocyanate and 0.13g (0.05wt%) dibutyltin dilaurate and start stirring; another 0.695g (0.262wt%) p-Hydroxyanisole, 1.39g (0.525wt%) 2,6-di-tert-butyl-4-methylphenol and 64.6g (0.1mol) octylphenol ethoxylate (OP-10), 40g (0.08 mol) polyethylene glycol monomethyl ether 500 and 34.83g (0.3mol) hydroxyethyl acrylate, fully mixed until completely dissolved, transferred to a constant pressure dropping funnel, and slowly added dropwise to the above-mentioned three-necked flask at room temperature (the The reaction is violently exothermic, control the drop rate to avoid local...

Embodiment 3

[0047] 1. Preparation of high wear-resistant hydrophilic resin:

[0048] (a) Add 17.35 g (0.03 mol) of dipentaerythritol hexaacrylate and 9.46 g (0.09 mol) of diethanolamine into a 100 mL three-necked flask, start stirring and raise the temperature to 65 ° C for 2 h to obtain a hydrophilic modified prepolymer 1;

[0049] (b) Take another 250mL three-necked flask, add 40.01g (0.18mol) isophorone diisocyanate and 0.055g (0.05wt%) dibutyltin dilaurate and start stirring; another 0.29g (0.262wt%) is weighed in turn p-Hydroxyanisole, 0.58g (0.525wt%) 2,6-di-tert-butyl-4-methylphenol and 59.4g (0.09mol) nonylphenol ethoxylate (TX-10) and 11.71g ( 0.09mol) of hydroxypropyl acrylate, fully mixed until completely dissolved, transferred to a constant pressure dropping funnel, and slowly added dropwise to the above-mentioned three-necked flask at room temperature (the reaction is violently exothermic, control the drop rate to avoid local overheating), drop After continuing the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com