Anti-mist liquid, anti-mist cloth and preparation method of anti-mist cloth

An anti-fog liquid and anti-fog technology, applied in chemical instruments and methods, other chemical processes, textiles and papermaking, etc., can solve the problems of insufficient anti-fog effect, aerosol pollution safety, slow drying speed, etc., and achieve improved Anti-fog persistence, speed up solution volatilization, and reduce the effect of fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

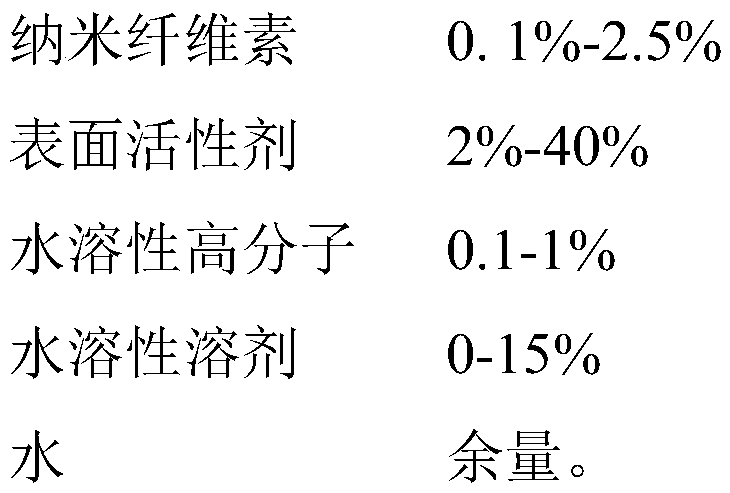

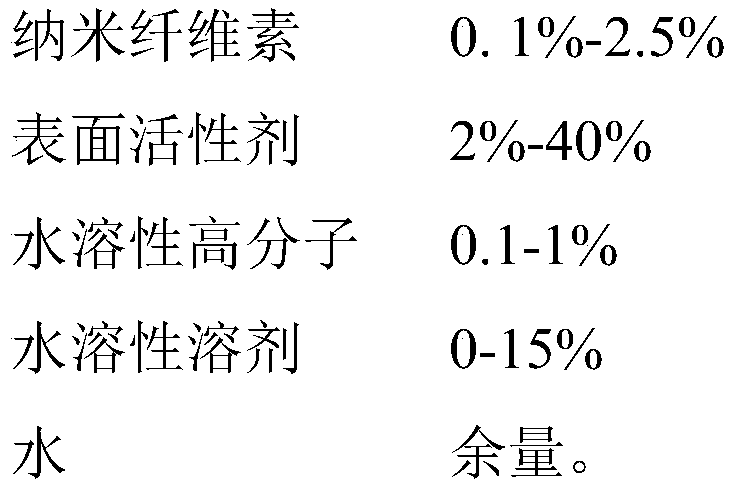

Method used

Image

Examples

Embodiment 1

[0029] An anti-fog liquid, which comprises 1% by mass of nanocellulose, 20% by mass of fatty alcohol polyoxyethylene ether (tergitol 15-s-7), 0.25% by mass of polyethylene oxide, 10% by mass of of ethanol, and the balance is water. Wherein, the nanocellulose is nanocellulose with negatively charged carboxyl groups on the surface, and the diameter of the nanocellulose is 3-6 nm; the length is 400-800 nanometers.

[0030] The method of using the anti-fog solution described in this example to prepare an anti-fog cloth is as follows: take the non-woven fabric of the same quality and the anti-fog solution described in this example, immerse the non-woven fabric in the anti-fog solution, and wait until the anti-fog solution is completely covered. After the non-woven fabric is absorbed, it is dried to obtain an anti-fog cloth.

[0031] Each component of the obtained anti-fog cloth accounts for the mass content of the dry weight of the nonwoven fabric: the mass content of nanocellulos...

Embodiment 2

[0034] An anti-fog liquid, which comprises 0.5% by mass of nanocellulose, 15% by mass of dodecyl glucoside, 0.5% by mass of polyacrylic acid, and the balance being water. The nanocellulose is nanocellulose with negatively charged phosphoric acid groups on the surface.

[0035] The method of using the anti-fog solution described in this example to prepare the anti-fog cloth is as follows: take the non-woven fabric and the anti-fog solution described in this example with twice the mass of the non-woven fabric, immerse the non-woven fabric in the anti-fog solution, and wait for the anti-fog solution After the fog liquid is completely absorbed by the non-woven fabric, it is dried to obtain the anti-fog cloth.

[0036] The weight content of each component of the obtained anti-fog cloth based on the dry weight of the non-woven fabric is as follows: the weight content of nanocellulose is 1%, the weight content of lauryl glucoside is 30%, and the weight content of polyacrylic acid is ...

Embodiment 3

[0039] An anti-fog liquid, which comprises 2% by mass of nanocellulose, 20% by mass of cationic fluorocarbon surfactant, 20% by mass of dodecyl glucoside, and 0.2% by mass of polyvinyl alcohol, The balance is water. The nanocellulose is nanocellulose with negatively charged phosphoric acid groups on the surface.

[0040] The method of using the anti-fog solution described in this example to prepare an anti-fog cloth is as follows: take the non-woven fabric of the same quality and the anti-fog solution described in this example, immerse the non-woven fabric in the anti-fog solution, and wait until the anti-fog solution is completely covered. After the non-woven fabric is absorbed, it is dried to obtain an anti-fog cloth.

[0041] The mass content of each component of the obtained anti-fog cloth in the dry weight of the non-woven fabric is: the mass content of nanocellulose is 2%, the mass content of cationic fluorocarbon surfactant is 20%, and the mass content of dodecyl gluco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com