A kind of preparation method of water-based normal temperature self-crosslinking superhydrophilic anti-fog coating

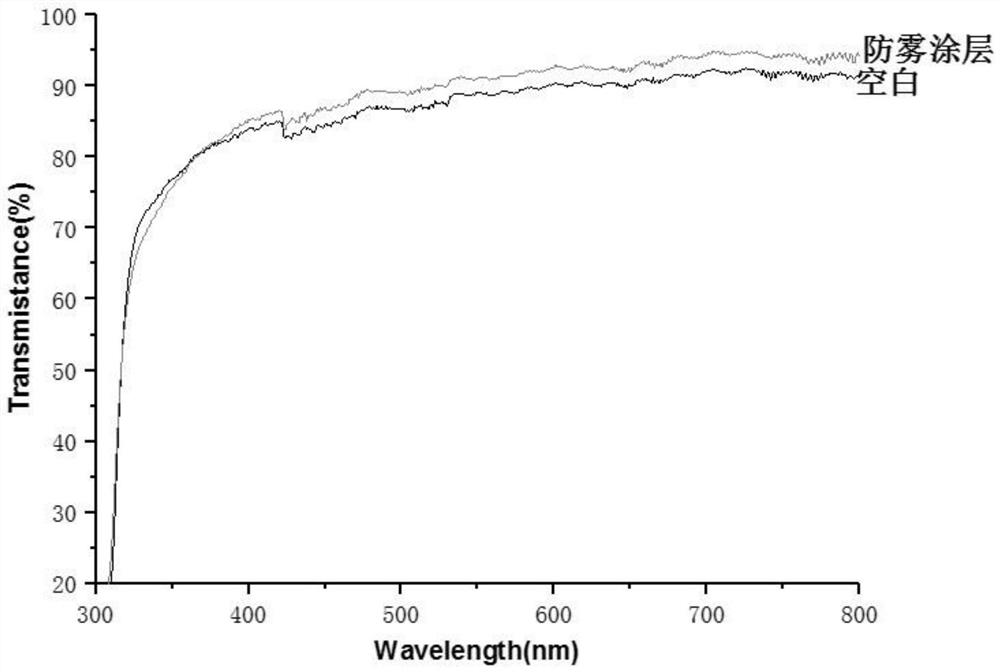

An anti-fog coating and super-hydrophilic technology, applied in the direction of coating, can solve the problems of poor weather resistance, not resistant to washing, not resistant to wiping, etc., and achieve the effect of excellent comprehensive performance, good anti-fog durability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 30 g of acrylic, 10 g of hydroxyethyl ethyl ester, 100 g acrylamide, 5G vinyl triethoxysilane and 1 g of azo diisobutyronitrile were added to the reactor containing 200 g of water-free ethanol, and the mixture was constructed after mixing. The reaction was stirred in a water bath at 70 ~ 80 ° C for 30 to 40 min, and 55 g of 55 g of a mass ratio of 4: 6 is prejected in advanced mohal methanol methyl methacrylate and an ethyl acrylate mixed solution, dripping The acceleration was controlled at 0.5 to 1 drop / s, and then the constant temperature was continued after 4 to 5 h after 2.5 h, after the reaction was completed, anhydrous ethanol was added to a polyacrylate solution having a mass concentration of 30%.

[0039] Take 30 g of tetraeth ester (TEOS) is dispersed in 51 g of anhydrous ethanol. After stirring is uniform, 12 g of deionized water and 3 g of glacial acetic acid are added, and stirred at room temperature for 40min, and then drop 6 gγ-shrinkage Glycerol ether oxyl...

Embodiment 2

[0043] 115 g of acrylic acid, 10 g of methacrylic acid, 15 g n-hydroxymethyl acrylamide, 5 gγ-methacryloyloxypropyltrimethoxysilane and 1 g of oxidative dibenzoyloylophytic acid were added to the loaded 200 g of isopropyl alcohol In the reactor, the mixture was stirred even after mixing, the reaction was stirred in a water bath of 70 to 80 ° C for 30 to 40 min, and the reaction to the system was added dropwise to 5: 5 in advance of 5: 5, methacrylic acid. The methyl ester and acrylate mixed solution were controlled at 0.5 to 1 drop / s. After the mixture was added, the reaction was continued for 4 to 5 hours, and after the reaction was completed, the addition of isopropyl alcohol was diluted with a mass concentration of 30% polyacrylic acid. Ester solution.

[0044] Take 20 g of tetraeth (TEOS) is dispersed in 72 g of isopropyl alcohol. After stirring is uniform, 7 g of deionized water and 1 g hydrochloric acid are added, and stirred at room temperature for 40min, and then add 1 g...

Embodiment 3

[0048] 80 g of acrylic acid, 35 g n, N-dimethylacrylamide, 10 g ethyl methacrylic acid, 15 g N-hydroxymethyl acrylamide, 5 gγ-methylproxylpropyl trimethoxysilane and 1 g of diioxide The formyl addition to the reaction vessel containing 200 g isopropyl alcohol, stirred even after mixing the system in a water bath of 70 to 80 ° C for 30 min, then adding 55g to the system to pre-mass ratio of 6: 4 The methyl methacrylate and acrylate mixed solution dispersed in isopropyl alcohols, and the drip speed is controlled at 0.5 to 1 drip / s. After the dropwise addition, the constant temperature is continued for 4 to 5 hours, and the reaction is completed, and isopropion The alcohol is diluted to a polyacrylate solution having a mass concentration of 20%.

[0049] Take 20 g of tetraethyl ester (TEOS) in 72 g of isopropyl alcohol, and then stirred and uniform, 7 g of deionized water and 1 g hydrochloric acid were added, and stirred at normal temperature for 40min, and then dropped with 3 gamm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com