A kind of preparation method of urethane acrylate anti-fog coating containing hydroxyl ammonium salt cured by UV

A technology of ester acrylate and carbamic acid, which is applied in the field of acrylate preparation, can solve problems such as fogging, limiting light transmission and optical efficiency, and achieve the effects of reducing contact angle, high process yield, and improving curing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

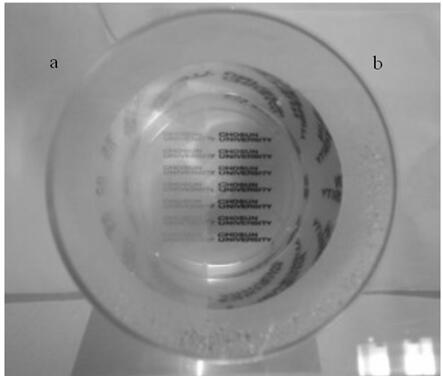

Image

Examples

Embodiment 1

[0021] (1) Synthesis of ammonium salt monomer: Add 10.16 g (0.166 mol) of ethanolamine into a 250 mL three-necked flask equipped with a water bath, thermometer, reflux condenser, dropping funnel, and magnetic stirring bar, and heat under stirring to 60°C. 86.55 g (0.357 mol) of carbon dodecyl to tetradecyl glycidyl ether was slowly added, and the mixture was reacted at 70° C. for 2 h. 20.9g (0.166mol) of dimethyl sulfate and 29.8g (0.4138mol) of methyl ethyl ketone were added dropwise to the stirred mixture while keeping the temperature at 60°C and reacted for 3h to obtain ammonium salt monomer.

[0022] (2) Preparation of urethane acrylate oligomer with ammonium salt: Add 34.5g IPDI (0.16mol) and 100g PETA (0.32mol) at 10°C under stirring, add 0.02g (0.0001 mol) dibutyltin dilaurate (DTBDL). After the addition was complete, the mixture was stirred at 10 °C for 4 h. Then, 20 mL of methyl ethyl ketone and 96.2 g of AS monomer (0.16 mol) were added to the above reaction produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com