Preparation method of a heat-insulating, anti-fog, self-cleaning superhydrophilic transparent coating

A transparent coating and self-cleaning technology, applied in the field of preparation of super-hydrophilic transparent coatings, can solve the problems of poor thermal insulation effect, poor anti-fog durability, and single function of thermal insulation coating, and achieve excellent thermal insulation function , the effect of improving water resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of a heat-insulating, anti-fog self-cleaning super-hydrophilic transparent coating, the specific steps are:

[0038] Step 1: Prepare nano-insulation powder slurry dispersion; weigh nano-insulation powder, solvent and dispersant, place them in a ball mill, and weigh zirconia balls according to the ratio of 4:1 to 8:1 The ball mill speed is 400r / min, and the ball milling time is 4-8h. After ball milling, a uniformly dispersed nano-insulation powder dispersion slurry is obtained. The mass of nano-insulation powder accounts for 20%-30% of the mass of the dispersion slurry, the mass of the solvent accounts for 61%-76% of the mass of the dispersion slurry, and the mass of the dispersant accounts for 4%-9% of the mass of the dispersion slurry; The heat insulating powder is one or more mixtures of lanthanum hexaboride, tin antimony oxide and cesium tungsten bronze powder; the solvent is one or more of pure water, ethanol, isopropanol, ethyl acetate or A m...

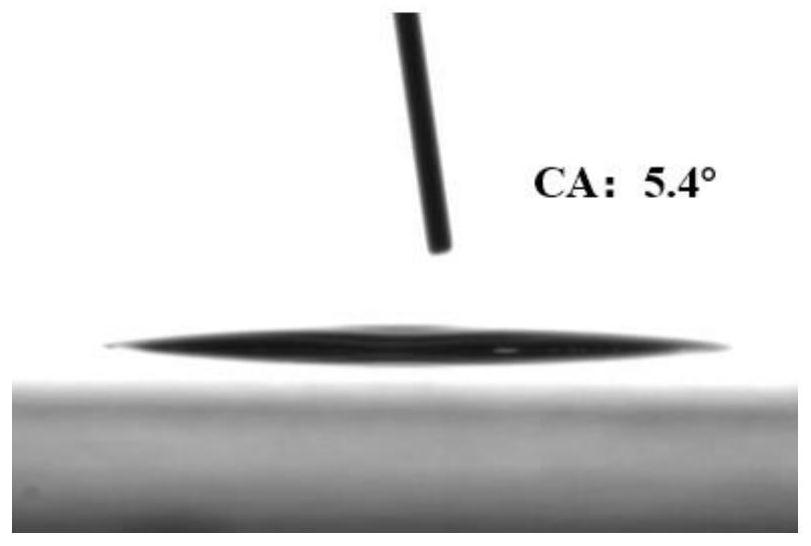

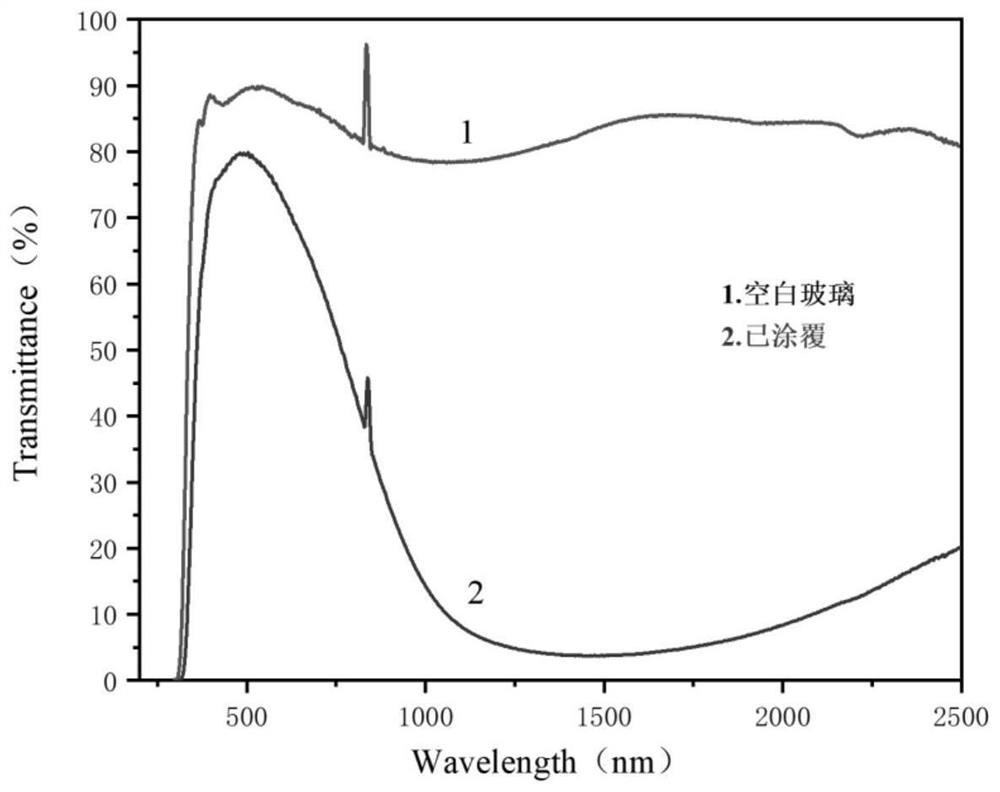

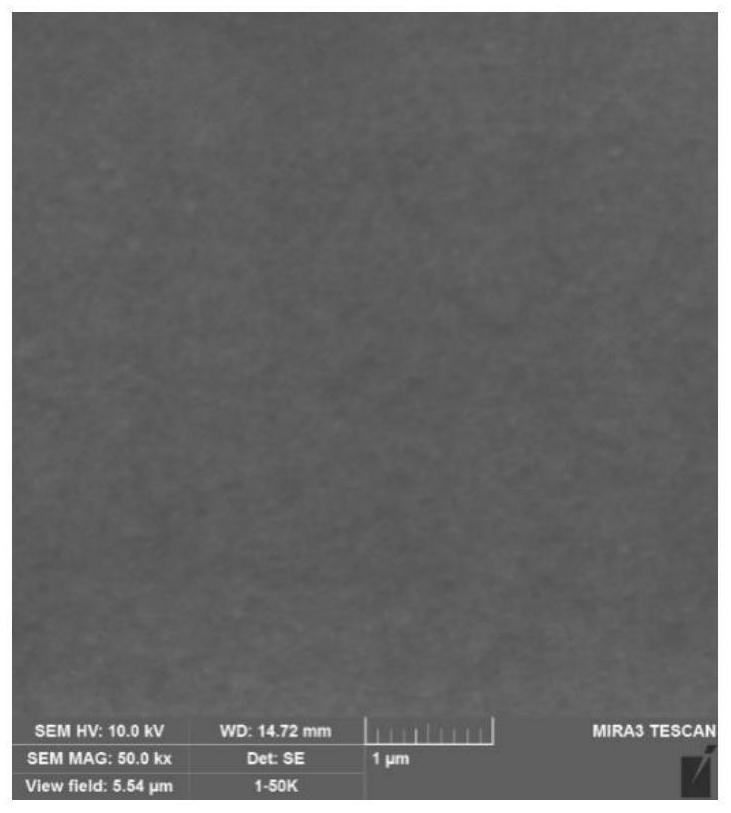

Embodiment 1

[0044] Weigh 3g of nano-cesium tungsten bronze, 6.1g of ethanol, and 0.9g of acid group-containing polyester dispersant and place them in a ball mill. The ball milling time was 4h. After ball-milling, nano cesium tungsten bronze dispersion slurry (the solid content of cesium tungsten bronze is 30%) is obtained. Disperse 0.3g of polyacrylic acid aqueous solution and 0.7g of polypropylene glycol-400 in 2.4g of ethanol, stir magnetically for 10min uniformly, then add 0.08g of γ-methacryloyloxypropyltrimethoxysilane to it, and then magnetically stir it at room temperature. After stirring for 30min, a hydrophilic polymer solution with a certain degree of crosslinking was obtained. Then take 1g of nano-cesium tungsten bronze dispersion slurry into a hydrophilic polymer with a certain degree of cross-linking, add 0.05g of leveling agent, stir magnetically for 30min, and then spray the solution on the surface of the glass substrate. The glass was baked in an oven at 80°C for 30 minu...

Embodiment 2

[0046] Weigh 2g of nano-cesium tungsten bronze, 7.6g of pure water, and 0.4g of polyfatty acid oligomer dispersant and place them in a ball mill. The ball milling time was 4h. After ball-milling, nano cesium tungsten bronze dispersion slurry (the solid content of cesium tungsten bronze is 20%) is obtained. Disperse 0.4g maleic anhydride and 0.6g polyvinyl alcohol in 2.4g pure water, stir magnetically for 10min uniformly, add 0.1g γ-aminopropyltriethoxysilane to it, and stir magnetically for 30min at room temperature, both A hydrophilic polymer solution with a certain degree of crosslinking is obtained. Then take 1g of nano-cesium tungsten bronze dispersion slurry into a hydrophilic polymer with a certain degree of cross-linking, add 0.05g of leveling agent, stir magnetically for 30min, and then spray the solution on the surface of the glass substrate. The glass was baked in an oven at 80°C for 30 minutes, and the coating was obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com