Ultraviolet light cured antifogging coating

An anti-fog coating and ultraviolet light technology, applied in the coating and other directions, can solve the problems of difficulty in achieving both wear resistance, water resistance and anti-fog performance, inability to achieve anti-fog effect, and swelling on the surface of the anti-fog coating. Long-lasting anti-fog performance, excellent anti-fog durability, and the effect of reducing migration tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

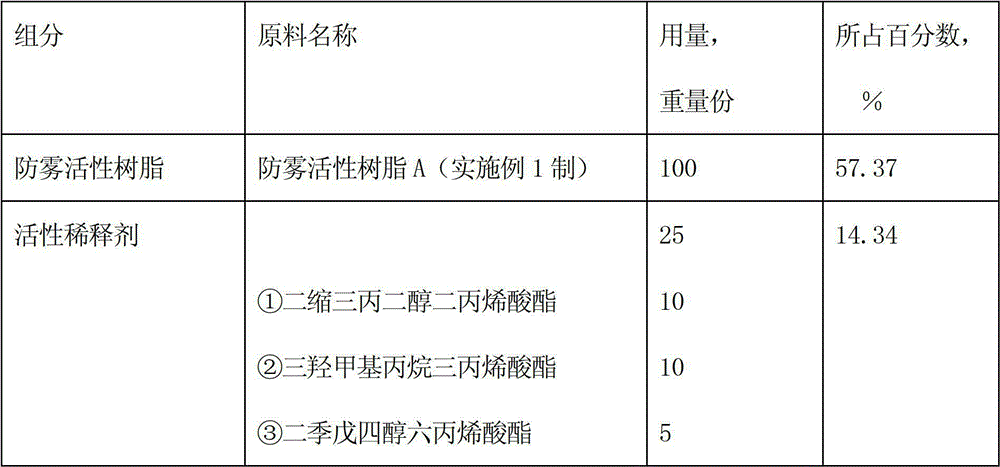

[0017] Example 1 Preparation of UV-cured anti-fog coating

[0018] (1) Preparation of anti-fog active resin A

[0019] Specific steps are as follows:

[0020] ① Prepare the raw materials

[0021] The specific dosage is: 40 parts by weight of reactive nonionic surfactant SN-10, 15 parts by weight of acrylic acid, 45 parts by weight of butyl acrylate, and the total amount of the three is 100 parts by weight; 50 parts by weight of butyl acetate, 50 parts by weight of propylene glycol methyl ether Parts by weight, 1.6 parts by weight of initiator azobisisobutyronitrile; 20 parts by weight of glycidyl methacrylate (the ratio of glycidyl methacrylate to acrylic acid is 20:15=1.33);

[0022] ②Preparation process

[0023] 40 parts by weight of butyl acetate and all propylene glycol methyl ether are mixed and put into the reactor, and the temperature is raised to 90° C., and a total of 100 parts by weight of reactive nonionic surfactant SN-10, acrylic acid and butyl acrylate and 75 ...

Embodiment 2

[0032] Example 2 Preparation of UV-curable anti-fog coating

[0033] (1) Preparation of anti-fog active resin B

[0034] Specific steps are as follows:

[0035] ① Prepare the raw materials

[0036] The specific dosage is: 30 parts by weight of reactive nonionic surfactant SN-15, 15 parts by weight of acrylic acid, 55 parts by weight of butyl methacrylate, and the total amount of the three is 100 parts by weight; 50 parts by weight of butyl acetate, propylene glycol methyl ether 50 parts by weight, 1.6 parts by weight of initiator azobisisobutyronitrile; 20 parts by weight of glycidyl methacrylate (the ratio of glycidyl methacrylate to acrylic acid is 20:15=1.33);

[0037] ②Preparation process

[0038] Except for different raw materials and dosages, the specific preparation steps were the same as in Example 1 to obtain the anti-fog active resin B.

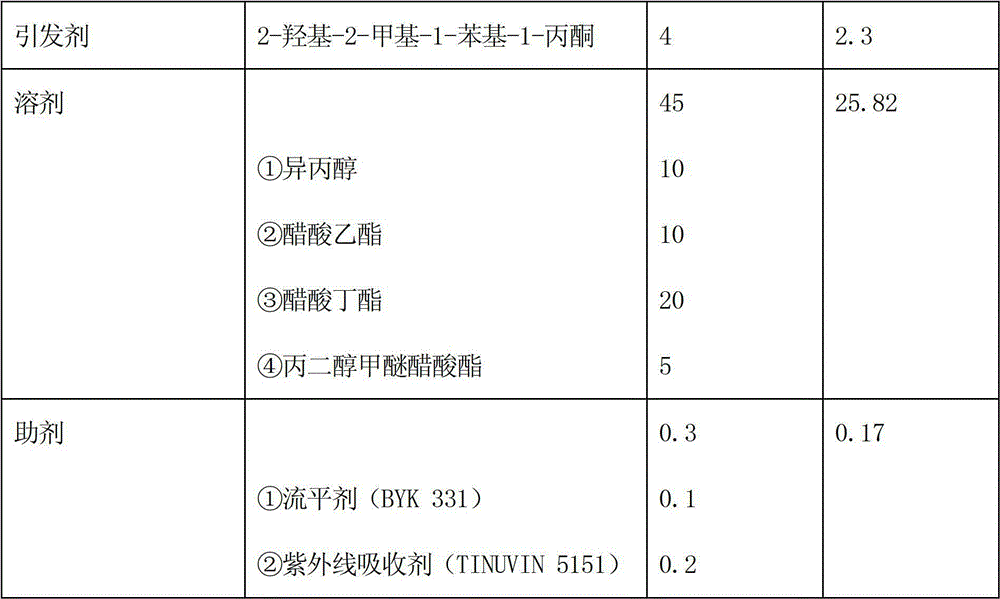

[0039] (2) Preparation of UV-curable anti-fog coating

[0040] ① See Table 2 for coating formulations.

[0041] Table 2

[...

Embodiment 3

[0045] Example 3 Preparation of UV-cured anti-fog coating

[0046] (2) Preparation of anti-fog active resin C

[0047]Specific steps are as follows:

[0048] ① Prepare the raw materials

[0049] The specific dosage is: 25 parts by weight of reactive nonionic surfactant SN-20, 20 parts by weight of methacrylic acid, 55 parts by weight of butyl acrylate, and the total amount of the three is 100 parts by weight; 50 parts by weight of butyl acetate, propylene glycol methyl 50 parts by weight of ether, 1.6 parts by weight of initiator azobisisobutyronitrile; 22 parts by weight of glycidyl methacrylate (the ratio of glycidyl methacrylate to methacrylic acid is 22:20=1.1);

[0050] ②Preparation process

[0051] Except for different raw materials and dosages, the specific preparation steps were the same as in Example 1 to obtain the anti-fog active resin C.

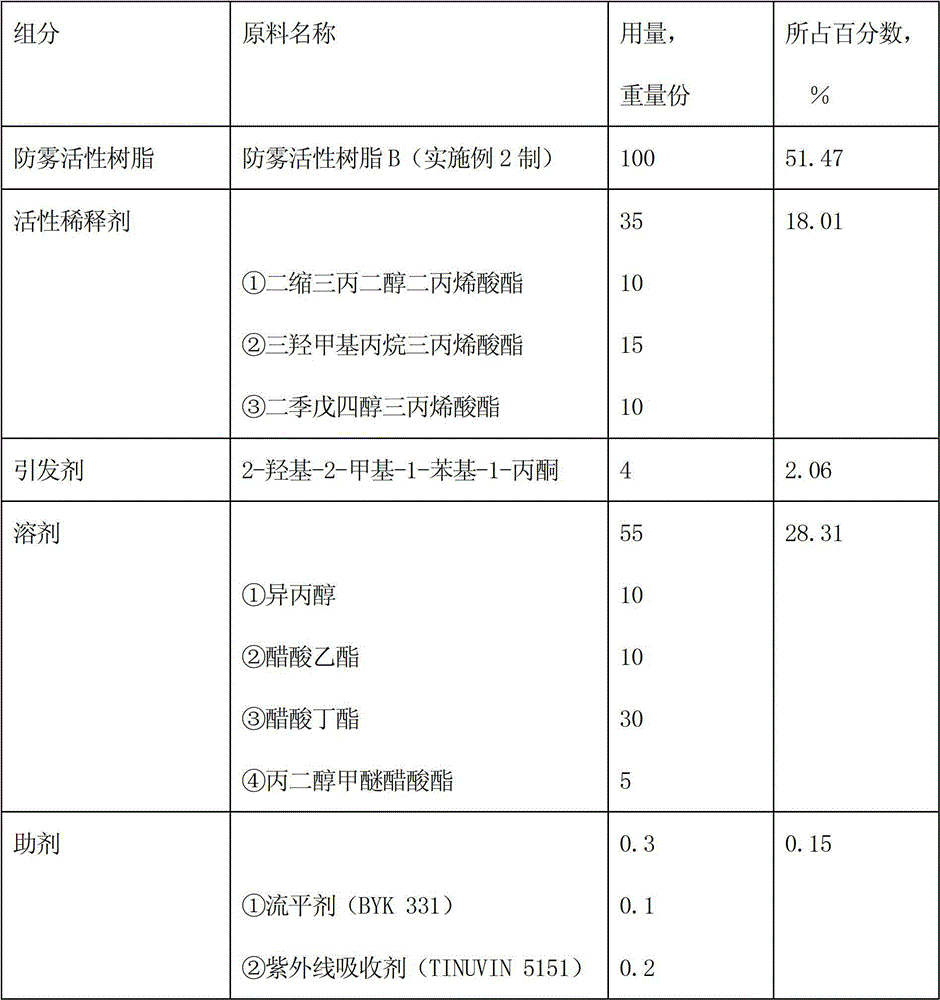

[0052] (2) Preparation of UV-curable anti-fog coating

[0053] ① See Table 3 for coating formulations.

[0054] table 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com