Polysiloxane and application thereof

A technology of polysiloxane and organosiloxane, which is applied in the direction of coating, etc., can solve the problems of long curing time, continuous industrial production, low hardness, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

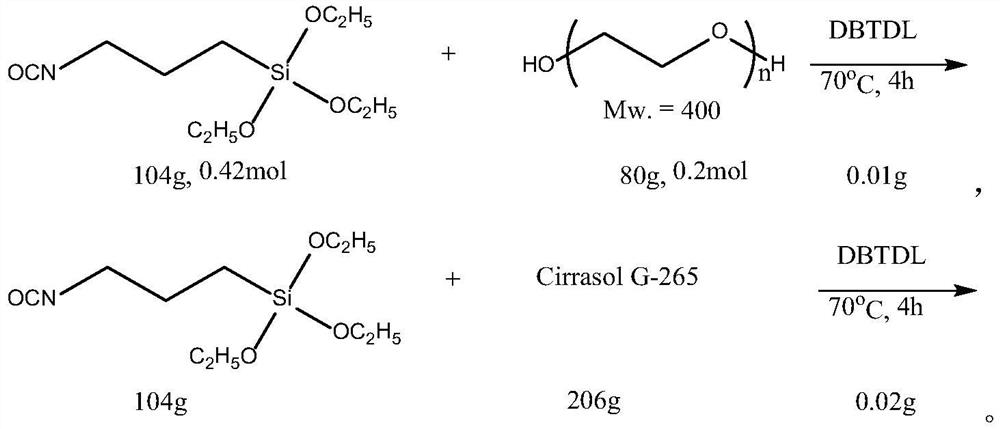

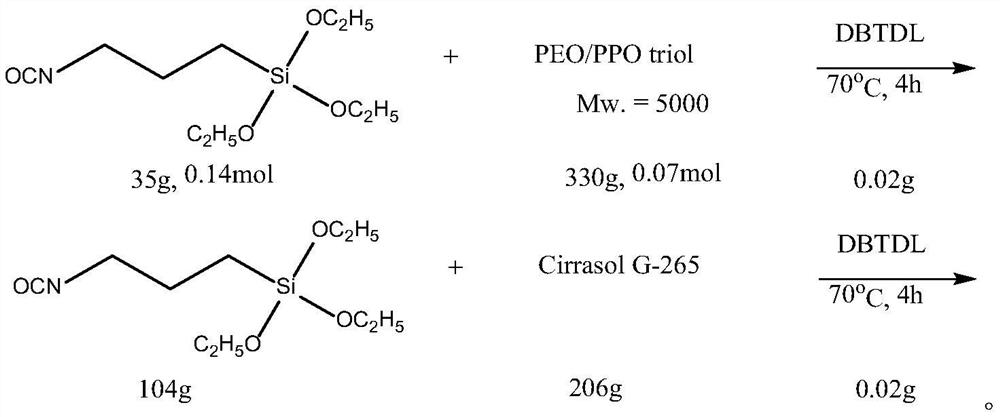

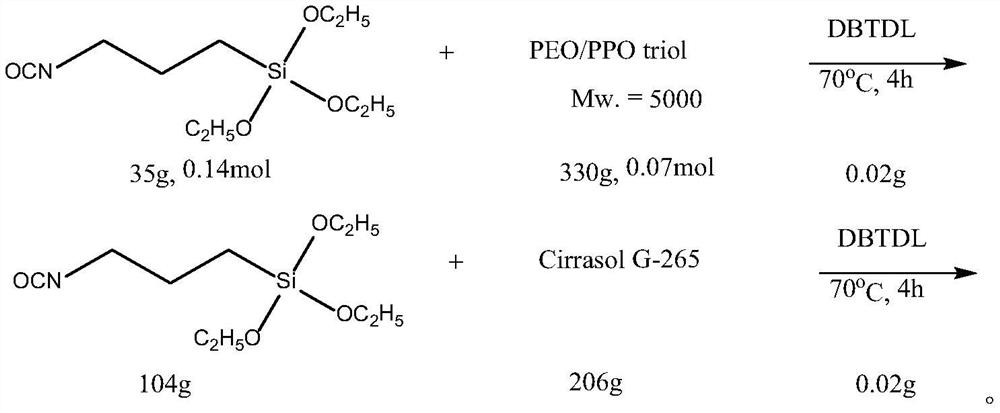

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 anti-fog coating

[0040](a) Preparation of semi-blocked isocyanate prepolymer: add 133.38g (0.6mol) isophorone diisocyanate IPDI and 0.2g (0.1wt%) dibutyltin dilaurate DBTDL in the three-neck flask of 500mL and start stirring; Sequentially weigh 0.5394g (0.262wt%) p-hydroxyanisole MEHQ, 1.0788g (0.525wt%) 2,6-di-tert-butyl-4-methylphenol BHT and 70.05g (0.602mol) hydroxyethyl acrylate HEA, mixed well until completely dissolved, transferred to a constant pressure dropping funnel, and slowly added dropwise to the above-mentioned three-necked flask at room temperature (the reaction is violently exothermic, control the dropping speed to avoid local overheating), after dropping, continue to react at room temperature for 30 minutes , heat up to 70°C and react until the content of the isocyanate group (-NCO) of the mixture reaches the theoretical value (measured by the di-n-butylamine hydrochloride method), then cool down to obtain a semi-block...

Embodiment 2

[0047] The preparation of embodiment 2 anti-fog coating

[0048] (a) Preparation of semi-blocked isocyanate prepolymer: add 266.76g (1.2mol) isophorone diisocyanate IPDI and 0.4g (0.1wt%) dibutyltin dilaurate DBTDL in the three-necked flask of 500mL and start stirring; Weigh in turn 1.0788g (0.262wt%) p-hydroxyanisole MEHQ, 2.1576g (0.525wt%) 2,6-di-tert-butyl-4-methylphenol BHT and 140.1g (1.204mol) hydroxyethyl acrylate HEA, mixed well until completely dissolved, transferred to a constant pressure dropping funnel, and slowly added dropwise to the above-mentioned three-necked flask at room temperature (the reaction is violently exothermic, control the dropping speed to avoid local overheating), after dropping, continue to react at room temperature for 30 minutes , heat up to 70°C and react until the content of the isocyanate group (-NCO) of the mixture reaches the theoretical value (measured by the di-n-butylamine hydrochloride method), then cool down to obtain a semi-blocked...

Embodiment 3

[0055] The preparation of embodiment 3 anti-fog coating

[0056] (a) Preparation of semi-blocked isocyanate prepolymer: add 266.76g (1.2mol) isophorone diisocyanate IPDI and 0.4g (0.1wt%) dibutyltin dilaurate DBTDL in the three-necked flask of 500mL and start stirring; Weigh in turn 1.0788g (0.262wt%) p-hydroxyanisole MEHQ, 2.1576g (0.525wt%) 2,6-di-tert-butyl-4-methylphenol BHT and 140.1g (1.204mol) hydroxyethyl acrylate HEA, mixed well until completely dissolved, transferred to a constant pressure dropping funnel, and slowly added dropwise to the above-mentioned three-necked flask at room temperature (the reaction is violently exothermic, control the dropping speed to avoid local overheating), after dropping, continue to react at room temperature for 30 minutes , heat up to 70°C and react until the content of the isocyanate group (-NCO) of the mixture reaches the theoretical value (measured by the di-n-butylamine hydrochloride method), then cool down to obtain a semi-blocked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com