Fluorescent x-ray analyzer and fluorescent x-ray analysis method

An analysis device and X-ray technology, applied in the direction of material analysis, measurement device, and material analysis using wave/particle radiation, can solve the problems of deviation of analysis results, preparation time, labor and time, etc., to achieve noise suppression, The effect of reduced preparation time and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

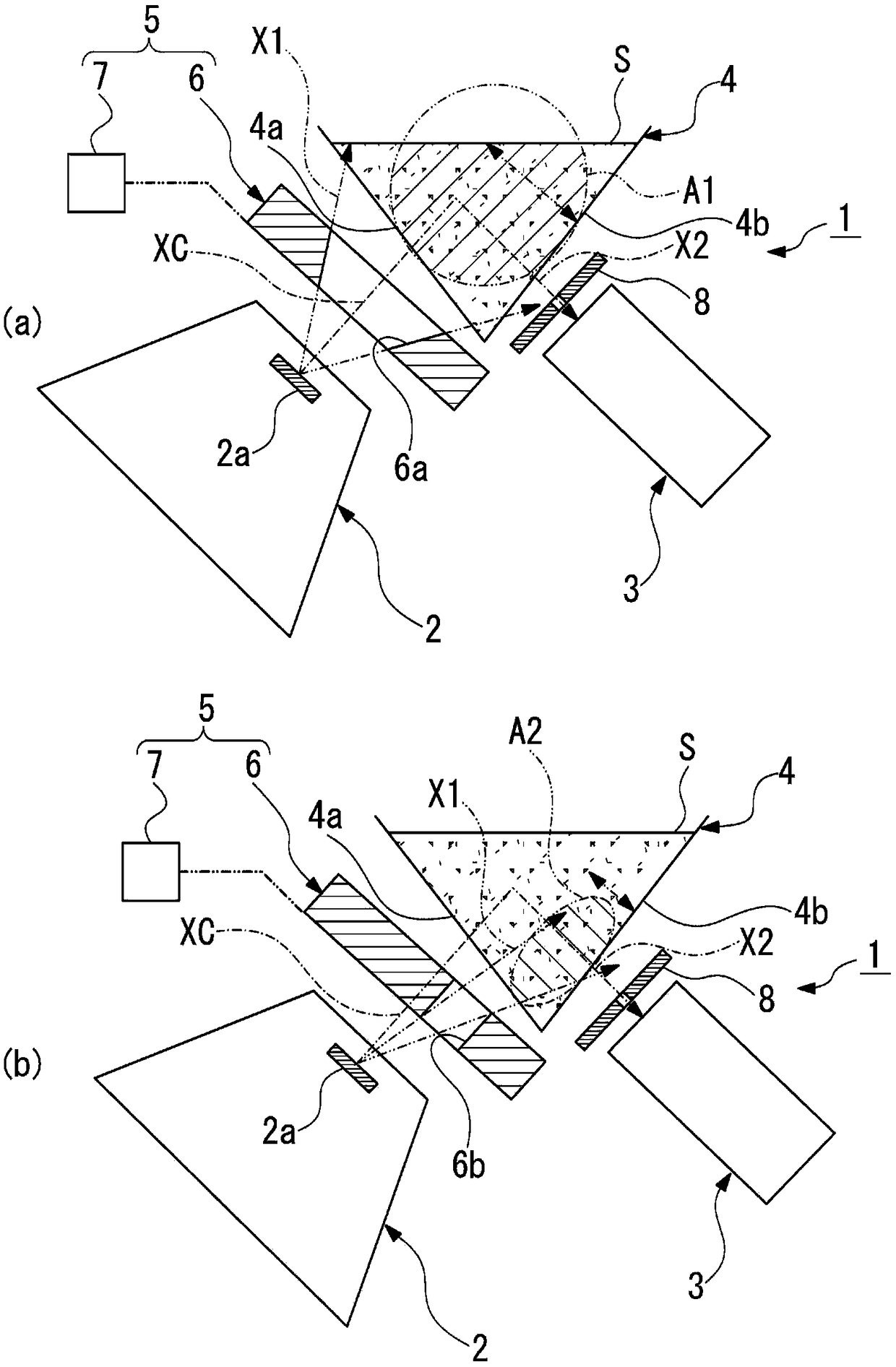

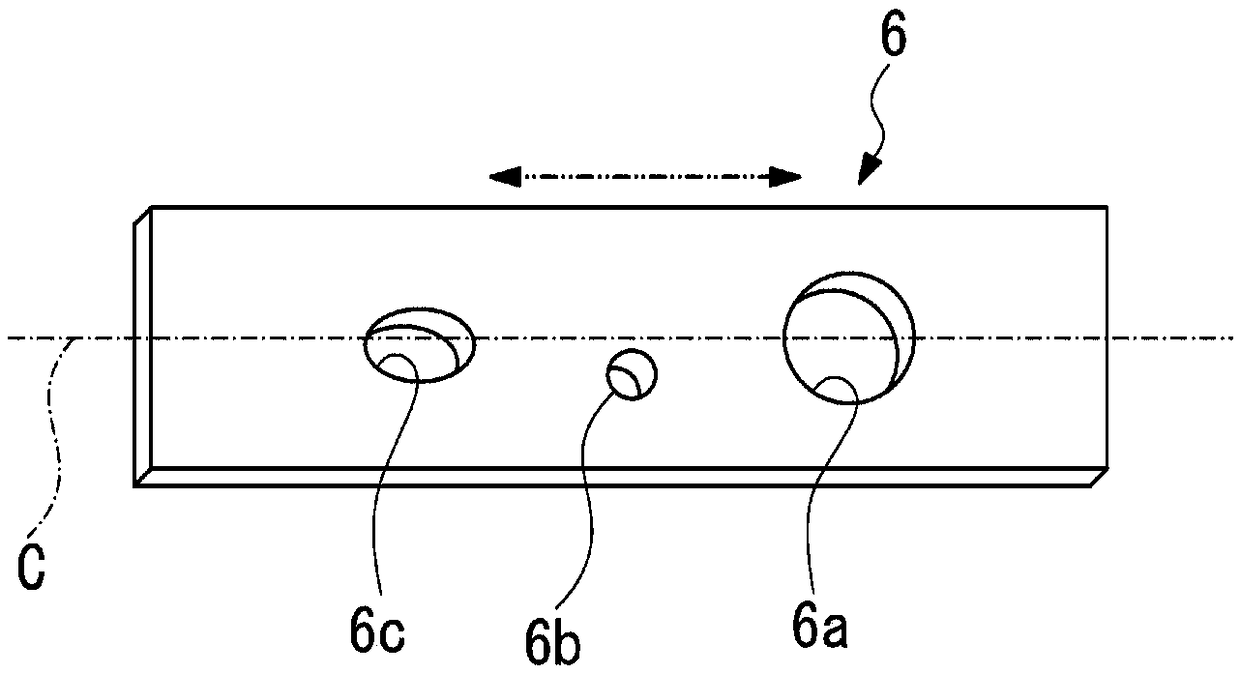

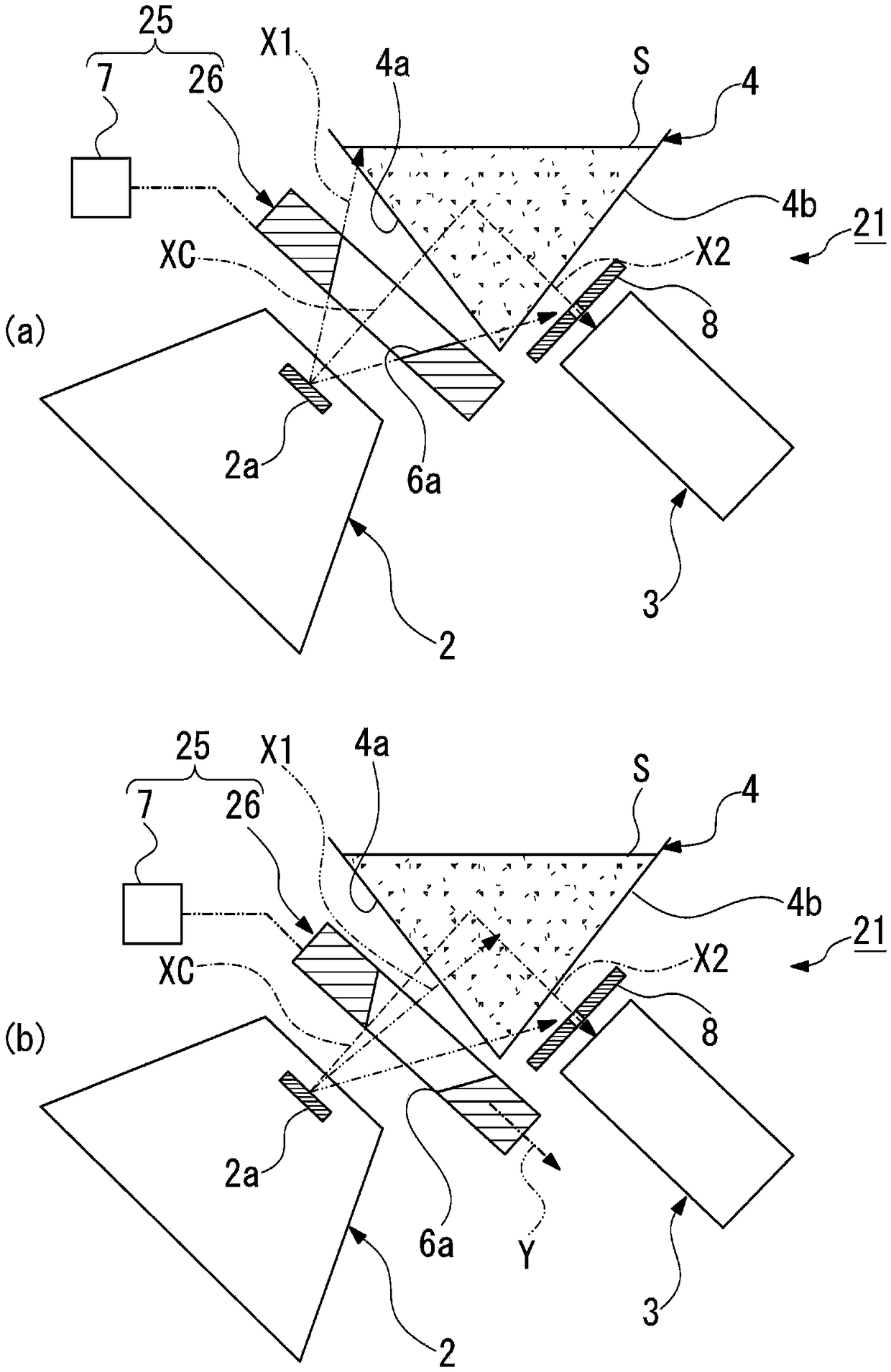

[0036] Below, refer to figure 1 and figure 2 A first embodiment of the fluorescent X-ray analysis device and the fluorescent X-ray analysis method of the present invention will be described.

[0037] Such as figure 1 As shown, the fluorescent X-ray analysis device 1 of this embodiment has: a sample container 4 that can accommodate a granular or powdery sample S; an X-ray source 2 that irradiates the sample S with primary X-rays. X1; a detector 3 that detects the fluorescent X-ray X2 generated from the sample S irradiated with the primary X-ray X1; and an irradiation range changing mechanism 5 that can change the irradiation source to the sample S in the sample container 4. Grade X-ray X1 scope.

[0038] Such as figure 1 As shown in (b), the above-mentioned irradiation range changing mechanism 5 can be changed to local irradiation and wide-area irradiation. Sample S irradiates primary X-ray X1, in this wide-range irradiation, such as figure 1 As shown in (a), the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com