Method for preparing nano titanium dioxide by using surfactant peptization method

A technology of nano-titanium dioxide and surfactant, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of difficult operation in the filtration and cleaning process, difficult elution of impurity ions, and inability to obtain nanoparticles, etc., to achieve The effect of low cost, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

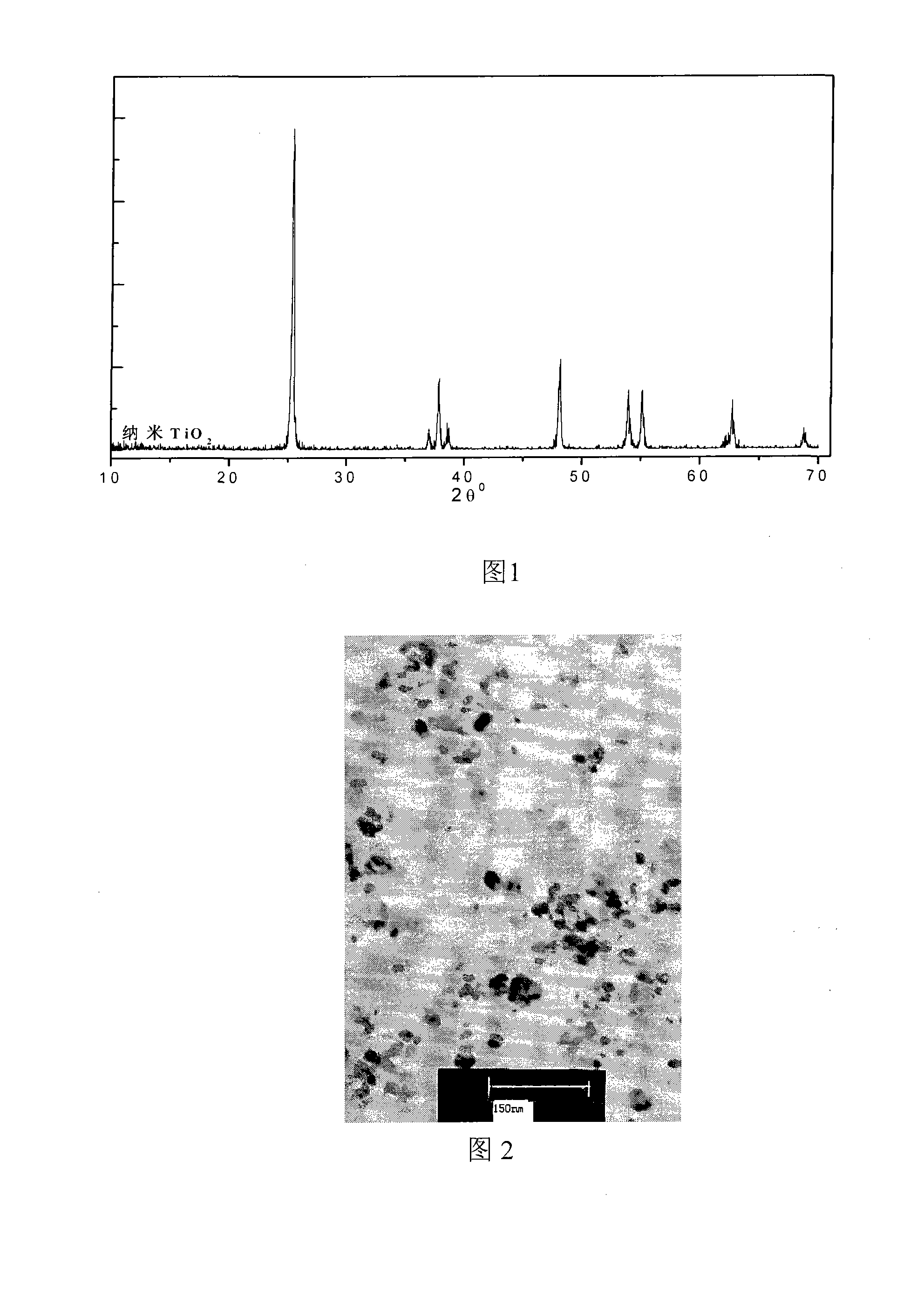

Embodiment 1

[0025] (1) Add distilled water to metatitanic acid, the intermediate product after cleaning and bleaching in the process of producing titanium dioxide by the sulfuric acid method in the titanium dioxide factory, and adjust to the metatitanic acid powder-water suspension with a concentration of 0.125mol / L, and then Add acetic acid, oxalic acid, citric acid, Tween 20, Span 40, polyethylene glycol 2000 and polyvinyl alcohol 2000 to form a peptizer, metatitanic acid: acetic acid: oxalic acid: citric acid: Tween 20: Span 40 : polyethylene glycol 2000: polyvinyl alcohol 2000 in a molar ratio of 1: 0.2: 0.4: 0.3: 0.01: 0.01: 0.01: 0.01. The peptization reaction was carried out at a water bath temperature of 50° C. (stirring for 1 minute every 5 minutes), and the water bath time was 60 minutes to obtain a nano-scale metatitanic acid colloid solution. The reaction formula is as follows:

[0026] TiO(OH) 2 -(HO) 2 OTi+nR - =TiO(OH) 2 R n / 2 +TiO(OH) 2 R n / 2

[0027] R represents...

Embodiment 2

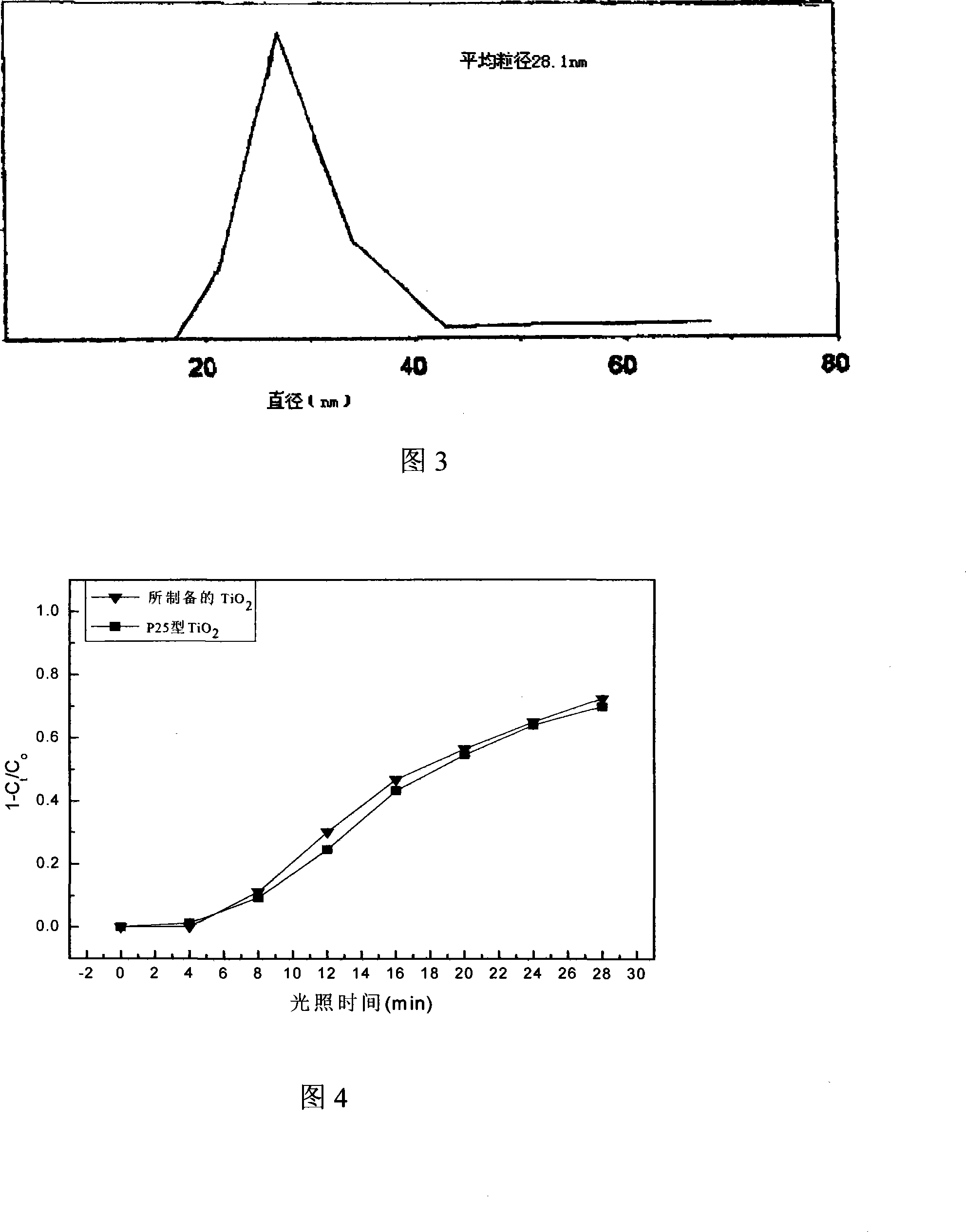

[0031](1) Use metatitanic acid, an intermediate product after cleaning and bleaching in the process of producing titanium dioxide by the sulfuric acid method in the titanium dioxide factory, add deionized water, and adjust to a concentration of 0.25mol / L metatitanic acid powder-water suspension , and then add acetic acid, oxalic acid, citric acid, Tween 20, Span 40, polyethylene glycol 2000 and polyvinyl alcohol 2000 to form a peptizer, metatitanic acid: acetic acid: oxalic acid: citric acid: Tween 20: Division The molar ratio of disc 40 : polyethylene glycol 2000 : polyvinyl alcohol 2000 was 1 : 0.2 : 0.2 : 0.2 : 0.01 : 0.01 : 0.01 : 0.01. The peptization reaction was carried out at a water bath temperature of 90° C. (stirring for 1 minute every 5 minutes), and the water bath time was 30 minutes to obtain a nanoscale metatitanic acid colloid solution. The particle size of the colloid was determined to be 28.1 nm by a Malvern laser scattering instrument. Figure 3.

[0032] (...

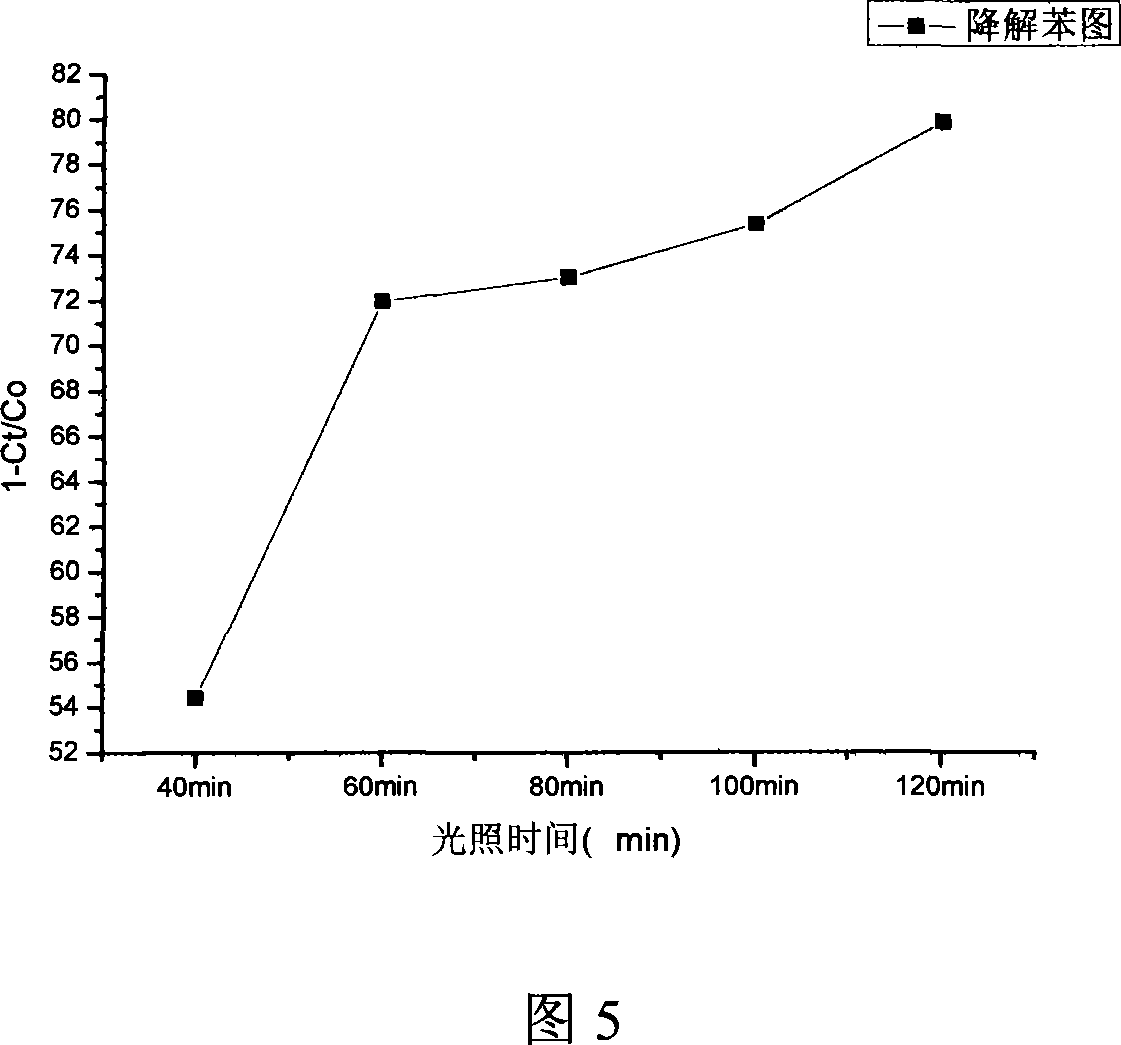

Embodiment 3

[0035] (1) Add distilled water to metatitanic acid, the intermediate product after cleaning and bleaching in the process of producing titanium dioxide by the sulfuric acid method in the titanium dioxide factory, and adjust to the metatitanic acid powder-water suspension with a concentration of 0.5mol / L, and then Add acetic acid, oxalic acid, citric acid, Tween 20, Span 40, polyethylene glycol 2000 and polyvinyl alcohol 2000 to form a peptizer, metatitanic acid: acetic acid: oxalic acid: citric acid: Tween 20: Span 40 : polyethylene glycol 2000: polyvinyl alcohol 2000 in a molar ratio of 1: 1.5: 1.6: 0.5: 0.05: 0.05: 0.05: 0.02. The peptization reaction was carried out at a water bath temperature of 70° C. (stirring for 1 minute every 5 minutes), and the water bath time was 60 minutes to obtain a nano-scale metatitanic acid colloid solution.

[0036] (2) Place the nano-scale metatitanic acid colloid solution obtained in step (1) in an ultrasonic machine with a water bath, and v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com