Copper-filled carbon monoxide medium temperature shift catalyst and preparation method thereof

A technology for transforming catalysts and carbon monoxide, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve catalyst performance degradation, catalyst activity and thermal stability degradation, etc. problems, achieve high thermal stability, small copper crystals, and high copper surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

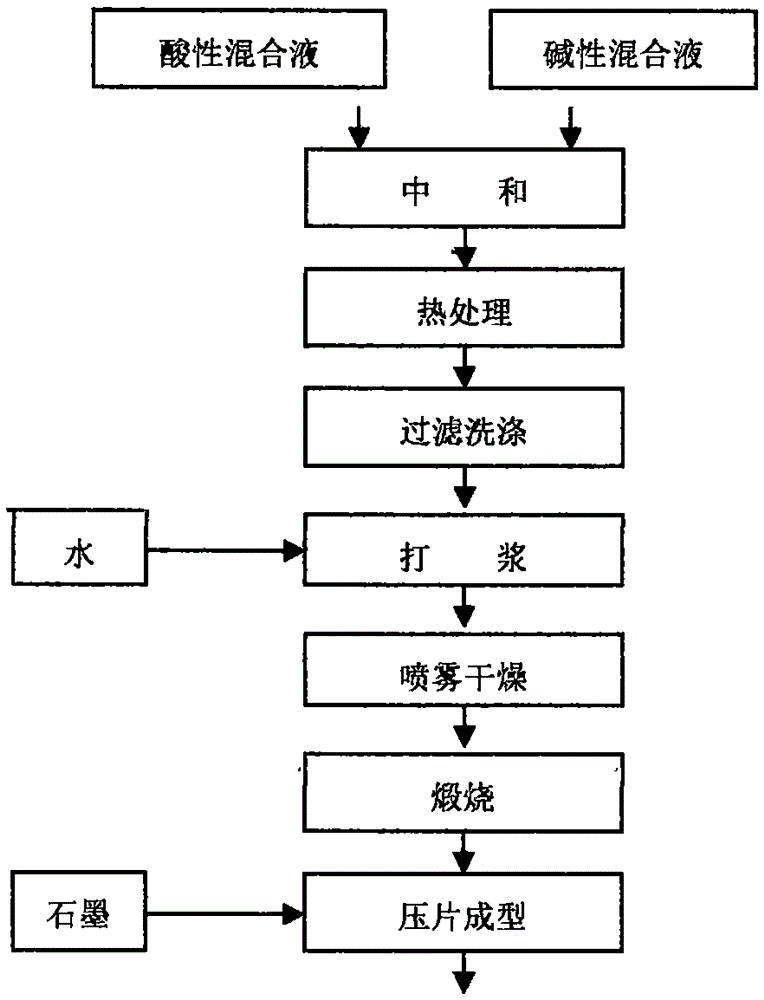

[0032] The first preparation method of copper-based carbon monoxide medium temperature shift catalyst, the process flow is as follows:

[0033] a. Raw material preparation: preparation concentration is 1555g of copper nitrate solution of 19.295%, concentration is 2864g of zinc nitrate solution of 17.46%, takes by weighing 975g slightly acid aluminum for subsequent use, prepares 12000g of sodium carbonate solution of 16.67% concentration, takes 30g graphite fine powder for subsequent use ;

[0034] b. Add copper nitrate solution and zinc nitrate solution into the premix tank, start stirring, add aluminum nitrate after 10 minutes, stir well and set aside, carry out co-precipitation reaction between the mixed solution and sodium carbonate solution in the reactor, and control the neutralization Precipitation temperature 40-80°C, pH value 6-9, static aging for 30 minutes;

[0035] c. Heat the precipitation slurry to 65-95°C and heat-treat for 4-8 hours;

[0036] d. Then filter an...

Embodiment approach

[0042] The second embodiment of the first preparation method, the process flow is as follows:

[0043] a. Raw material preparation: preparation concentration is 1555g of copper nitrate solution of 19.295%, concentration is 2864g of zinc nitrate solution of 17.46%, prefabricated 459g sodium aluminate, prepares 293g of nitric acid, prepares 12000g of sodium carbonate solution of 16.67% concentration, gets 30g fine graphite powder spare;

[0044]b. Add copper nitrate solution and zinc nitrate solution into the premix tank, start stirring, add aluminum nitrate after 10 minutes, stir well and set aside, carry out co-precipitation reaction between the mixed solution and sodium carbonate solution in the reactor, and control the neutralization Precipitation temperature 40-80°C, PH value 6-9, static aging for 30 minutes, after neutralization, immediately prepare a neutralization solution of sodium aluminate and nitric acid, at room temperature, pH 4-6, add sodium aluminate nitric acid ...

specific Embodiment 3

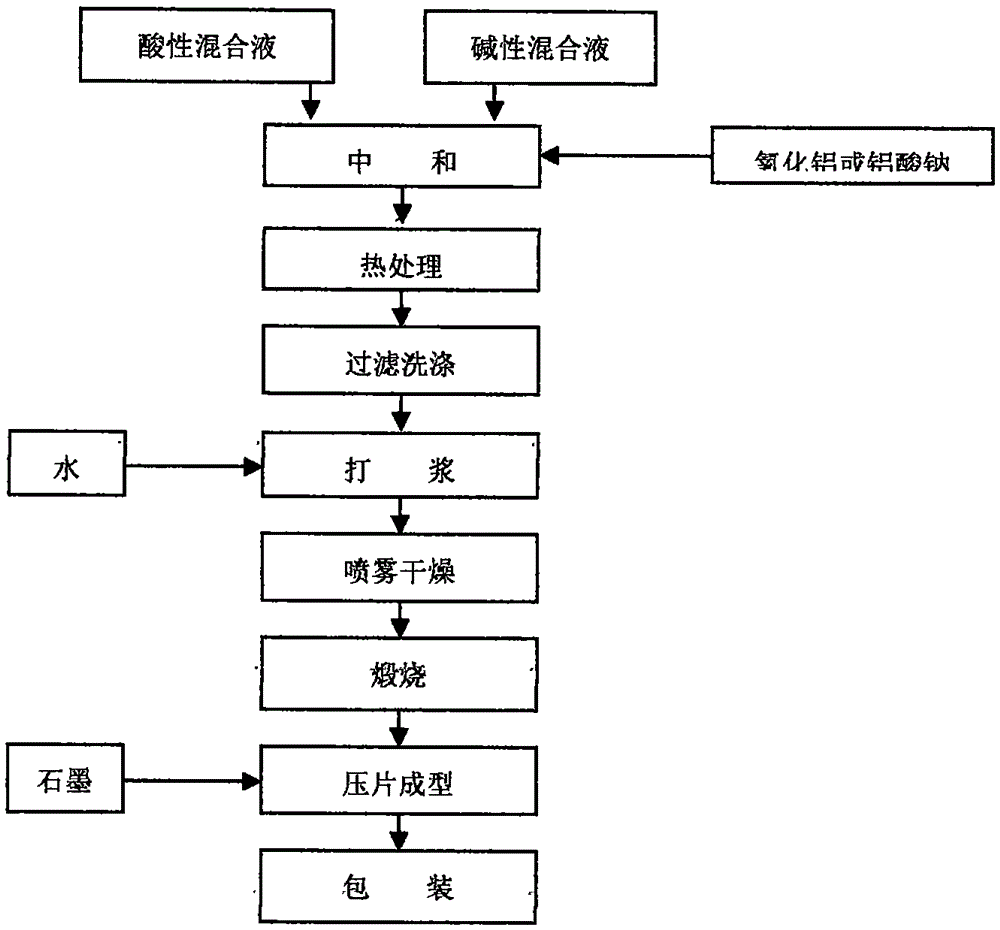

[0052] The second preparation method of the copper-based carbon monoxide medium temperature shift catalyst, the technological process is as follows:

[0053] A. preparation concentration is 1819g of copper nitrate solution of 19.295%, 2057g of zinc nitrate solution of 17.46%, it is standby to take by weighing 527g aluminum oxide, preparation concentration is 12000g of sodium carbonate solution of 16.67%, it is standby to get 30g fine graphite powder;

[0054] b. Add the copper nitrate solution and the zinc nitrate solution into the premix tank, start stirring, stir well and then set aside; carry out coprecipitation reaction between the mixed solution and sodium carbonate solution in the reactor, and control the neutralization precipitation temperature to 40-80°C, PH value 6-9, static aging for 30 minutes, adding alumina dry powder, stirring for 5 minutes;

[0055] c. Heat the precipitation slurry to 65-95°C and heat-treat for 4-8 hours;

[0056] d. Then filter and wash with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com