Preparation method of biodiesel composite additive

A composite additive, biodiesel technology, applied in the field of fuel additives, to achieve good fuel performance, good combustion, and maintain the effect of low temperature flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

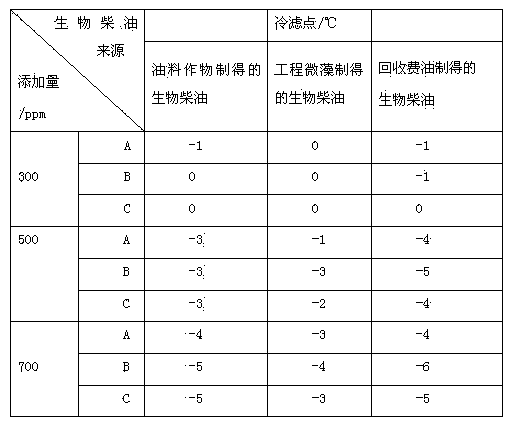

Examples

Embodiment 1

[0065] Take 18 parts by volume of lauryl methacrylate, 18 parts of octadecyl methacrylate, 14 parts of isooctyl nitrate, and 4 parts of diethyl phthalate and add them to the raw material mixing tank in proportion , after stirring evenly, add 15 parts of maleic anhydride and 5 parts of isooctyl alcohol and stir evenly, then add 8 parts of tert-butylamine and 8 parts of dihexadecyldimethylammonium chloride, and stir for 30-35 minutes; Add 5 parts of polyoxyethylene cetylphenol ether and 5 parts of phenyl propargyl ether, heat to 45°C-50°C, stir at 0.5-1.0MP for 20-30 minutes, let stand for 24 hours, filter, remove Precipitate, obtain biodiesel composite additive A of the present invention.

Embodiment 2

[0067] Take 23 parts by volume of lauryl methacrylate, 23 parts of octadecyl methacrylate, 12 parts of isooctyl nitrate, and 3 parts of diethyl phthalate and add them to the raw material mixing tank in proportion , after stirring evenly, add 12 parts of maleic anhydride and 8 parts of isooctyl alcohol and stir evenly, then add 7 parts of tert-butylamine and 5 parts of dihexadecyldimethylammonium chloride, and stir for 30-35 minutes; Add 4 parts of polyoxyethylene cetylphenol ether and 3 parts of phenyl propargyl ether, heat to 45°C-50°C, stir at 0.5-1.0MP for 20-30 minutes, let stand for 24 hours, filter, remove Precipitate to obtain the biodiesel composite additive B of the present invention.

Embodiment 3

[0069] Take 20 parts by volume of lauryl methacrylate, 20 parts of octadecyl methacrylate, 8 parts of isooctyl nitrate, and 4 parts of diethyl phthalate and add them to the raw material mixing tank in proportion , after stirring evenly, add 12 parts of maleic anhydride and 9 parts of isooctyl alcohol and stir evenly, then add 8 parts of tert-butylamine and 8 parts of dihexadecyldimethylammonium chloride, and stir for 30-35 minutes; Add 6 parts of polyoxyethylene cetylphenol ether and 5 parts of phenyl propargyl ether, heat to 45°C-50°C, stir at 0.5-1.0MP for 20-30 minutes, let stand for 24 hours, filter, remove Precipitate to obtain the biodiesel composite additive C of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com