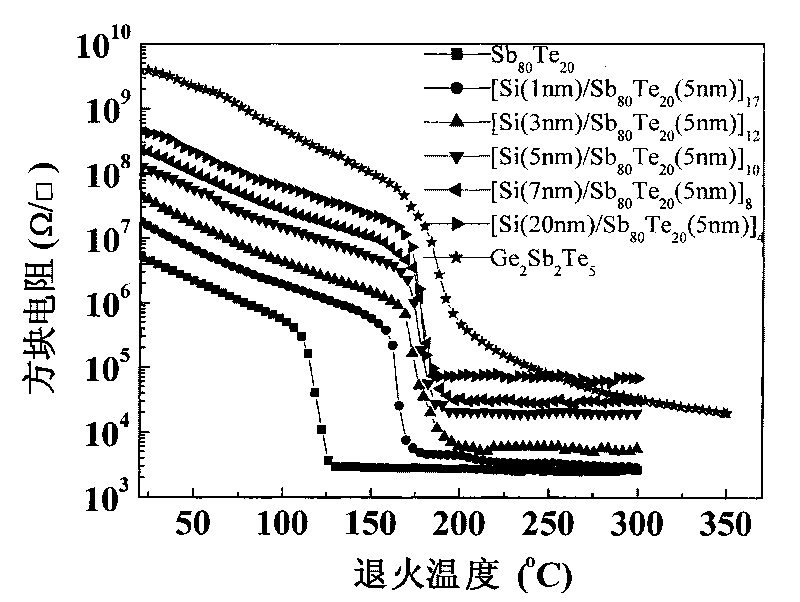

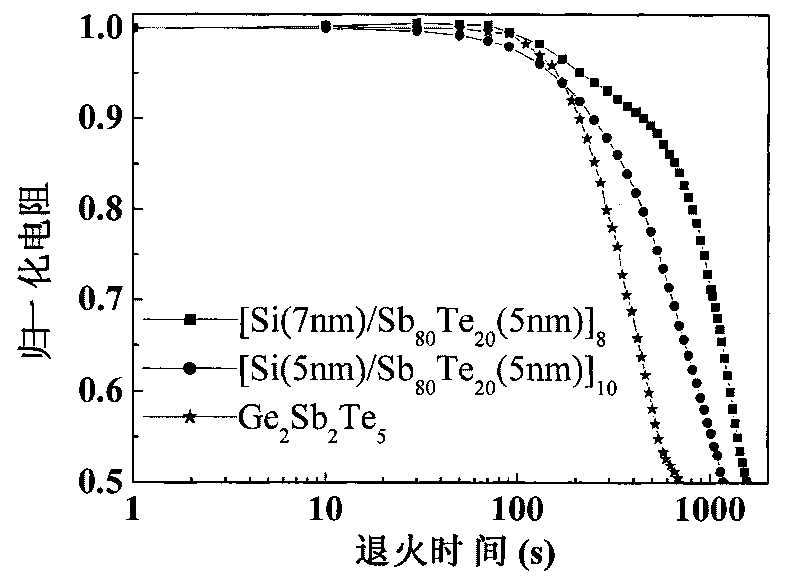

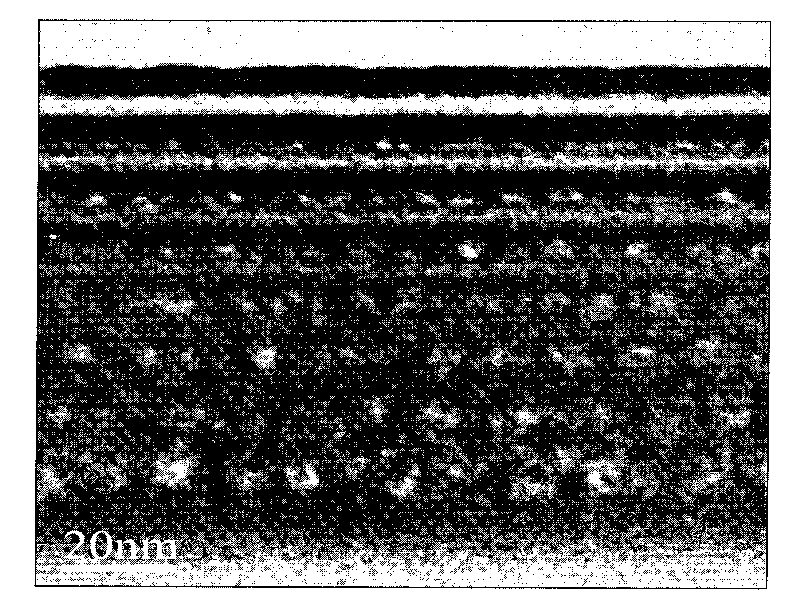

Si/Sb80Te20 nanometer compound multi-layer phase change film and method for preparing same

A sb80te20, nanocomposite technology, applied in the field of materials in the field of microelectronics technology, can solve the problems of long crystallization process time, low phase transition speed, low melting point, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1 Clean SiO 2 / Si(100) substrate;

[0034] Step 2 prepares Si, Sb by room temperature magnetron sputtering 80 Te 20 Phase change film preparation:

[0035] a) Prepare Si single crystal targets and Sb with a diameter of 50.8mm and a thickness of 5mm 80 Te 20 Alloy target, the purity of Si single crystal target is 99.9999% (mass percentage), Sb 80 Te 20 The purity of the alloy target is 99.999% (mass percentage), and the background vacuum is better than 1×10 -4 Pa;

[0036] b) The radio frequency power is set at 20W;

[0037] c) Ar gas with a purity of 99.999% is used as the sputtering gas, the gas flow rate is controlled at 30 SCCM, and the sputtering pressure is 0.2 Pa. Step 3 prepares [Si(1nm) / Sb by magnetron alternate sputtering method 80 Te 20 (5nm)] 17 Nanocomposite multilayer phase change film:

[0038] a) Rotate the substrate to Sb 80 Te 20 target, open Sb 80 Te 20 RF power on the target, start sputtering Sb 80 Te 20 Thin film, the sputteri...

Embodiment 2

[0042] Step 1, step 2 are identical with embodiment 1;

[0043] Step 3: Prepare [Si(3nm) / Sb 80 Te 20 (5nm)] 12 Nanocomposite multilayer phase change film:

[0044] a) Rotate the substrate to Sb 80 Te 20 target, open Sb 80 Te 20 RF power on the target, start sputtering Sb 80 Te 20 Thin film, the sputtering time is 16s;

[0045] b) Sb 80 Te 20 After film sputtering is complete, turn off the Sb 80 Te 20 The RF power applied on the target, the substrate is rotated to the Si target position, the RF power on the Si target is turned on, and the Si film is sputtered, and the sputtering time is 72s;

[0046] c) Repeat a) and b) two steps, that is, in SiO 2 / Si(100) substrate prepared thin film structure as [Si(3nm) / Sb 80 Te 20 (5nm)] 12 The nanocomposite multilayer phase change film, the total thickness of the film is controlled at 100nm.

Embodiment 3

[0048] Step 1, step 2 are identical with embodiment 1;

[0049] Step 3: Prepare [Si(5nm) / Sb 80 Te 20 (5nm)] 10 Nanocomposite multilayer phase change film:

[0050] a) Rotate the substrate to Sb 80 Te 20 target, open Sb 80 Te 20 RF power on the target, start sputtering Sb 80 Te 20 Thin film, the sputtering time is 16s;

[0051] b) Sb 80 Te 20 After film sputtering is complete, turn off the Sb 80 Te 20 The RF power applied on the target, the substrate is rotated to the Si target position, the RF power on the Si target is turned on, and the Si film is sputtered, and the sputtering time is 120s;

[0052] c) Repeat a) and b) two steps, that is, in SiO 2 / Si(100) substrate prepared thin film structure as [Si(5nm) / Sb 80 Te 20 (5nm)] 10 The nanocomposite multilayer phase change film, the total thickness of the film is controlled at 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com