Nano-quantum-dot-level fuel borne catalyst for diesel vehicle as well as preparation method and application thereof

A technology of nano-quantum dots and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. and other problems, to achieve the effect of convenient operation, more selectivity of raw materials, and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

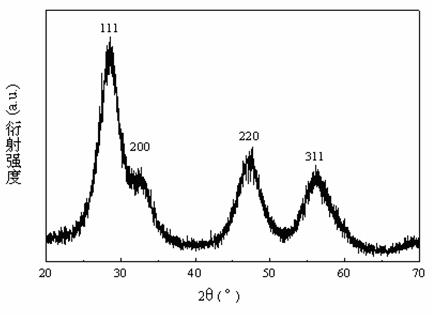

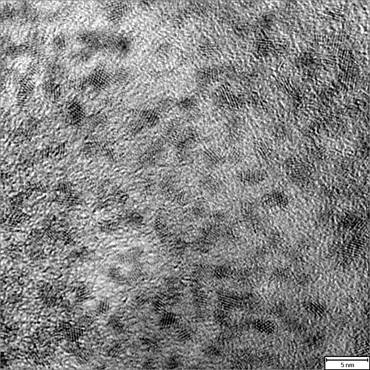

[0035] Weigh 0.868 g Ce(NO 3 ) 3 ·6H 2O was added to a three-necked flask containing 50 mL of triethylene glycol, condensed and refluxed at 100 °C for 30 min, and then heated to 160 °C and condensed and refluxed for 30 min to obtain quantum CeO below 5 nm. 2 colloid.

Embodiment 2

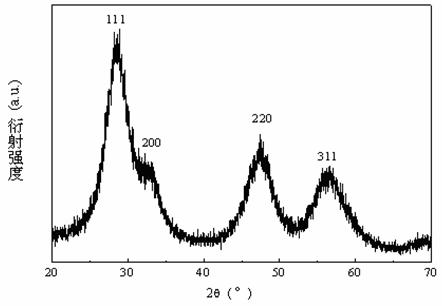

[0037] Weigh 0.7812 g Ce(NO 3 ) 3 ·6H 2 O and 0.0808 g Fe(NO 3 ) 3 9H 2 O was added to a three-necked flask containing 50 mL of triethylene glycol, condensed and refluxed at a temperature of 100 °C for 30 min, continued to heat up to 200 °C and kept at this temperature for 90 min to obtain Colloidal cerium-iron composite oxide, in which the atomic ratio of Fe / (Ce+Fe) is 10%.

Embodiment 3

[0039] By deposition precipitation method, the CeO 2 Deposited on the soot to achieve the effect of close contact between soot and catalyst, the ratio of soot to catalyst is 1:9. The specific method is to add 0.0396 g of soot to 50 mLCeO 2 In the colloid, ultrasonically disperse for 30 minutes and mix evenly, then add absolute ethanol and ammonia water to the mixture according to the ratio of 1:1:1.5, centrifuge at 9000 r / min for 60 minutes, and the obtained precipitate is vacuum-dried in a vacuum oven at 80 °C 24 h, to get CeO 2 Samples in close contact with soot.

[0040] o 2 The temperature-programmed oxidation test was carried out in a fixed-bed reactor. Dilute 50 mg CeO with quartz wool 2 The sample and soot sample were packaged in a quartz reaction tube, heated to 200 °C in 50 mL / min He gas, and pretreated for 30 min. After cooling down to room temperature, switch to a reaction gas of 200 mL / min, where O 2 The concentration is 5 vol.%, and the balance gas is He ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com