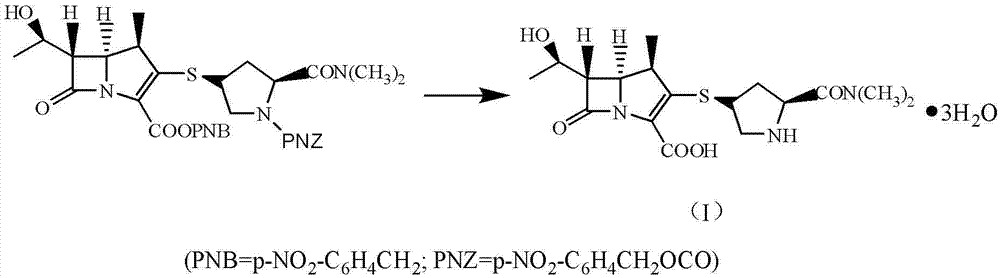

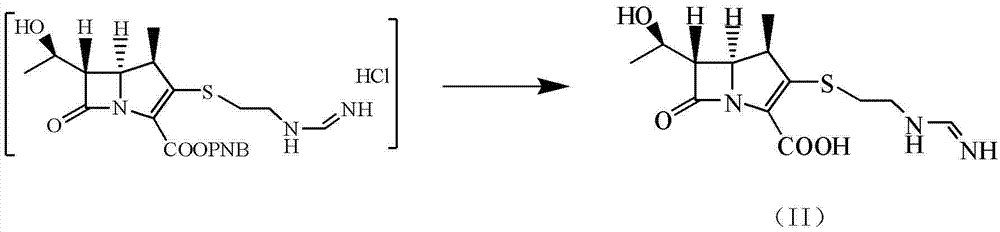

Preparation method of high-activity palladium-carbon catalyst for synthesis of imipenem antibiotics

The technology of a palladium-carbon catalyst and an antibiotic is applied in the field of preparation of a high-activity palladium-carbon catalyst, which can solve the problems of low catalyst activity and selectivity, poor filterability and the like, and achieve the effects of improving the effective utilization rate and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

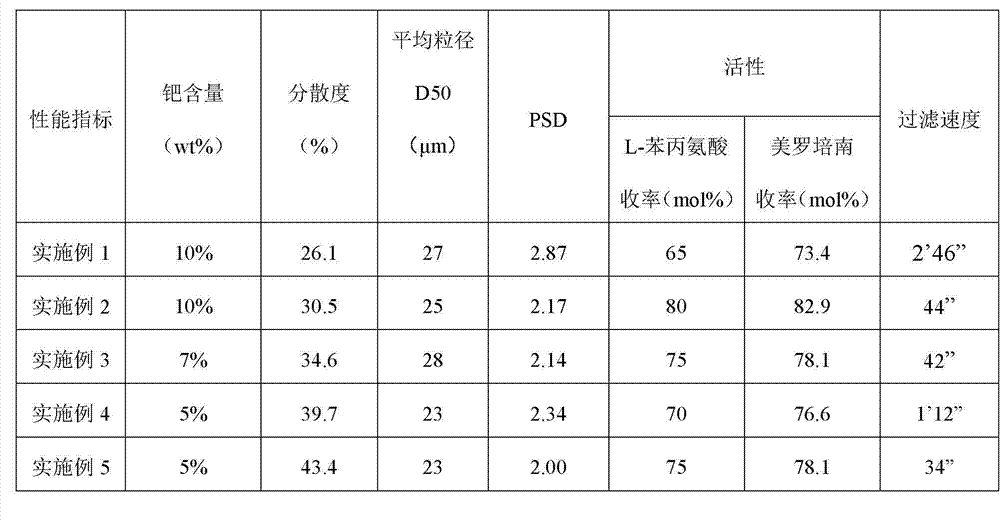

Examples

preparation example Construction

[0035] The preparation method of the palladium-carbon catalyst used for the synthesis of penem antibiotics of the present invention uses chloropalladium acid and its salt as the precursor compound of the active component palladium, takes powdered activated carbon as the carrier, and adds sodium citrate or sodium citrate in the Pd impregnation solution Sodium acetate, then the Pd impregnation solution is adsorbed on the active carbon in sections, and obtains the palladium carbon catalyst through wet chemical reduction, and the concrete steps are as follows:

[0036] (1) In the mixed slurry of activated carbon and ionized water, pre-adsorb sodium citrate or sodium acetate complexing agent;

[0037] (2) prepare palladium salt solution, add dropwise in the slurry that step (1) obtains, palladium load is 5%~10%;

[0038] (3) Sectional adsorption of palladium salt solution, the pH of the first step is controlled between 4 and 5, and the pH of the second step is controlled between 9 ...

Embodiment 1

[0050] Example 1: 1) Weigh 180 g (dry weight) of activated carbon, add it to a 5 L reactor, add 0.9 L of water, and stir for 2 h;

[0051] 2) Weigh 33.2 g PdCl 2 , add 20 ml of concentrated hydrochloric acid and 1 L of deionized water, heat to boiling to dissolve, and cool to room temperature;

[0052] 3) Add the palladium salt solution obtained in step) 2 to the activated carbon slurry at a constant speed. After dropping, adjust the pH of the slurry to 4.5 with 10% NaOH, stir and adsorb for 5 h, and then add 10% NaOH dropwise to adjust the pH value , keep the pH value between 9-10, and stir the deposition to continue to adsorb for 16 h;

[0053] 4) At 80 °C, add 70 ml of formaldehyde, keep the pH at 9-10, and reduce for 4 h;

[0054] 5) Cool, let it stand overnight, filter, wash with deionization until the filtrate is neutral, and obtain a 10% Pd / C catalyst with a water content of 58.6%.

Embodiment 2

[0055] Example 2: 1) Weigh 180 g (dry weight) of activated carbon and 13.5 g of sodium citrate into a 5 L reactor, add 0.9 L of water, and stir for 2 h;

[0056] 2) Weigh 33.2 gPdCl 2 , add 20 ml of concentrated hydrochloric acid and 1 L of deionized water, heat until boiling and dissolve, add 20 g of sodium citrate, and heat for another 10 minutes, without bumping the solution, then cool to room temperature;

[0057] 3) Add the palladium salt solution obtained in step 2) into the activated carbon slurry at a constant speed. After dropping, use the slurry to have a pH of 4.6, stir and adsorb for 5 hours, then add 10% NaOH dropwise to adjust the pH value, and keep the pH value at 9 Between -10, the stirring deposition continued to adsorb for 16 h;

[0058] 4) At 80 °C, add 70 ml of formaldehyde, keep the pH at 9-10, and reduce the time for 4 h;

[0059] 5) Cool, let it stand overnight, filter, wash with deionization until the filtrate is neutral, and obtain a 10% Pd / C catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com