High-performance hard alloy with cobalt-based alloy as binding phase

A cemented carbide, cobalt-based alloy technology, applied in the field of high-performance cemented carbide, can solve the problems of many pores, WC grain growth, high cost, and achieve the effect of solving excessive pores and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

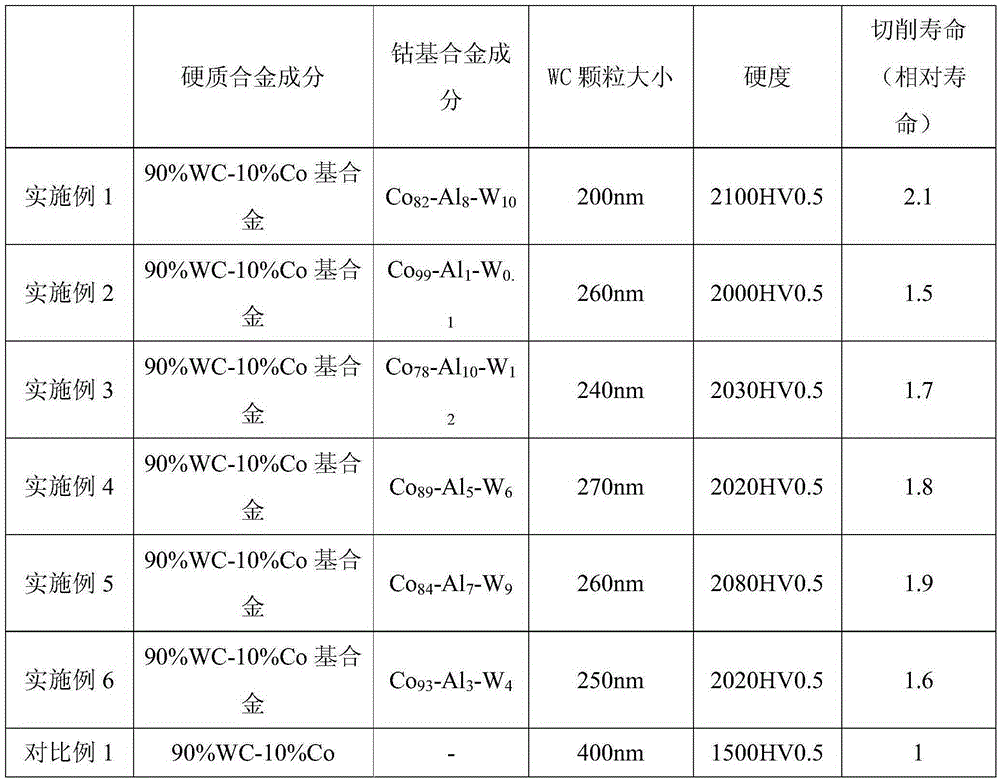

[0012] Embodiment 1: take cobalt-based alloy as the high-performance cemented carbide of bonding phase

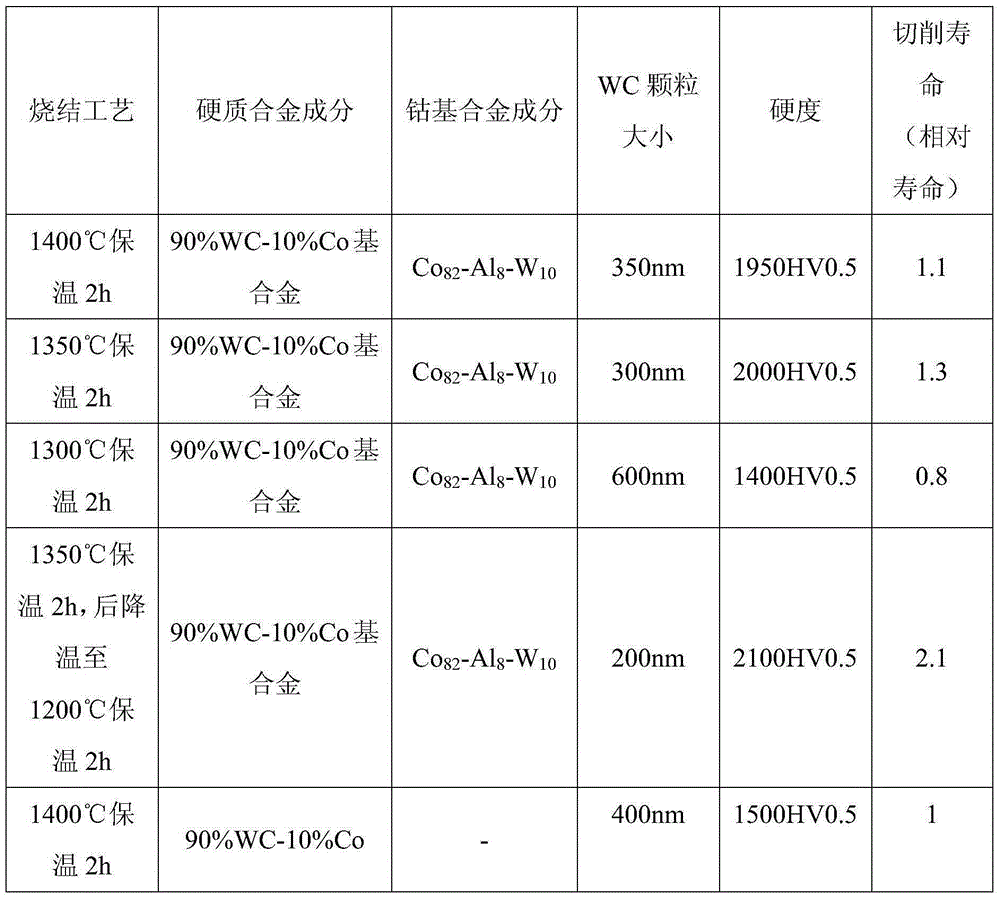

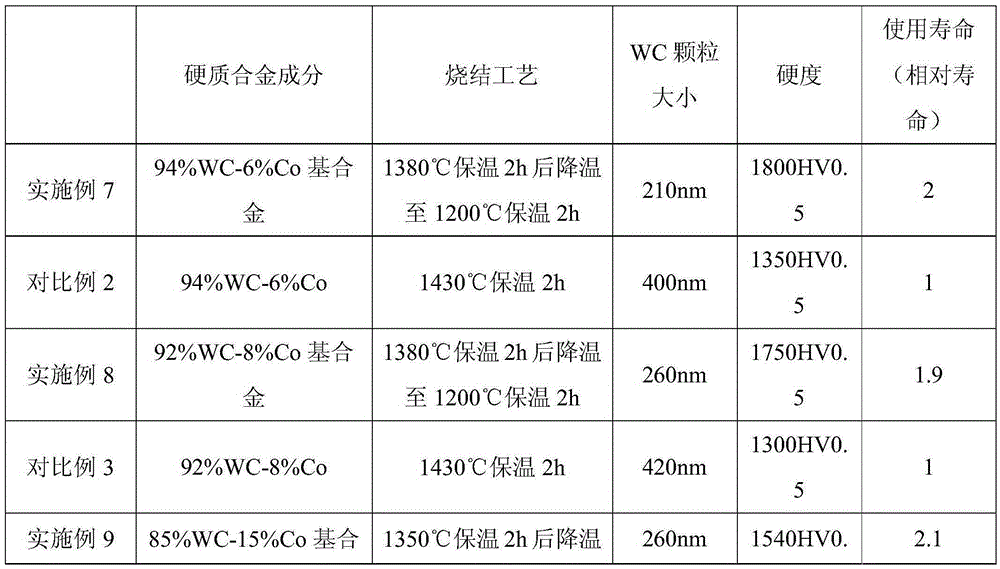

[0013] Select tungsten carbide powder (purity 99.9%, 300 mesh) to add cobalt-based alloy (Co 82 -Al 8 -W 10 ) as a raw material, wherein tungsten carbide powder accounts for 90wt% of the total raw material, and cobalt-based alloy accounts for 10wt% of the total raw material. After ball milling for 36 hours, the above prepared mixture was pressed into a compact, wherein the pressing pressure was 100 MPa. Vacuum sintering is carried out on the compacted compact, and the sintering process is as follows: first, heat to 1350° C., hold for 2 hours, then cool down to 1,200° C. and hold for 2 hours. The prepared cemented carbide WC has a particle size of 200mm, a hardness of 2100HV0.5, and a service life of 2.1 times that of the standard cemented carbide with the same composition.

Embodiment 2

[0014] Embodiment 2: take cobalt-based alloy as the high-performance cemented carbide of bonding phase

[0015] Select tungsten carbide powder (purity 99.9%, 300 mesh) to add cobalt-based alloy (Co 99 -Al 1 -W 0.1 ) as a raw material, wherein tungsten carbide powder accounts for 90wt% of the total raw material, and cobalt-based alloy accounts for 10wt% of the total raw material. After ball milling for 36 hours, the above prepared mixture was pressed into a compact, wherein the pressing pressure was 100 MPa. Vacuum sintering is carried out on the compacted compact, and the sintering process is as follows: first, heat to 1350° C., hold for 2 hours, then cool down to 1,200° C. and hold for 2 hours. The prepared cemented carbide WC has a particle size of 260nm, a hardness of 2000HV0.5, and a service life of 1.4 times that of the standard cemented carbide with the same composition.

Embodiment 3

[0016] Embodiment 3: take cobalt-based alloy as the high-performance cemented carbide of bonding phase

[0017] Select tungsten carbide powder (purity 99.9%, 300 mesh) to add cobalt-based alloy (Co 78 -Al 10 -W 12 ) as a raw material, wherein tungsten carbide powder accounts for 90wt% of the total raw material, and cobalt-based alloy accounts for 10wt% of the total raw material. After ball milling for 36 hours, the above prepared mixture was pressed into a compact, wherein the pressing pressure was 100 MPa. Vacuum sintering is carried out on the compacted compact, and the sintering process is as follows: first, heat to 1350° C., hold for 2 hours, then cool down to 1,200° C. and hold for 2 hours. The prepared cemented carbide WC has a particle size of 240nm, a hardness of 2030HV0.5, and a service life of 1.5 times that of the standard cemented carbide with the same composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com