Novel ice-covering-proof coating and preparation method thereof

An anti-icing and coating technology, applied in coatings, chemical instruments and methods, and other chemical processes, etc., can solve problems such as short circuit of transmission lines, collapse of towers, and power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

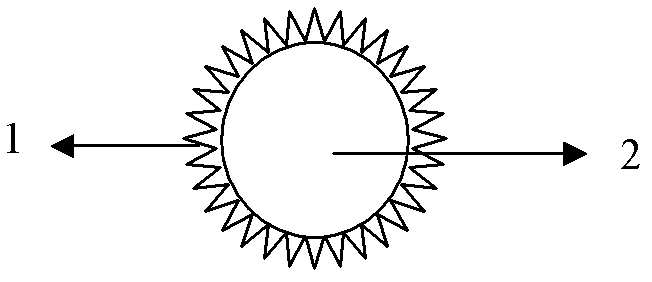

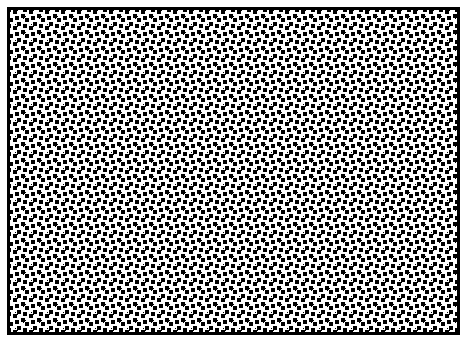

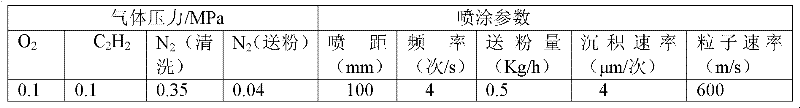

[0018] Using the method of gas explosion spraying, the mixed substance of glass powder and polytetrafluoroethylene with a particle size of 10 μm is sent into the explosion gun as a coating material, wherein the mass content of glass powder is 50%, and the content of polytetrafluoroethylene is 50%. The mass content is 50%; the mixed gas of 0.05-0.2MPa oxygen and 0.05-0.15MPa acetylene enters the flow tube, is ignited by a spark plug, and explodes, so that the glass powder material reaches the wire with a spray distance of 100mm at a speed of 600m / s. By controlling the spraying process, the thickness of the coating is 15 μm, and the surface morphology is a micro-nano structure with small raised structures; the specific process parameters are shown in Table 1. The transmission line made as figure 1 with figure 2 As shown, the anti-icing coating 1 with a small convex structure is sprayed on the surface of the transmission line 2 .

[0019] Table 1. The first group of gas explos...

Embodiment example 2

[0022] A new type of anti-icing coating was prepared by supersonic flame spraying. The prepared mixture of glass powder with a mass content of 70% and polytetrafluoroethylene with a mass content of 30% was used as the coating material, and its particle size was 25μm, through the supersonic flame spraying (HVOF), make it at the oxygen flow rate of 400L / min, C 3 h 8 The flow rate is 30L / min, the spraying pressure is 0.4MPa, and the spraying distance is 100mm. By controlling the spraying process, the thickness of the coating is 20μm, and the surface morphology is a micro-nano structure with small convex structures.

Embodiment example 3

[0024] Using the method of gas explosion spraying, the mixed substance of glass powder and polytetrafluoroethylene with a particle size of 50 μm is sent into the explosion gun as a coating material, wherein the mass content of glass powder is 90%, and the content of polytetrafluoroethylene is 90%. The mass content is 10%; the mixed gas of 0.05-0.2MPa oxygen and 0.05-0.15MPa acetylene enters the flow tube, is ignited by a spark plug, and explodes, so that the glass powder material reaches the wire with a spray distance of 200mm at a speed of 800m / s. By controlling the spraying process, the thickness of the coating is 25 μm, and the surface morphology is a micro-nano structure with small raised structures; the specific process parameters are shown in Table 2.

[0025] Table 2. The second group of gas explosion spraying process parameters

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com