Preparation method of precious metal-containing low-carbon alkane dehydrogenation catalyst carrier

A technology for dehydrogenation catalysts and low-carbon alkanes, which can be used in catalyst carriers, metal/metal oxide/metal hydroxide catalysts, hydrocarbons, etc., and can solve the problems of affecting catalyst performance and easy aggregation and growth of metal particles. Achieve the effect of enhancing the anti-coking ability, uniform distribution and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

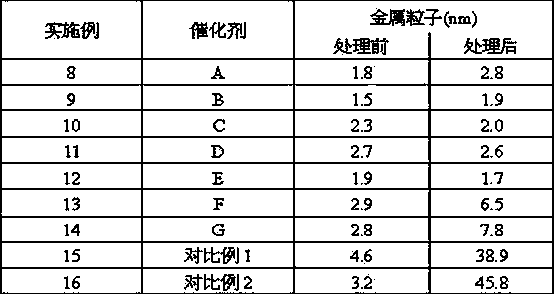

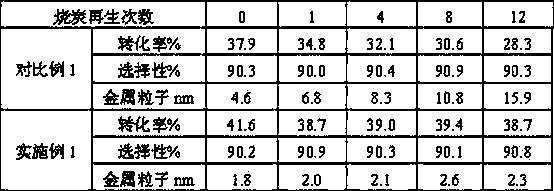

Examples

Embodiment 1

[0021] Get 60g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) be dissolved in 200ml deionized water, then by the amount of substance Al:Mg is the mixed aqueous solution of 1:1 preparation aluminum nitrate solution and magnesium nitrate; o C, under vigorous stirring, slowly drop the mixed aqueous solution into 5% ammonia water to form a precipitate, control the pH value to be about 10, filter the precipitate at room temperature overnight, wash, and wash at 120 o C drying, crushing, sieving, at 700 o C was calcined for 3 hours to obtain composite alumina supports with different proportions.

[0022] The composite alumina support that obtains adopts impregnation technology to load platinum and tin components, that is, the aqueous solution of required amount of chloroplatinic acid and tin chloride is impregnated with the obtained alumina support at room temperature for 24 hours (metal platinum loading 0.4%, Pt:Sn=1:2), then 60 o C drying, 530 in air flow o C roasting for 3 hours,...

Embodiment 2

[0026] The carrier and catalyst were prepared according to the method of Example 1, except that the ratio of Al:Mg was 2:1 according to the amount of substance, and the obtained catalyst was marked as B.

[0027]

Embodiment 3

[0029] The carrier and catalyst were prepared according to the method of Example 1, except that the ratio of Al:Mg was 4:1 according to the amount of substance, and the obtained catalyst was marked as C.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com