High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

A carbonitride and composite treatment technology, applied in the field of aluminum alloy materials and their high-quality treatment, to achieve the effect of improving strength and hardness and preventing coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

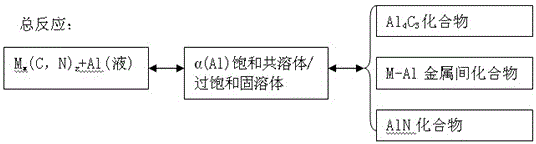

Method used

Image

Examples

Embodiment Construction

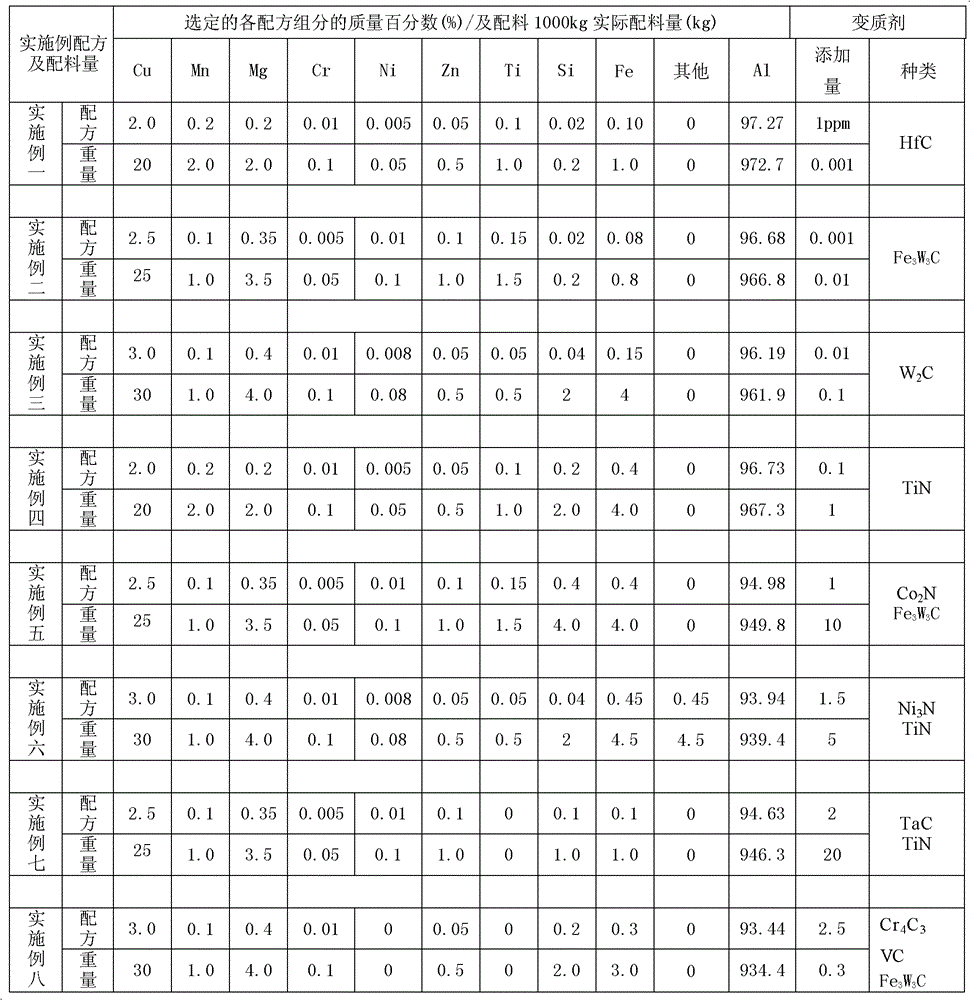

[0062] Step 1: Select the formula of each element and substance according to the table below, and calculate the weight of each substance required based on the total amount of the prepared alloy of 1000kg.

[0063]

[0064] Step 2: First add aluminum ingots or molten aluminum into the smelting furnace, heat it to melt it completely, add the alloy elements selected in step 1 according to the proportion of the formula, make it completely dissolved and melted, and heat it at 700-1000°C after refining Insulation; the melting process is completed in a closed environment;

[0065] Step 3: Use a mixed gas of nitrogen and argon (V / V 1:1), add a small amount of chlorine (volume ratio: 1%), degas and purify the melt, and make carbonitride powder (50 mesh) Add the gas into the alloy melt in a fluidized manner; stir at the same time so that the carbonitrides are evenly distributed in the alloy melt and fully react with the alloy melt; after adding the modifier, continue to feed the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com