Multifunctional engraving, punching and cutting all-in-one machine

An all-in-one machine and multi-functional technology, applied in metal processing machinery parts, other manufacturing equipment/tools, metal processing, etc., can solve complex process problems, improve precision and efficiency, save space occupied by equipment, and avoid cuts The effect of the brace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

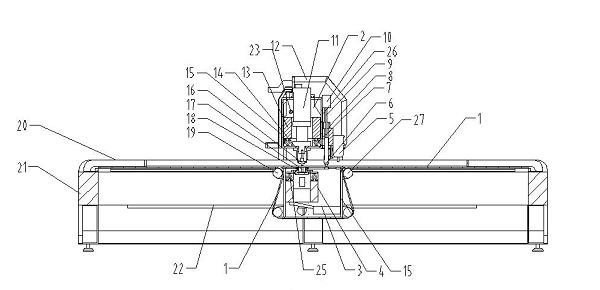

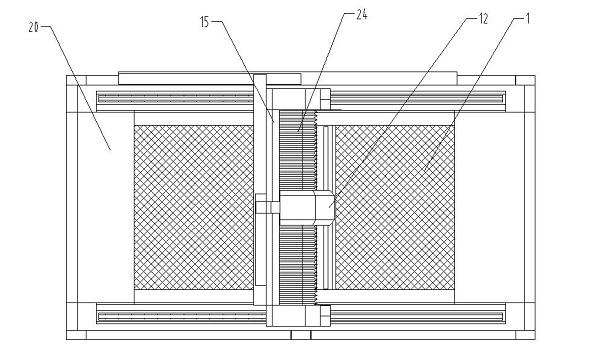

[0029] Examples such as figure 1 As shown, the all-in-one machine for engraving, punching and cutting includes a frame 21, a tackle 15 that can slide forward and backward is installed on the frame 21, and a machine head 2 that can move left and right is installed on the tackle 15. A punching device, a plasma cutting device and an engraving device are installed on the machine head 2 .

[0030] The upper part of the frame 21 is provided with a transmission net bag 1, the front and rear ends of the transmission net bag 1 are respectively fixedly connected with the frame 21, and the front end of the lower part of the trolley 15 is provided with two front supporting drive rollers arranged up and down. 27. The rear end is provided with two rear support drive rollers 19 arranged up and down, and the middle part of the conveying mesh bag 1 is staggered around the two front support drive rollers 27 and the two rear support drive rollers 19 and connected with the two front support drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com