Method for improving quality of brick and tile products and gas feeder

A gas supply device and product quality technology, which is applied to steam boiler components, steam boiler accessories, lighting and heating equipment, etc., can solve the problems that cannot meet production requirements, cannot meet the uniform addition of water, and is difficult to form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

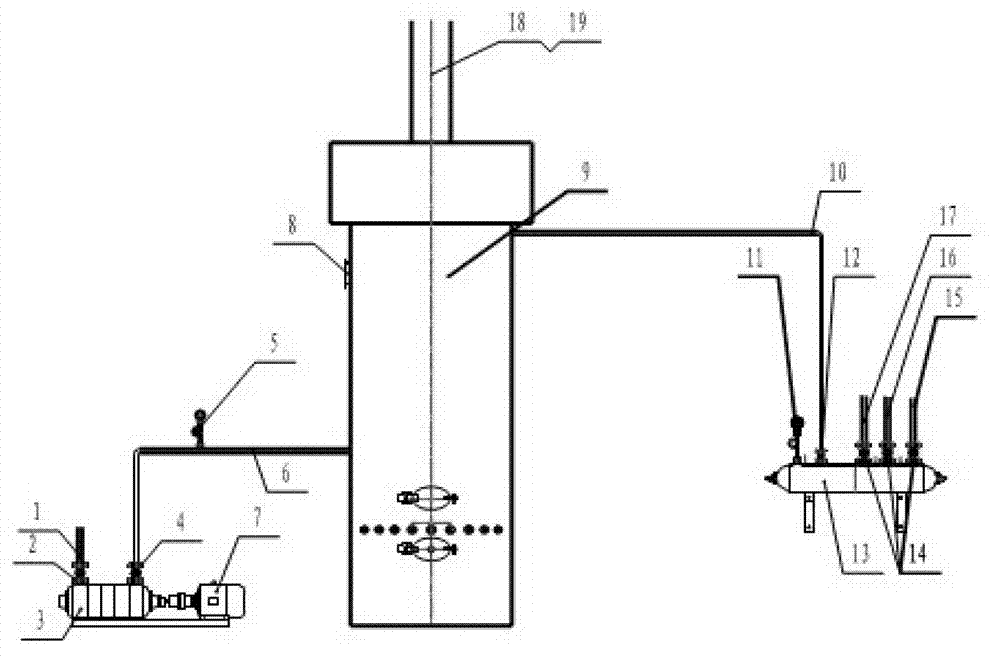

[0009] The method for improving the quality of brick and tile products is to pass water vapor with a pressure greater than 0.4 MPa into the middle part of the upper mixing tank of the vacuum extruder or the middle part of the ordinary mixer during the production of the brick and tile products.

[0010] The basic structure of the gas supply device is shown in the figure. It has a steam boiler 9 (vertical coal-fired steam boiler). The gas supply pipe 10 of the steam boiler 9 is connected to a sub-cylinder 13. The middle part of the superior mixing tank of the machine or the stirring tube in the raw material in the middle part of the ordinary mixer. The agitating tubes include the first agitating tube 15 for supplying air to the first agitator, the second agitating tube 16 for aerating the secondary agitator, the upper agitating tube 17 for the extruder superior agitating and aerating, and the first agitating tube 15. The second stirring pipe 16 and the upper stirring pipe 17 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com