Insert molding mold with insert local heating function and machining method thereof

A local heating and insert molding technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of melting and discoloration of the plating layer of metal terminals, and achieve the effect of ensuring injection molding quality and production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Such as Figure 13~Figure 16 As shown, the two groups of workpieces processed by the present invention include a group of workpiece one 27 and a group of workpiece two 28 . Work piece one 27 includes metal terminal one 271 . One end of the metal terminal one 271 is injection-molded with the insulator 26 through the molding die of the present application. Work piece two 28 includes metal terminal two 281 . One end of the second metal terminal 281 is injection-molded with the insulator 26 through the molding die of the present application. The first metal terminal 271 and the second metal terminal 281 are both sheet structures. The difference between the second workpiece 28 and the first workpiece 27 is that the first metal terminal 271 is provided with a bent portion, and the second metal terminal 281 is a planar structure.

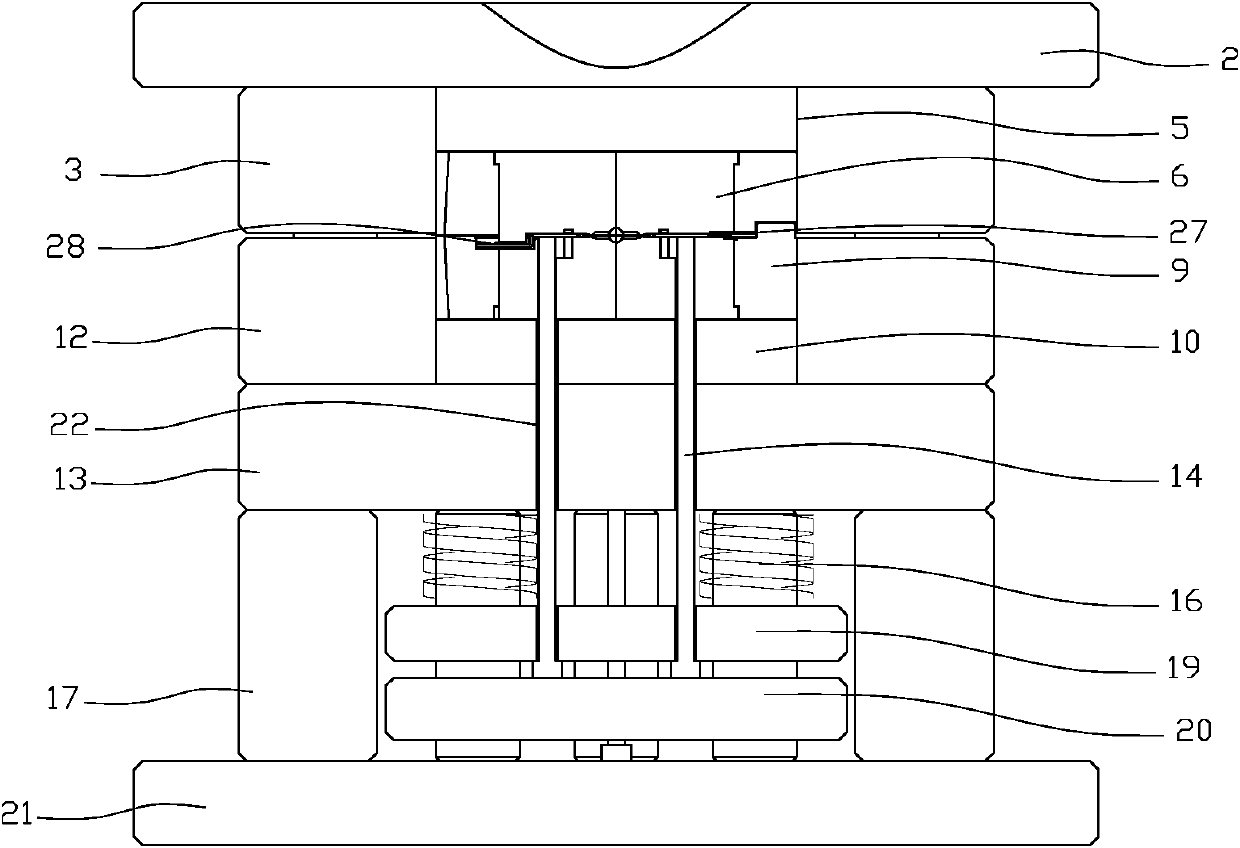

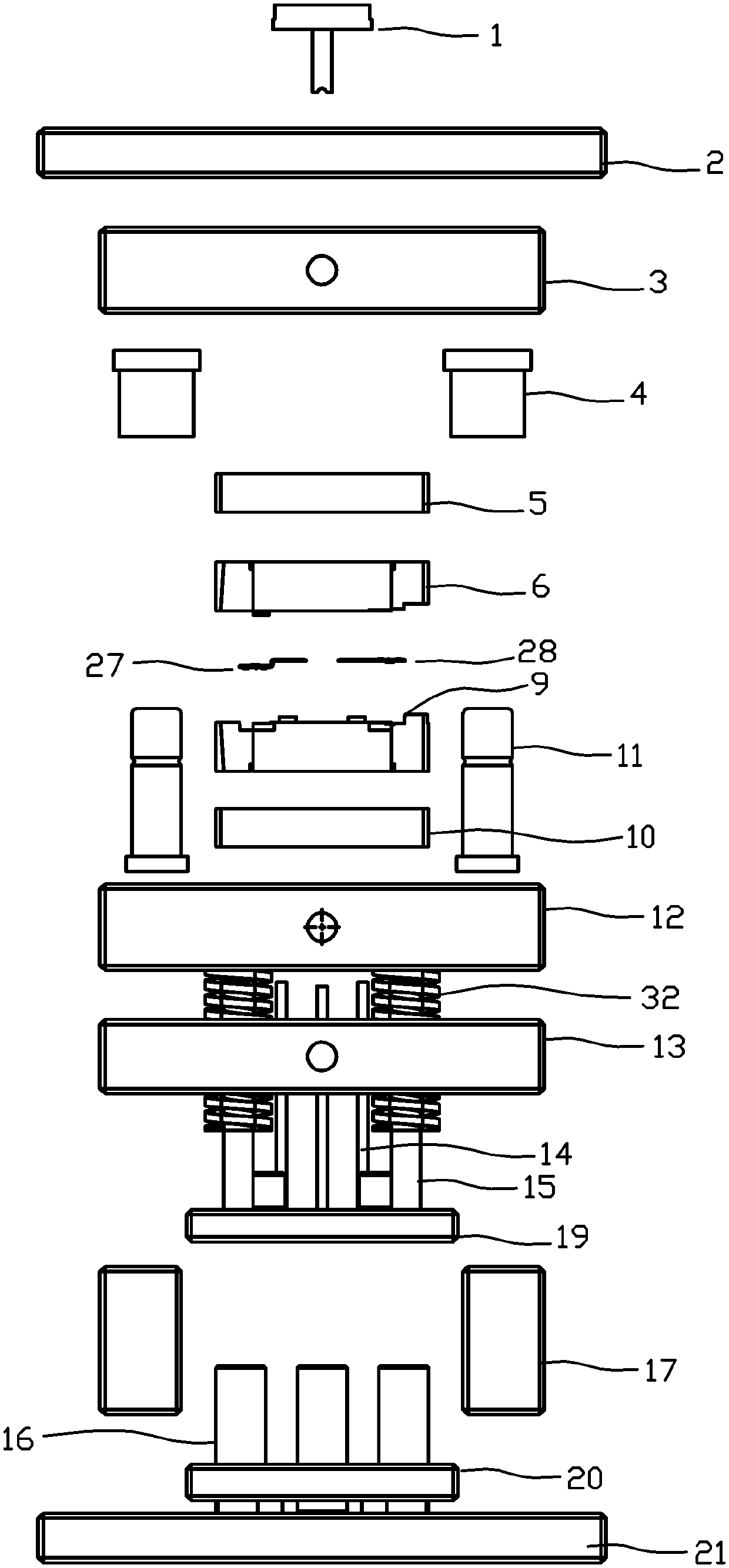

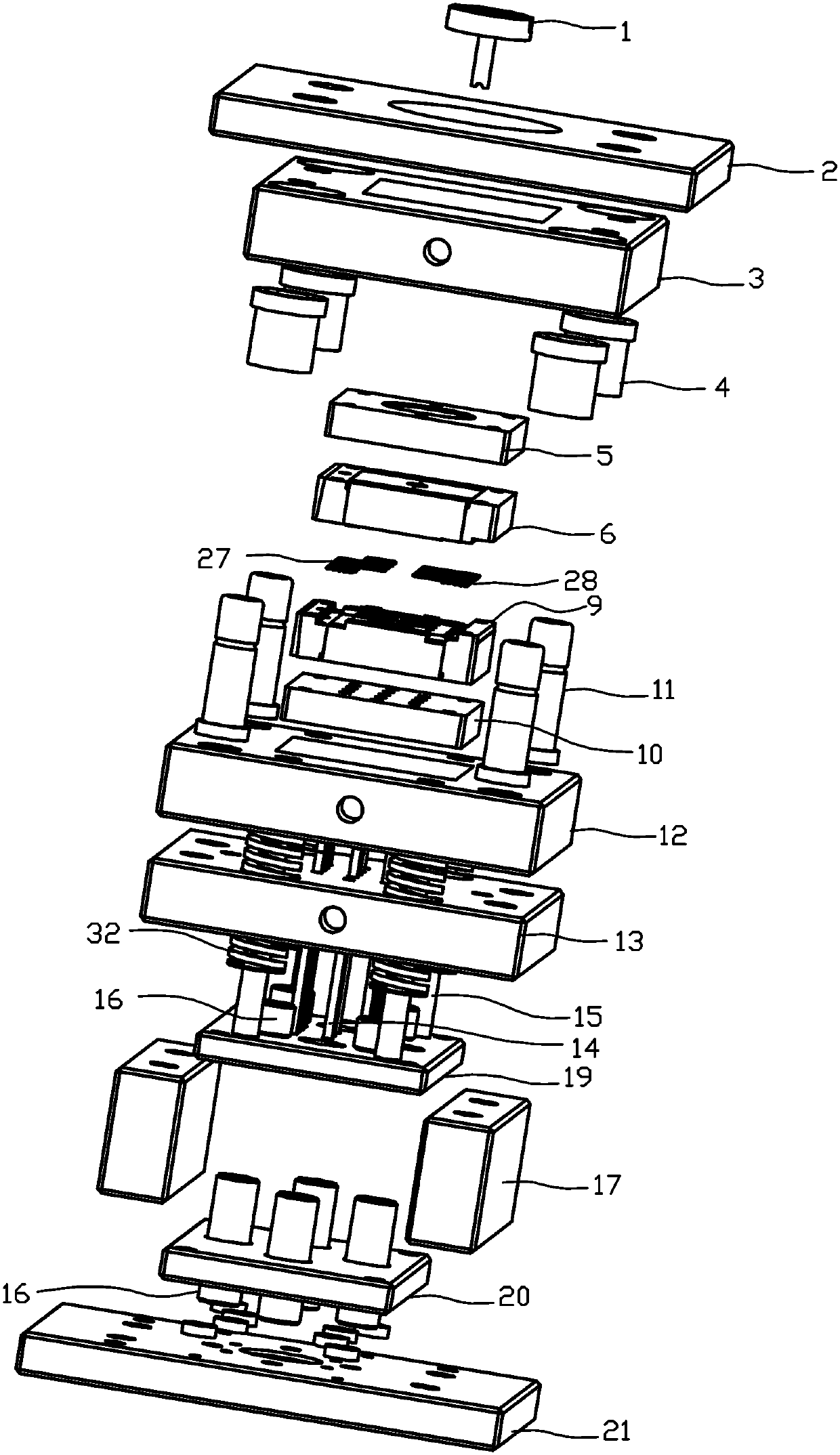

[0047] Such as Figure 1~Figure 12 As shown in the figure, an insert molding mold with partially heated inserts includes a fixed mold and a mov...

Embodiment 2

[0054] The processing method of the insert molding mold in which the insert is locally heated in Embodiment 1 comprises the following steps,

[0055] Step 1, loading; put the workpiece into the storage cavity of workpiece 1 27 and workpiece 2 28, store workpiece 1 27 and workpiece 2 28 through the movable mold core 9, and the ends of workpiece 1 27 and workpiece 2 28 that need to be injected correspond to each other Place in the injection molding cavity 36 in the receiving cavity of workpiece one 27 and workpiece two 28;

[0056] Step 2, position limiting, mold closing; press down the mold so that the fixed mold and the movable mold are pressed together up and down, and the workpiece one 27 and the workpiece two 28 are limited in the workpiece receiving cavity between the fixed mold and the movable mold;

[0057] Step 3, processing injection molding; injecting workpiece 1 27 and workpiece 2 28 in the injection cavity 36 through sprue bushing 1; injecting through horizontal exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com