Patents

Literature

135results about How to "Guaranteed product yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

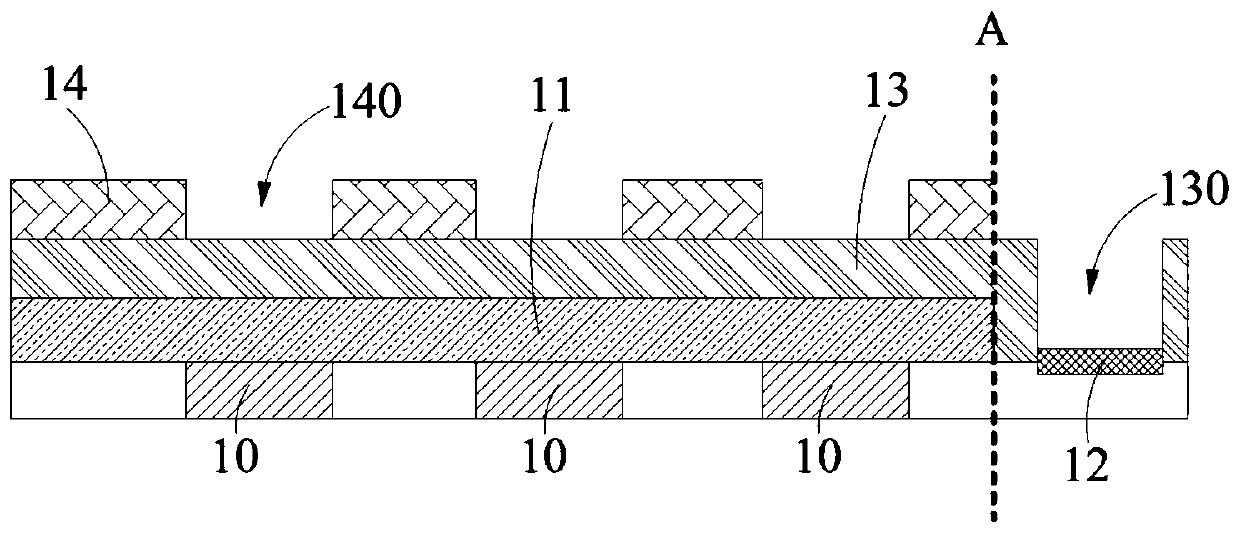

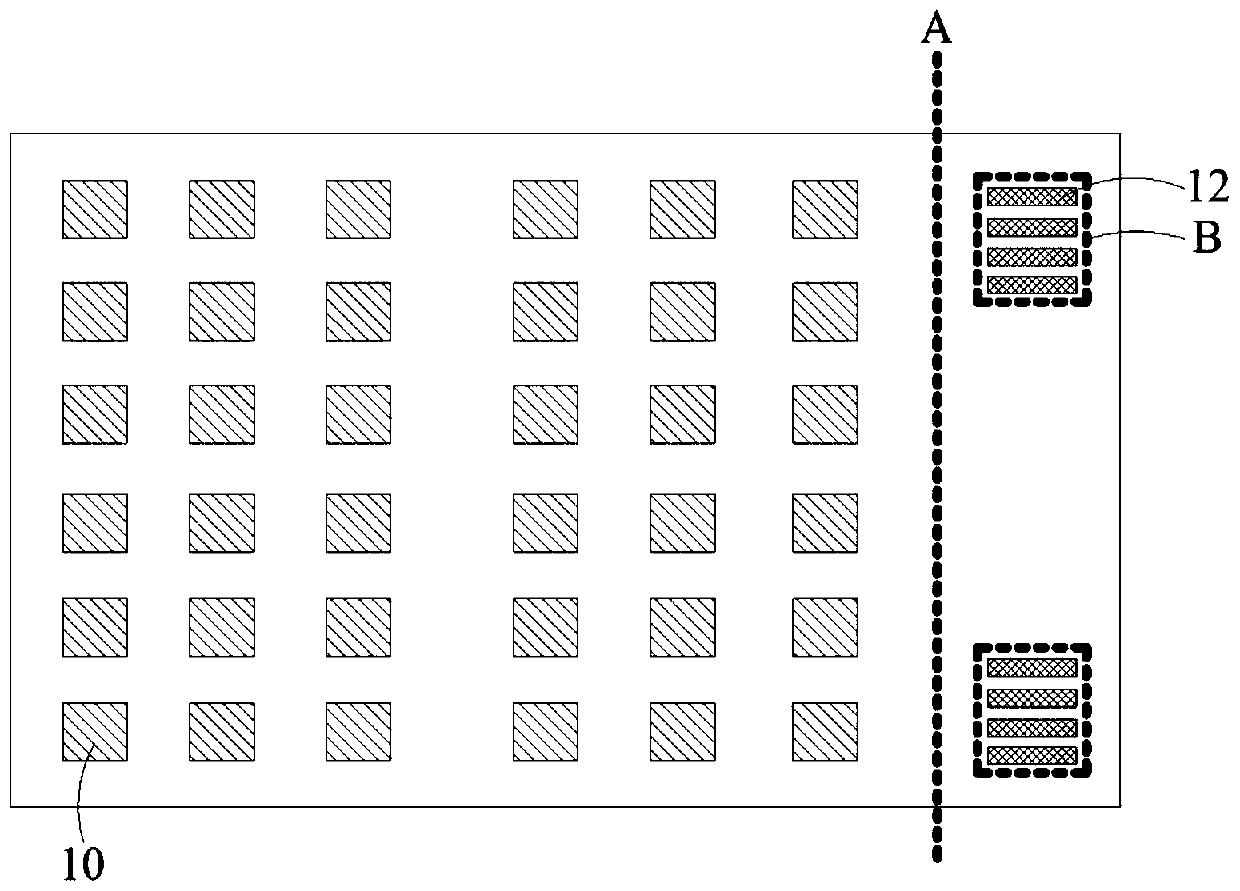

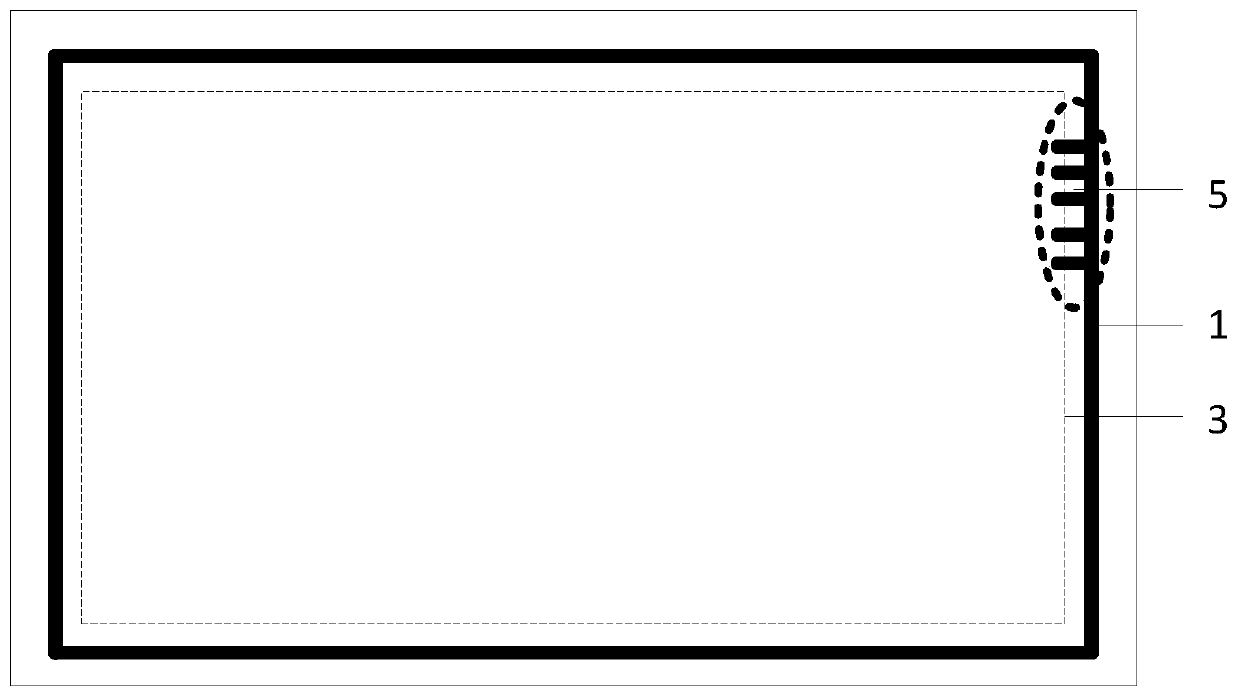

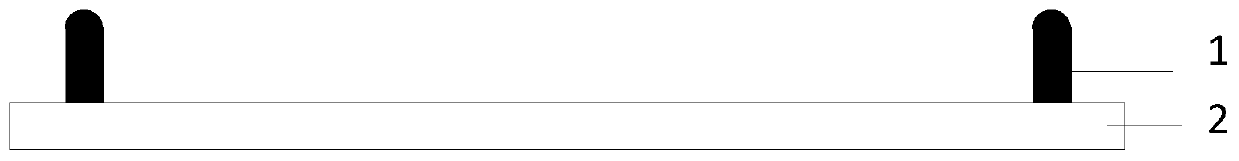

Display device

ActiveCN108594524AIncrease the screen ratioGuaranteed production efficiencyNon-linear opticsCamera lensDisplay device

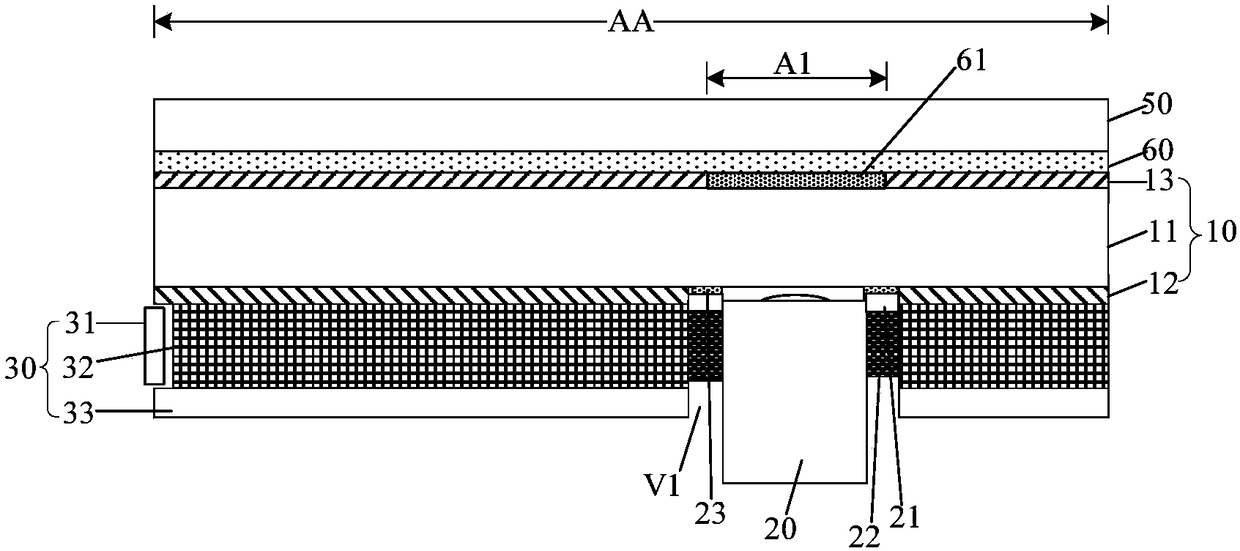

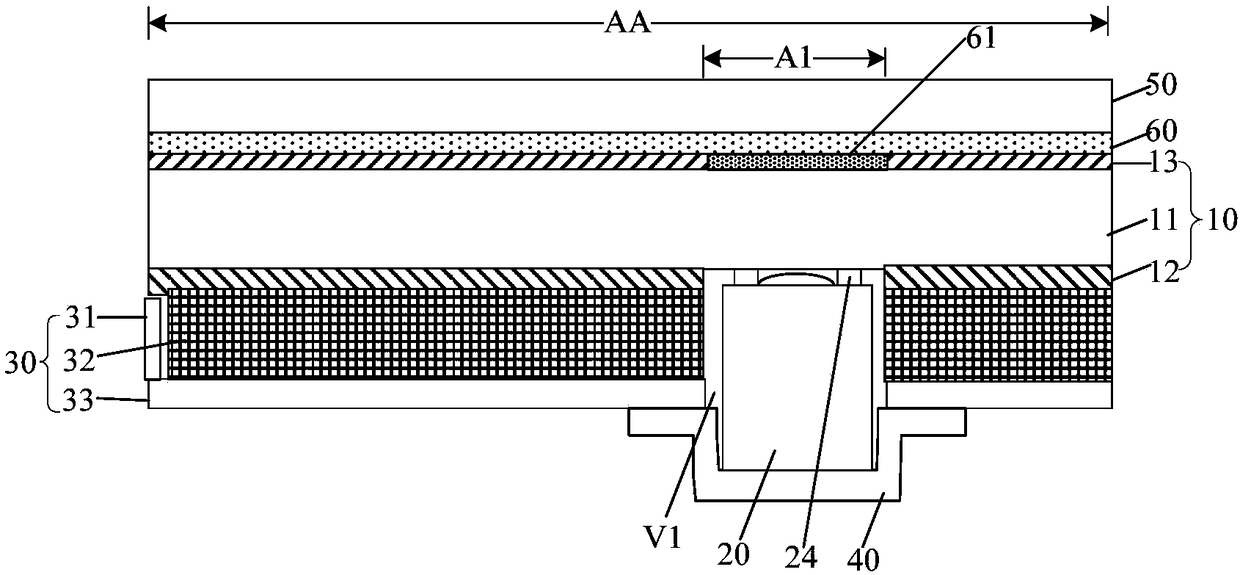

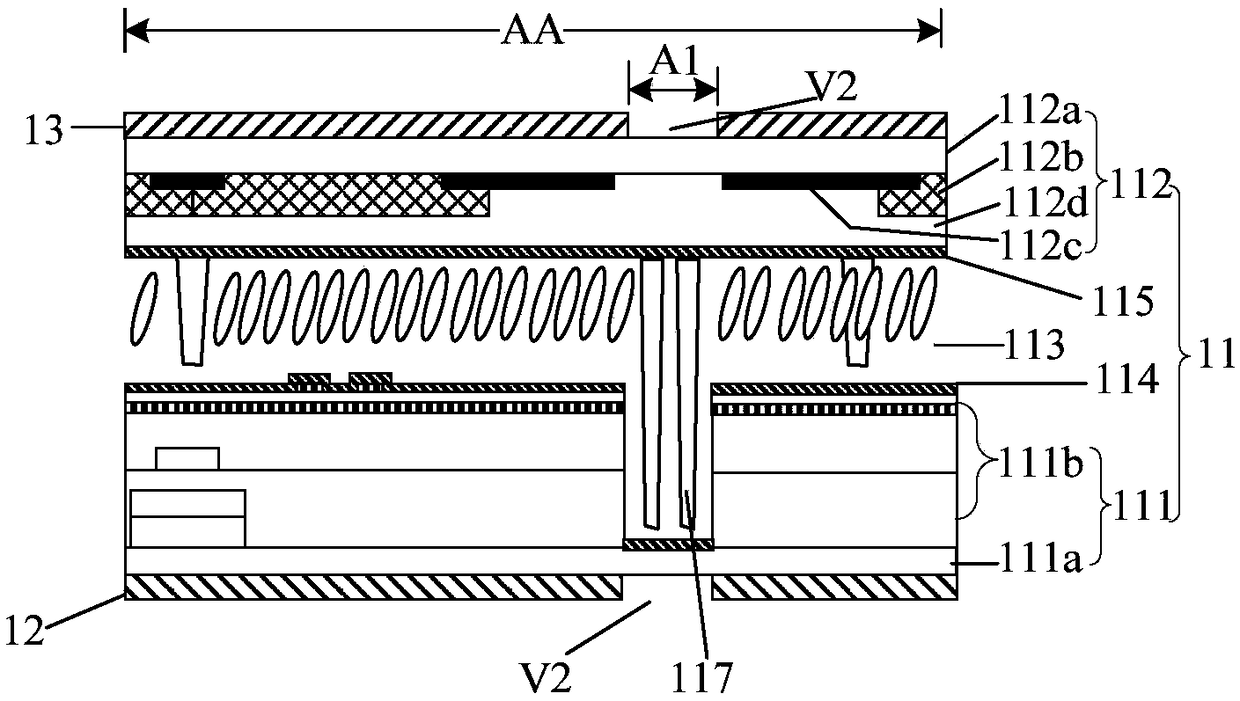

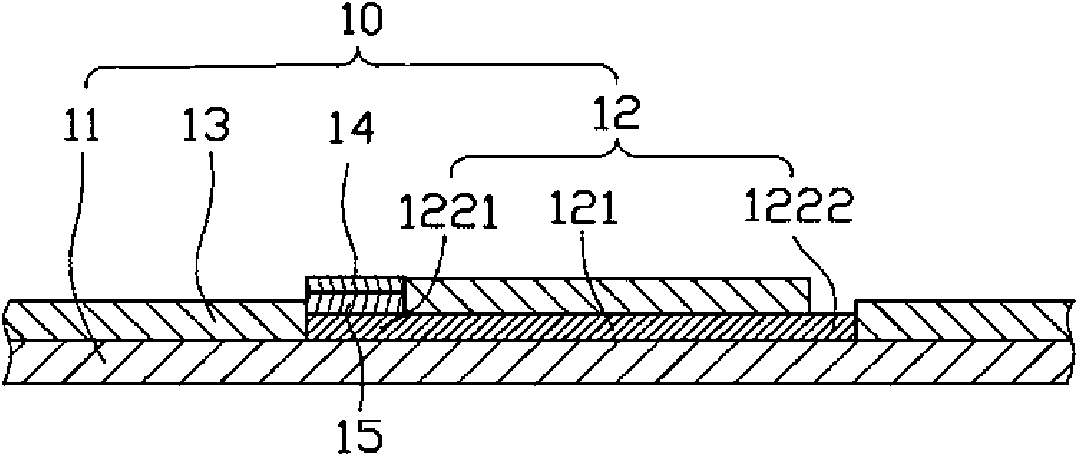

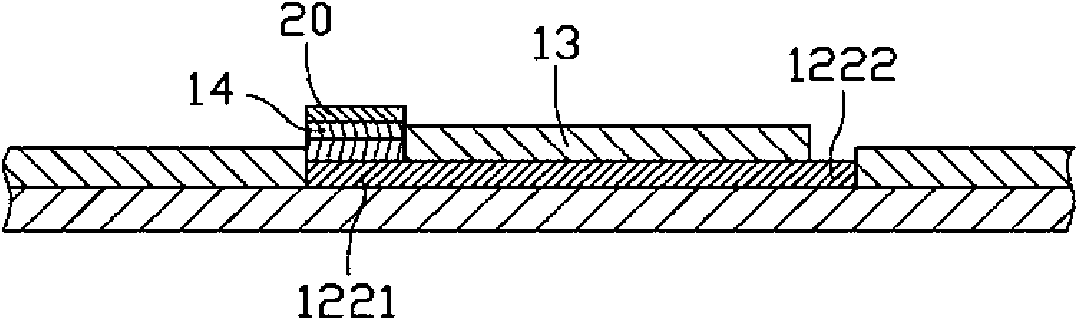

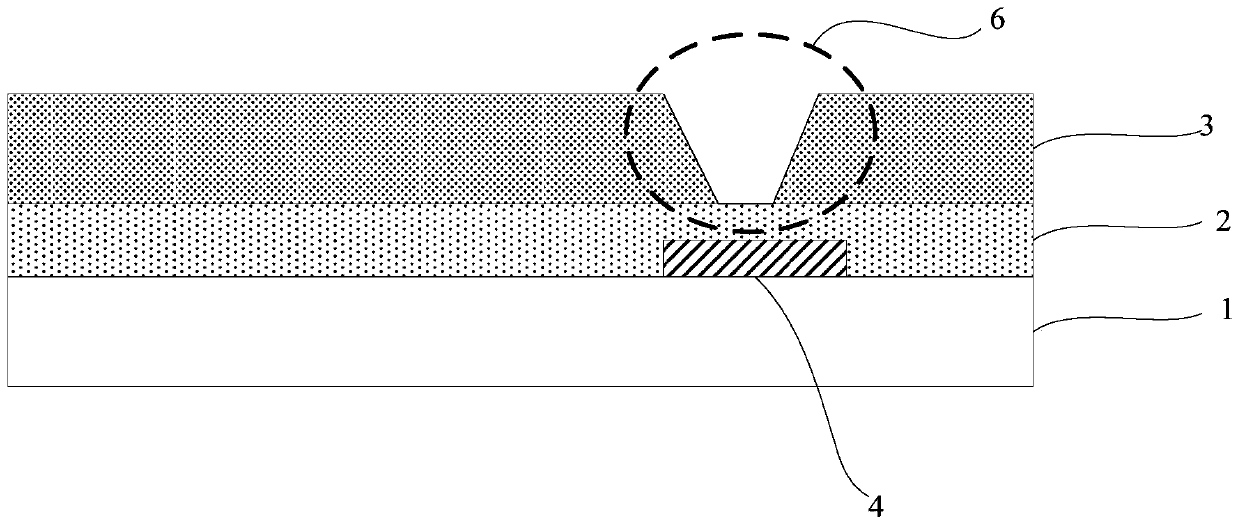

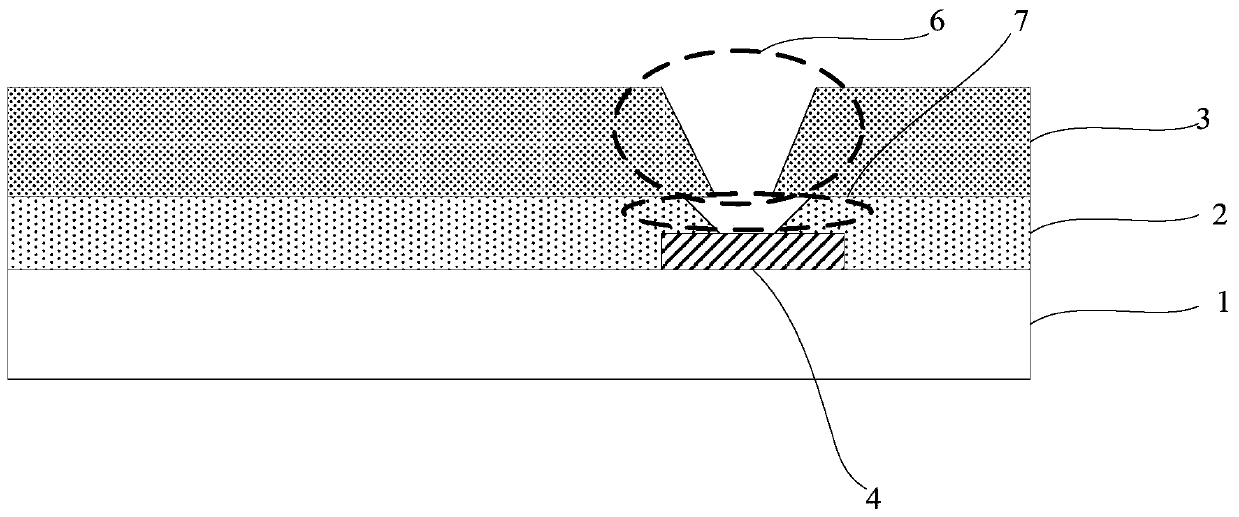

The invention provides a display device. The display device comprises a display module and a camera located in a display area of the display module and located on one side, backing to the light emergent direction, of the display module; the display area of the display module comprises a light incidence area corresponding to a lens of the camera, and the light incidence area allows outside light topenetrate through, so that the penetrating outside light is irradiated to the lens of the camera. The screen-to-body ratio of the display device can be increased under the condition that the production efficiency and the product yield are guaranteed.

Owner:BOE TECH GRP CO LTD +1

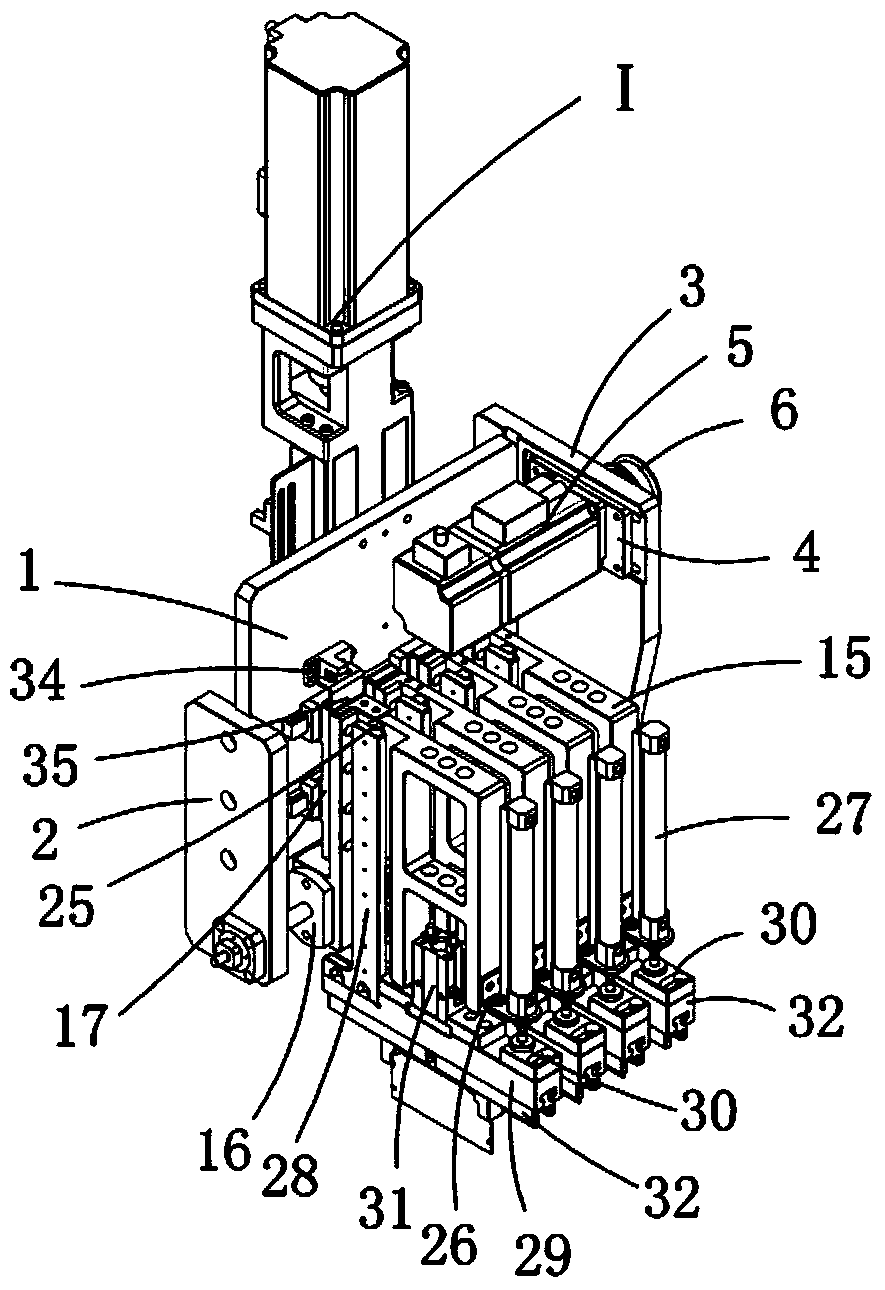

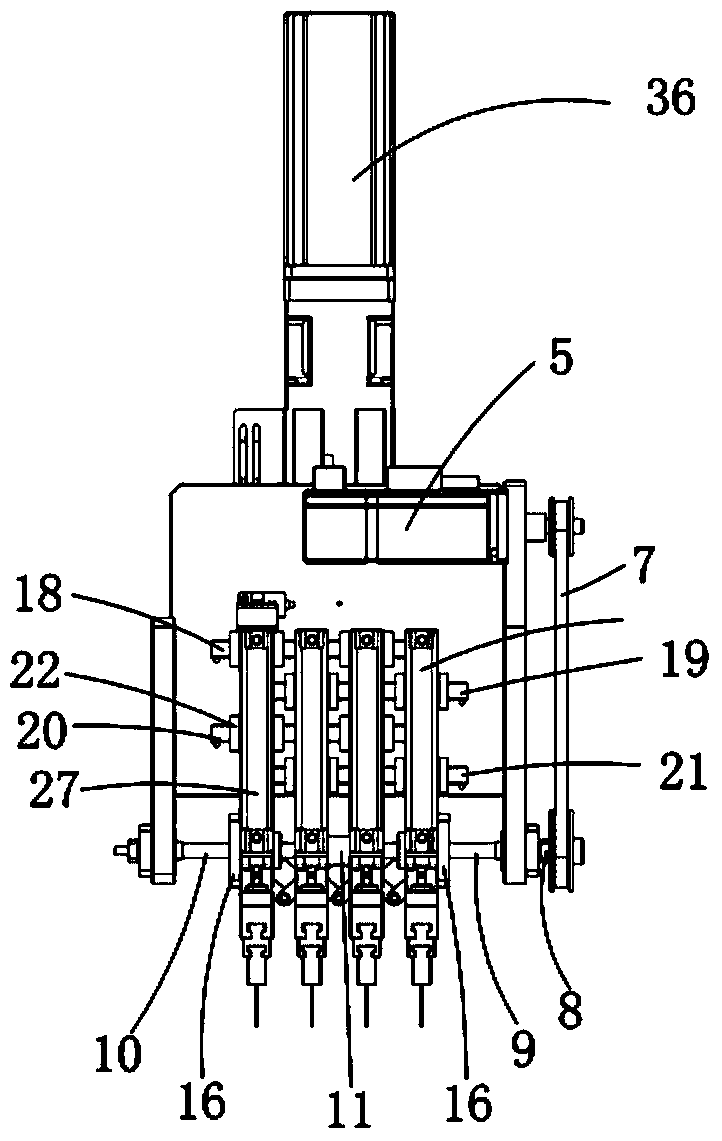

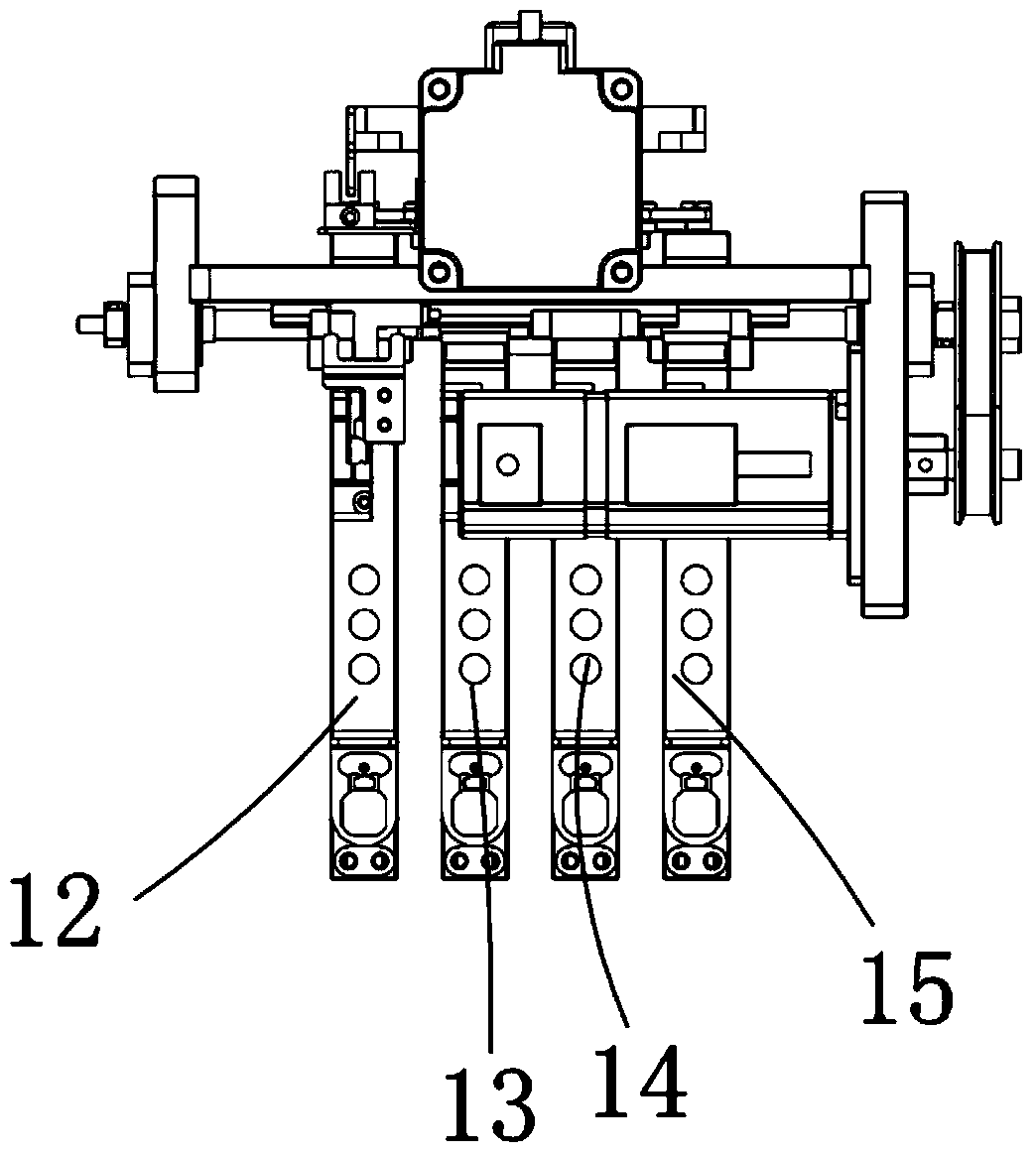

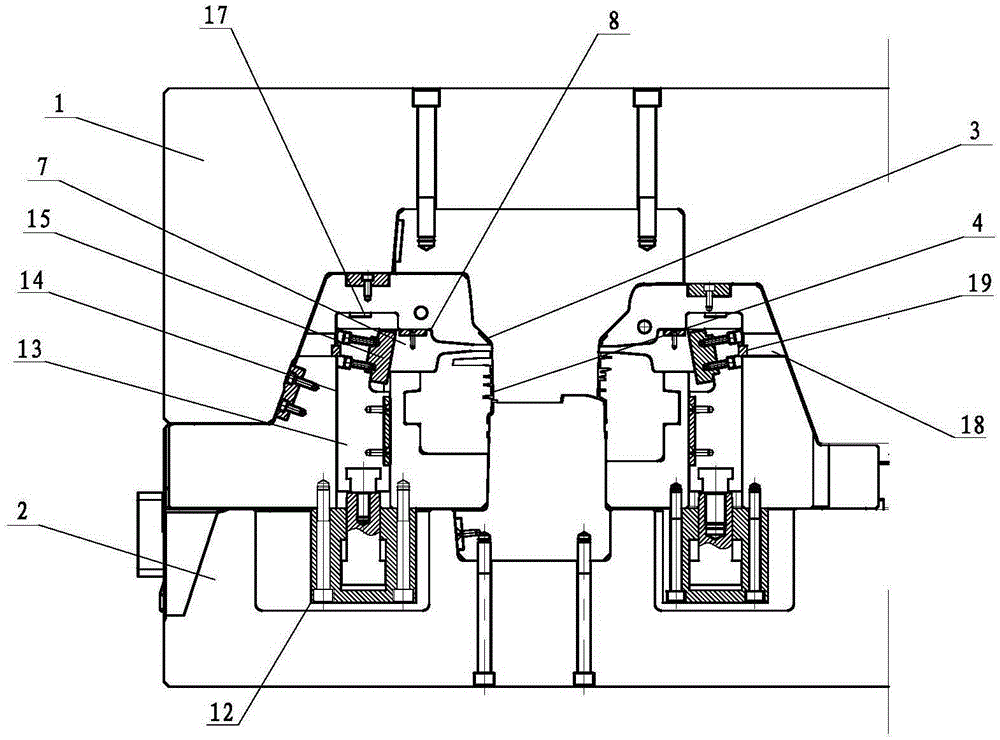

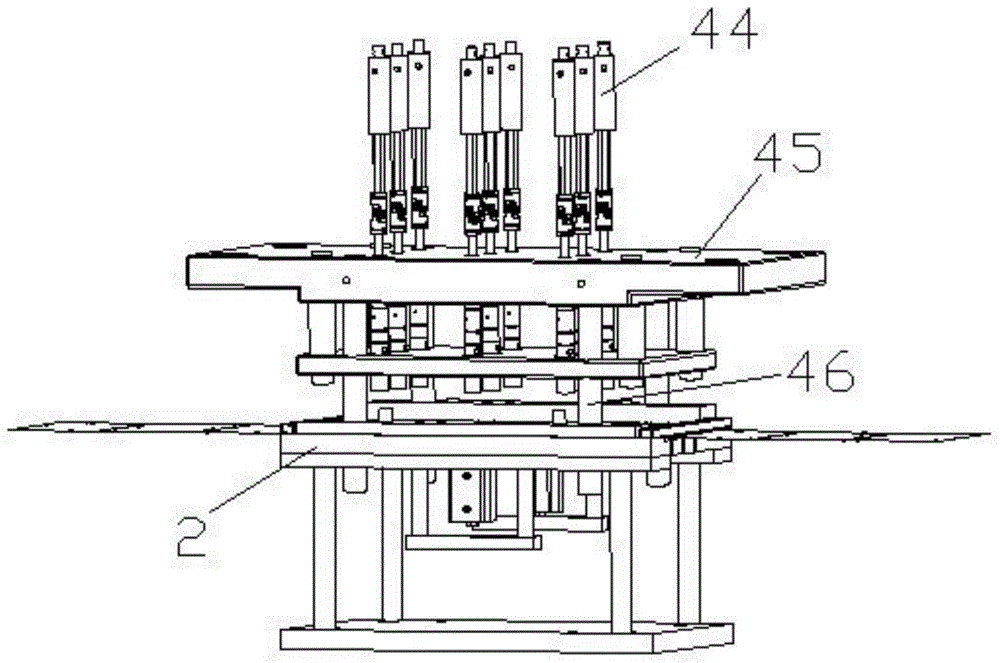

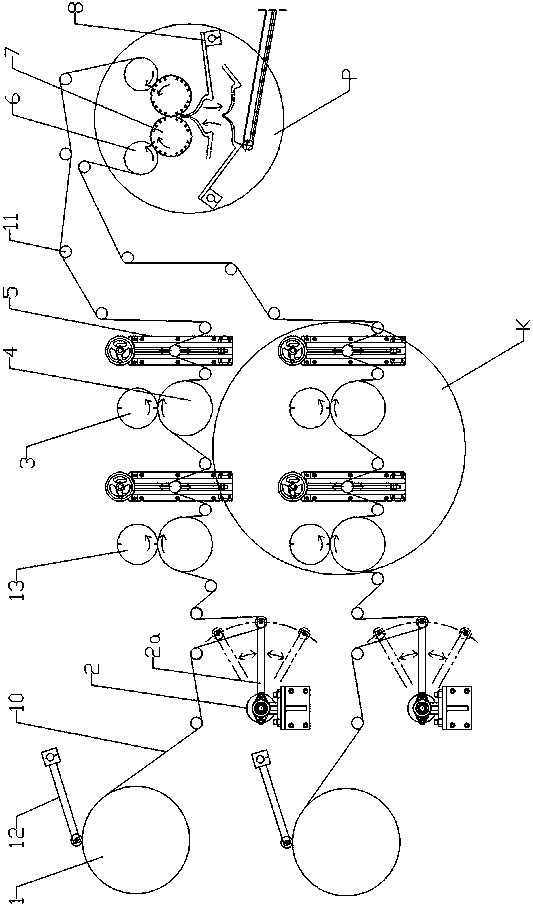

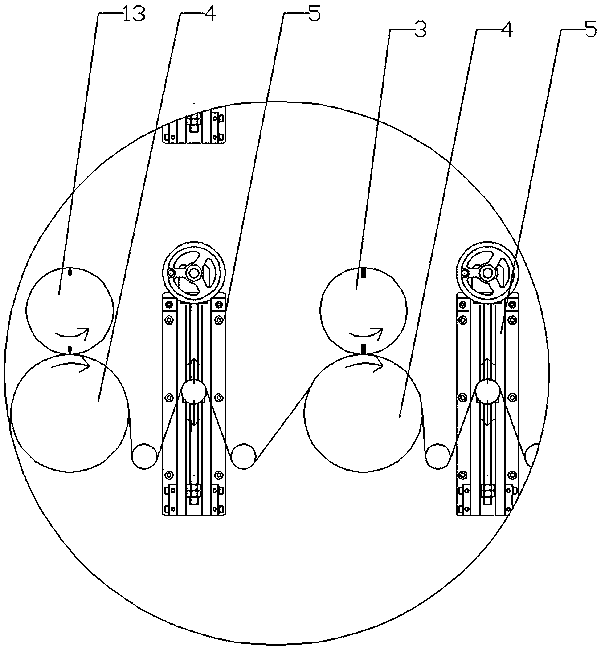

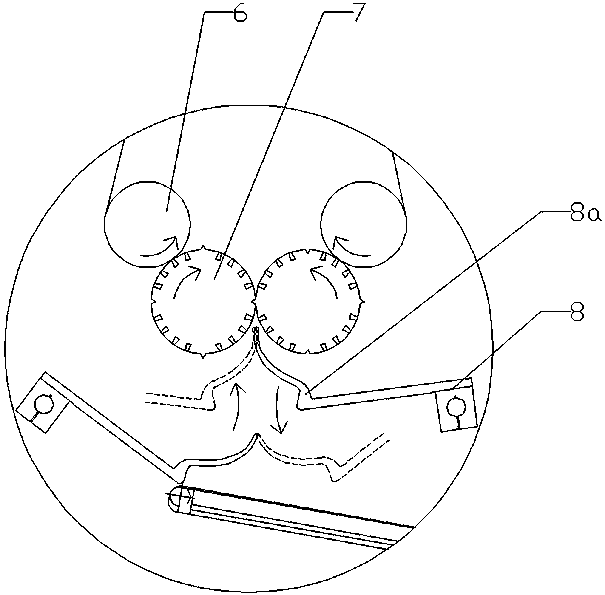

Retractable clamping jaw with changeable pitch

ActiveCN103707311AIncrease productivityHigh precisionGripping headsEngineeringMechanical engineering

The invention relates to a retractable clamping jaw with the changeable pitch. A Z-axis mechanism of the clamping jaw can adjust the vertical position of the whole device. A pitch adjusting motor transmits the power to a synchronous wheel b through a synchronous wheel a and a synchronous belt, the synchronous wheel b drives a lead screw b, the lead screw b rotates to drive a lead screw a to rotate, the distance between a first connecting plate and a fourth connecting plate can be adjusted through two reverse nuts, the distance between a second connecting plate and a third connecting plate can be driven by a connecting rod to be adjusted equally, and therefore the horizontal distance of each set of connecting plates can be adjusted within a certain range. A pneumatic finger drives two clamping jaw heads, the unfolding or folding of the finger can drive the two clamping jaw heads to move together, and therefore the function of placing and taking products can be achieved. The distance between the two clamping jaw heads can be manually adjusted. Each set of vertical lifting air cylinders can be independently operated to drive the clamping jaw connecting plates to ascend or descend and to enable each set of clamping jaw heads to be independently lifted. The clamping jaw can clamp different types of products with the size within a certain range, the distance between clamping jaws can be adjusted, and production efficiency is high.

Owner:BOZHON PRECISION IND TECH CO LTD

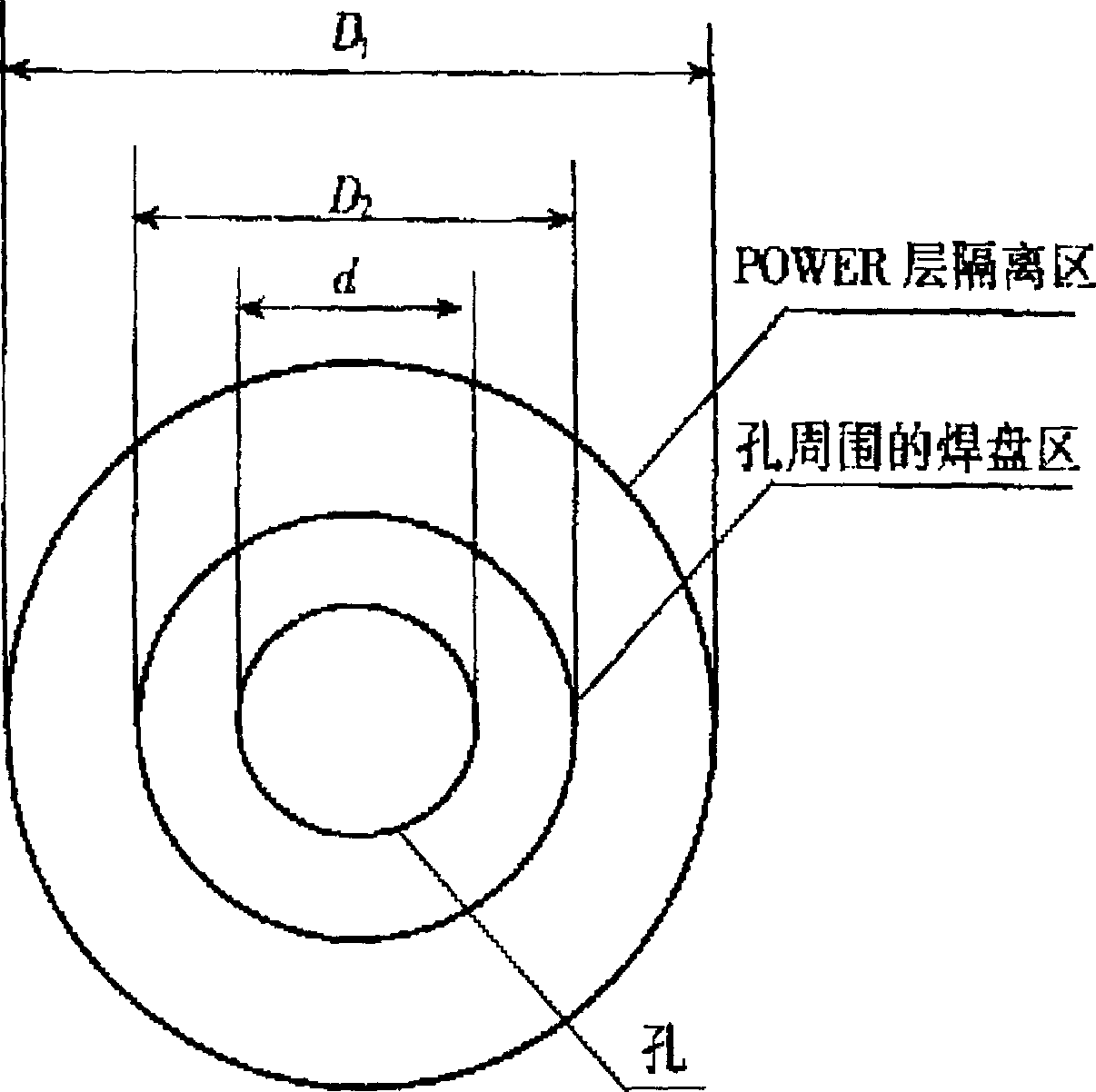

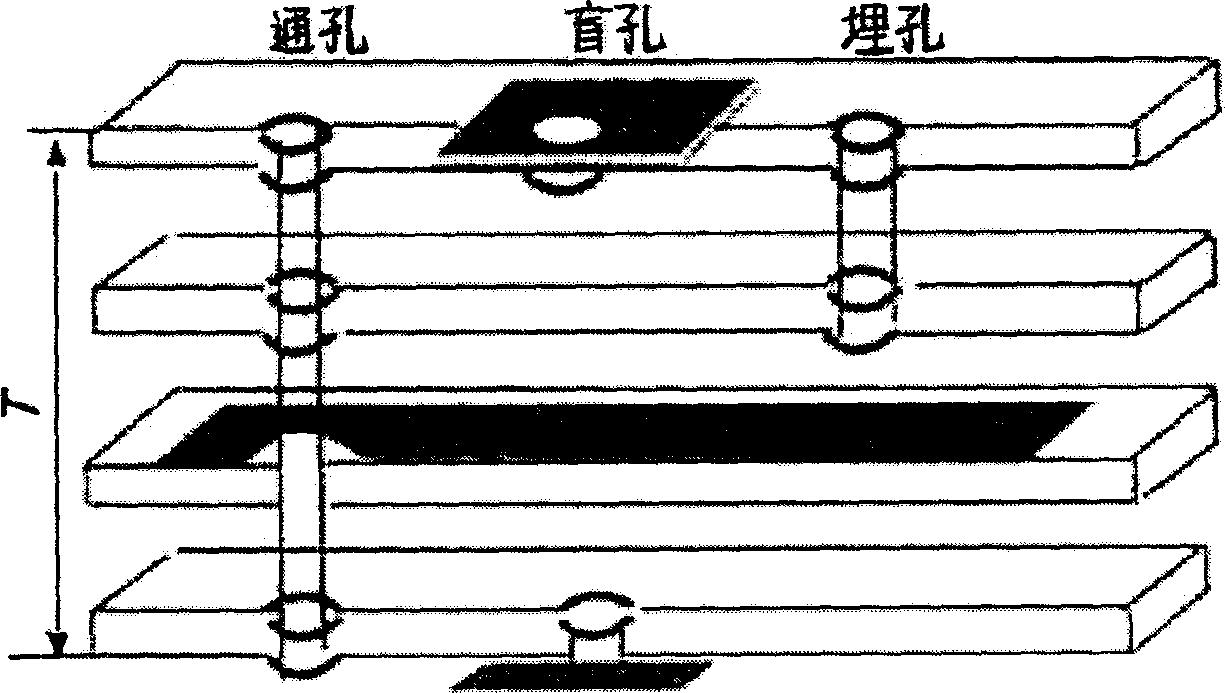

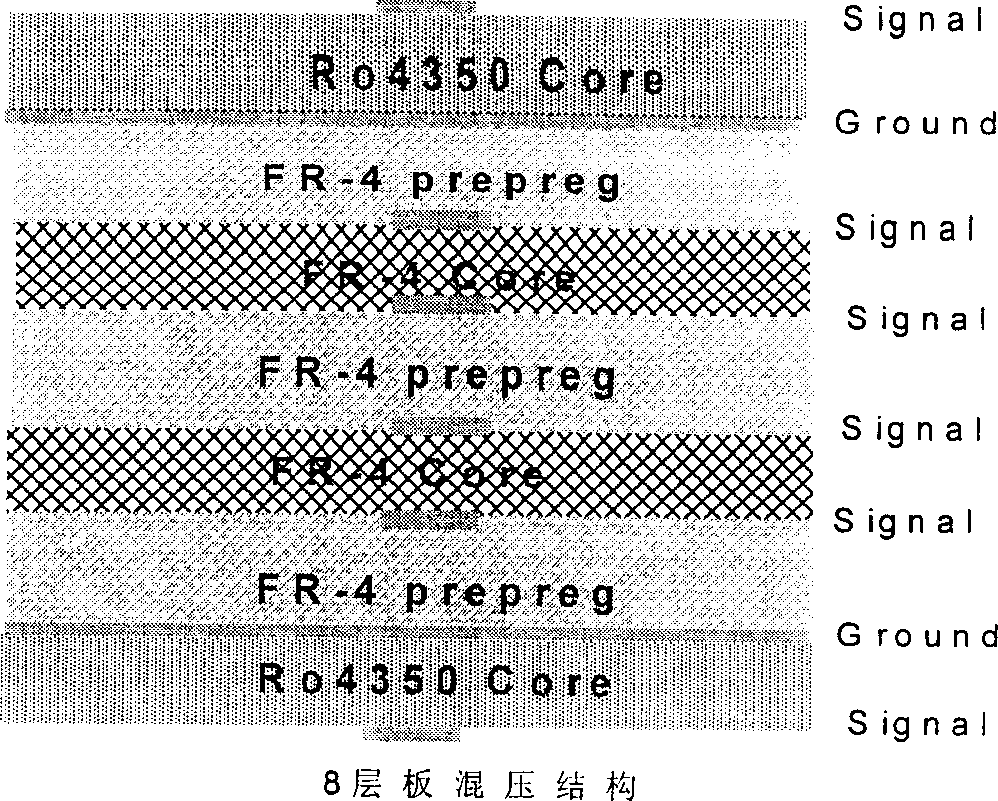

Printed circuit board capable of realizing high-speed signal transmission and making method

InactiveCN1852633ALow costOvercome limitationsCircuit susbtrate materialsMultilayer circuit manufactureCopper foilTransmission quality

The disclosed printing circuit board (PCB) is composed of two outer layers and one inner layer. The outer layer is made from plate of capable of transmitting signal in high speed; and the inner layer is made from general plate. Method for fabricating PCB includes following steps: carrying blackening / browning treatment; superimposing and pressing prepreg and outer copper foil together so as to form multilayer half finished board; drilling holes on multilayer board, plating via holes, using negative plate imaging and etching to prepare needed ducting lines in each core plate in inner layer; obtaining lines on outer layer so as to produce multilayer PCB in hybrid plates; back drilling technical holes in order to take out STUB with no connection and no attribute on end part of via holes. Features of the PCB are: high-speed signal transmission in low cost, high reliability, guaranteeing rate of good quality of PCB produced, and transmission quality of high-speed signal.

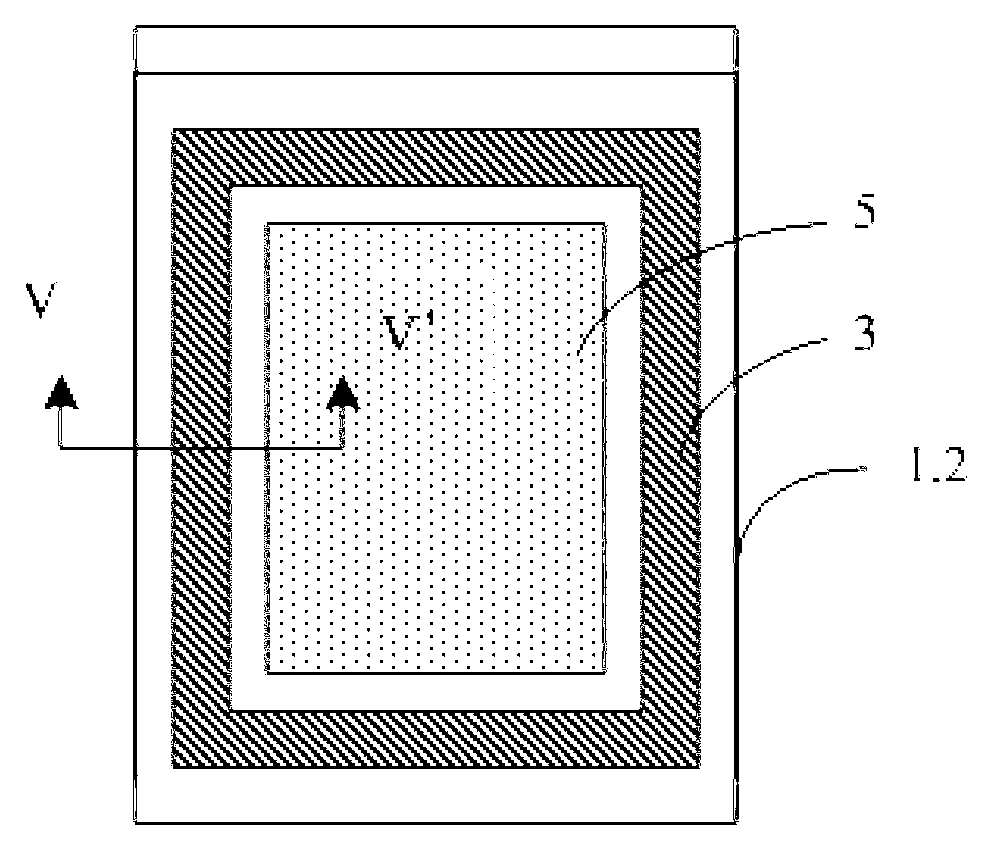

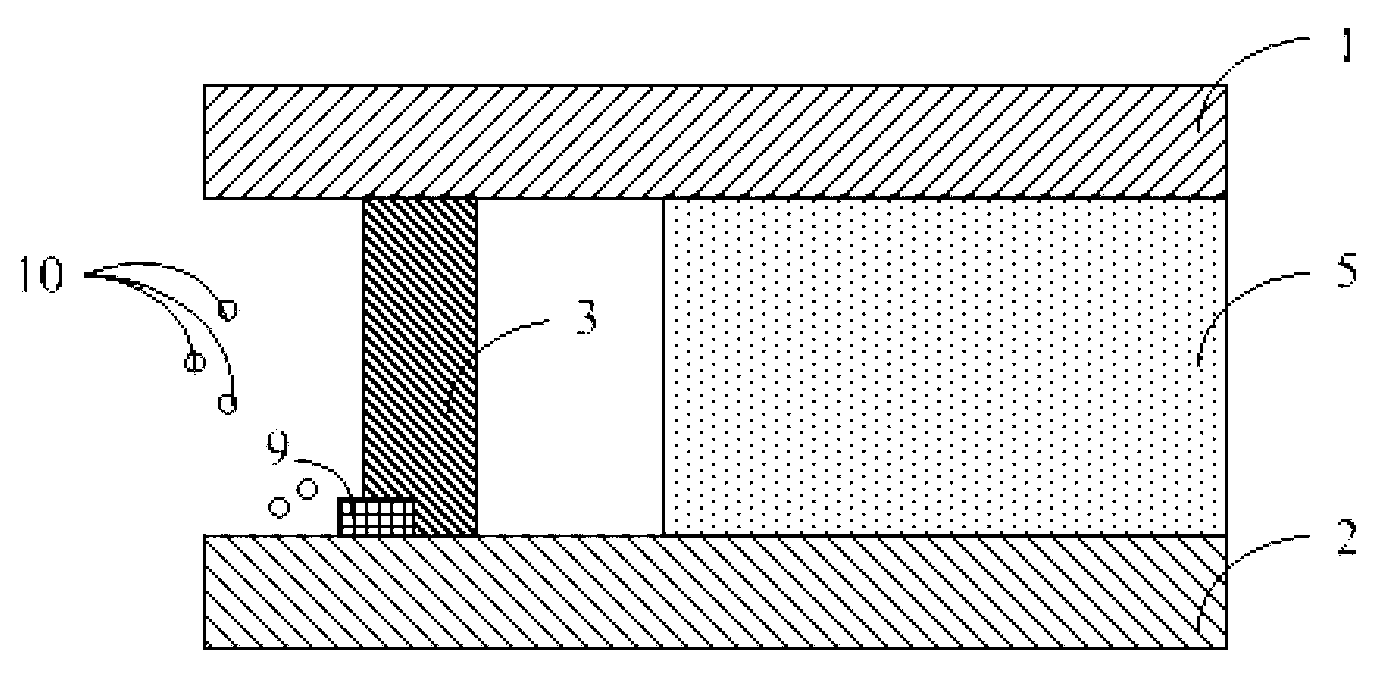

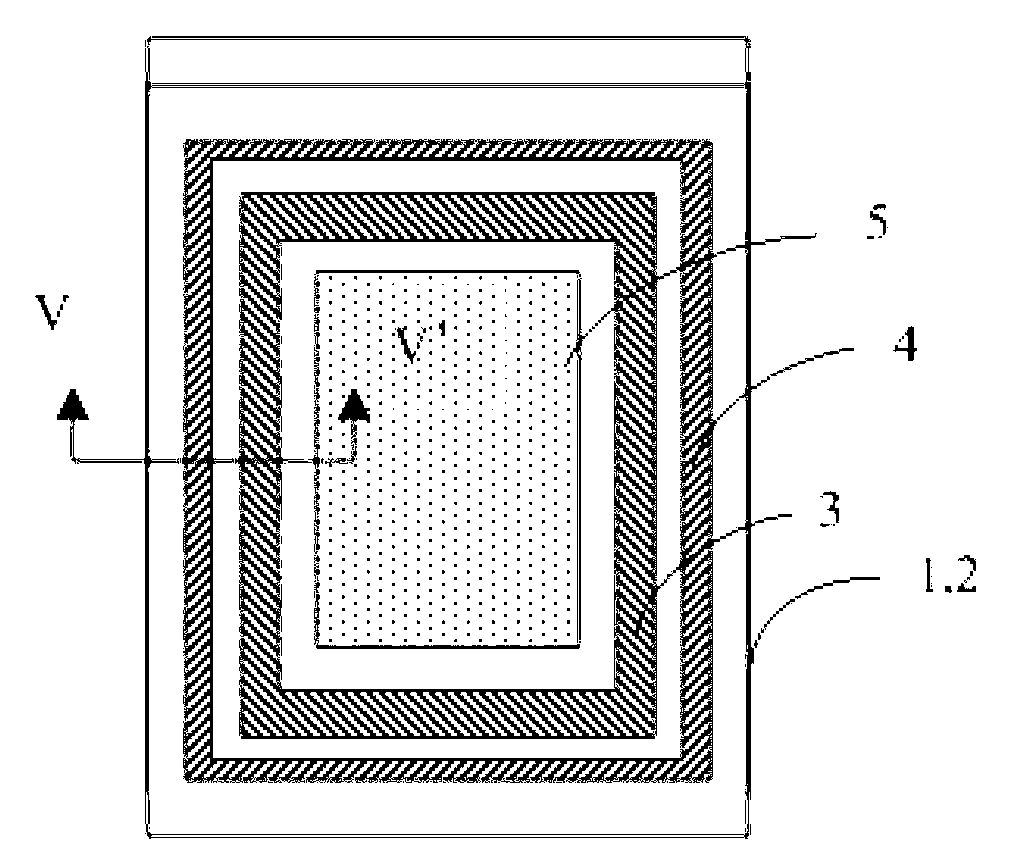

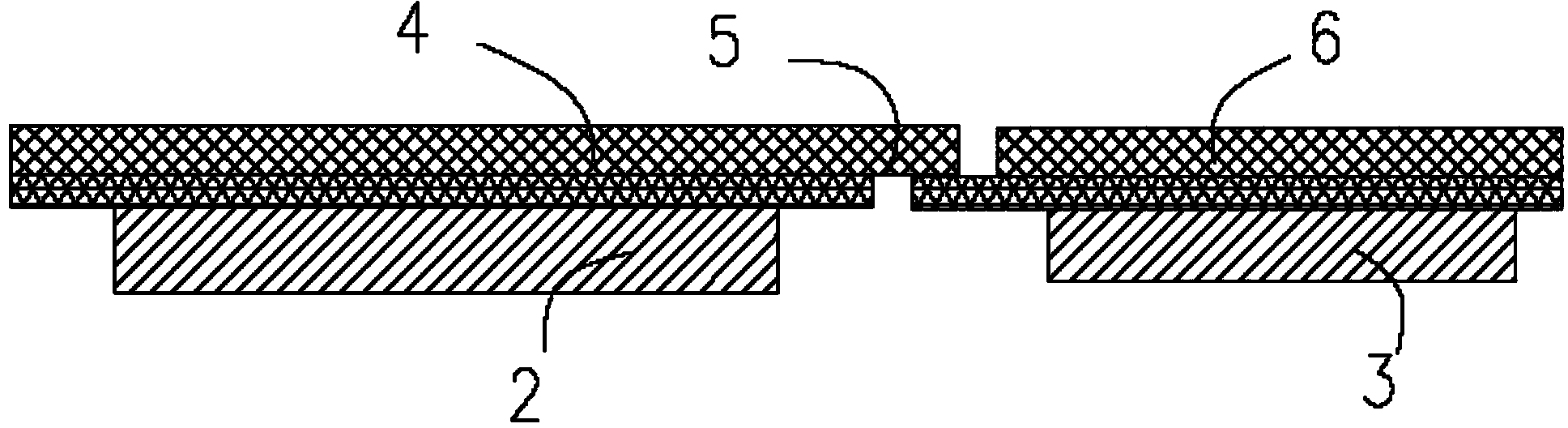

Display panel and display device

The invention belongs to the technical field of display and particularly relates to a display panel and a display device with the display panel. The display panel comprises a display area and a non-display area which surrounds the display area, wherein a frame-sealing adhesive is arranged in the non-display area and surrounds the display area; and an isolating frame is also arranged in the non-display area and outside the frame-sealing adhesive and surrounds the frame-sealing adhesive, so that the frame-sealing adhesive is completely separated from the exterior. According to the display panel, the isolating frame which can completely isolate the frame-sealing adhesive from the exterior is arranged in the display panel, so that water steam can be effectively prevented from invading the frame-sealing adhesive of the display panel, the quality of the display panel is ensured, and the quality of the display device is improved.

Owner:BOE TECH GRP CO LTD +1

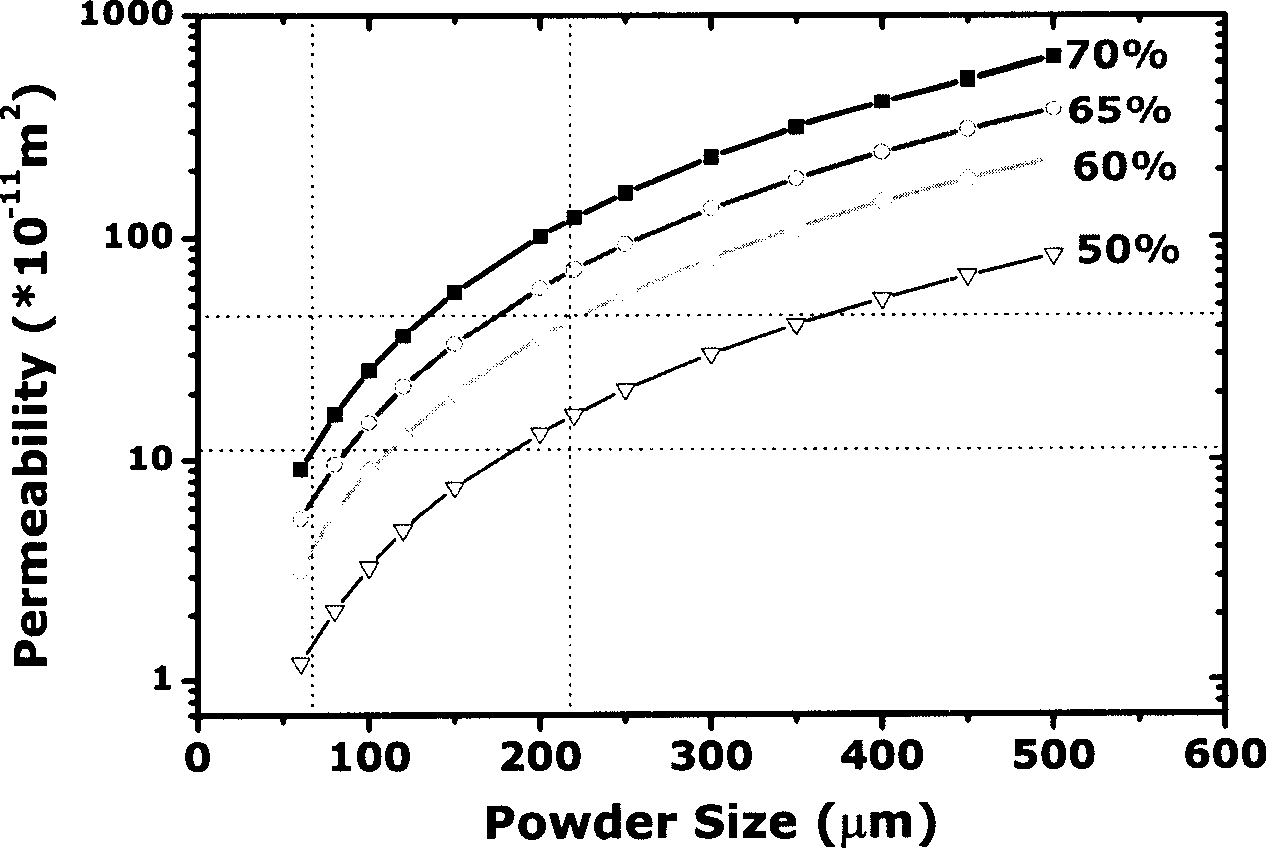

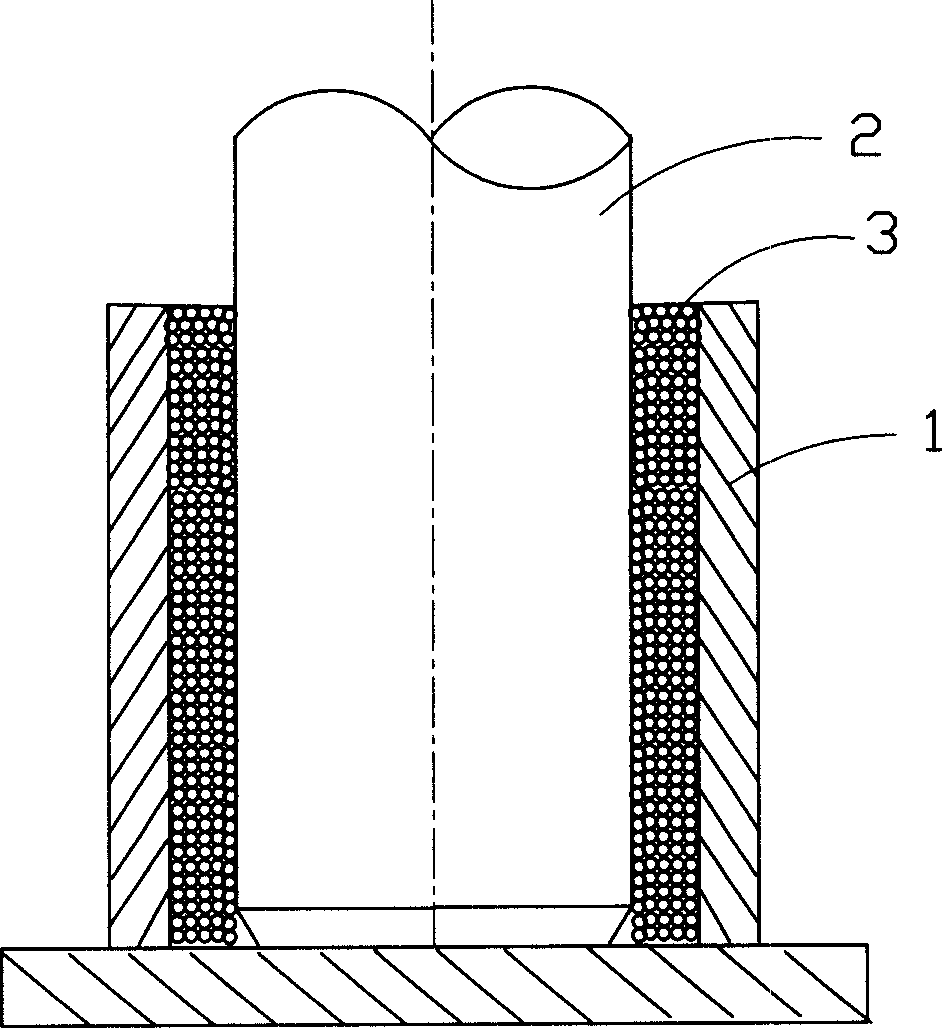

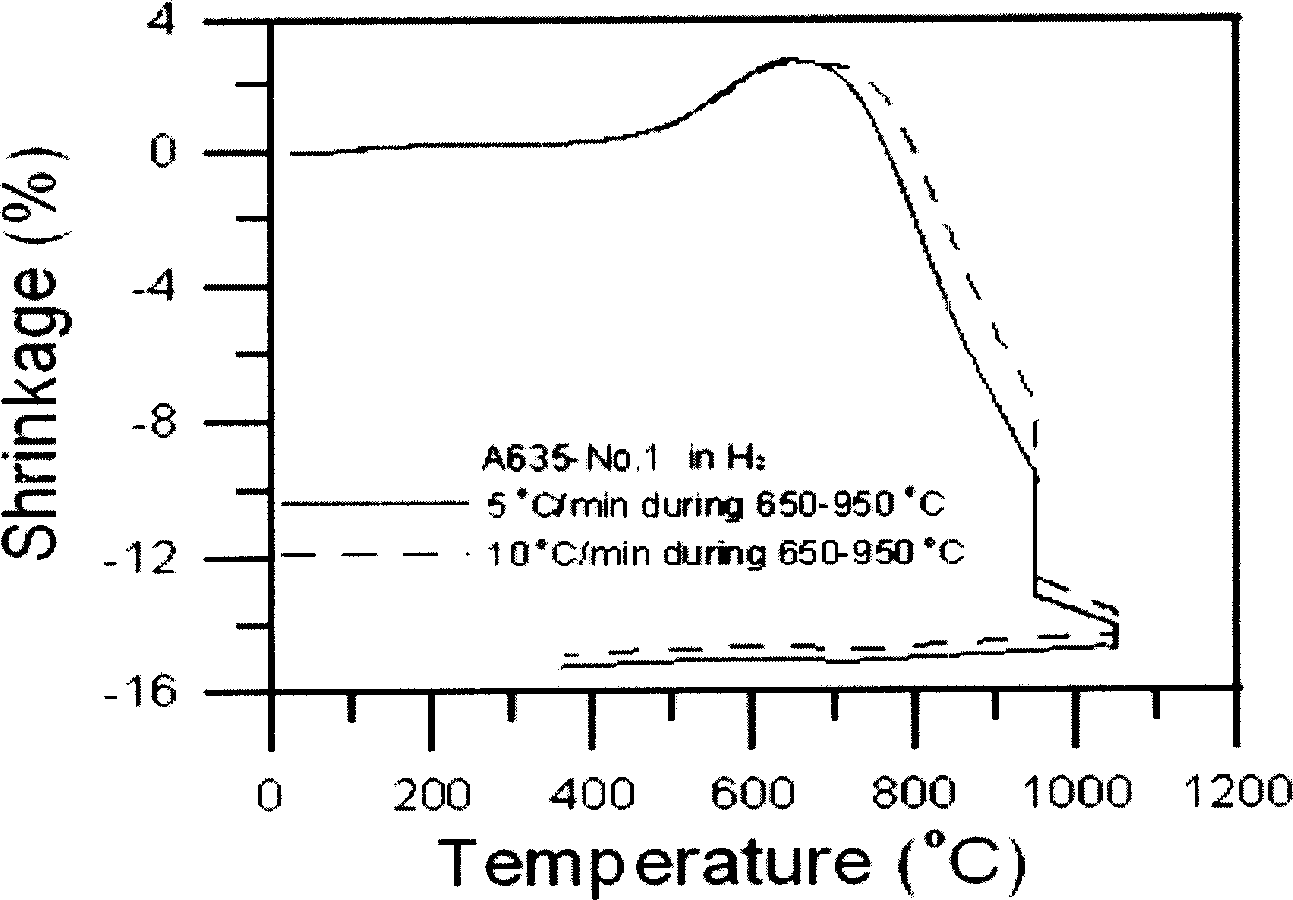

Heat pipe and manufacturing method thereof

InactiveCN1912521AReduce contact areaImprove adsorption capacityIndirect heat exchangersSurface bindingHeat pipe

A heat pipe consists of a heat conduction shell and a capillary structure. Its preparing method includes setting capillary structure in said shell, forming capillary structure by superposing screen mesh layer with particle layer, combining core bar surface with screen mesh, inserting core bar into said shell then filling micro powder in gas between said shell and screen mesh and sintering it with high temperature for obtaining product of heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

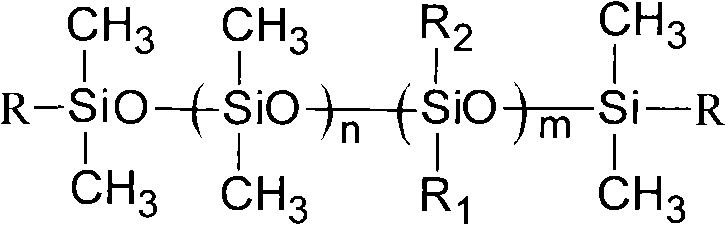

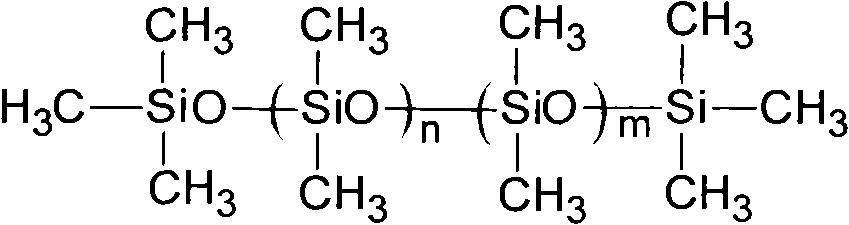

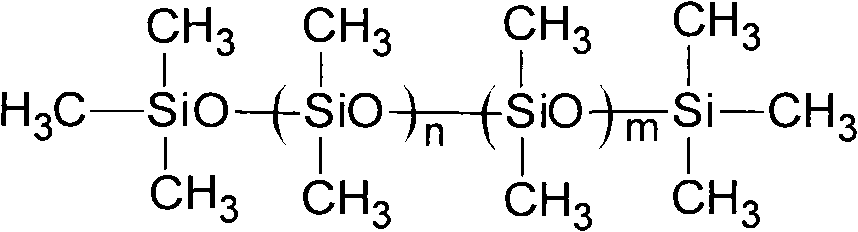

Silicone oil electric force compound grease and preparation method thereof

InactiveCN102024505AImprove high temperature resistanceImprove low temperature resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicone oilMetal powder

The invention discloses electric force compound grease and a preparation method thereof. The silicone oil electric force compound grease mainly comprises silicon oil, white carbon black and conductive metal powder, wherein the white carbon black is subject to surface treatment with a lipophilic processing agent. The silicone oil electric force compound grease comprises the following components in parts by weight: 100 parts of silicon oil, 20-33 parts of precipitated silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent, or the silicone oil electric force compound grease is also composed of the following components in parts by weight: 100 parts of silicon oil, 10-15 parts of fumed silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent. The silicone oil electric force compound grease disclosed by the invention has the advantages of high dropping point temperature, good attachment property, stable rationalizing property, long service life and good economic property.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

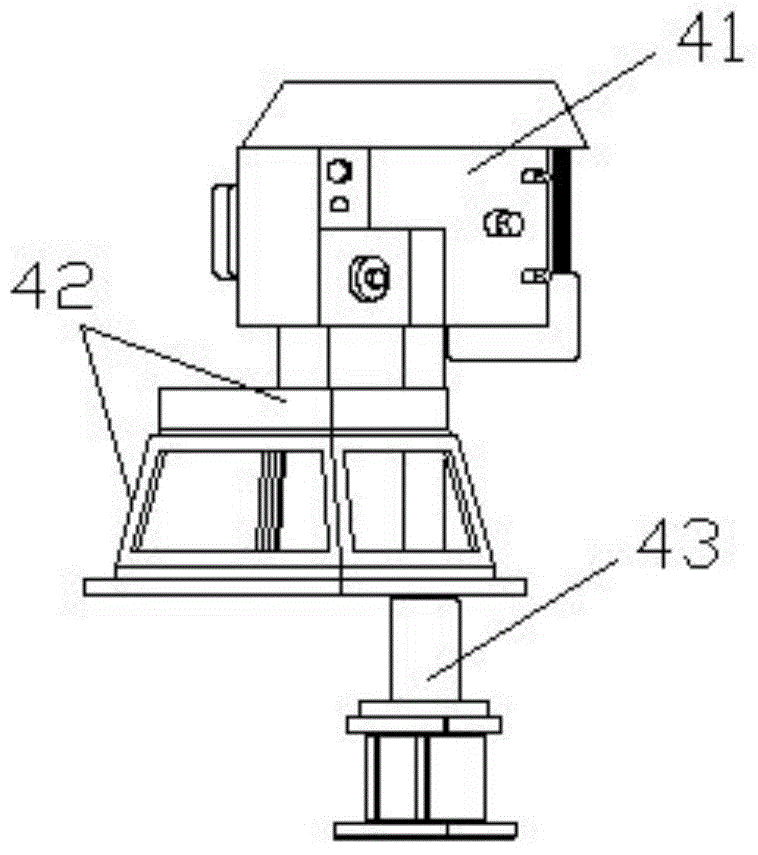

Monitoring system of surface mount technology (SMT) production line

InactiveCN105142357AIncrease productivityGuarantee production quality and yieldPrinted circuit assemblingMonitoring dataEngineering

The invention discloses a monitoring system of a surface mount technology (SMT) production line. The monitoring system comprises a printing machine, a connection table, a patch mounting machine, a reflow solder, an image acquisition device, a signal sending module, a display module, a data processing module and a signal receiving module, wherein the printing machine, the connection table, the patch mounting machine and the reflow solder are sequentially arranged, the image acquisition device and the signal sending module are arranged on the printing machine, the patch mounting machine and the reflow solder, the display module, the data processing module and the signal receiving module are arranged outside the SMT production line, the image acquisition device is used for respectively acquiring a printed circuit board (PCB) tin paste printing image in the printing machine, a patch image in the patch mounting machine and a welding image on the reflow solder, the signal sending module is used for sending the acquired image information to the signal receiving module, the data processing module is then used for processing the image information, and the display module is used for displaying a processing result. By the monitoring system, the data of the SMT production line can be effectively monitored, the production efficiency is improved, and the production quality and the finished rate are ensured.

Owner:SUZHOU XUANHE IOT TECH

Mirror surface display panel, manufacturing method thereof and mirror surface display device

ActiveCN110931540AAvoid the influence of light transmittanceImplement reflectionSolid-state devicesSemiconductor/solid-state device manufacturingSurface displayEngineering

The invention provides a mirror surface display panel, a preparation method thereof and a mirror surface display device, and belongs to the technical field of display. The mirror surface display panelcomprises: a display substrate having a display area and a non-display area located at the periphery of the display area, wherein the display area comprises a plurality of organic light-emitting diodes arranged in an array and a packaging film covering the organic light-emitting diodes, the non-display area comprises a binding position, and the binding position is provided with a plurality of binding pins arranged at intervals; an inorganic protective layer is formed on the display substrate and covers the display area and the non-display area, and the inorganic protective layer is provided with a first hollow hole corresponding to the binding position; and a metal reflection layer is formed on one side, deviating from the packaging film, of the inorganic protection layer, and the metal reflection layer is provided with a second hollow hole corresponding to the organic light emitting diode. According to the mirror surface display panel, while mirror surface display is achieved, the light transmittance can be improved, and the manufacturing yield of the mirror surface display panel is guaranteed.

Owner:BOE TECH GRP CO LTD +1

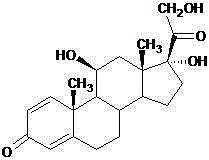

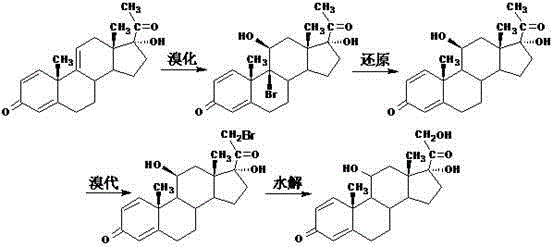

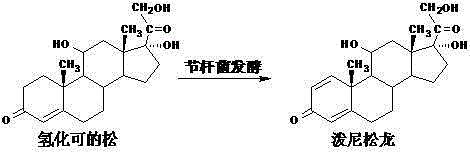

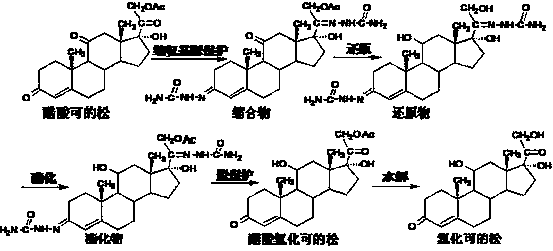

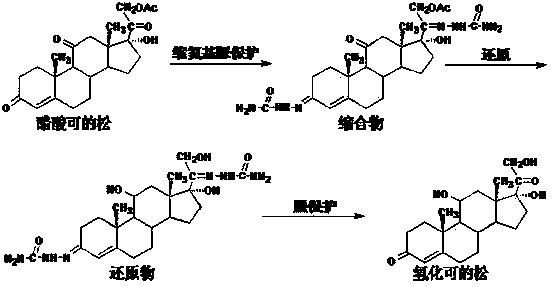

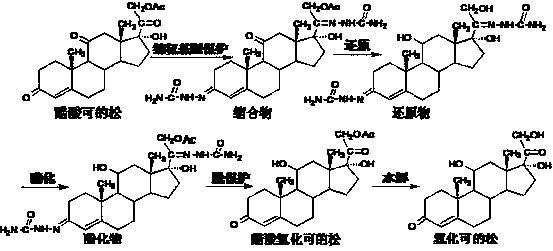

Preparation method of prednisolone

The invention relates to a preparation method of prednisolone. The preparation method comprises the steps of sequentially carrying out 3, 20-keto protective reaction, 11-keto reduction reaction, 21-hydroxyl esterification reaction, 3, 20-keto deprotection reaction and 21-acetic ester hydrolysis reaction by taking prednisone acetate as a raw material to obtain prednisolone. The invention provides a novel synthesis route sequentially comprising the steps of esterifying and deprotecting; nitrosification quenching reaction and resin hydrolysis reaction are omitted in the deprotection process; and ester hydrolysis reaction is finished under the protection of a mixed solvent and inert gases, so that the condition that byproducts are produced by hydrolysis reaction is avoided. The preparation method is novel in process route, simple and rapid in operation process, low in production cost and suitable for large-scale industrial production.

Owner:HUAZHONG PHARMA

Hydrogenation process for FCC recycle oil

ActiveCN104593059ALow ring-opening activityGuaranteed Product YieldTreatment with hydrotreatment processesZeoliteAmorphous silicon

The invention discloses a hydrogenation process for FCC recycle oil. The method comprises the following steps that: after mixing of FCC recycle oil with hydrogen, the obtained mixture enters a hydro-treating reaction zone and sequentially contacts with a hydro-protecting catalyst, a hydrofining catalyst and a hydro-upgrading catalyst A for hydrogenation reaction; the effluent obtained after hydro-treatment enters a hydro-upgrading reaction zone where a hydro-upgrading catalyst B containing amorphous silicon aluminum and modified Y zeolite is used, and undergoes hydro-upgrading reaction in the presence of hydrogen; and the effluent obtained after hydro-upgrading enters a hydro-finishing reaction zone and undergoes hydro-finishing reaction, and hydro-finishing products are separated so as to obtain transformer oil. The hydrogenation processing method for FCC recycle oil provided by the invention uses FCC recycle oil as a raw material to produce transformer oil, so raw material sources of transformer oil products can be broadened and special oil products meeting higher quality requirements can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

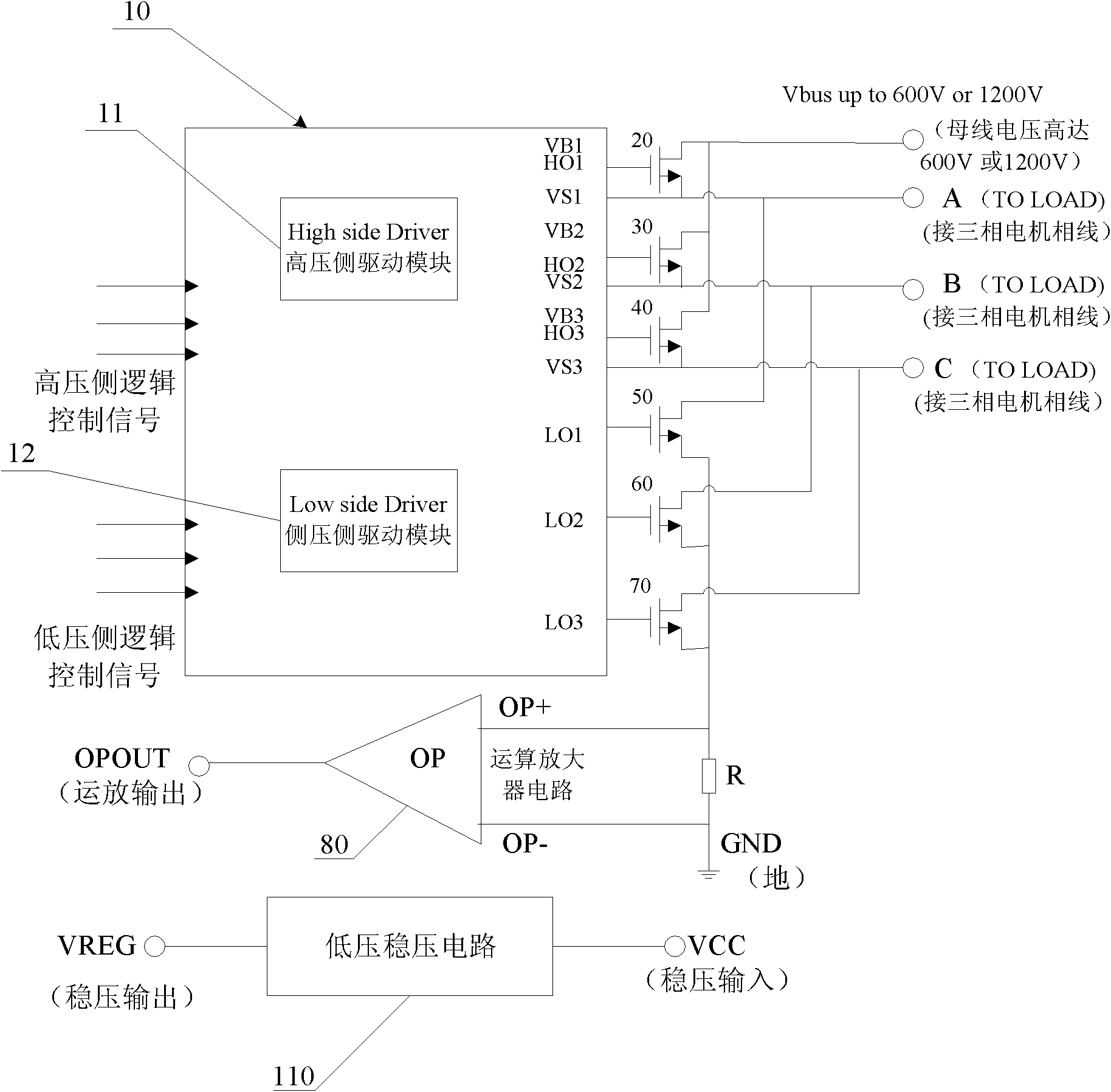

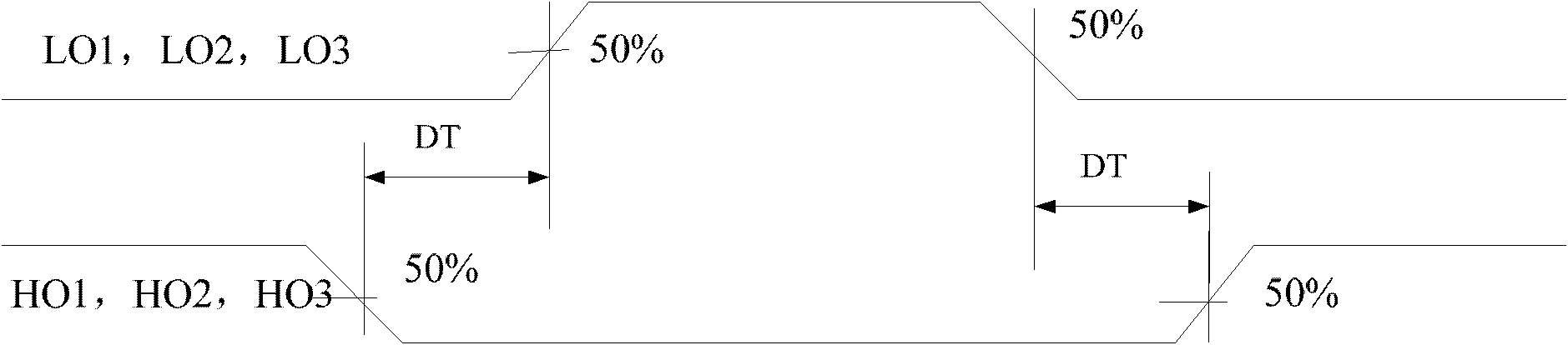

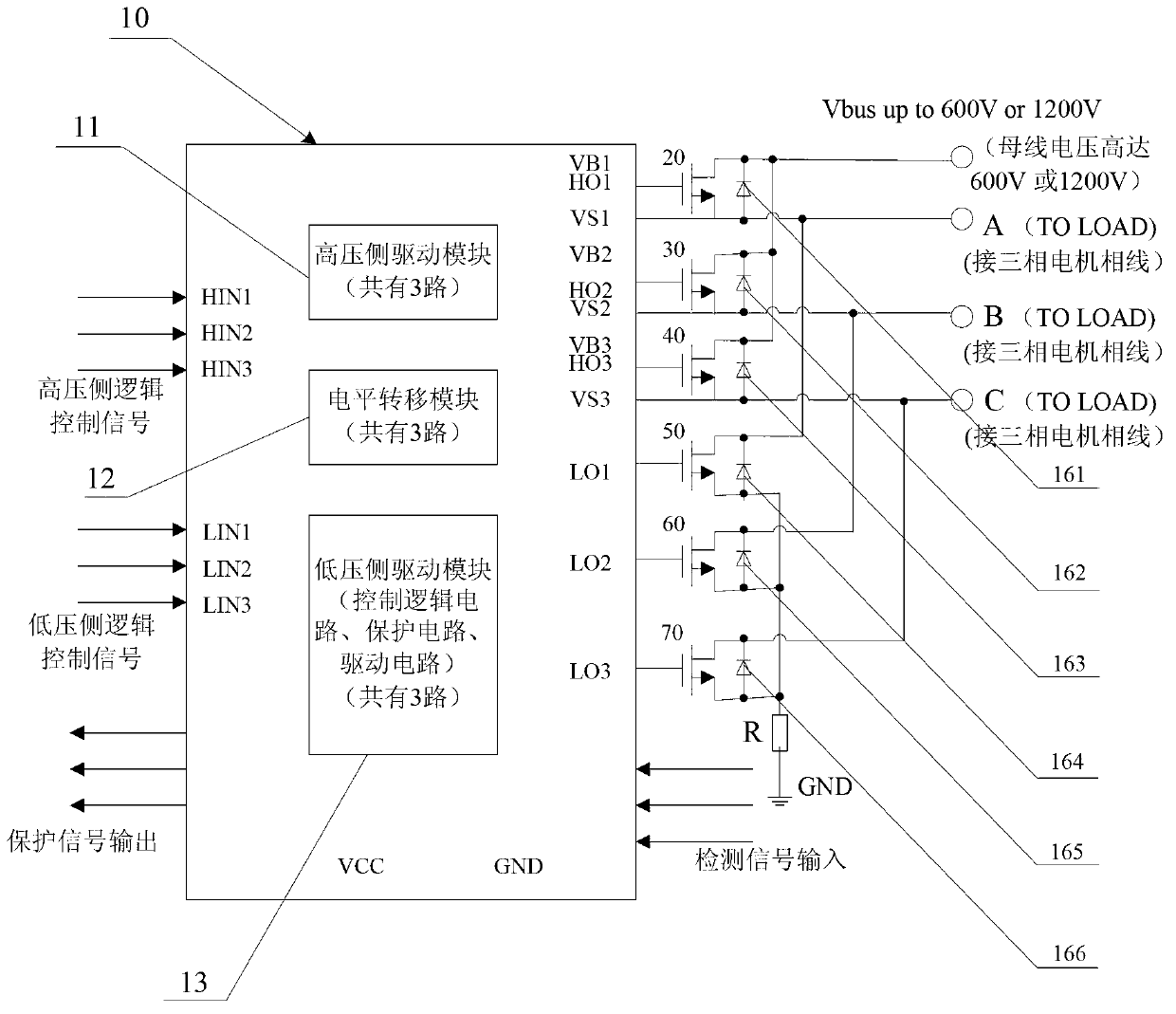

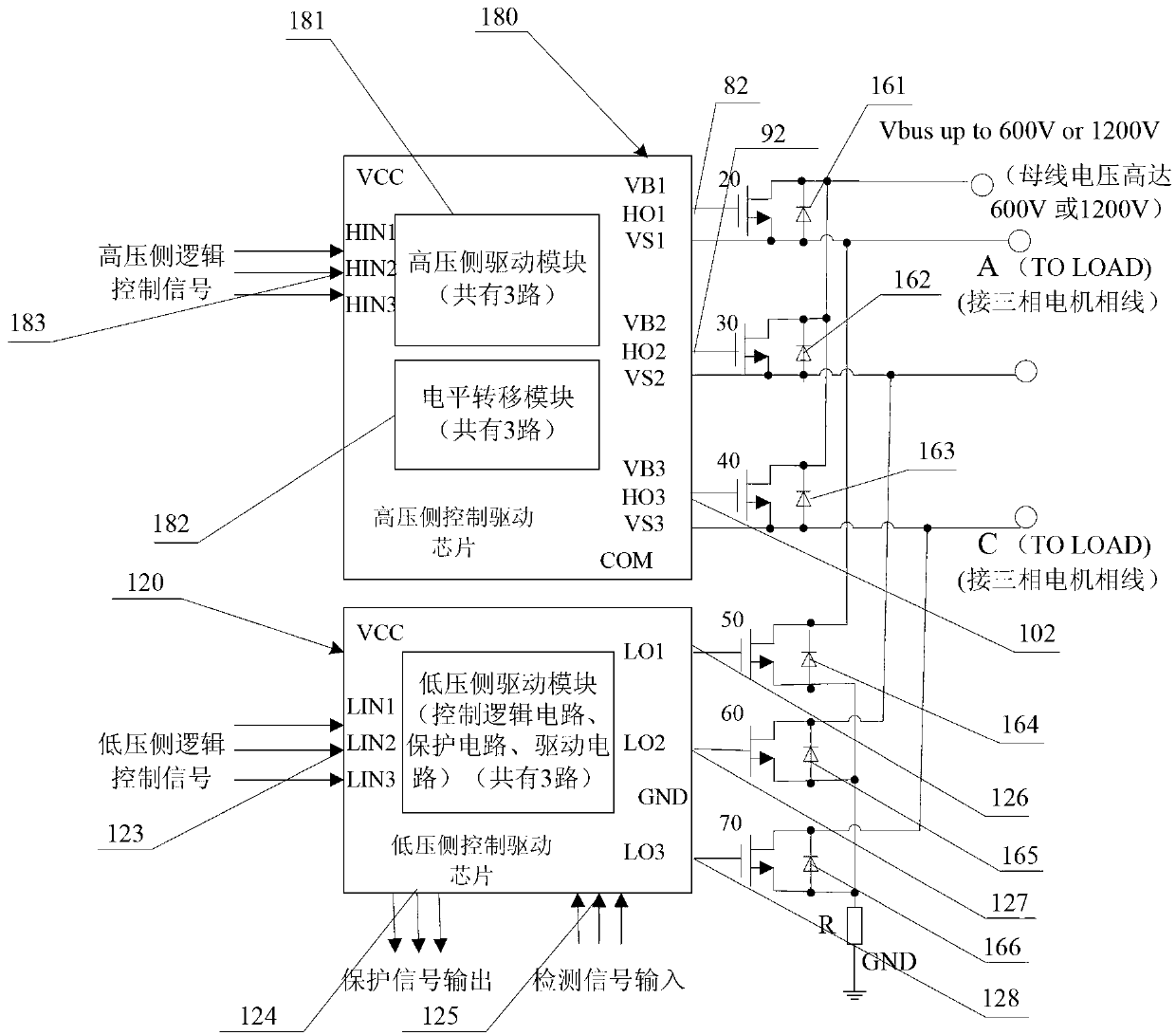

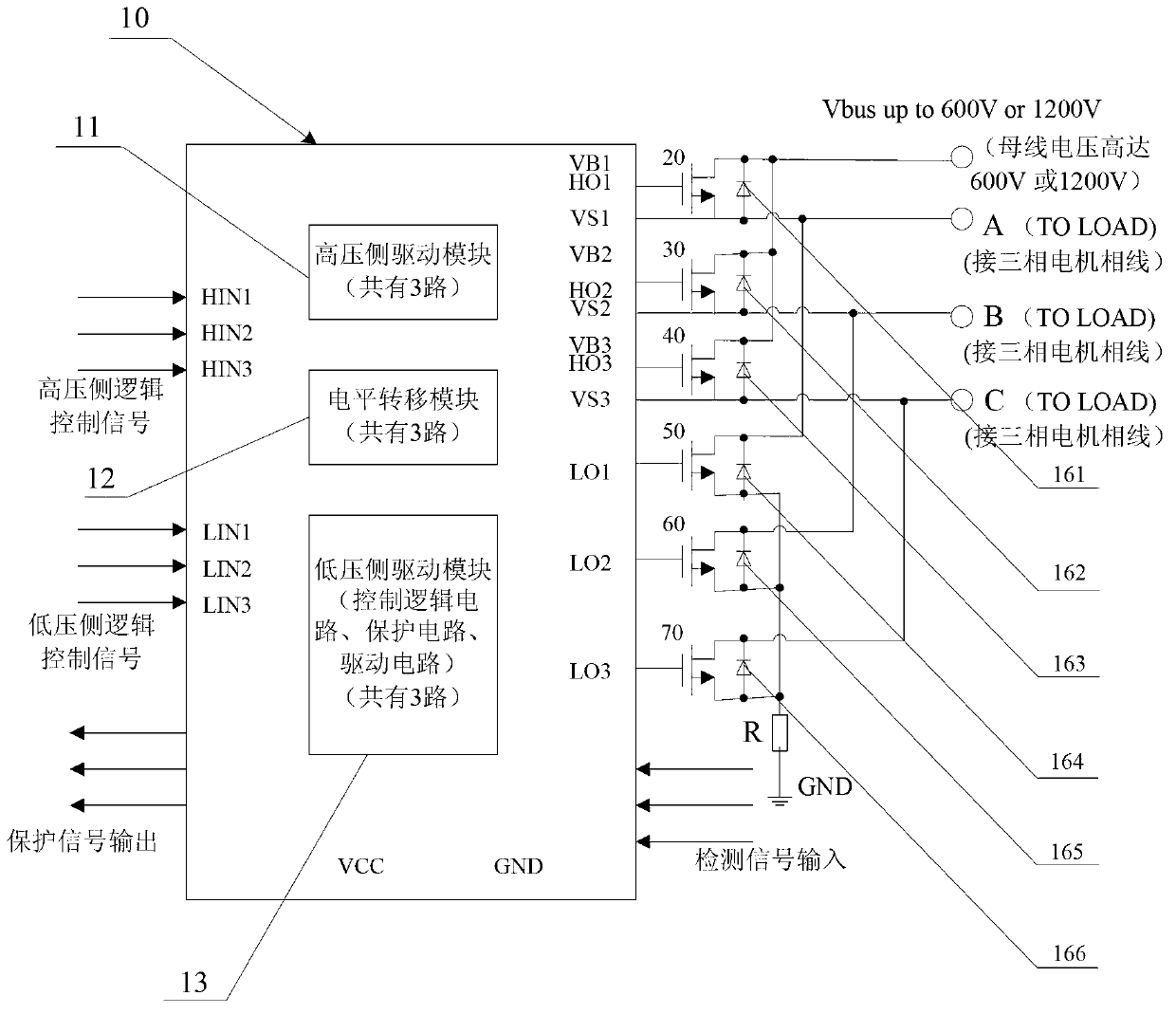

Bridge-driven IPM (intelligent power module) circuit for three-phase electric machine

ActiveCN102208865AThe production and processing process is easy to controlImprove yieldSolid-state devicesSemiconductor devicesOxide semiconductorCmos process

The invention discloses a bridge-driven IPM (intelligent power module) circuit for a three-phase electric machine, comprising gate drive chips, one group of high-pressure side power devices and one group of low-pressure side power devices, wherein the gate drive chips comprise high-pressure side control drive chips and low-pressure side control drive chips; the high-pressure side control drive chips are integrated by a high-pressure side drive module; and the low-pressure side control drive chips are integrated by a low-pressure side drive module, an operational amplifier and a low-pressure voltage-stabilizing circuit. The bridge-driven IPM circuit has the advantages that the high-pressure side control drive chips are produced by adopting a complicated high-pressure isolation manufacturing process, and the area of the high-pressure side control drive chips is smaller, so the production process of the high-pressure side control drive chips is easier to control and beneficial to improving the yield. A common CMOS (complementary metal oxide semiconductor) process is adopted to produce the low-pressure side control drive chips, the process conditions of the CMOS process are simple, the technology of the CMOS process is mature, and the character lines of the CMOS process are thinner, so the chip area is smaller, thus ensuring the production yield effectively and saving the cost.

Owner:NINGBO SEMICON INT CORP

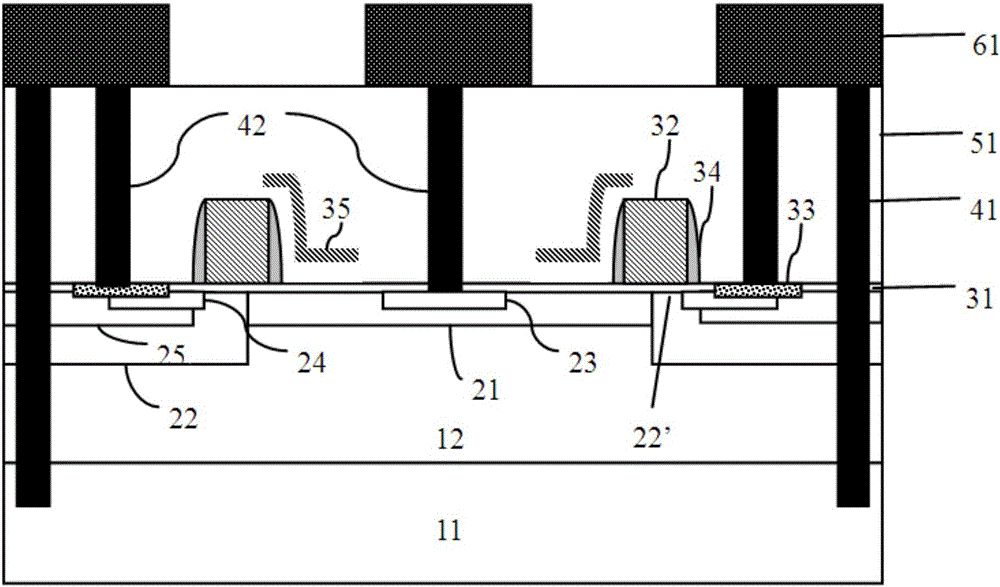

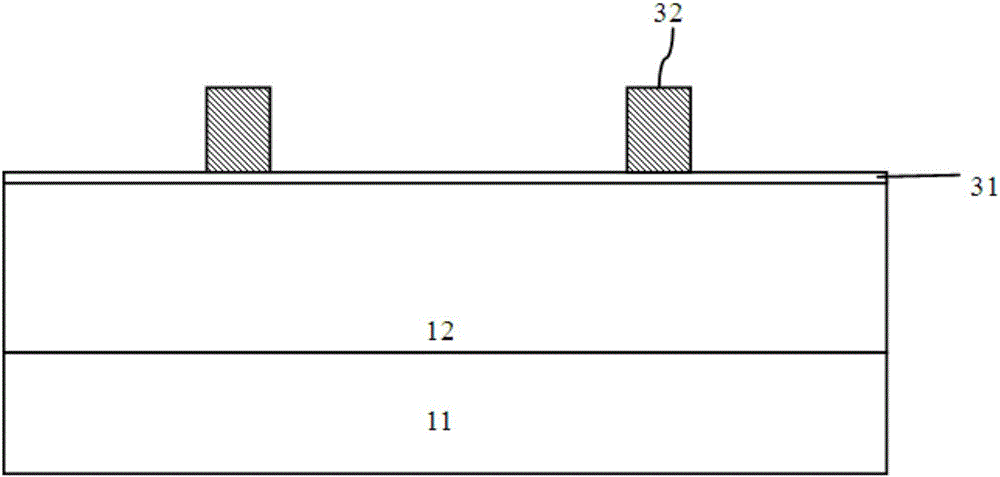

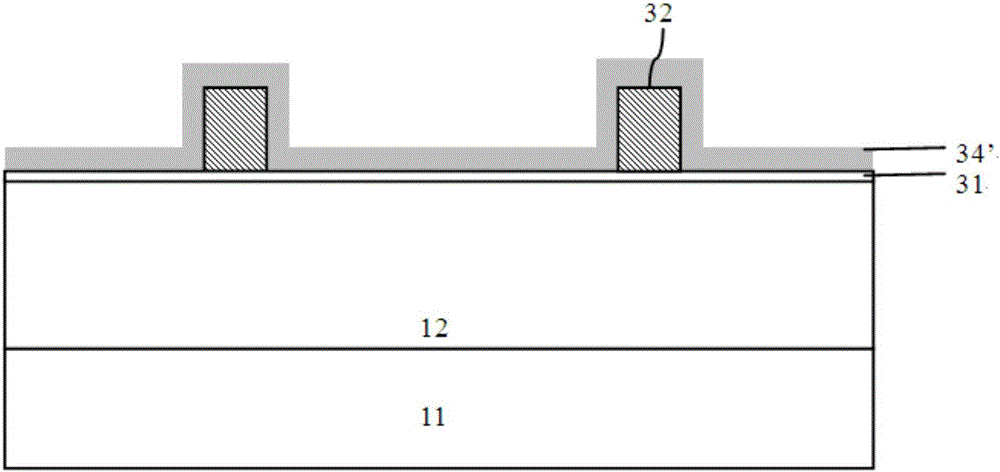

LDMOS device structure and manufacture method thereof

InactiveCN105845736AImplement self-aligned injectionSolve the problem of lithography alignment accuracySemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSEtching

The invention discloses an LDMOS device structure which comprises a metal connection layer. Through the metal connection layer, an LDMOS device source electrode is connected with a substrate from the surface. An LDMOS device channel is a concentration gradient channel. The invention further discloses the manufacture method of the device structure. According to the invention, after polysilicon etching, a medium layer of high step coverage rate is deposited and is used as an injection barrier layer; the problem of photoetching alignment accuracy is solved; self-alignment injection of gate length below 0.25um is realized; through the metal connection layer, the source electrode is connected with the substrate from the surface; after a device is formed, a metal connection layer process is carried out, and gate length below 0.25um is realized; and the manufacture yield and the uniformity can be ensured.

Owner:KUNSHAN HUATAI ELECTRONICS TECH CO LTD

Method for manufacturing circuit board

ActiveCN102111964AGuaranteed product yieldConvenience guaranteedNon-metallic protective coating applicationElectrode potentialEngineering

The invention provides a method for manufacturing a circuit board, which comprises the following steps of: providing the circuit board, wherein the circuit board comprises an insulating layer, a conducting layer formed on the insulating layer and a plating layer formed on part of the conducting layer; the material of the conducting layer has a first electrode potential; the plating layer is in an electric contact with the conducting layer; the material of the plating layer has a second electrode potential; the second electrode potential is greater than the first electrode potential; forming a protective layer on the plating layer; performing wet treatment on the circuit board by wet treatment liquid, wherein the wet treatment liquid is an electrolyte, and during the wet treatment process, the protective layer and at least part of the conducting layer are exposed to the wet treatment liquid; removing the protective layer to obtain the circuit board which is subjected to the wet treatment. By the method for manufacturing the circuit board provided by the technical scheme, and galvanic corrosion between the plating layer and part of the exposed conducting layer in the wet treatment liquid is avoided, so the manufacturing yield and excellent performance of the circuit board are guaranteed.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

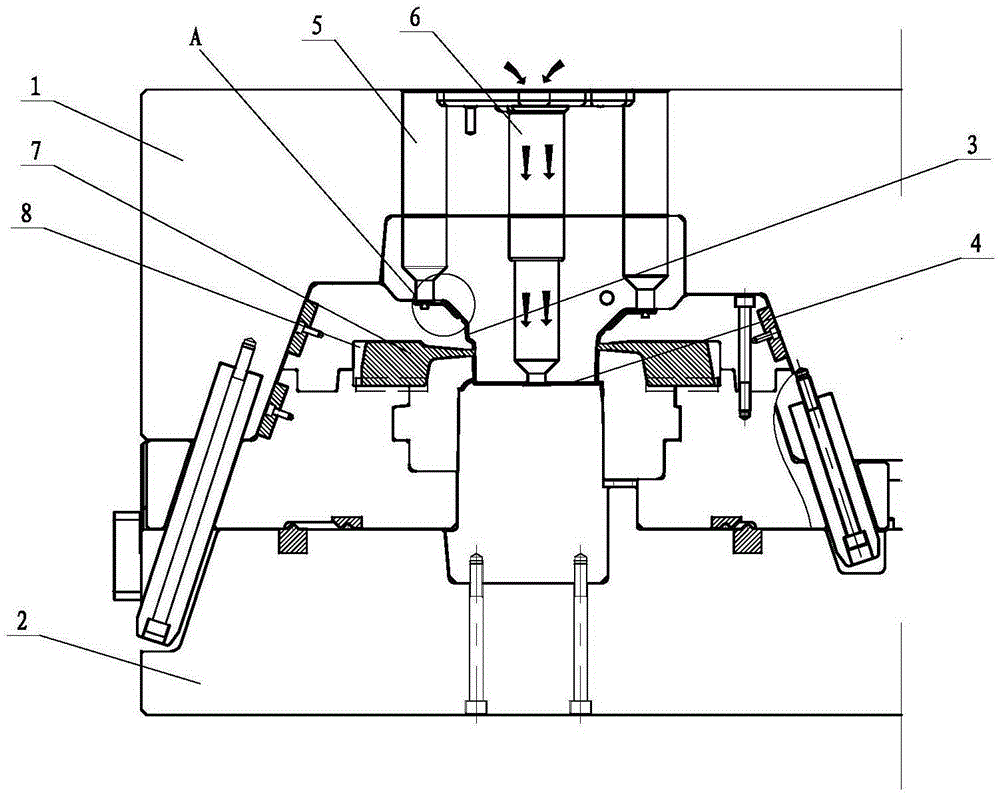

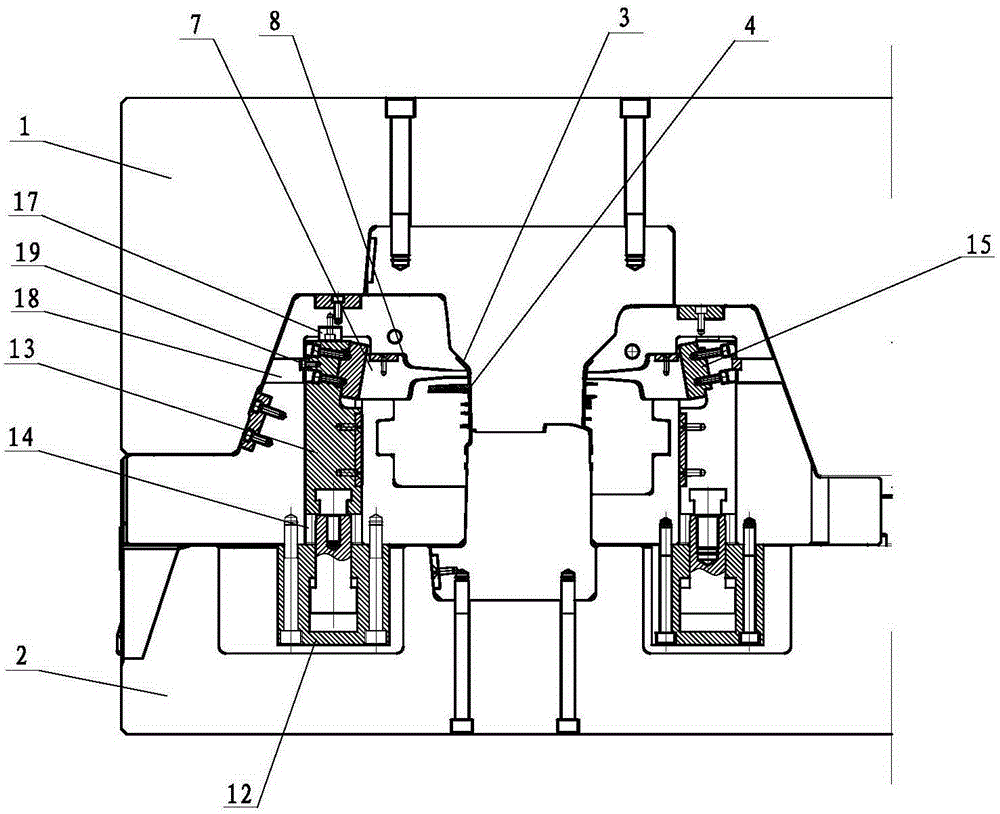

Two-color mold

Owner:NINGBO FANGZHENG TOOL

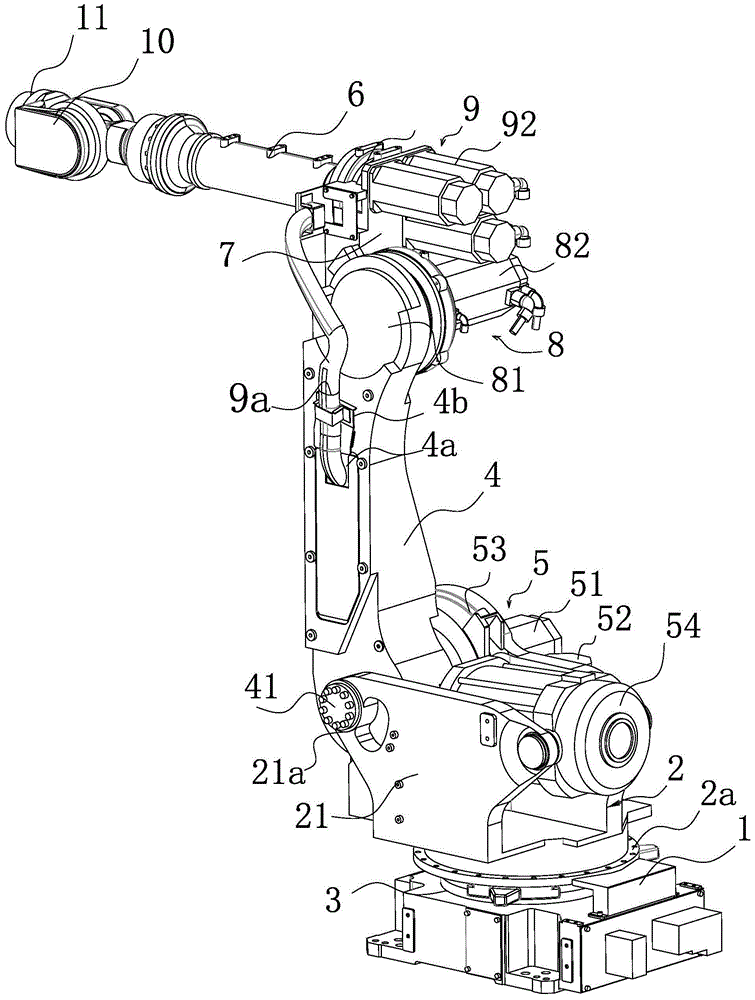

Six-axis mechanical arm

InactiveCN105729463AReasonable designStable structureProgramme-controlled manipulatorEngineeringManipulator

The invention belongs to the technical field of manipulators, in particular to a six-axis manipulator. It includes a gear box fixing seat, a driving arm seat is arranged on the gear box fixing seat, a first rotary drive capable of driving the driving arm seat to rotate in the circumferential direction is arranged on the gear box fixing seat, and the lower end of the driving arm seat The bottom flange is connected to the first rotary drive, side plates are provided on both sides of the drive arm seat, a drive arm is provided at one end of the two side plates, and first hinge joints are respectively provided on both sides of the lower end of the drive arm. shaft, the first hinge shaft is set in the first hinge hole of the side plate, and a drive arm drive group capable of driving the drive arm to swing around the first hinge shaft is arranged on the outside of one of the side plates, which is different from the existing technology The advantages of this six-axis manipulator are: 1. The design is reasonable, the structure is firm, the movement accuracy is high, and it can complete various actions to ensure the reliability of the product after production, ensure the production yield, and improve the enterprise's efficiency.

Owner:HOPE IN HUZHOU MACHINERY TECH CO LTD

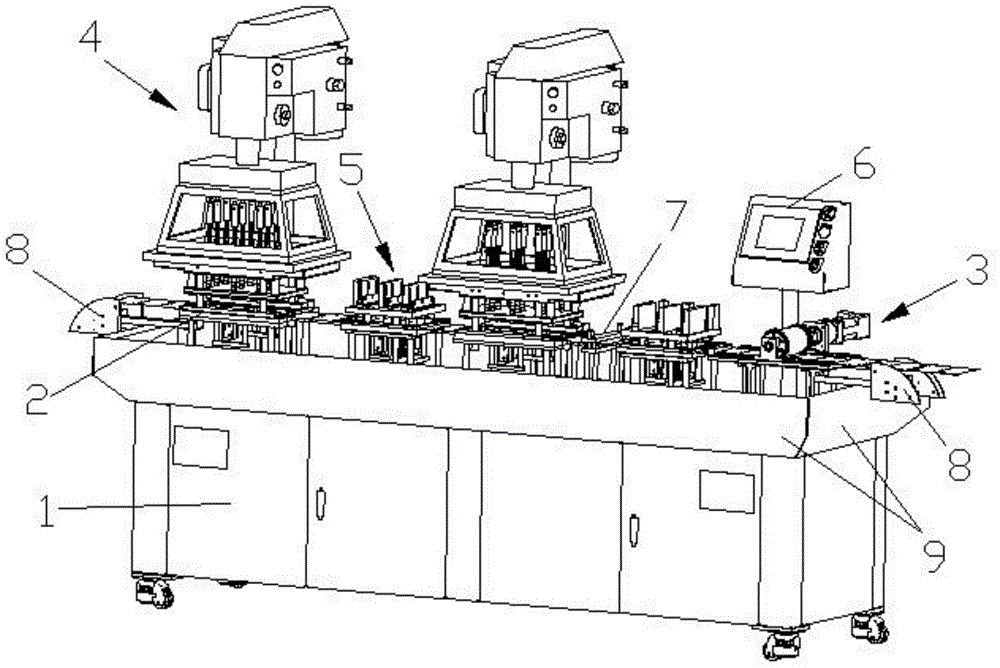

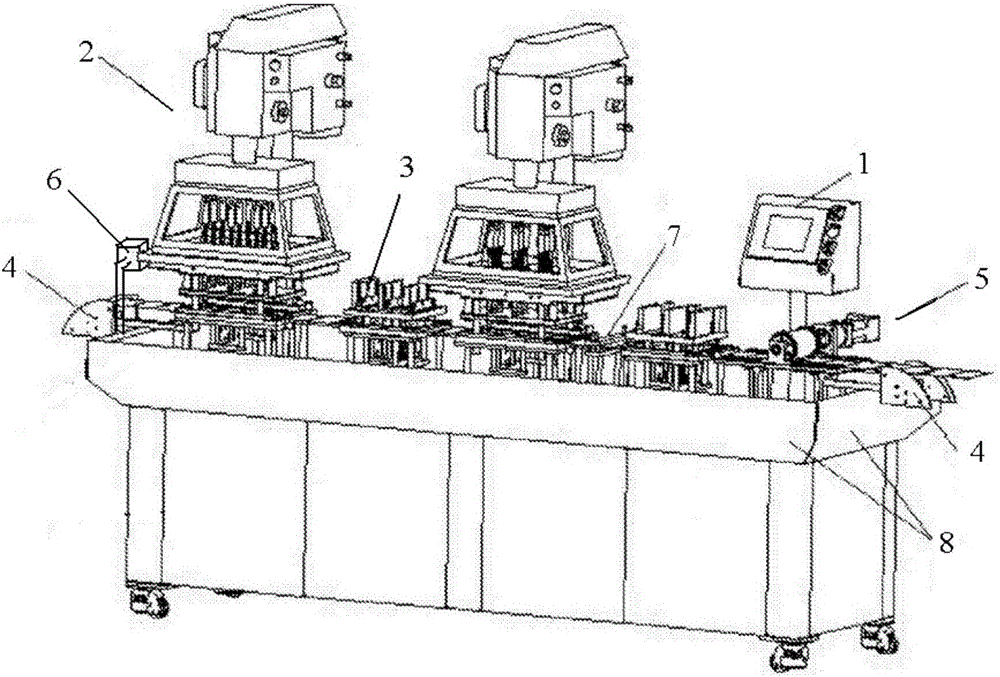

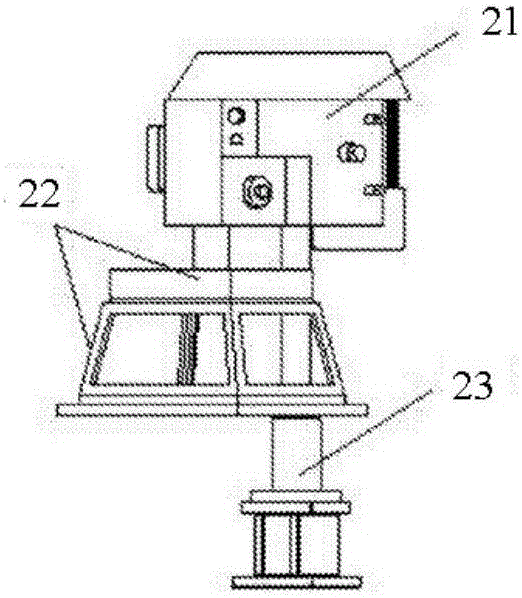

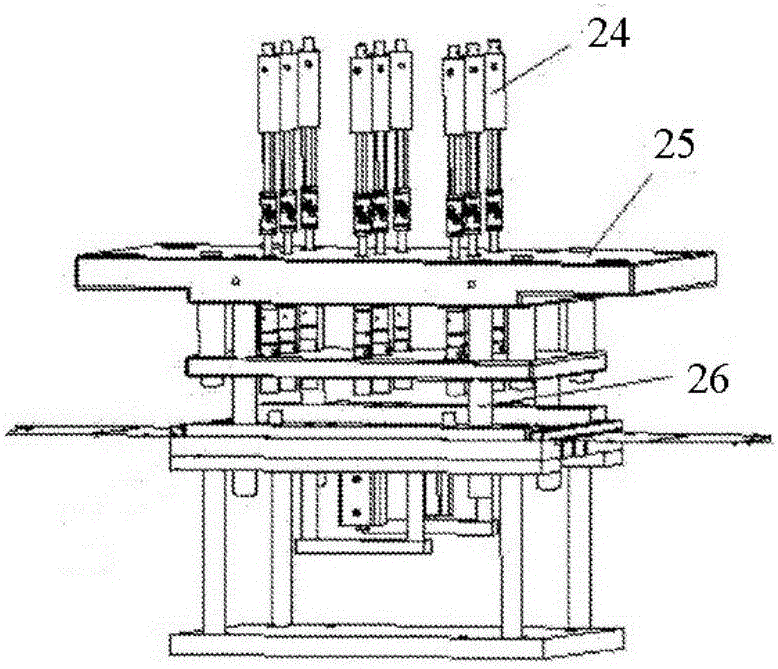

Automatic multi-axis tapping machine with monitoring function

InactiveCN105033767AAvoid it happening againIncrease productivityThread cutting machinesMeasurement/indication equipmentsControl systemEngineering

The invention discloses an automatic multi-axis tapping machine with a monitoring function. The automatic multi-axis tapping machine comprises a motor cabinet, a support, a material drawing device, at least one multi-axis tapping device, at least one multi-threaded-hole detection device and a PLC control system. The support is arranged on the surface of the motor cabinet in a linear manner and sequentially provided with the multi-axis tapping devices, the multi-threaded-hole detection devices and the material drawing device. The multi-axis tapping devices, the multi-threaded-hole detection devices and the PLC control system through signals. The PLC control system comprises a screw tap service life monitoring module and a threaded-hole detection module. The positions of all screw taps in the multi-axis tapping devices correspond to the positions of all detection needles of the multi-threaded-hole detection devices. By means of the automatic multi-axis tapping machine, the manual detection time and process are saved, and on-line screw tap service life detection and threaded-hole detection are achieved; the screw taps can be replaced timely so that rejects can be avoided, and the production yield is guaranteed; detection is accurate, and the production cost is saved; and production efficiency is improved.

Owner:SUZHOU JINYIKANG AUTOMATION EQUIP

Cross guide type plastic bag packaging structure and manufacturing method of plastic bags of this type

InactiveCN109677010AQuick and easy extractionGuaranteed accuracyBag making operationsPaper-makingEngineeringPlastic bag

The invention relates to the technical field of a method used for continuously manufacturing plastic bags and a plastic bag packaging structure, in particular to a cross guide type plastic bag packaging structure and a manufacturing method of plastic bags of this type. According to the packaging structure, the plastic bags are stacked in an end-to-end cross and overlapping manner, the bag tails are covered with the bag heads, the bag tails can generate a certain pulling function to bag openings, and the plastic bags are grabbed more conveniently during drawing of next time; and the plastic bags are already completely cut off, and time saving and rapidness are achieved during pulling. The manufacturing method for producing the plastic bags of the this type with low cost and high efficiencys further disclosed. Two sets of continuous thin films are adopted for feed, hot-press sealing openings are machined on the surfaces of the continuous thin films, the path is adjusted by recognizing the hot-press sealing openings, and the continuous thin films are fixed through vacuum adsorption; and after heat sealing, the continuous thin films are cut off by a cutting knife, and the processing precision and the yield of finished products are guaranteed.

Owner:中侨路易塑胶制品(东莞)有限公司

Lead-free steam turbine seal grease and preparation method thereof

InactiveCN102690630AImprove adhesionImprove corrosion resistanceOther chemical processesIron powderFerrotitanium

The invention provides lead-free steam turbine seal grease and belongs to the field of sealant preparation. The lead-free steam turbine seal grease is composed of refined grease and inorganic filler, and the inorganic filler is made of compound ferrotitanium powder, graphite powder, white carbon black, whisker calcium carbonate and reduced iron powder. The reduced iron powder and the compound ferrotitanium powder are innovatively added into the inorganic filler without red lead powder. The prepared seal grease has the advantages of uniformity in viscosity, high resistance to corrosion, high temperature and high pressure and environment friendliness.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

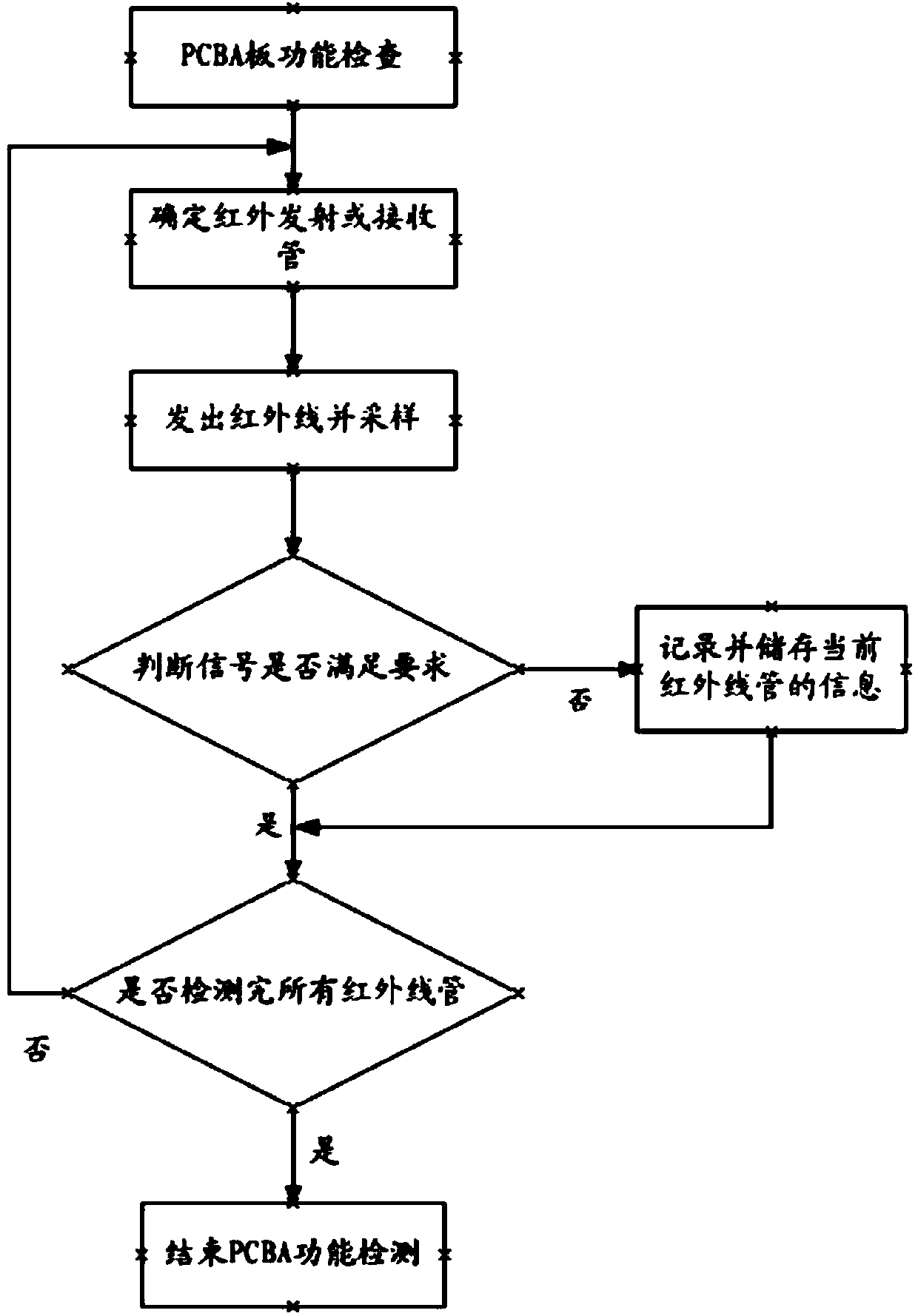

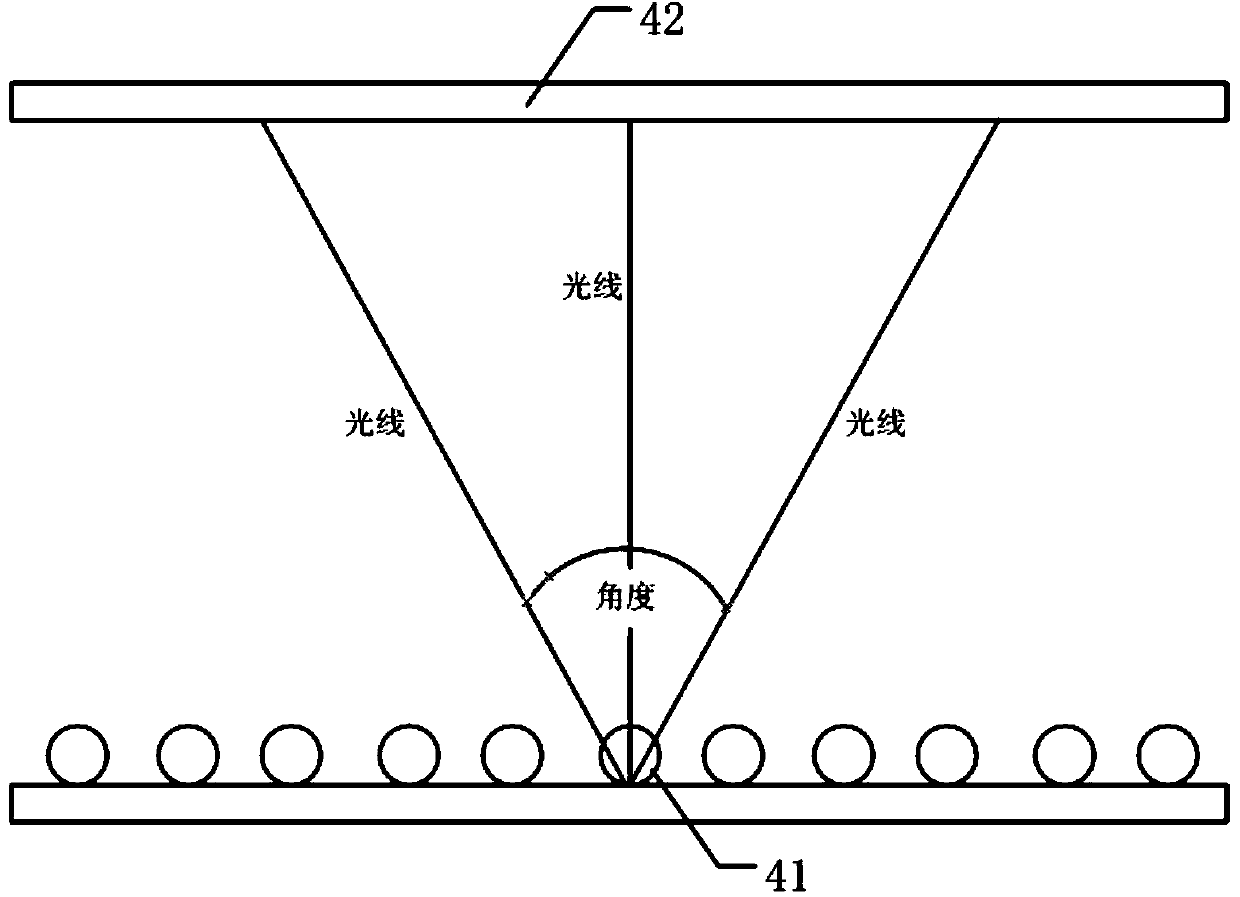

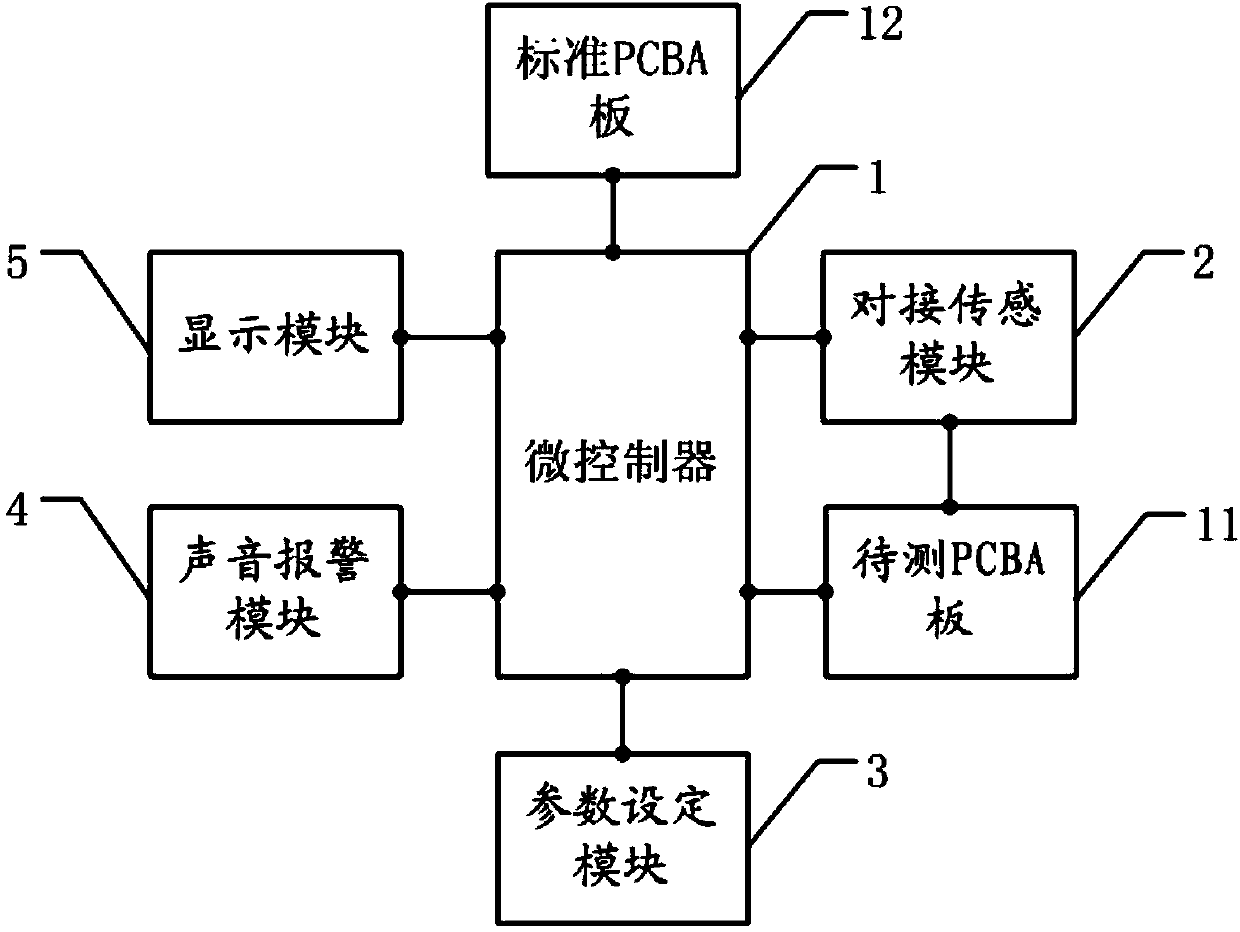

Detection method and device for PCBA board

ActiveCN104181458AMany pinsGuaranteed production efficiencyElectronic circuit testingComputer moduleEngineering

The invention discloses a detection method and device for a PCBA board of an infrared tube touch frame. When detection is conducted according to the method, the short circuit condition and the open circuit condition of internal modules of the PCBA board can be detected firstly, and when some internal modules of the PCBA board are not connected in the static state and signals can not be continuously transmitted, closed circuits can be formed by triggering the internal modules which are not connected in the static state in the to-be-detected PCBA board through the detection device, and therefore the aims of short circuit detection and open circuit detection are achieved. According to the method, short circuits or closed circuits between insertion pins inside the to-be-detected PCBA board can be detected, for example, some closed circuits, should not be formed, formed when tin connection appears in the product machining process, and therefore functions of the PCBA board can not be influenced.

Owner:GUANGZHOU HUAXIN ELECTRONICS TECH

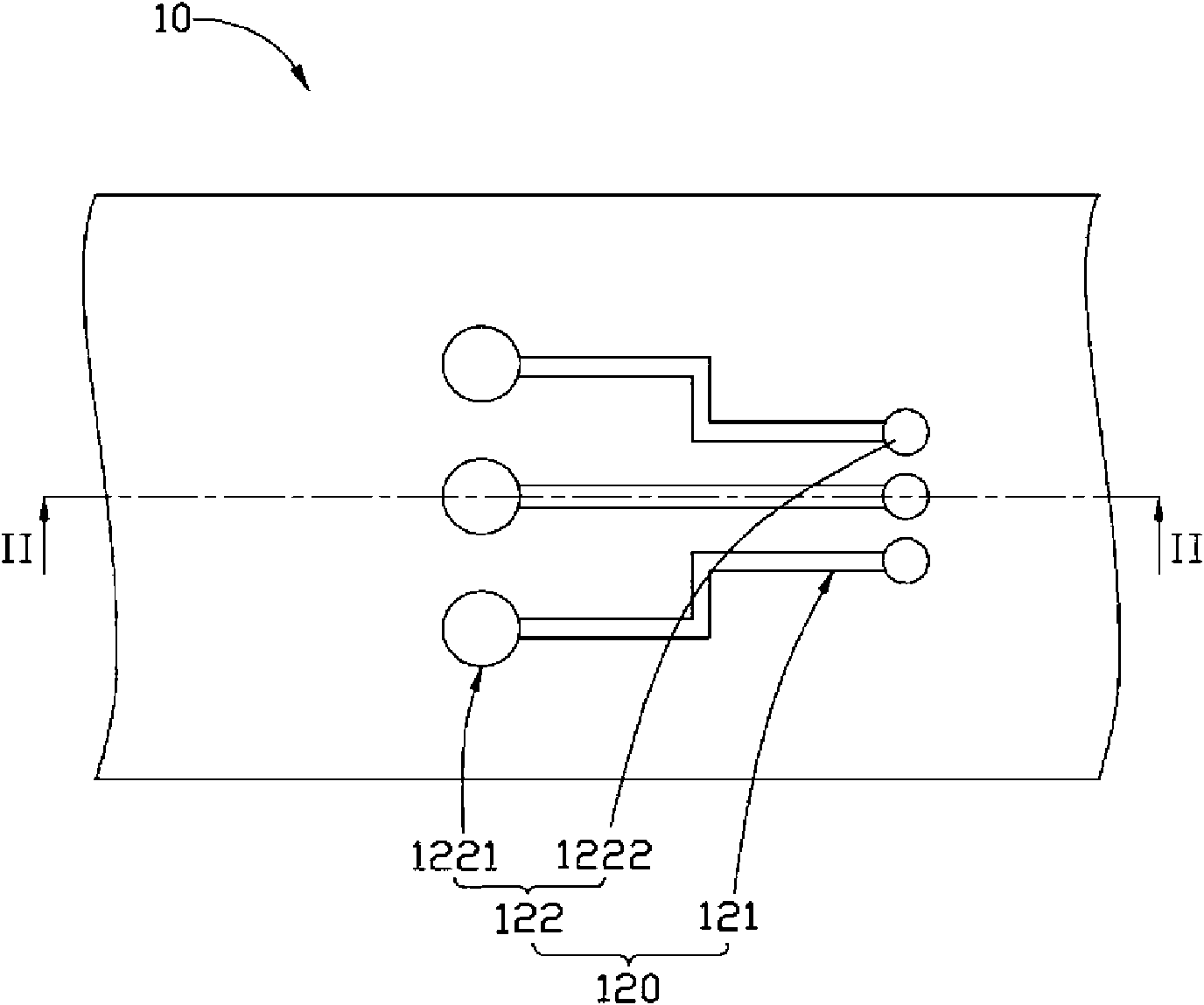

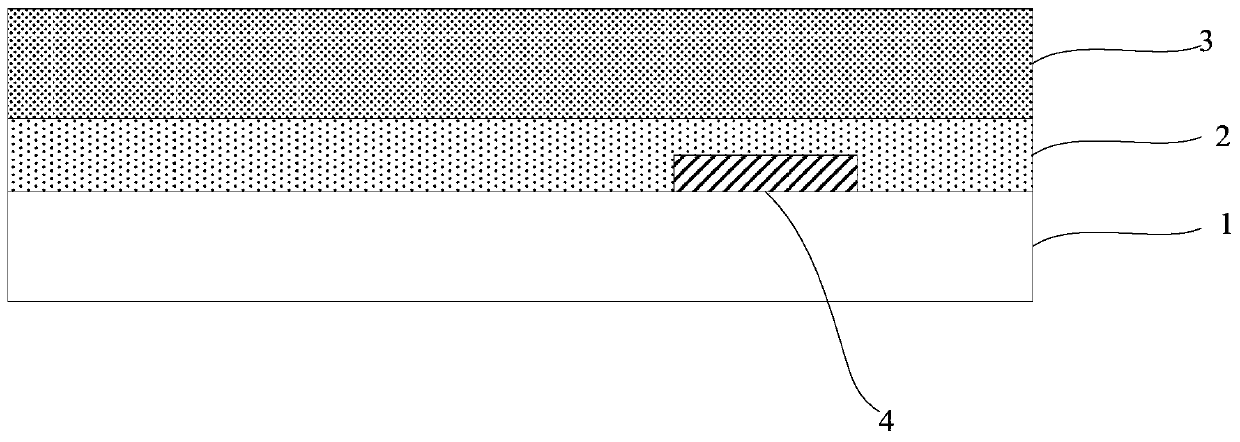

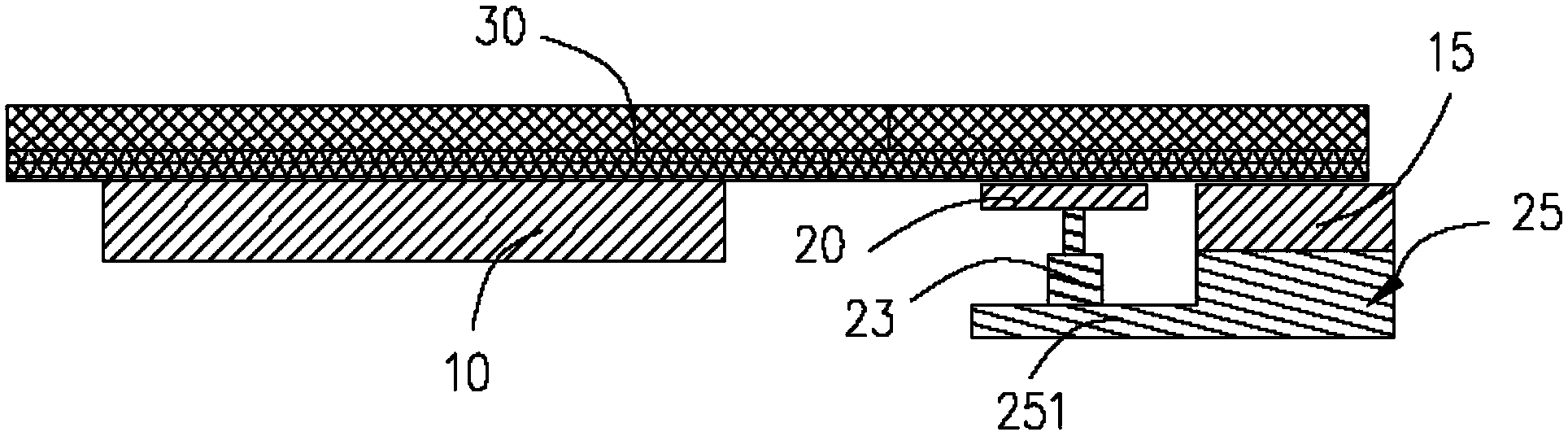

Display substrate, manufacturing method thereof and display device

PendingCN111524957AGuaranteed connection reliabilityGuaranteed product yieldSolid-state devicesSemiconductor devicesElectrically conductiveDisplay device

The invention provides a display substrate, a manufacturing method thereof and a display device, and belongs to the technical field of display. The display substrate comprises a first conductive pattern, an insulating layer and a second conductive pattern which are sequentially arranged in the direction, away from the display substrate, of a substrate body, the first conductive pattern and the second conductive pattern are connected through a via hole penetrating through the insulating layer, and the slope angle of the side wall of the via hole is not larger than 60 degrees. According to the technical scheme, the product yield of the display device can be improved.

Owner:BOE TECH GRP CO LTD +1

Glass substrate cutting and bearing device and cutting system

ActiveCN104211294AGuaranteed product yieldAvoid scratchesGlass severing apparatusDriven elementEngineering

The invention provides a glass substrate cutting and bearing device, comprising an upstream bearing platform, a downstream bearing platform, an auxiliary bearing platform and a mobile bracket, wherein the downstream bearing platform is arranged adjacently to the upstream bearing platform; the upstream bearing platform, the auxiliary bearing platform and the downstream bearing platform jointly load a to-be-cut glass substrate; the downstream bearing platform and the auxiliary bearing platform are arranged on the mobile bracket; the auxiliary bearing platform is arranged between the upstream bearing platform and the downstream bearing platform and is connected with a lifting drive element; the lifting drive element adjusts the height of the auxiliary bearing platform relatively to the upstream bearing platform; and after the glass substrate is cut, the auxiliary bearing platform ascends to the height of the overhead upstream bearing platform, is propped against the cut glass substrate, and drives the downstream bearing platform and the auxiliary bearing platform to depart from the upstream bearing platform through the mobile bracket.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Dust removal and purification system for surface mounting technology (SMT) production line

InactiveCN105127170AGuarantee production quality and yieldSimple structureDirt cleaningEngineeringSurface mounting

The invention discloses a dust removal and purification system for a surface mounting technology (SMT) production line. The dust removal and purification system comprises a movable purification device, a controller, a displayer and dust concentration detection sensors. The dust concentration detection sensors are arranged in an SMT production line workshop and used for detecting the concentration of dust in the workshop. The controller receives and processes data of the dust concentration detection sensors and then controls the movable purification device to move in the SMT production line workshop according to processing results; the movable purification device performs dust removal and purification on the SMT production line workshop. The dust concentration detection sensors are uniformly arranged in the SMT production line workshop, and each dust concentration detection sensor has a unique ID number for recognizing the position where the dust concentration detection sensor is located. The controller controls the movable purification device to move according to the ID numbers of the dust concentration detection sensors and dust concentration information, and accordingly automatic dust removal and purification can be performed on the SMT production line workshop automatically and efficiently, and the production quality and the yield are guaranteed.

Owner:SUZHOU XUANHE IOT TECH

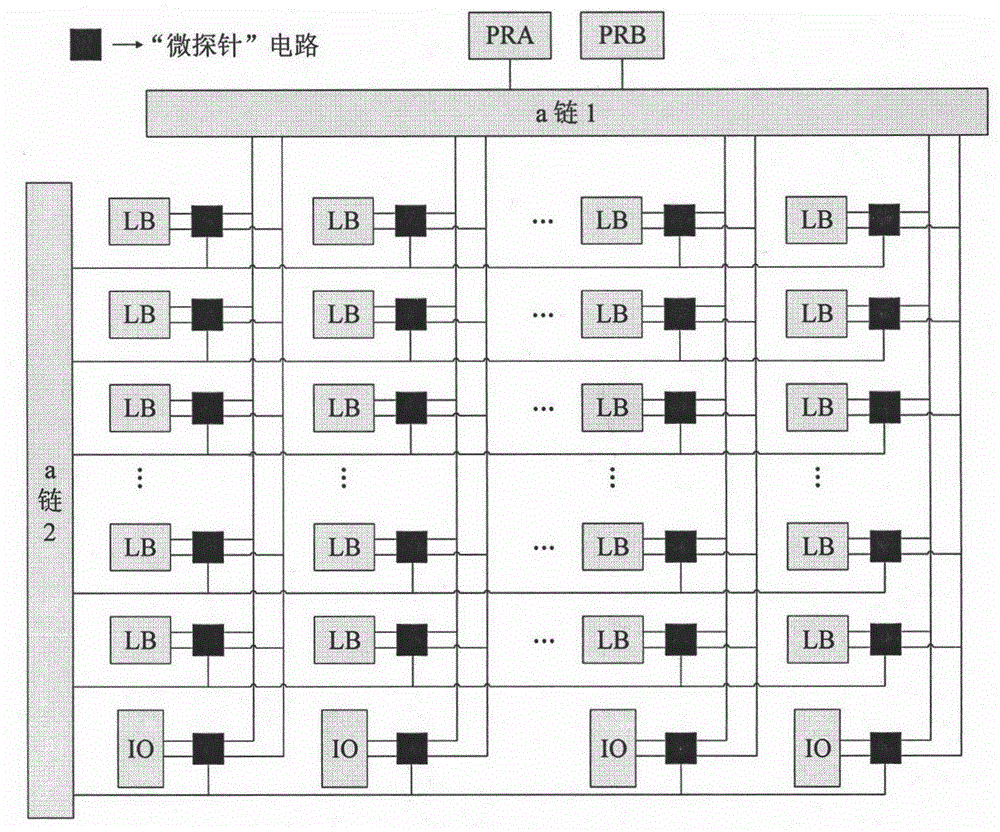

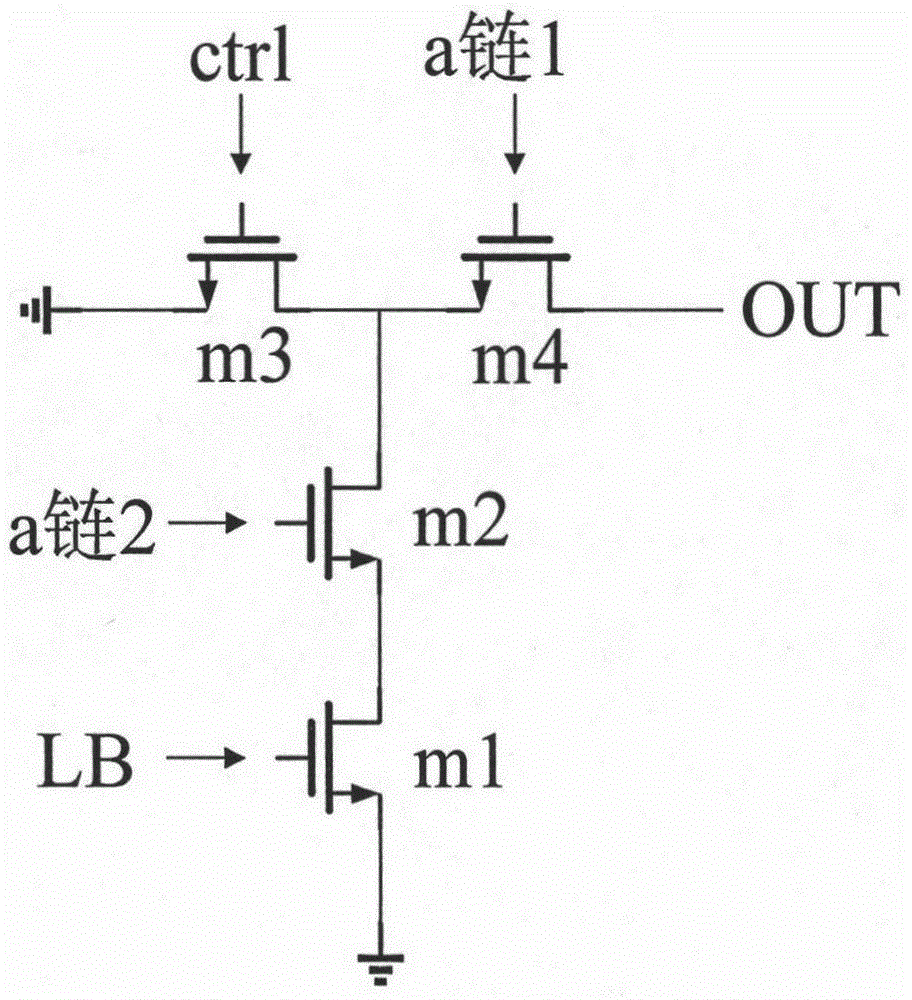

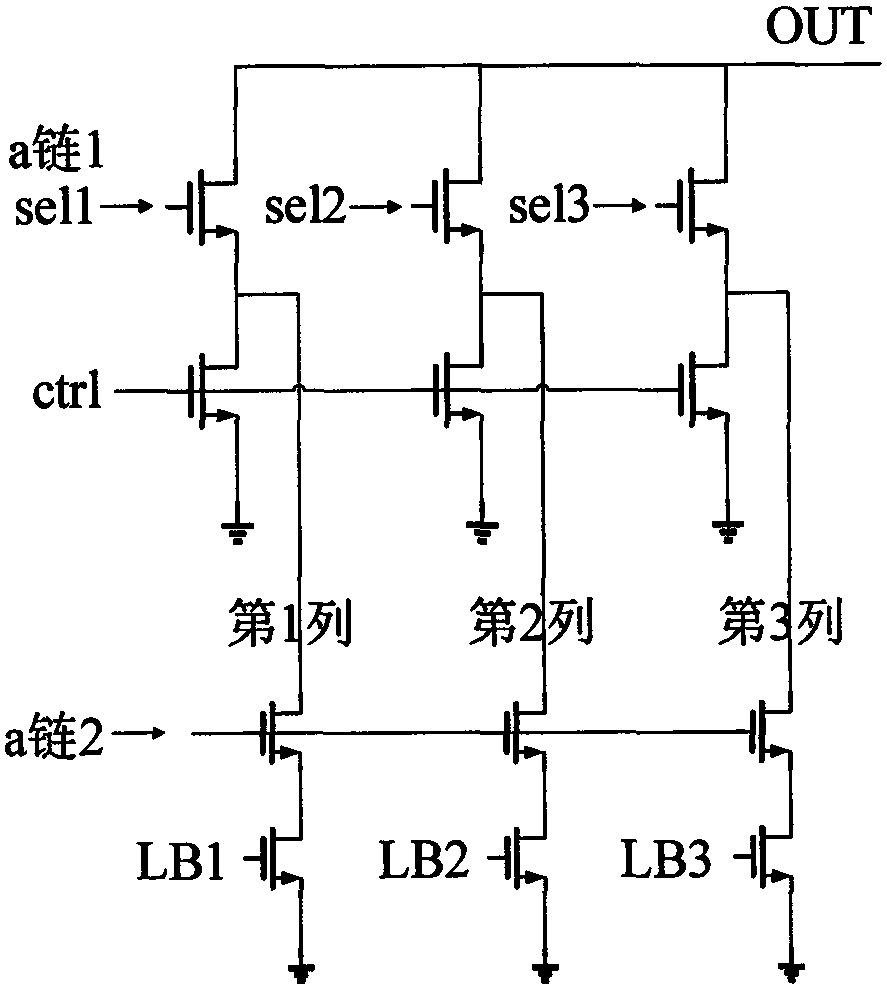

Real-time dynamic testing circuit for anti-fuse FPGA microprobe

InactiveCN106468758ASimple structureImprove performanceElectronic circuit testingTime dynamicsIntegrated circuit

The invention belongs to the integrated circuit field, and relates to a real-time dynamic testing circuit for anti-fuse FPGA microprobe. In particular, through this form of structure, it is not only possible to help achieve the digital function of a chip, but also to effectively ensure the qualification rate of chip manufacturing. And the microprobe can enable users to detect any node inside the circuit in the application stage after the anti-fuse FPGA programming is completed so as to determine whether the function of the chip is correct or not. The structure of such dynamic testing circuit occupies few chip resources and involves only a very few digitalized circuit modules. With the conception of simulated design, the circuit structure can be simplified; the performance of the circuit can be optimized; accordingly, the circuit can work normally and efficiently.

Owner:华晋书

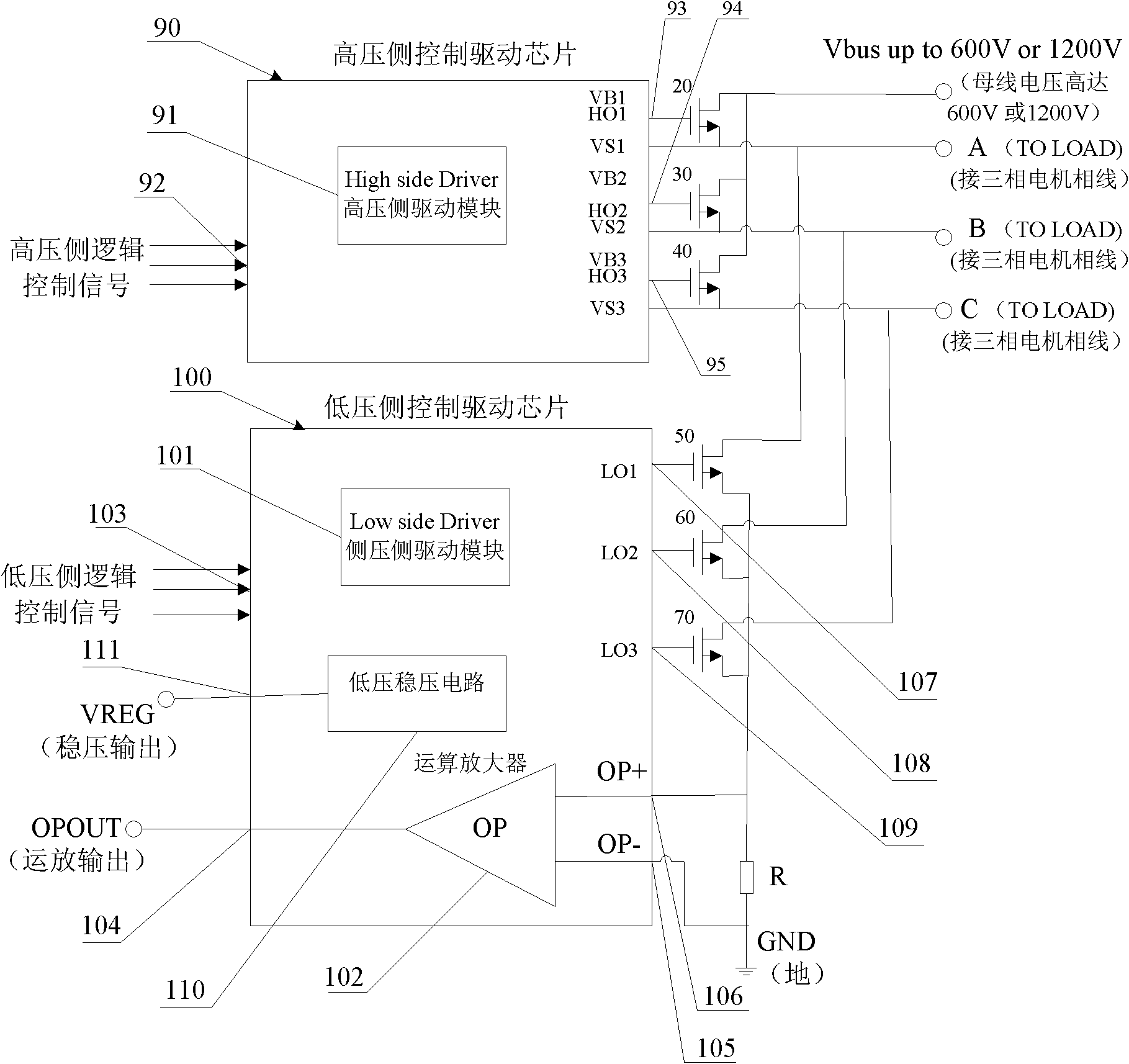

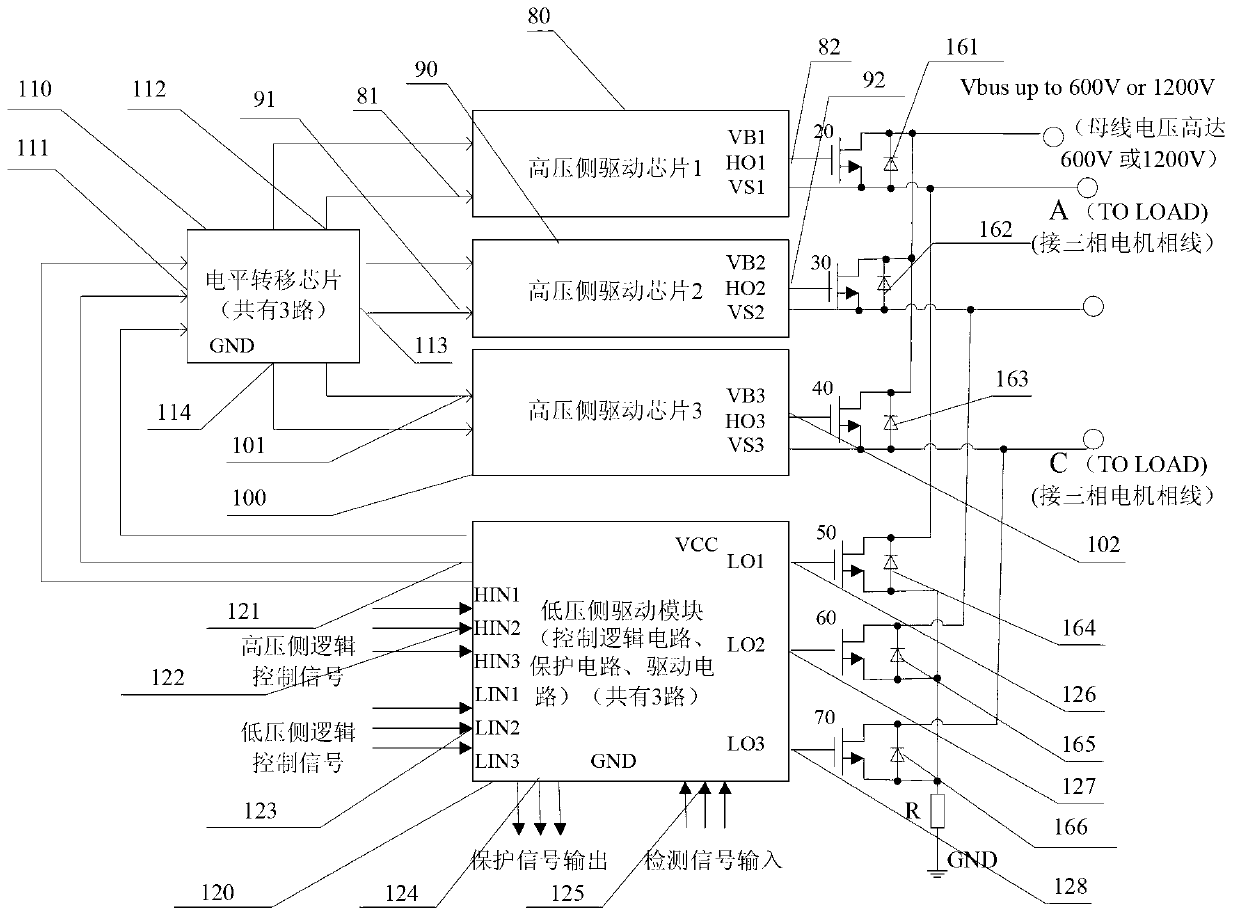

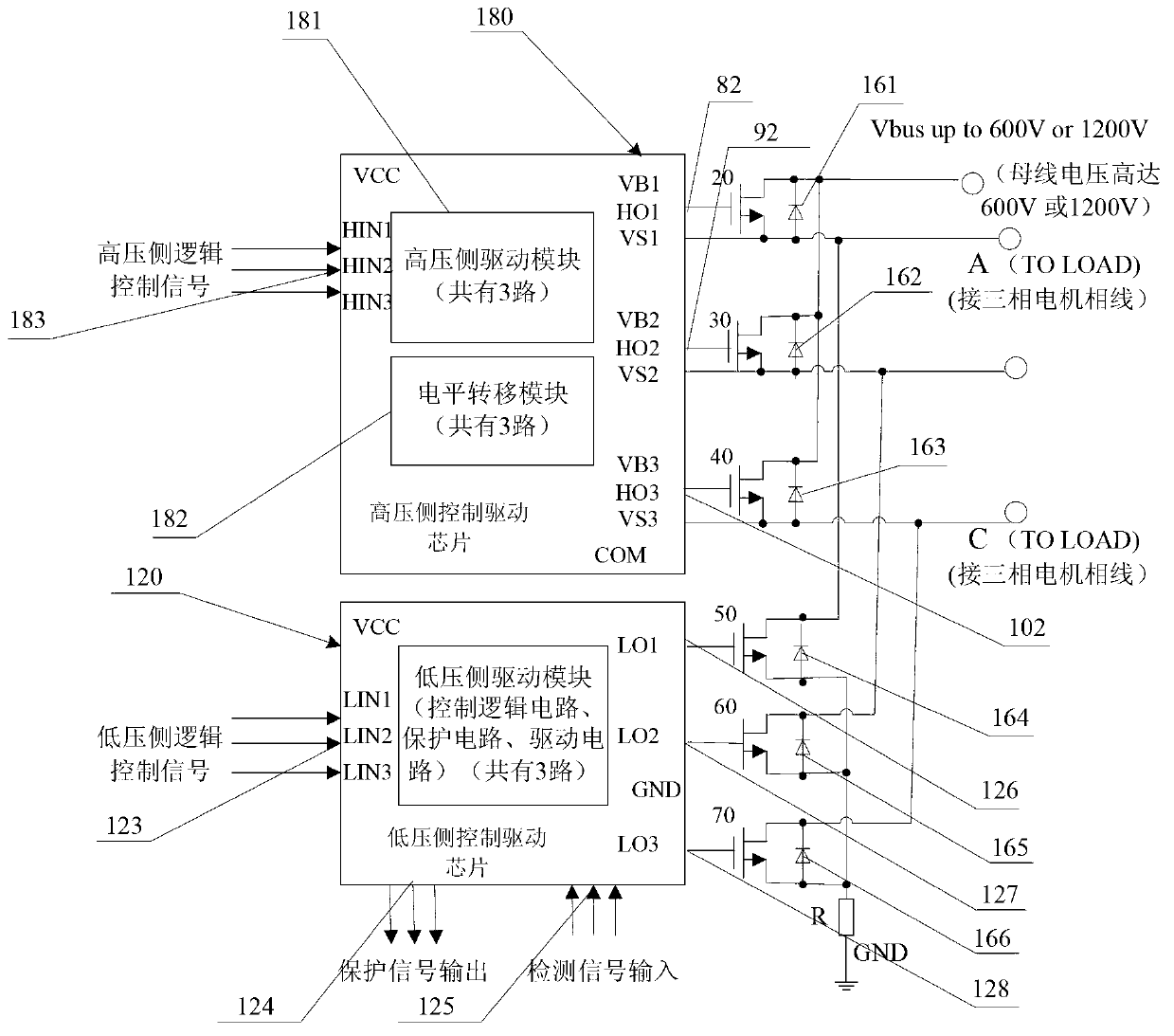

Intelligent power module for three-phase bridge type driving

ActiveCN103280950ASimple process conditionsMature technologySolid-state devicesSemiconductor devicesManufacturing technologyLow voltage

The invention discloses an intelligent power module for three-phase bridge type driving. The intelligent power module is realized by segmenting a common integrated chip of a high-voltage side driving module, a level transfer module and a low-voltage side driving module again and dividing the integrated chip into a level transfer chip, a high-voltage side control driving chip and a low-voltage side control driving chip. Only the level transfer chip is produced by a complex high-voltage insulation manufacture technology. The high-voltage side control driving chip and the low-voltage side control driving chip are produced by a common CMOS (Complementary Metal-Oxide-Semiconductor Transistor) technology. The trouble of integrating the high-voltage insulation manufacture technology in the common CMOS technology to produce all the chips and then encapsulating all the chips, power devices and a free-wheel diode together is saved in the production of the intelligent power module for three-phase bridge type driving. The more easily controlled process for producing the level transfer chip of the intelligent power module is favorable to the increase of the qualified rate. The areas of the high-voltage side control driving chip and the low-voltage side control driving chip can be further reduced, and the production qualified rate can be ensured.

Owner:NINGBO SEMICON INT CORP

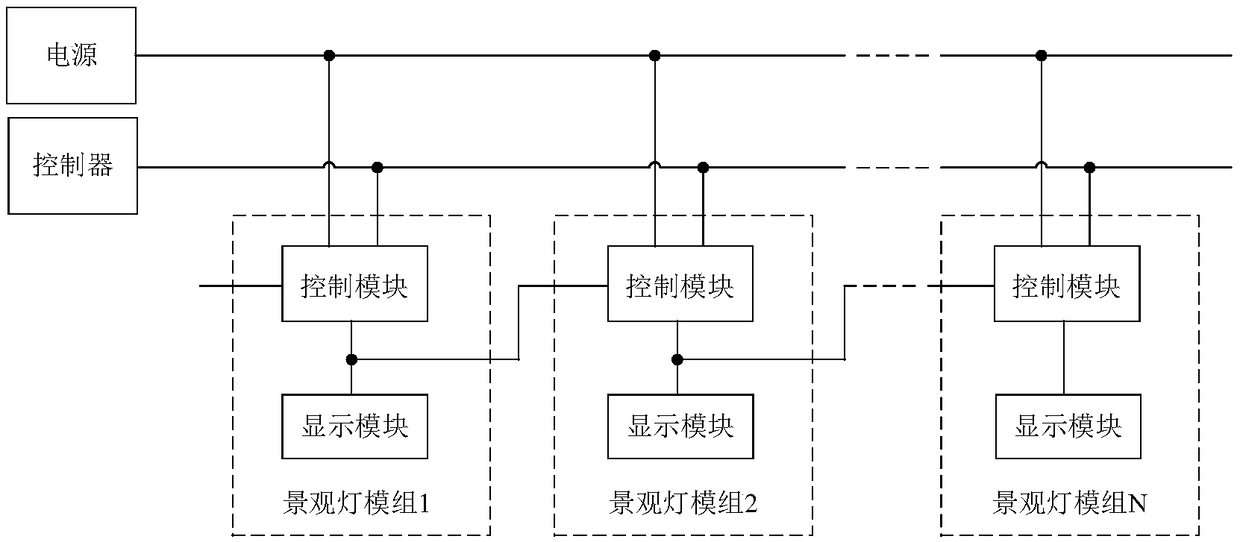

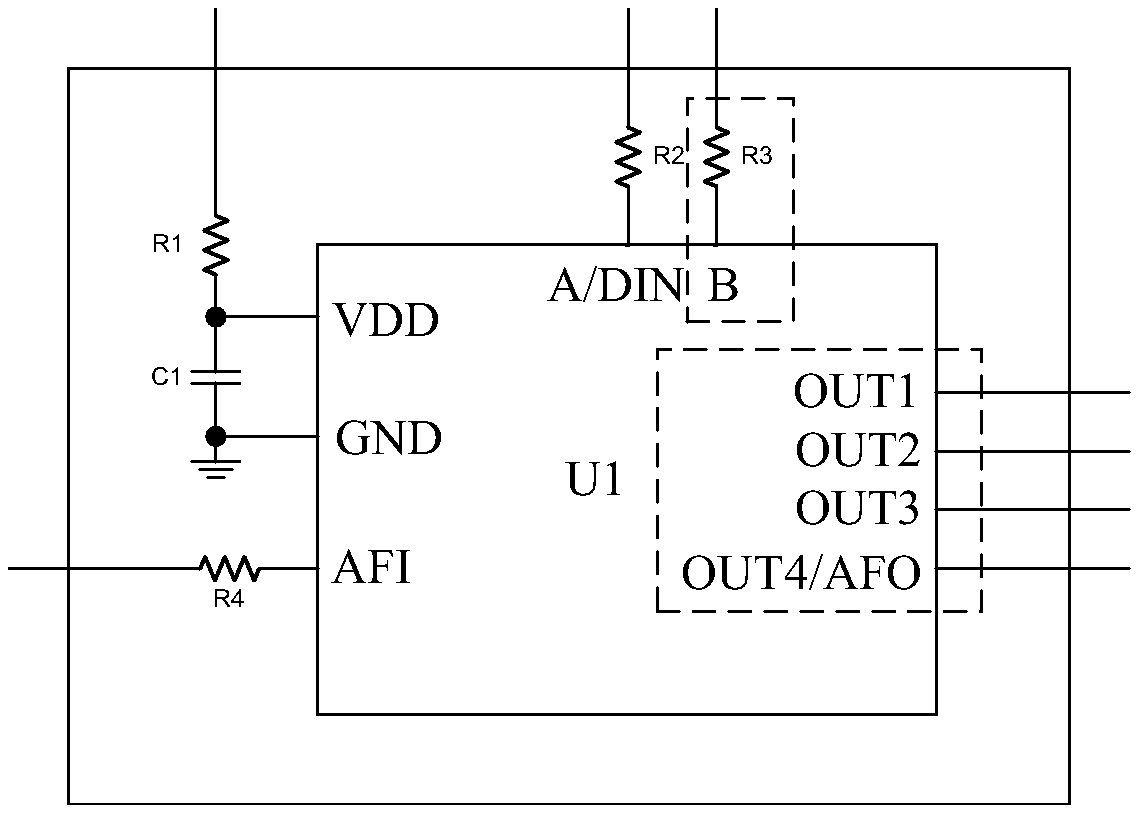

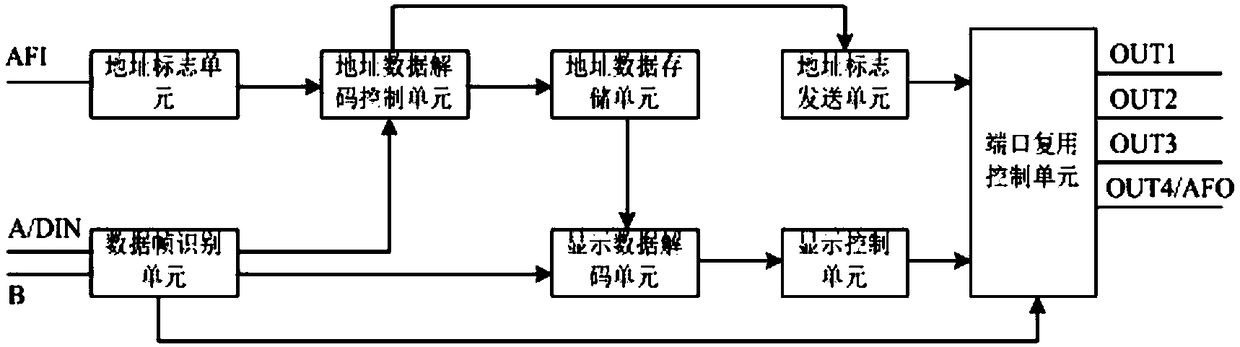

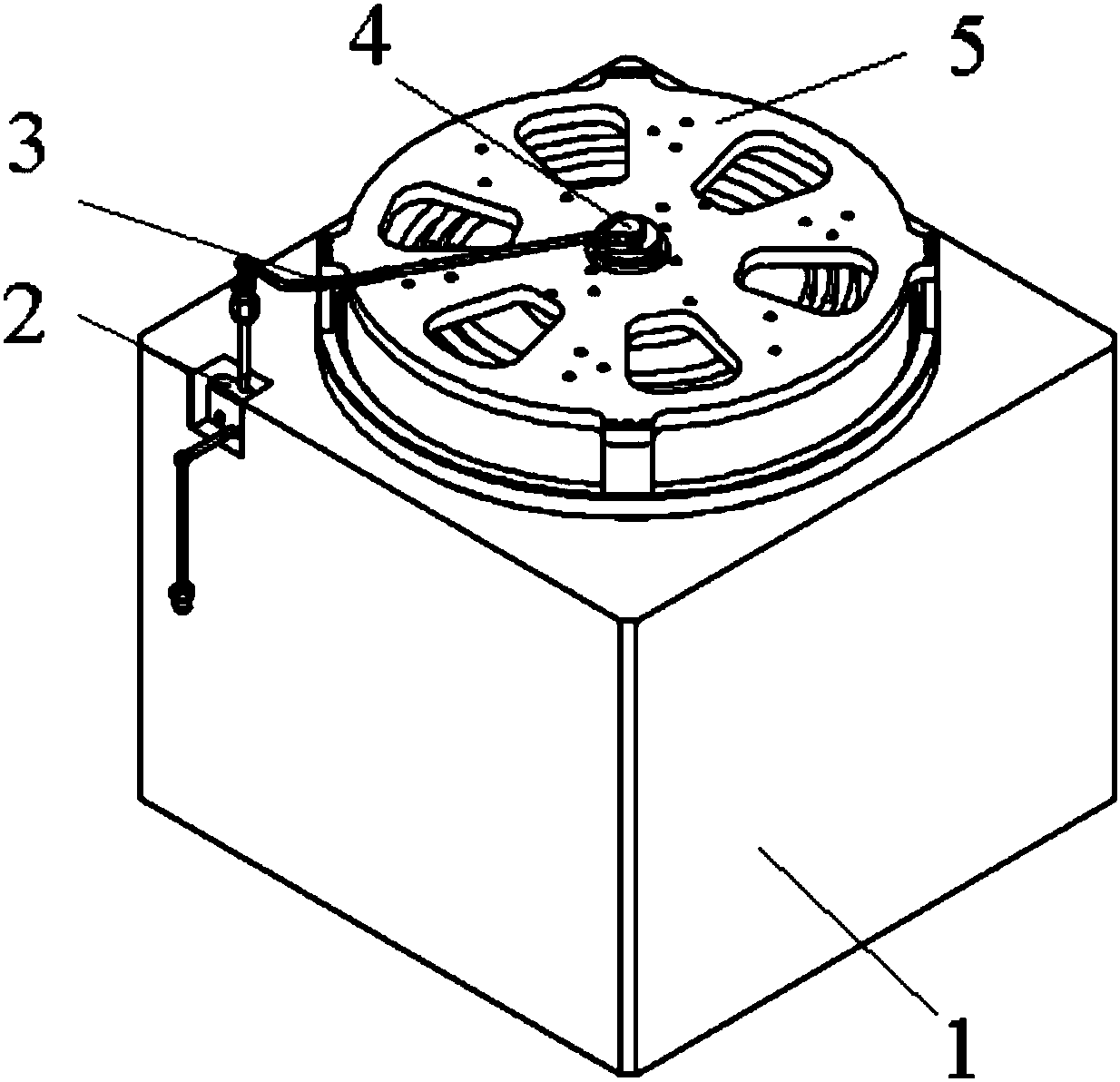

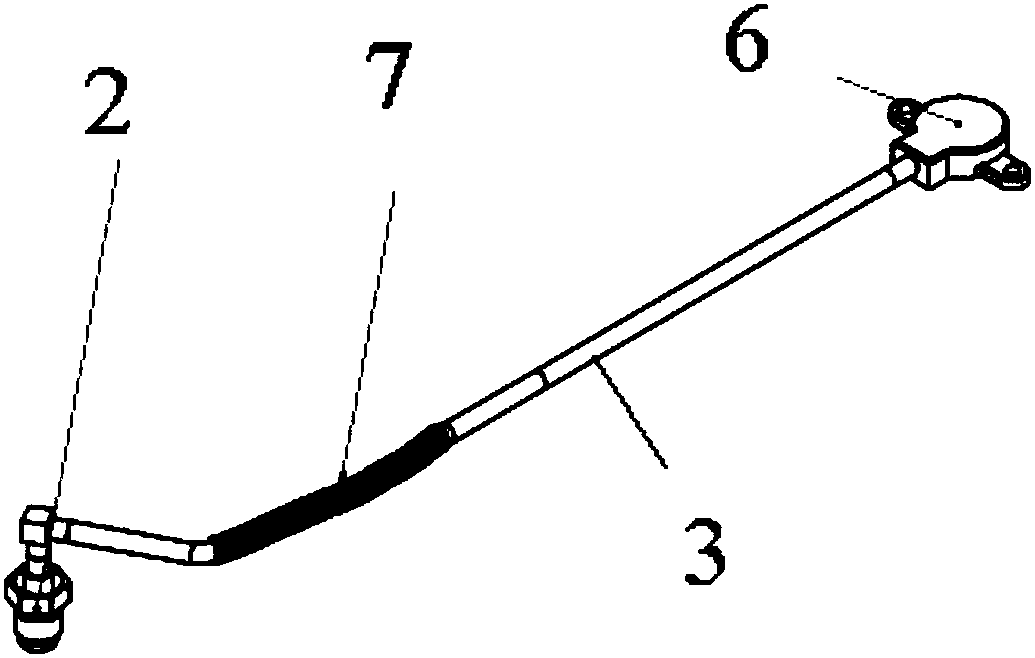

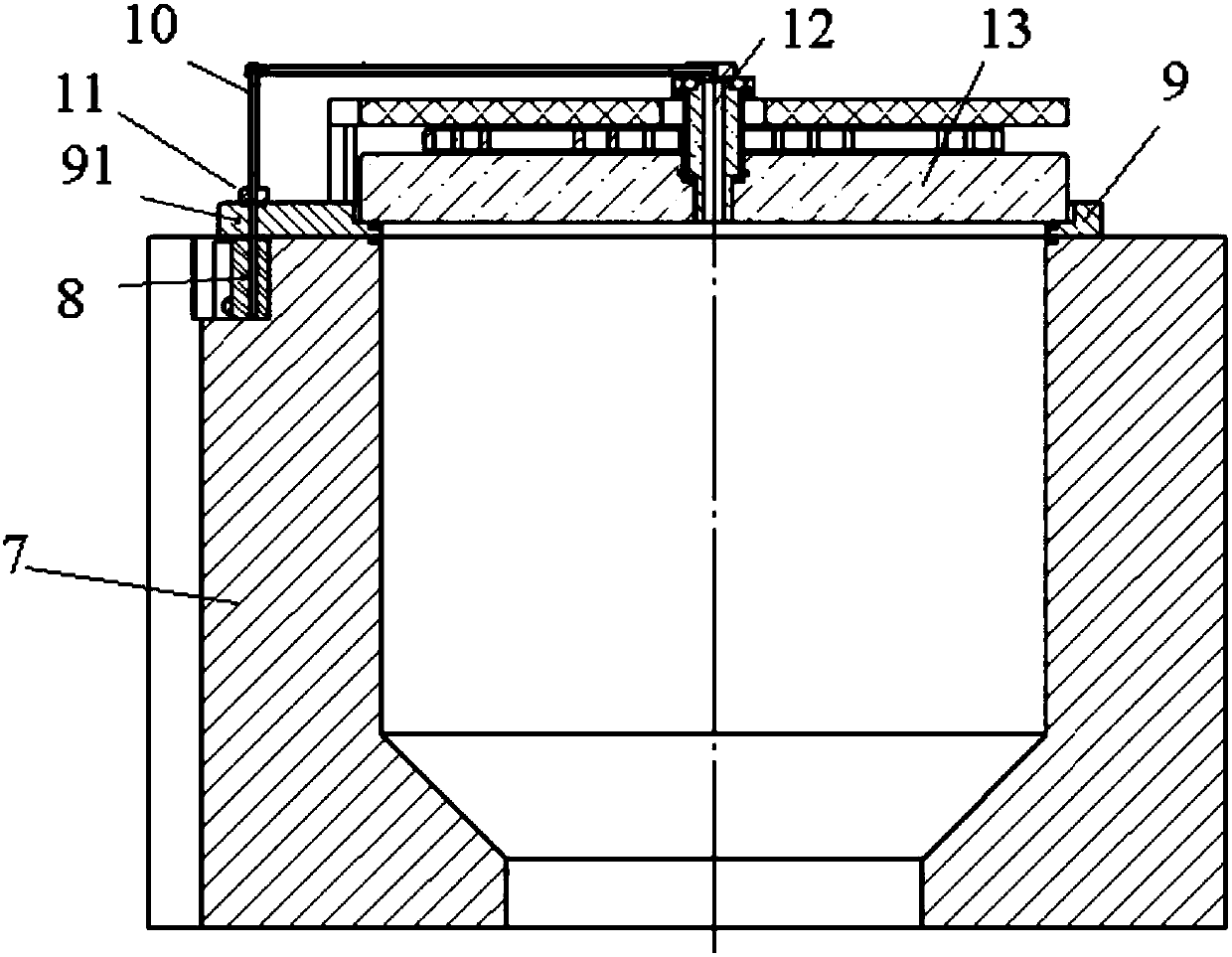

Landscape lamp system and method for port multiplexing thereof

ActiveCN108834268AGuaranteed product yieldLow costElectrical apparatusStatic indicating devicesComputer moduleEngineering

The invention provides a landscape lamp system and a method for port multiplexing thereof. The landscape lamp system comprises a power source, a controller and a plurality of landscape lamp modules, wherein each landscape lamp module is composed of a control module and a display module, the control module is connected to the display module and the control module of the next landscape light modulewith the same group of ports, and the control module is internally provided with a control chip. The landscape lamp system of the invention is characterized in that the control module uses the same group of ports to control the display module and the next control module, and the most basic 10 pins of the control chip is reduced to 9 or less, so that the control chip can be normally packaged in ESOP8, SOP8 and other small package, so as to meet the special requirements for the specific structure of the lamp in special occasions.

Owner:深圳智芯半导体科技有限公司

Reaction chamber and semiconductor processing apparatus

ActiveCN109659213AReduce depositionReduce pollutionElectric discharge tubesSemiconductorReaction chamber

The present invention provides a reaction chamber and a semiconductor processing apparatus. The reaction chamber comprises a cavity, a dielectric window, a support member used for fixing the dielectric window to the top of the cavity, and an air intake mechanism used for conveying gas to the interior of the cavity. The air intake mechanism includes an intake passage disposed in the support member;the air intake mechanism further includes a first pipeline and a second pipeline, the first pipeline is disposed on the cavity and is in detachable seal connection with one end of the intake passage,the first pipeline is configured to transmit gases to the second pipeline through the intake passage; the second pipeline is arranged on the support member and is in fixed seal connection with the other end of the intake passage, and the second pipeline is configured to transmit the gases into the cavity. The reaction cavity simplifies the cavity maintenance process, reduces the maintenance cost,reduces the deposition of reaction by-products in the intake passage and reduces metal pollution, thereby ensuring process results and product yield.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Automatic tapping machine

InactiveCN105728868AIncrease productivityAccurate detectionThread cutting machinesMeasurement/indication equipmentsControl systemEngineering

The invention relates to the technical field of tapping equipment, in particular to an automatic tapping machine. An automatic tapping machine, comprising a worktable, a control system, a material guide system and at least one tapping unit are also arranged on the worktable, the control system is respectively connected to the material guide system and the tapping unit, and the tapping The unit includes a tapping device and a tapping hole position detection device that are respectively connected to the control system and are arranged above the material guide system. Material device and positioning detection device. Multi-axis taps tap at the same time to improve production efficiency; the positioning detection device detects on-line whether the positioning of the material tape that has not entered the working area of the tapping device is accurate, reducing the probability of defective products; the tapping hole position detection device replaces damaged taps in time , to ensure production yield, accurate detection, save the time and process of human detection, improve production efficiency and save production costs.

Owner:KUNSHAN FEIPENG METAL IND CO LTD

Method for preparing hydrocortisone

The invention relates to a method for preparing hydrocortisone. The method includes: subjecting a cortisone acetate raw material to sites No. 3,20-keto protective reaction, site No.11-keto reduction reaction, site No.21-hydroxy esterification reaction, sites No. 3,20-ketone deprotection reaction, and site No. 21-acetate hydrolysis to obtain hydrocortisone. The method provides a new synthetic route containing esterification and deprotection in order, greatly improves the reaction selectivity, easily separates deprotection reaction products and avoids the posttreatment of tedious several times of extraction of a large amount of solvents in the traditional deprotection reaction process, and also avoids the side reaction caused by quenching reaction in the posttreatment of the traditional process; and the ester hydrolysis reaction is carried out under protection of inert gases in a mixed solvent, so as to avoid by-products produced in the hydrolysis reaction. The process route of the invention is novel, simple for operation, low in production cost, and applicable to industrial scale production.

Owner:HUAZHONG PHARMA

Display mother board, preparation method thereof and electroluminescence display panels

ActiveCN110289290AGuaranteed product yieldNo cutting damageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBlock structure

The invention discloses a display mother board, a preparation method thereof and electroluminescence display panels, so as to prevent a sealant from flowing to a cutting area and ensure the display product preparation yield. The display mother board provided by the embodiment of the invention comprises a display substrate and a cover plate which are arranged oppositely. The display mother board is divided to a display panel area and a peripheral area surrounding the display panel area; the display panel area comprises multiple electroluminescence display panels; the peripheral area comprises a cutting area and a packaging area surrounding the cutting area; and the packaging area comprises the sealant sealing the display substrate and the cover plate and surrounding the cutting area and a sealant blocking structure located at one side, facing the cutting area, of the sealant.

Owner:BOE TECH GRP CO LTD +1

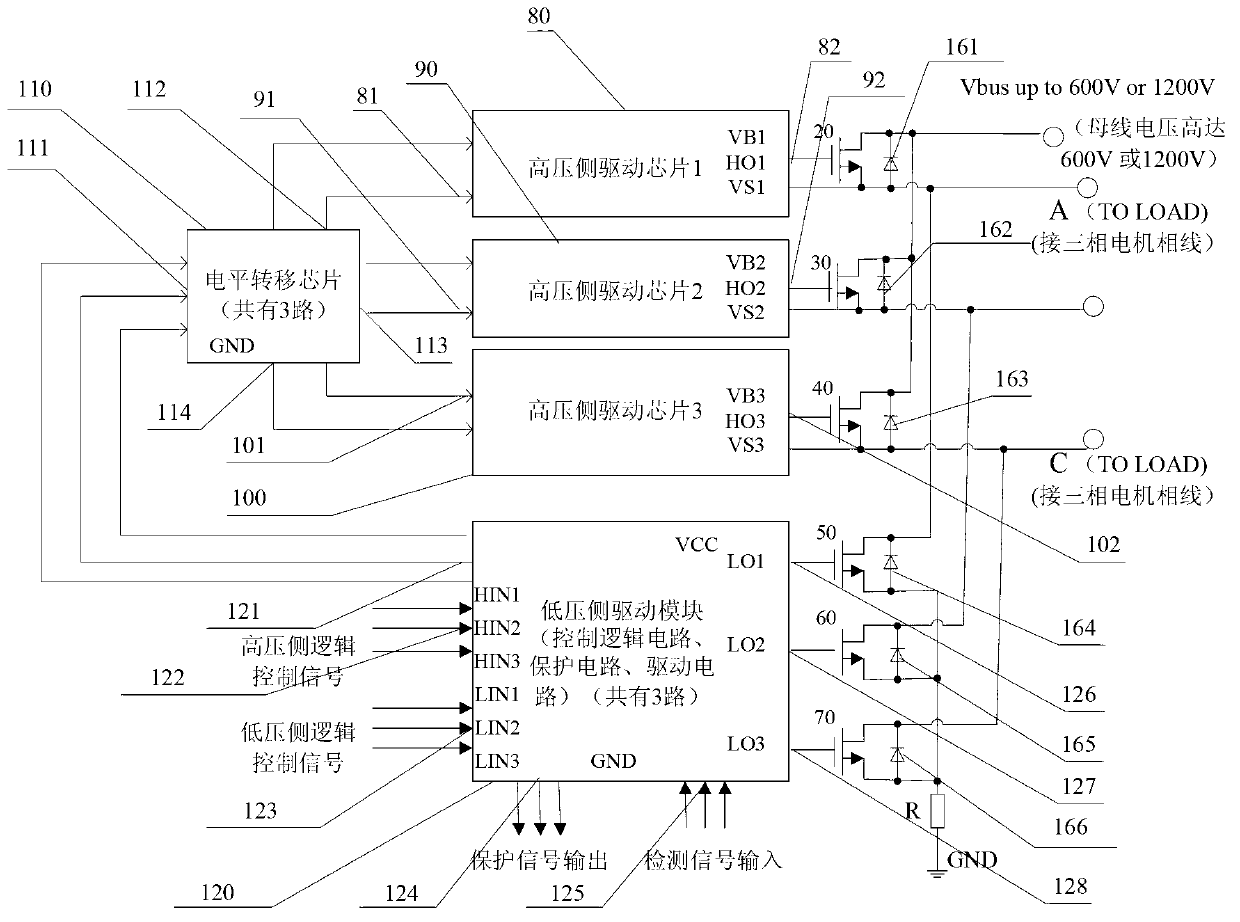

Intelligent power module for three-phase bridge type drive

ActiveCN103280949ASimple process conditionsMature technologySolid-state devicesSemiconductor devicesCMOSLow voltage

The invention discloses an intelligent power module for three-phase bridge type drive. A conventional chip integrated with a high-voltage side driver module, a level shifter module and a low-voltage side driver module is redivided into a level shifter chip, a high-voltage side control driver chip and a low-voltage side control driver chip, the complex high-voltage isolation production technique is adopted to only produce the level shifter chip, the ordinary CMOS (complementary metal oxide semiconductor) technique is adopted to produce the high-voltage side control driver chip and the low-voltage side control driver chip, therefore the ordinary CMOS technique integrated with the high-voltage isolation production technique does not need to be adopted to product each chip, and each chip, power devices and fly-wheel diodes are then packaged together to form the intelligent power module for three-phase bridge type drive. The production process of the level sifter chip of the intelligent power module can be more easily controlled, which can help to increase the yield rate; moreover, the area of the high-voltage side control driver chip and the low-voltage side control driver chip can be small, and the yield rate of production can be guaranteed.

Owner:NINGBO SEMICON INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com