Automatic tapping machine

A tapping machine and automatic technology, applied in the direction of thread cutting machine, metal processing machinery parts, measuring/indicating equipment, etc., can solve the problems of untimely detection of parts, lack of hole position detection, waste of processing time, etc., to reduce residual The probability of defective products, the effect of saving time and processes, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

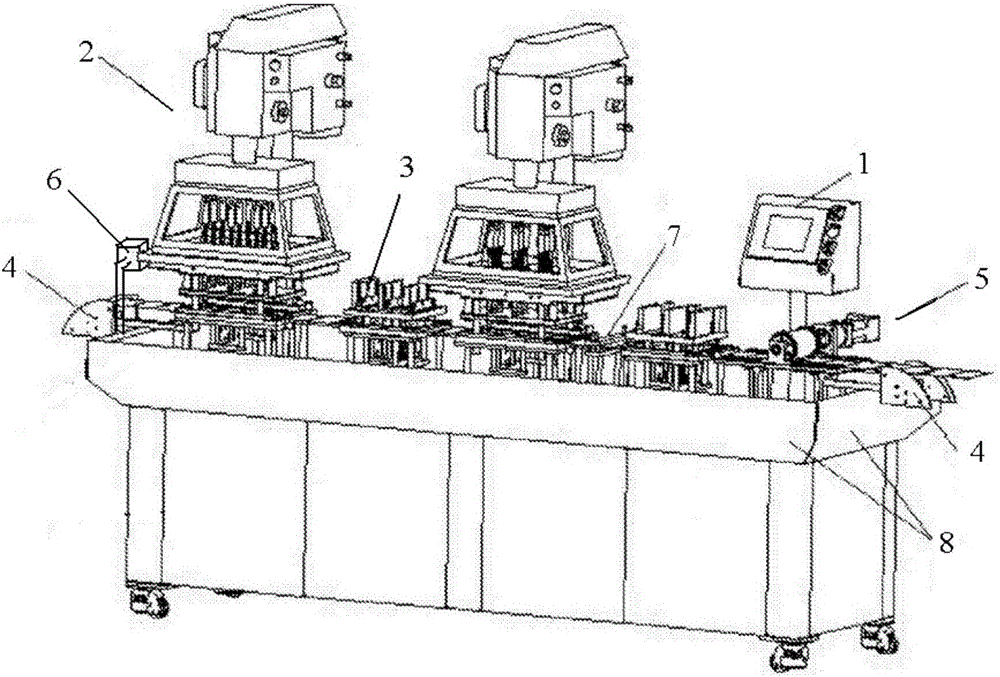

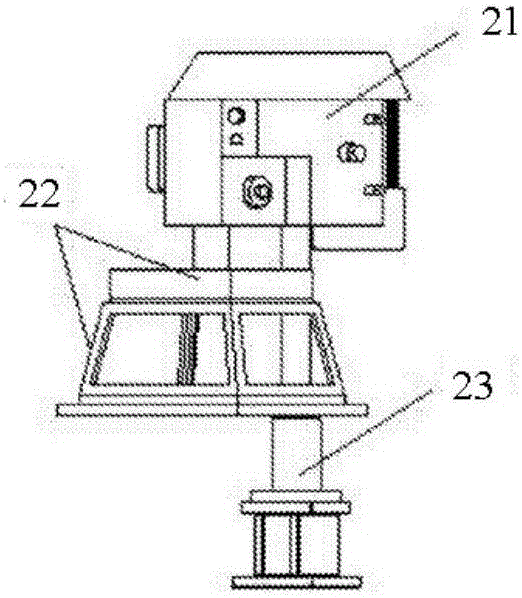

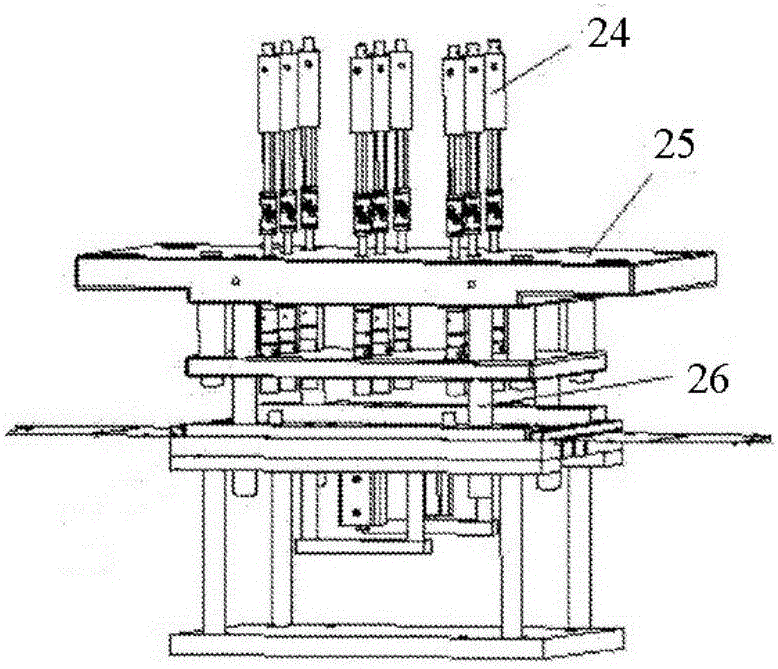

[0024] An automatic tapping machine, such as figure 1 As shown, it includes a worktable, and the worktable is also provided with a control system 1, a material guide system and at least one tapping unit, and the control system 1 is connected to the material guide system and the tapping unit respectively, and the tapping unit includes The tapping device 2 and the tapping hole position detection device 3 respectively connected to the control system 1 are arranged above the material guide system, such as Figure 2-3 As shown, the tapping device 2 includes a tapping drive mechanism 21 and a support frame 23, the tapping drive mechanism 21 is fixed above the tapping guide plate 25 through the support frame 23, and the tapping drive mechanism 21 is connected to At least one tap 24 passes through a tap guide plate 25 .

[0025] Such as Figure 4 As shown, the tapping hole position detection device 3 includes a detection needle fixing plate 32 for fixing the detection needle 35, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com