Silicone oil electric force compound grease and preparation method thereof

A power compound grease and silicone oil technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low base oil dropping point, poor adhesion, etc., to improve viscosity, prevent oxidation, good high temperature resistance and The effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

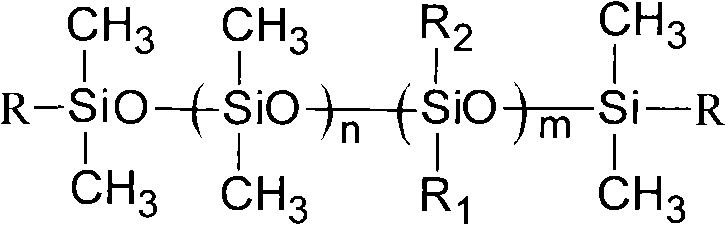

[0072] This embodiment relates to a method for preparing the silicone oil, and the method includes the following steps:

[0073] (I) Add 100 parts by weight of octamethylcyclotetrasiloxane (hereinafter referred to as D) into the reactor equipped with stirring, thermometer and reflux condenser. 4 ), 1 part by weight of hexamethylsiloxane (hereinafter referred to as MM) and 0.5 part by weight of tetramethylammonium hydroxide silicon alkoxide catalyst, stir the above mixture at a stirring speed of 20 rpm, and stir At the same time, slowly increase the temperature to 95±5℃ and react for 5 hours;

[0074] (II) Then the temperature is further increased to 150°C for 30 minutes;

[0075] (III) Vacuum the inside of the reactor until the internal vacuum is greater than or equal to -0.08MPa, and further heat to 180°C for heating until there is almost no effluent, cool to room temperature, and stop the vacuum , The silicon oil with the following structure can be obtained after discharge:

[0076...

Embodiment 2

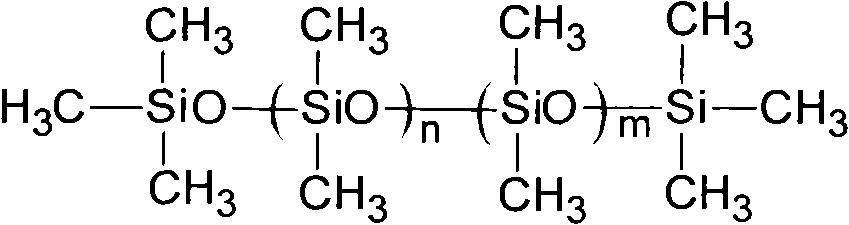

[0080] This embodiment relates to a method for preparing the silicone oil, and the method includes the following steps:

[0081] (I) Add 100 parts by weight of D to the reactor equipped with stirring, thermometer and reflux condenser 4 , 1.5 parts by weight of MM and 0.5 parts by weight of tetramethylammonium hydroxide silicon alkoxide catalyst, stir the above mixture at a stirring speed of 30 rpm, and slowly heat up to 100±5°C for 2.5 hours while stirring ;

[0082] (II) Then the temperature is further increased to 150°C for 30 minutes;

[0083] (III) Vacuum the inside of the reaction kettle until its internal vacuum is greater than or equal to -0.08MPa. Under the conditions, further heat the temperature to 200°C for heating until there is almost no effluent, cool to room temperature, and stop Vacuum and discharge the silicon oil with the following structure:

[0084]

[0085] In the formula, n=156; m=0.

Embodiment 3

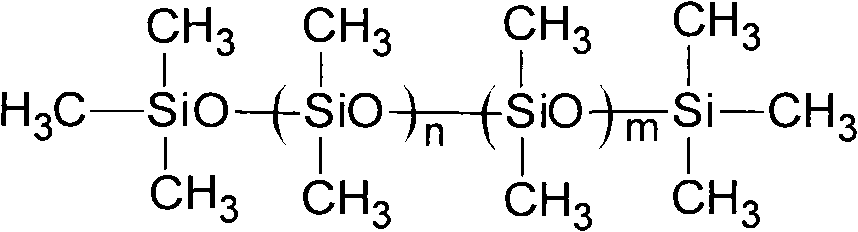

[0087] This embodiment relates to a method for preparing the silicone oil, and the method includes the following steps:

[0088] (I) Add 100 parts by weight of D to the reactor equipped with stirring, thermometer and reflux condenser 4 , 1.7 parts by weight of MM and 0.5 parts by weight of tetramethylammonium hydroxide silicon alkoxide catalyst, stir the above mixture at a stirring speed of 30 rpm, and slowly raise the temperature to 100±5°C for 4 hours while stirring ;

[0089] (II) Then the temperature is further increased to 150°C for 30 minutes;

[0090] (III) Vacuum the inside of the reaction kettle until its internal vacuum is greater than or equal to -0.08MPa. Under the conditions, further heat the temperature to 190°C for heating until there is almost no effluent, cool to room temperature, and stop Vacuum and discharge the silicon oil with the following structure:

[0091]

[0092] In the formula, n=125; m=0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com