Two-color mold

A technology of two-color mold and cavity, applied in the field of two-color mold, can solve the problems of short maintenance cycle of mold, complicated ejection mechanism, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

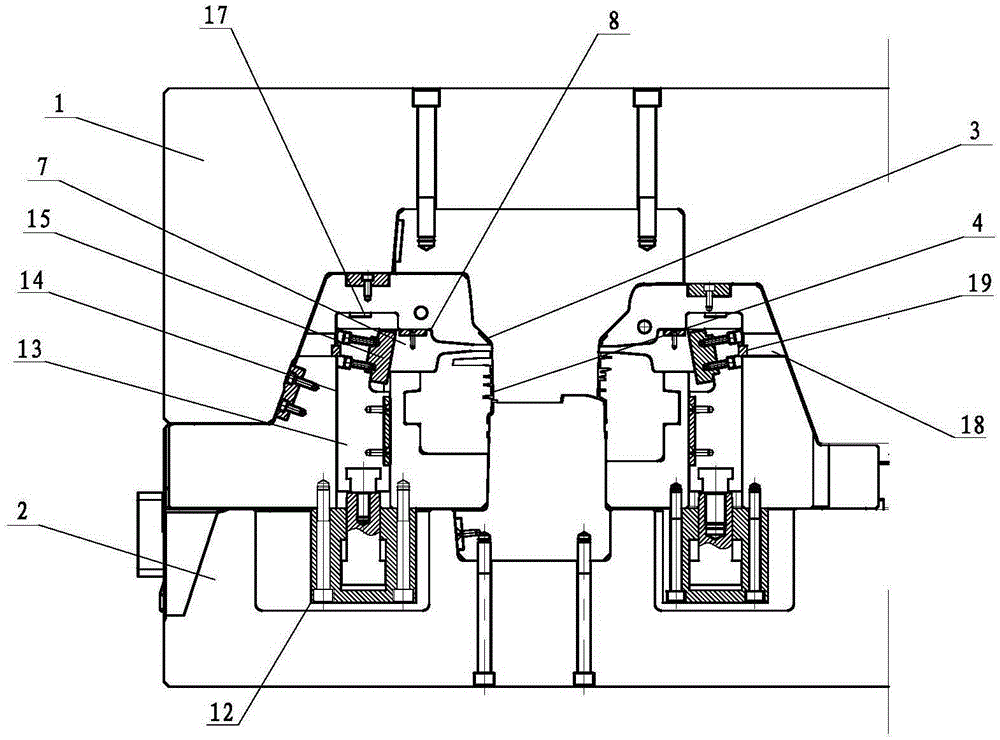

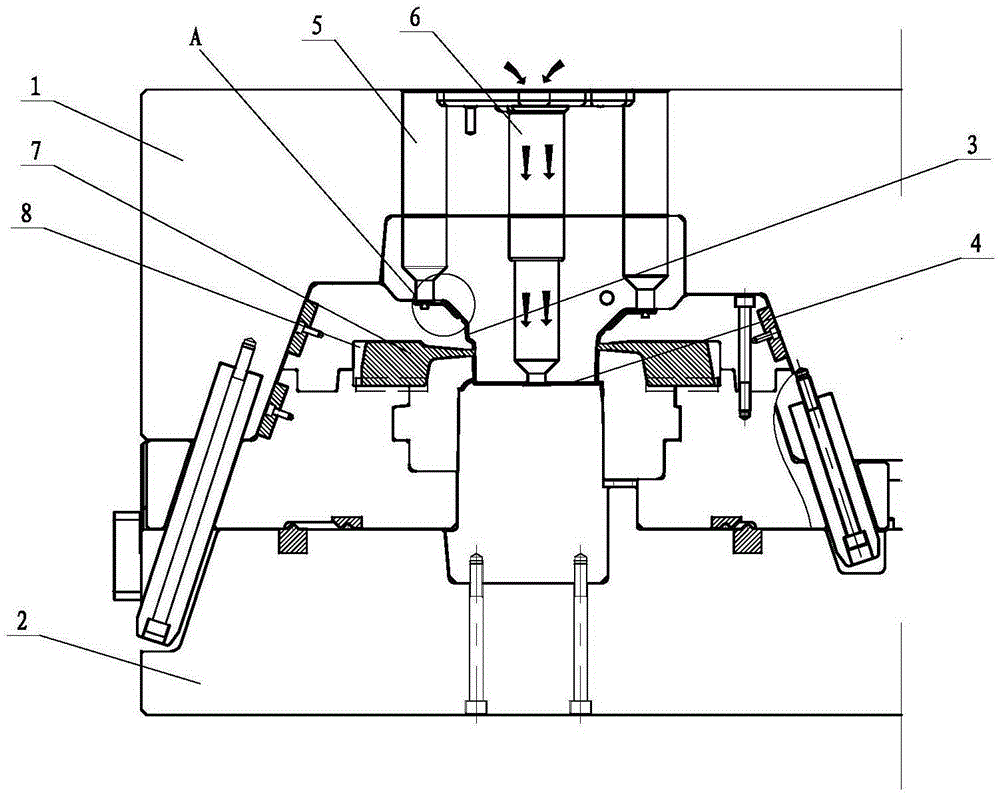

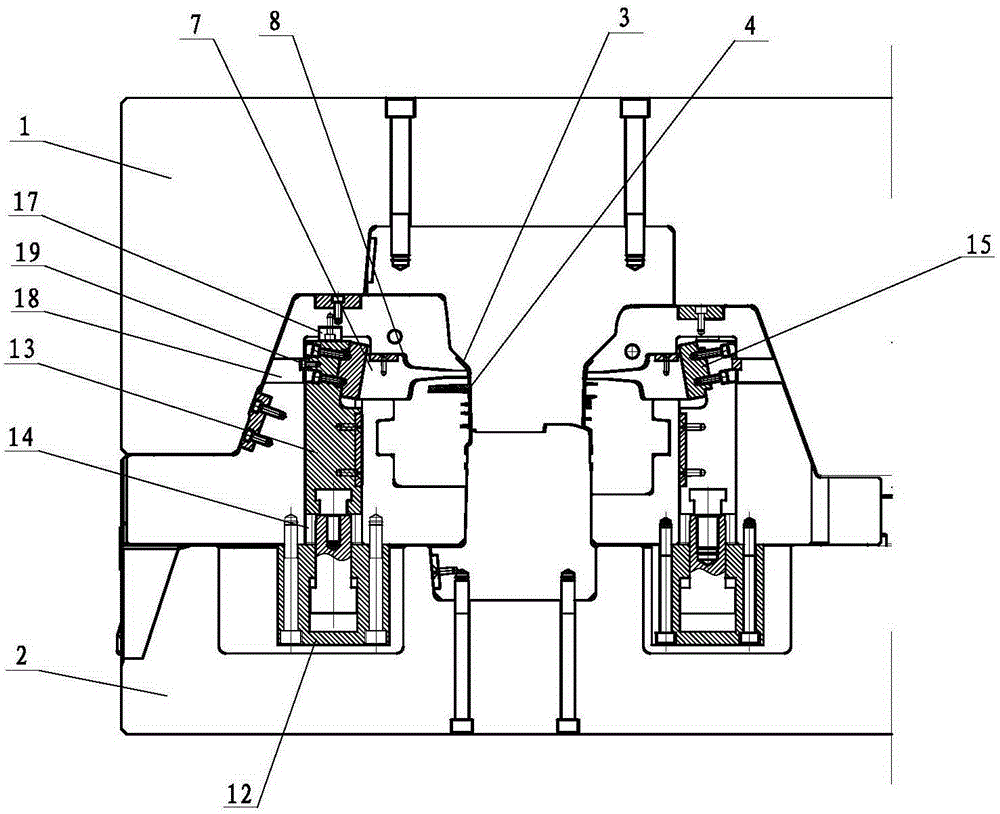

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Shown, a kind of two-color mold, it comprises fixed mold 1 and movable mold 2 (certainly also comprises other components, but because do not relate to the invention point of the present invention, so do not repeat them here), described fixed mold 1 After closing with the movable mold 2, a mold cavity is formed, and the mold cavity is divided into a soft rubber cavity 3 and a hard rubber cavity 4, and the fixed mold 1 is provided with a soft rubber gate 5 and a hard rubber gate 6 , and the soft rubber gate 5 and the hard rubber gate 6 communicate with the soft rubber mold cavity 3 and the hard rubber mold cavity 4 respectively, and the movable mold 2 is slidably connected with the soft rubber mold cavity 3 and the hard rubber mold cavity 4 Separated blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com