Heat pipe and manufacturing method thereof

一种制造方法、热管的技术,应用在间接换热器、照明和加热设备等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

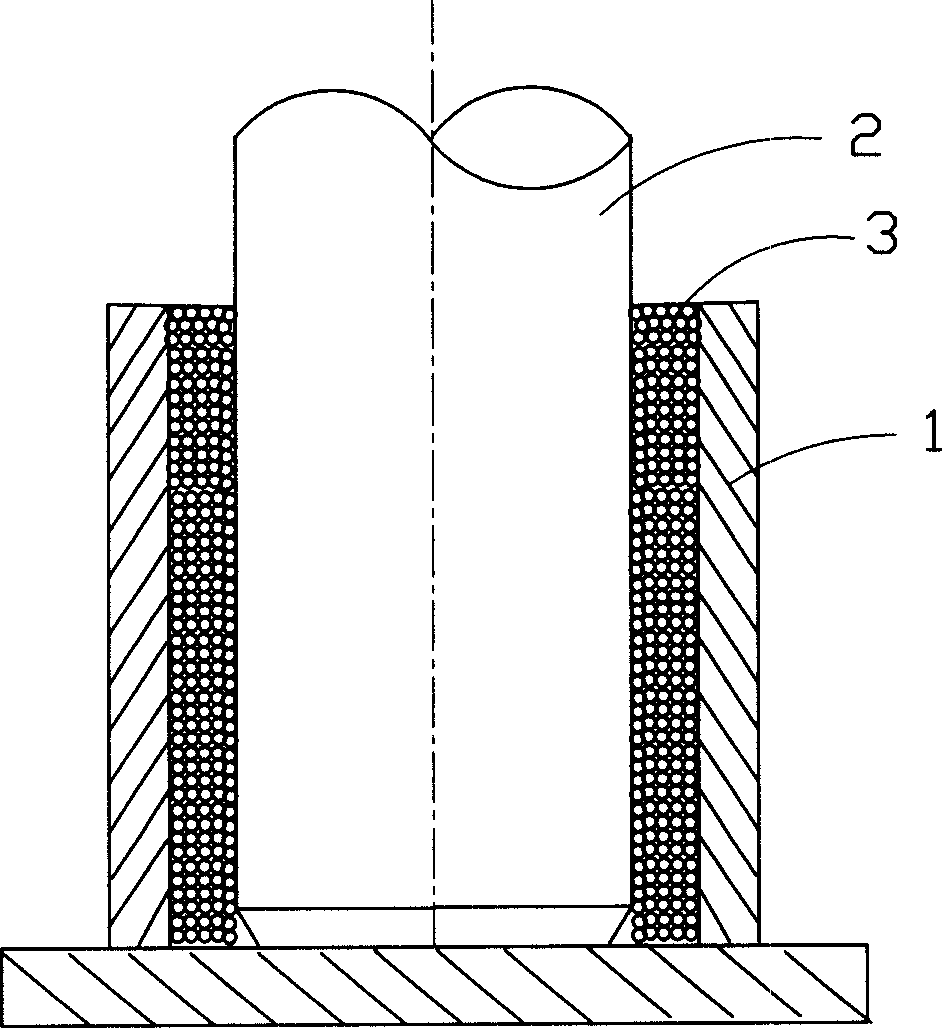

[0025] Figure 4 It is a flow chart of a preferred manufacturing process of the heat pipe of the present invention, which is to first set a screen 20 on the outer surface of a mandrel 10, and then insert this combined component into a heat-conducting shell 30, such as Figure 5 and Image 6 shown. Of course, in this step, the mandrel 10 can also be inserted into the heat-conducting housing 30 first, and then the screen 20 is bonded to the outer surface of the mandrel 10. An operation mode in which the rod 10 is combined with the screen 20 and then inserted into the heat conduction housing 30 .

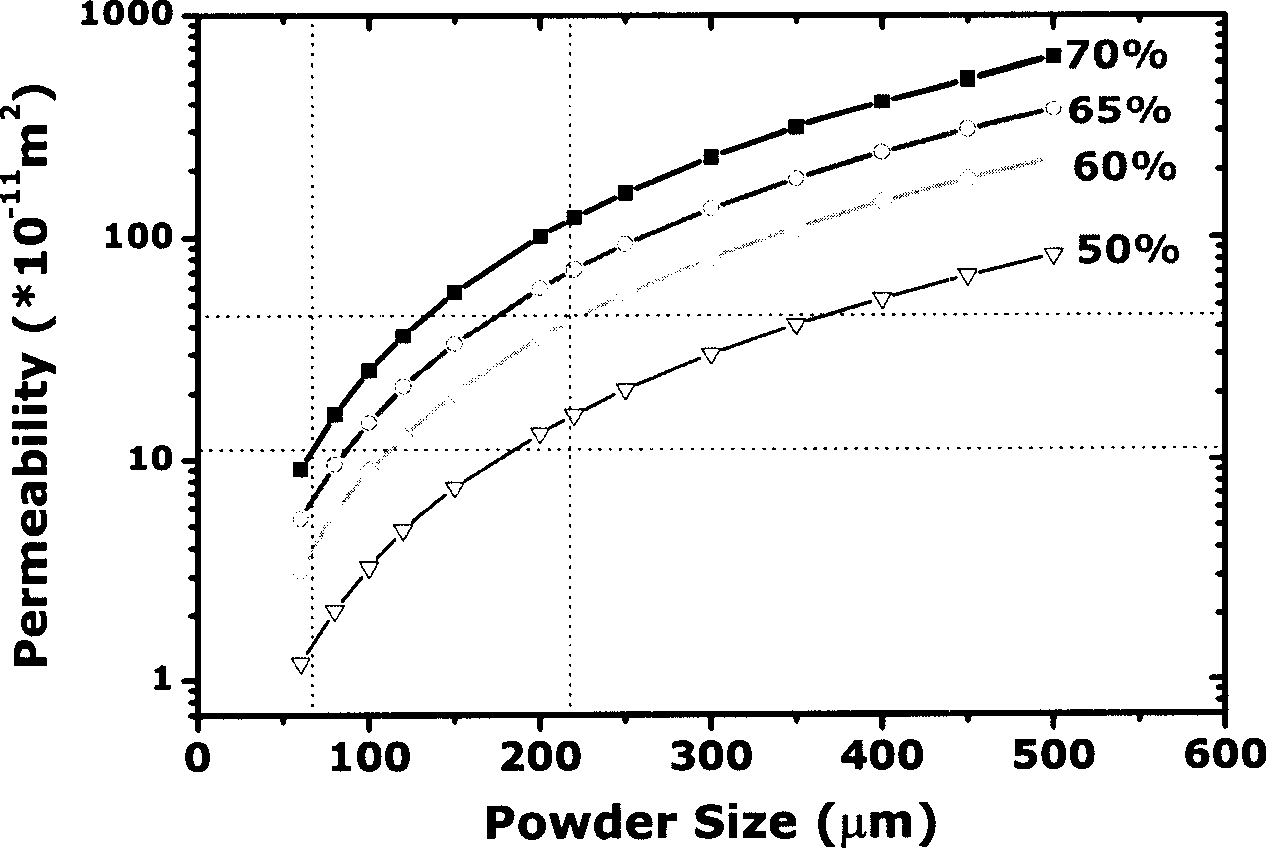

[0026] Next, fill the fine powder 40 of appropriate density in the gap between the inner wall of the heat conduction shell 30 and the screen 20, in order to facilitate the positioning of the mandrel 10 and prevent the filled powder 40 from leaking out, the bottom of the heat conduction shell 30 The end 31 can be pre-formed into a neck shape, such as Figure 5 As shown, the mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com