Six-axis mechanical arm

A six-axis manipulator and wrist technology, applied in the field of manipulators, can solve the problems of insufficient firm structure, limited moving range, and insufficient precision, and achieve the effects of simple disassembly and assembly, low maintenance cost, and improved enterprise efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

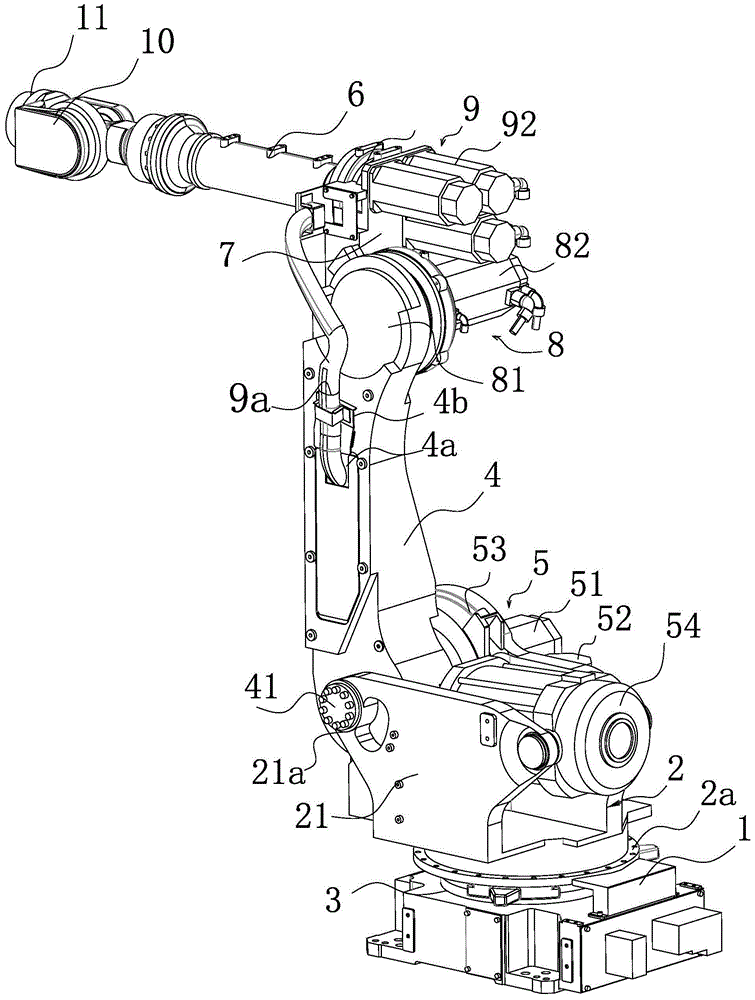

[0014] Such as figure 1 As shown, the six-axis manipulator includes a gear box fixing base 1, on which a driving arm base 2 is arranged, and on the gear box fixing base 1, there is provided a first motor that can drive the driving arm base 2 to rotate in a circumferential direction. Rotary drive 3, the lower end of the driving arm seat 2 is connected to the first rotary drive 3 through the bottom flange 2a, side plates 21 are arranged on both sides of the driving arm seat 2, and a driving arm 4 is provided at one end of the two side plates 21, and the driving arm 4 The two sides of the lower end are respectively provided with first hinge shafts 41, and the first hinge shafts 41 are arranged in the first hinge holes 21a of the side plates 21, and on the outside of one of the side plates 21, there is a drive arm 4 that can drive the drive arm 4 around the first hinge shaft. 41 swinging drive arm drive group 5, the drive arm drive group 5 includes a first drive motor 51 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com